Laser Engraving Machine Market Report

Published Date: 31 January 2026 | Report Code: laser-engraving-machine

Laser Engraving Machine Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Laser Engraving Machine market, covering trends, size, growth rates, and regional insights from 2023 to 2033. It aims to inform stakeholders about current market conditions and future forecasts.

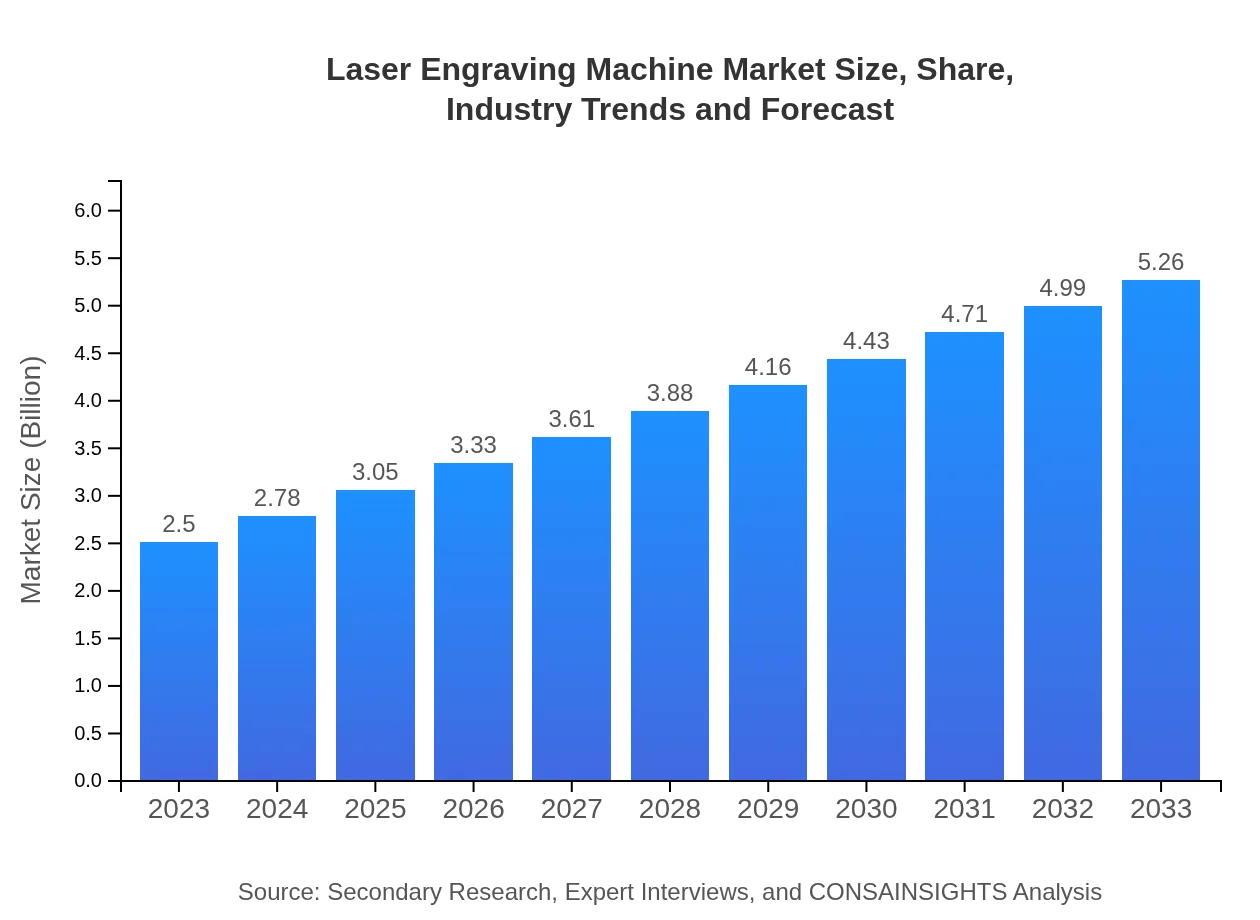

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $5.26 Billion |

| Top Companies | Epilog Laser, Trotec Laser, Gravotech, Universal Laser Systems |

| Last Modified Date | 31 January 2026 |

Laser Engraving Machine Market Overview

Customize Laser Engraving Machine Market Report market research report

- ✔ Get in-depth analysis of Laser Engraving Machine market size, growth, and forecasts.

