Lathe Machines Market Report

Published Date: 22 January 2026 | Report Code: lathe-machines

Lathe Machines Market Size, Share, Industry Trends and Forecast to 2033

This report delves into the Lathe Machines market, presenting market size, growth forecasts, and trends from 2023 to 2033. It covers market segmentation, technological advancements, key players, and regional analysis, providing a comprehensive framework to understand the dynamics of this industry during the forecast period.

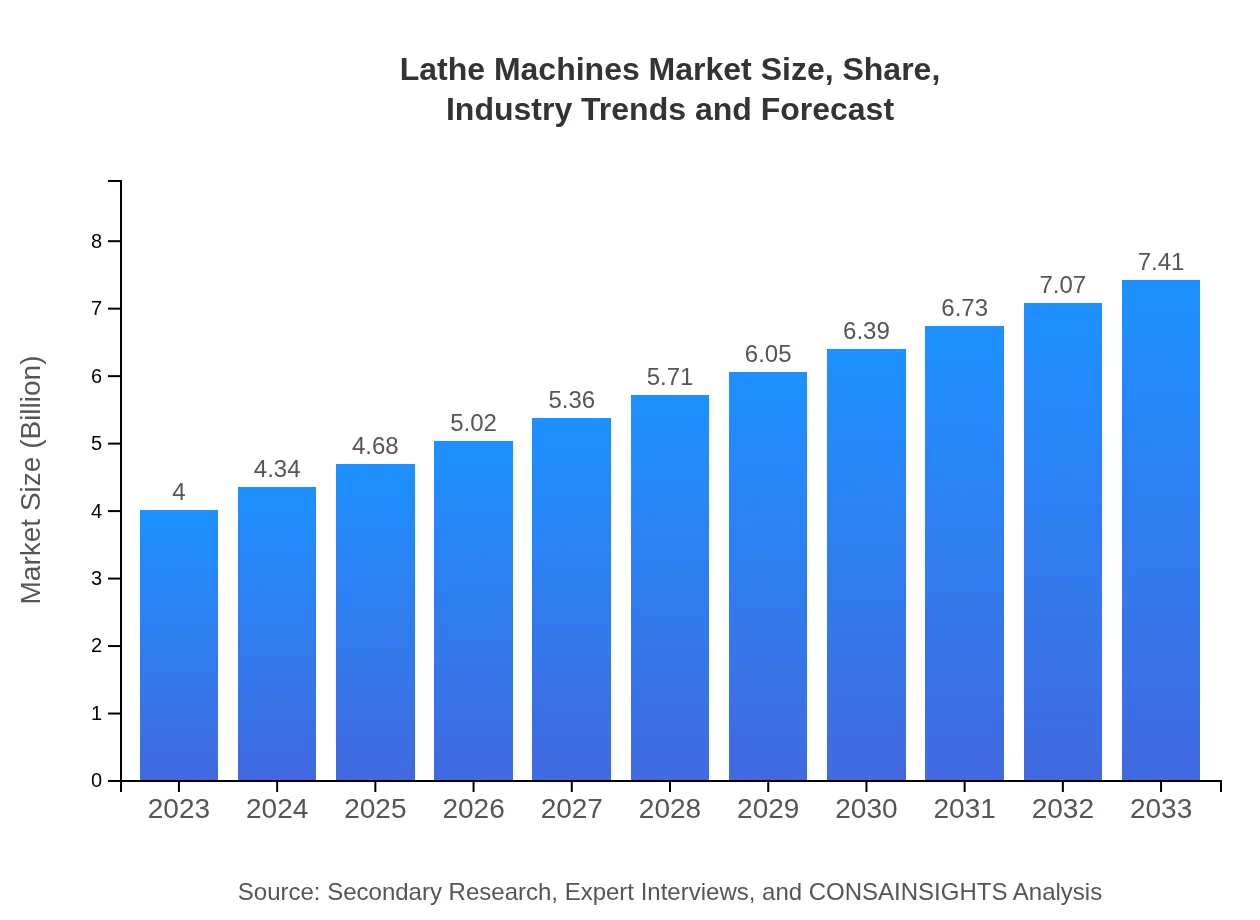

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $4.00 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $7.41 Billion |

| Top Companies | Haas Automation, Inc., Mazak Corporation, DMG MORI, Okuma Corporation, Yamazaki Mazak |

| Last Modified Date | 22 January 2026 |

Lathe Machines Market Overview

Customize Lathe Machines Market Report market research report

- ✔ Get in-depth analysis of Lathe Machines market size, growth, and forecasts.

- ✔ Understand Lathe Machines's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Lathe Machines

What is the Market Size & CAGR of Lathe Machines market in 2023?