- ✔ Understand Laser Engraving Machine's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Laser Engraving Machine

What is the Market Size & CAGR of Laser Engraving Machine market in 2023?

Laser Engraving Machine Industry Analysis

Laser Engraving Machine Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Laser Engraving Machine Market Analysis Report by Region

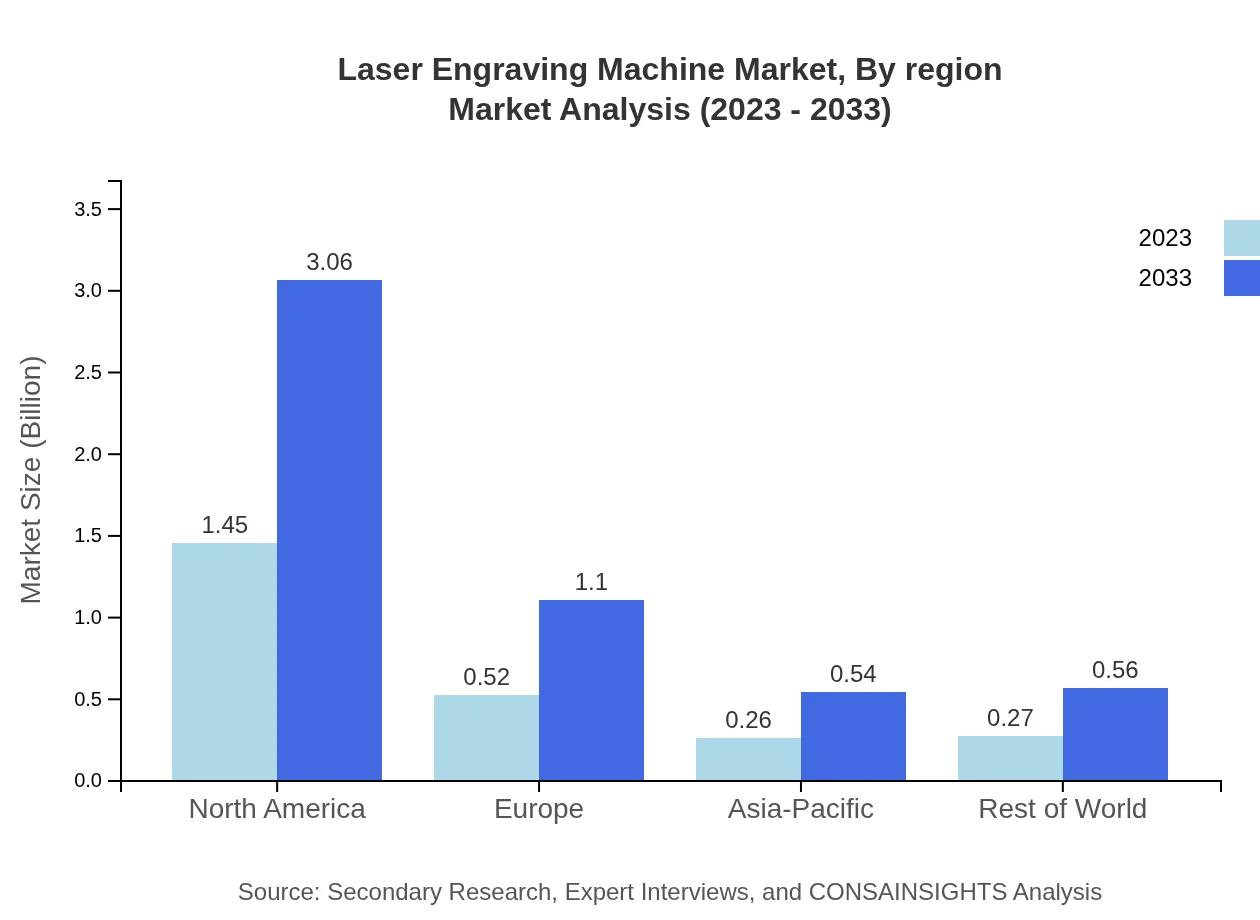

Europe Laser Engraving Machine Market Report:

Europe's laser engraving market is forecasted to grow from $0.83 billion in 2023 to $1.75 billion by 2033, as industries increasingly adopt laser engraving for its efficiency and precision, especially in the automotive and aerospace sectors.Asia Pacific Laser Engraving Machine Market Report:

The Asia Pacific region is anticipated to witness steady growth, with the market size projected to increase from $0.39 billion in 2023 to $0.82 billion by 2033. This growth is fueled by rising industrialization, particularly in countries like China and India, which are investing heavily in manufacturing and custom engraving technologies.North America Laser Engraving Machine Market Report:

North America holds a significant share of the market, valued at approximately $0.91 billion in 2023, projected to reach $1.92 billion by 2033. The region’s growth can be attributed to high demand for automation in manufacturing and advancements in laser technologies.South America Laser Engraving Machine Market Report:

In South America, the market is smaller, expected to grow from $0.02 billion in 2023 to $0.05 billion by 2033. Economic development and increasing adoption of laser technology in small and medium enterprises are driving this growth.Middle East & Africa Laser Engraving Machine Market Report:

The Middle East and Africa region is expected to see growth from $0.34 billion in 2023 to $0.72 billion by 2033. This increase is driven by infrastructure development and a boost in the retail and decoration sectors adopting personalized engraving solutions.Tell us your focus area and get a customized research report.