Lathe Machines Industry Analysis

Lathe Machines Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Lathe Machines Market Analysis Report by Region

Europe Lathe Machines Market Report:

Europe's lathe machines market is set to expand from $1.23 billion in 2023 to $2.28 billion by 2033. The region is characterized by a strong focus on precision engineering and innovative manufacturing practices. Furthermore, stringent regulatory standards in automotive and aerospace industries drive demand for high-quality machining solutions, fostering growth across key markets.Asia Pacific Lathe Machines Market Report:

The Asia-Pacific region, with a market size of $0.75 billion in 2023, is anticipated to grow to $1.40 billion by 2033. This growth is fueled by expanding manufacturing sectors in countries like China, India, and Japan. An increasing emphasis on automation and technology adoption is driving demand for advanced lathe machines, particularly in the automotive and consumer goods industries.North America Lathe Machines Market Report:

North America is projected to increase its market size from $1.42 billion in 2023 to $2.64 billion by 2033. The presence of major manufacturing hubs, coupled with advancements in machining technologies, positions North America as a key player in the lathe machines market. Moreover, the shift towards automation and Industry 4.0 will further bolster market growth in the region.South America Lathe Machines Market Report:

In South America, the Leath Machines market is expected to grow from $0.20 billion in 2023 to $0.37 billion by 2033. The positive growth trajectory is attributed to ongoing industrialization efforts and the demand for machinery in local manufacturing processes. However, economic fluctuations and limited investments may create certain challenges in this region.Middle East & Africa Lathe Machines Market Report:

The Middle East and Africa market is expected to grow from $0.39 billion in 2023 to $0.73 billion by 2033. This growth will be propelled by rising construction and infrastructure projects, alongside increasing investments in manufacturing technologies. While challenges persist in terms of market maturity, there are significant opportunities for growth driven by modernization efforts in various industries.Tell us your focus area and get a customized research report.