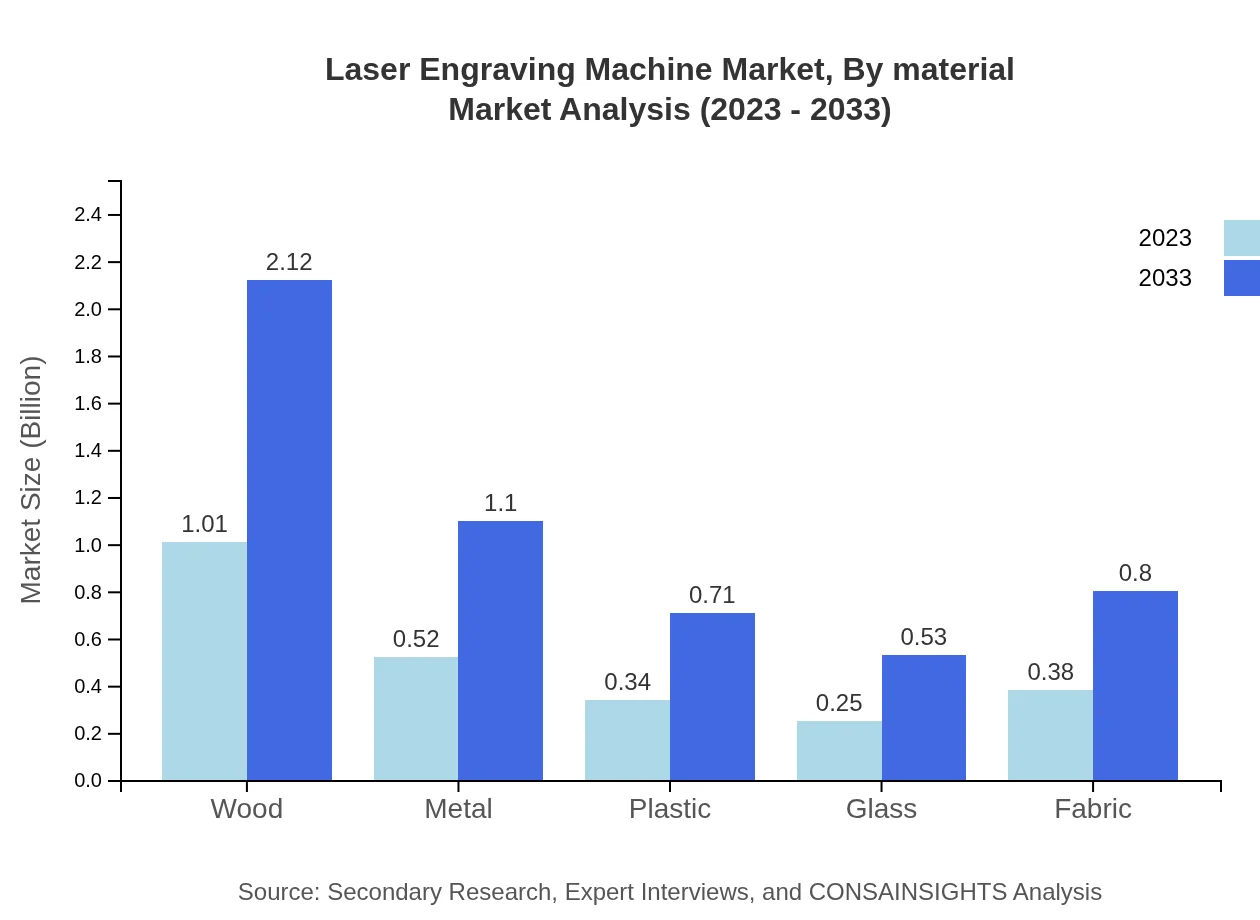

Laser Engraving Machine Market Analysis By Material

The material segmentation includes wood, metal, plastic, glass, and fabric. Wood leads the market at $1.01 billion (40.33% share in 2023), while metal and plastic follow, accounting for significant shares as industries leverage laser engraving for diverse materials.

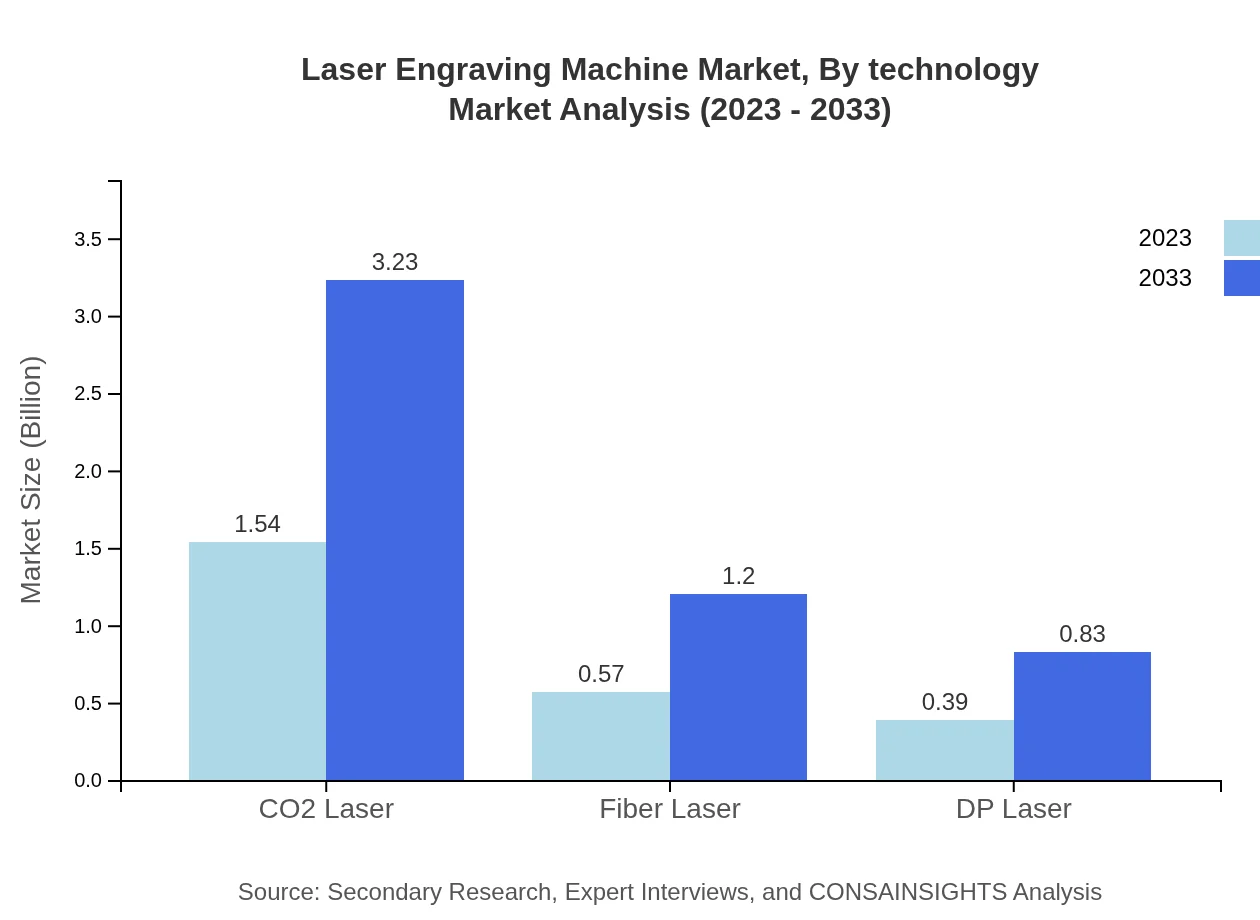

Laser Engraving Machine Market Analysis By Technology

Market trends indicate CO2 lasers dominate, holding a 61.44% share in 2023 with a market size of $1.54 billion. Fiber and DP lasers are also notable, focusing on precision applications in industrial marking and personalization.

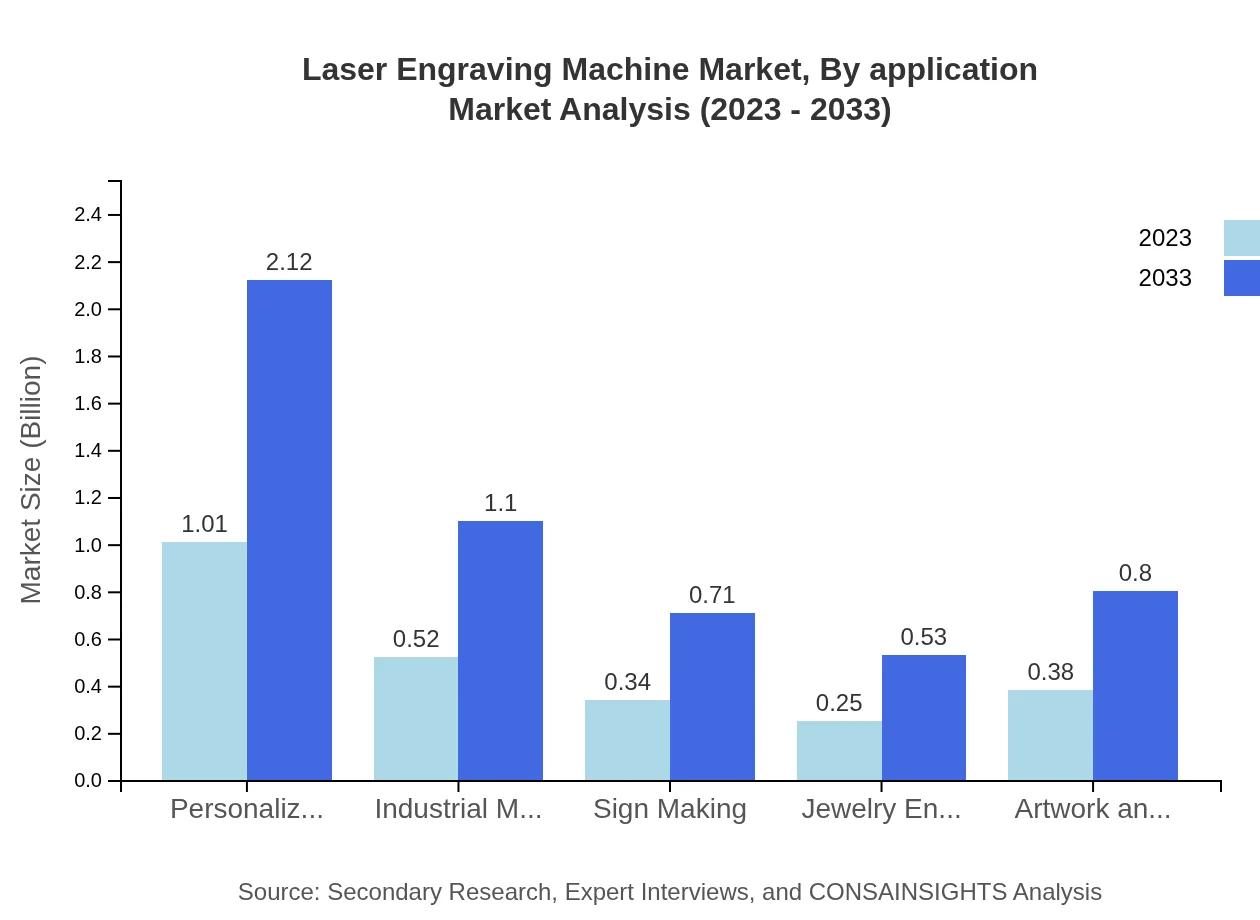

Laser Engraving Machine Market Analysis By Application

Applications span personalization, industrial marking, jewelry engraving, and sign making. Personalization leads with $1.01 billion (40.33% share), showcasing the demand for customized solutions in various sectors.

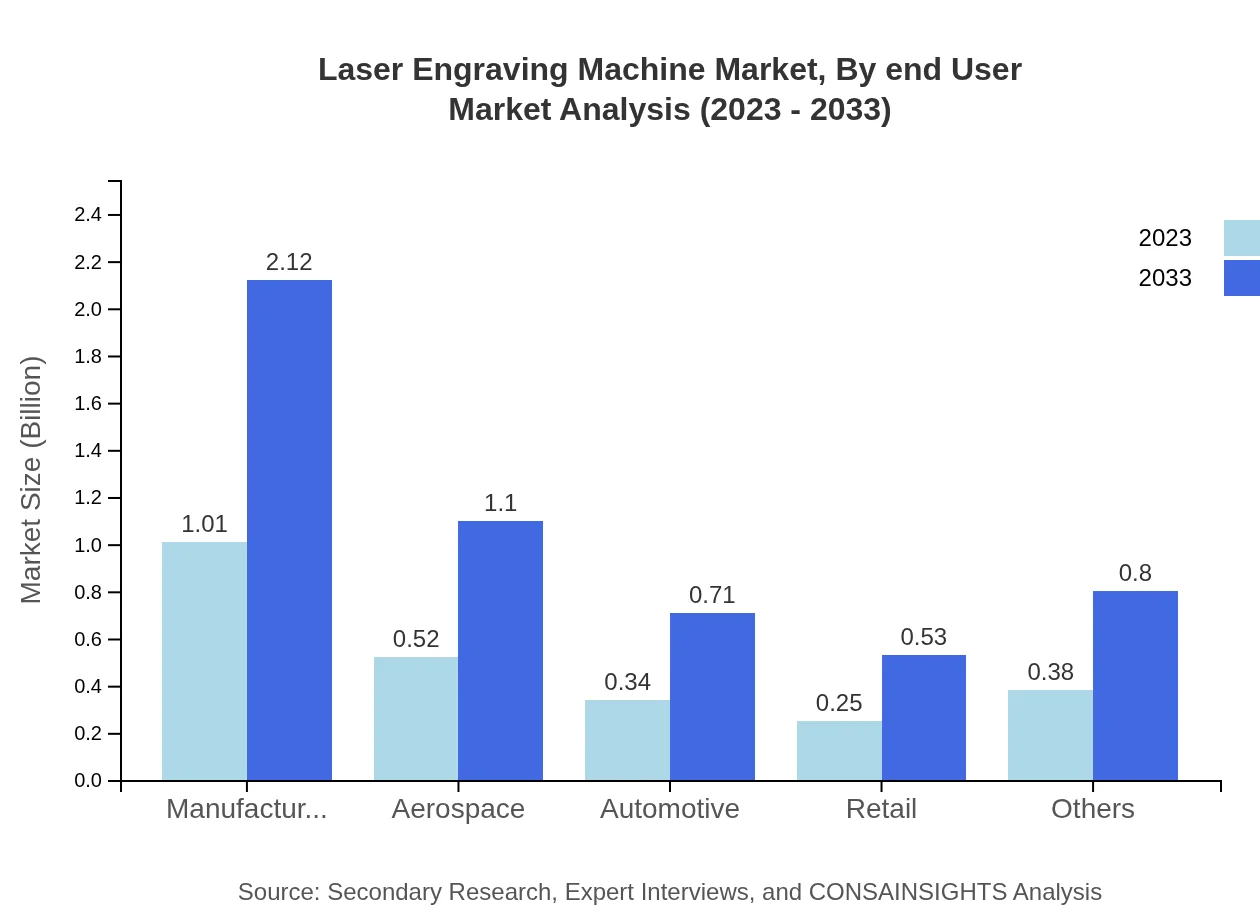

Laser Engraving Machine Market Analysis By End User

The end-user segmentation includes manufacturing, aerospace, automotive, and retail. Manufacturing dominates with a 40.33% market share, indicating extensive integration of laser systems into production lines.

Laser Engraving Machine Market Analysis By Region

The regional analysis showcases varying market dynamics, with North America as a key player followed by Europe and Asia Pacific. Each region's unique demands and technological adoption rates shape the overall market landscape.

Laser Engraving Machine Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Laser Engraving Machine Industry

Epilog Laser:

Epilog Laser provides high-quality, innovative laser engraving machines used across various industries, well-positioned due to advanced technology and user-friendly interfaces.Trotec Laser:

Trotec Laser is a leading manufacturer known for its powerful laser systems and software, catering to industrial marking and engraving markets with a reputation for reliability.Gravotech:

Gravotech specializes in laser engraving and marking solutions, offering versatile systems ideal for a range of applications, ensuring high precision and quality.Universal Laser Systems:

Universal Laser Systems manufactures advanced engraving and cutting solutions, focusing on integrating innovative technology in their laser systems for increased efficiency.We're grateful to work with incredible clients.

FAQs

What is the market size of laser Engraving Machine?

The global laser engraving machine market is projected to reach approximately $2.5 billion by 2033, growing at a CAGR of 7.5%. This growth is driven by rising applications across various industries including manufacturing, automotive, and personalization.

What are the key market players or companies in the laser Engraving Machine industry?

Key players in the laser engraving machine market include prominent companies such as Trotec, Epilog Laser, Universal Laser Systems, and Gravotech. These companies drive innovation and technological advancements in the laser engraving sector.

What are the primary factors driving the growth in the laser Engraving machine industry?

Key factors fueling growth include increasing demand for personalized products, advancements in laser technology, and a surge in applications across industries such as manufacturing and automotive. Additionally, the growing trend of customization enhances market expansion.

Which region is the fastest Growing in the laser Engraving machine market?

The fastest-growing region in the laser engraving machine market is North America, projected to reach $1.92 billion by 2033, growing from $0.91 billion in 2023, fueled by advancements in industrial applications and high adoption rates.

Does ConsaInsights provide customized market report data for the laser Engraving machine industry?

Yes, ConsaInsights offers customized market research reports catering to specific client requirements in the laser engraving machine industry, ensuring tailored insights for strategic decision-making and market analysis.

What deliverables can I expect from this laser Engraving Machine market research project?

Upon concluding the laser engraving machine market research project, clients can expect comprehensive deliverables such as detailed reports, market segmentation analysis, growth forecasts, and actionable insights into market trends.

What are the market trends of laser Engraving machine?

Current trends in the laser engraving machine market include the increasing use of CO2 lasers for diverse materials, growth in personalized product offerings, and advancements in automation technology in engraving processes, driving higher efficiency.