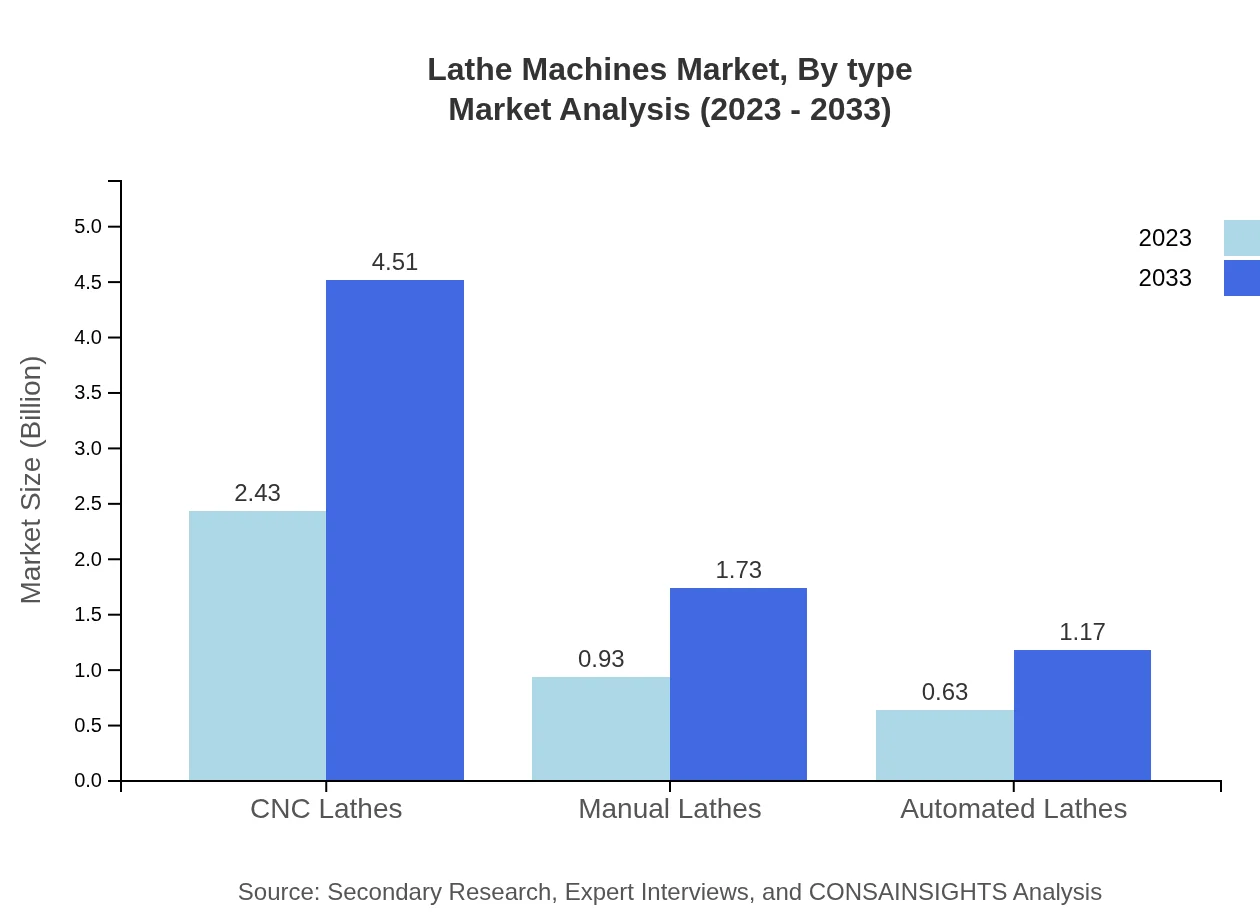

Lathe Machines Market Analysis By Type

The Lathe Machines market can be categorized into CNC lathes, manual lathes, and automated lathes. In 2023, the size of the CNC lathes segment stands at $2.43 billion and is expected to reach $4.51 billion by 2033, highlighting its dominance with a substantial share of 60.85% throughout the forecast period. In contrast, manual lathes, with a current size of $0.93 billion, are anticipated to grow to $1.73 billion, maintaining a 23.30% share. The automated lathes segment, currently at $0.63 billion, is set for growth to $1.17 billion, which constitutes a 15.85% market share.

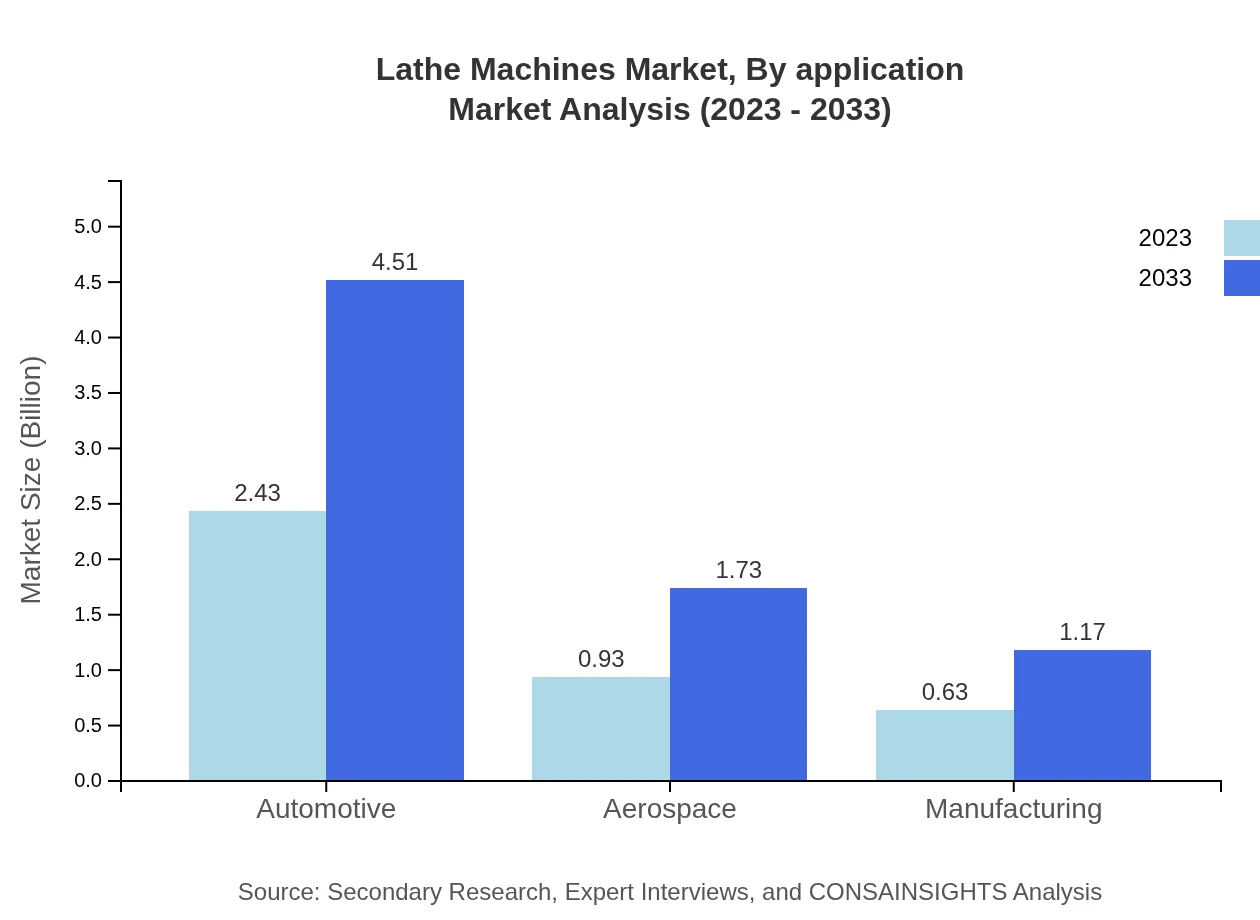

Lathe Machines Market Analysis By Application

Key applications of lathe machines are in the automotive, aerospace, electronics, and heavy machinery sectors. The automotive application leads the market, accounting for a share of 60.85%, with projected growth from $2.43 billion in 2023 to $4.51 billion by 2033. Aerospace and manufacturing are other vital applications, with shares of 23.30% and 15.85%, respectively, indicating a significant market opportunity.

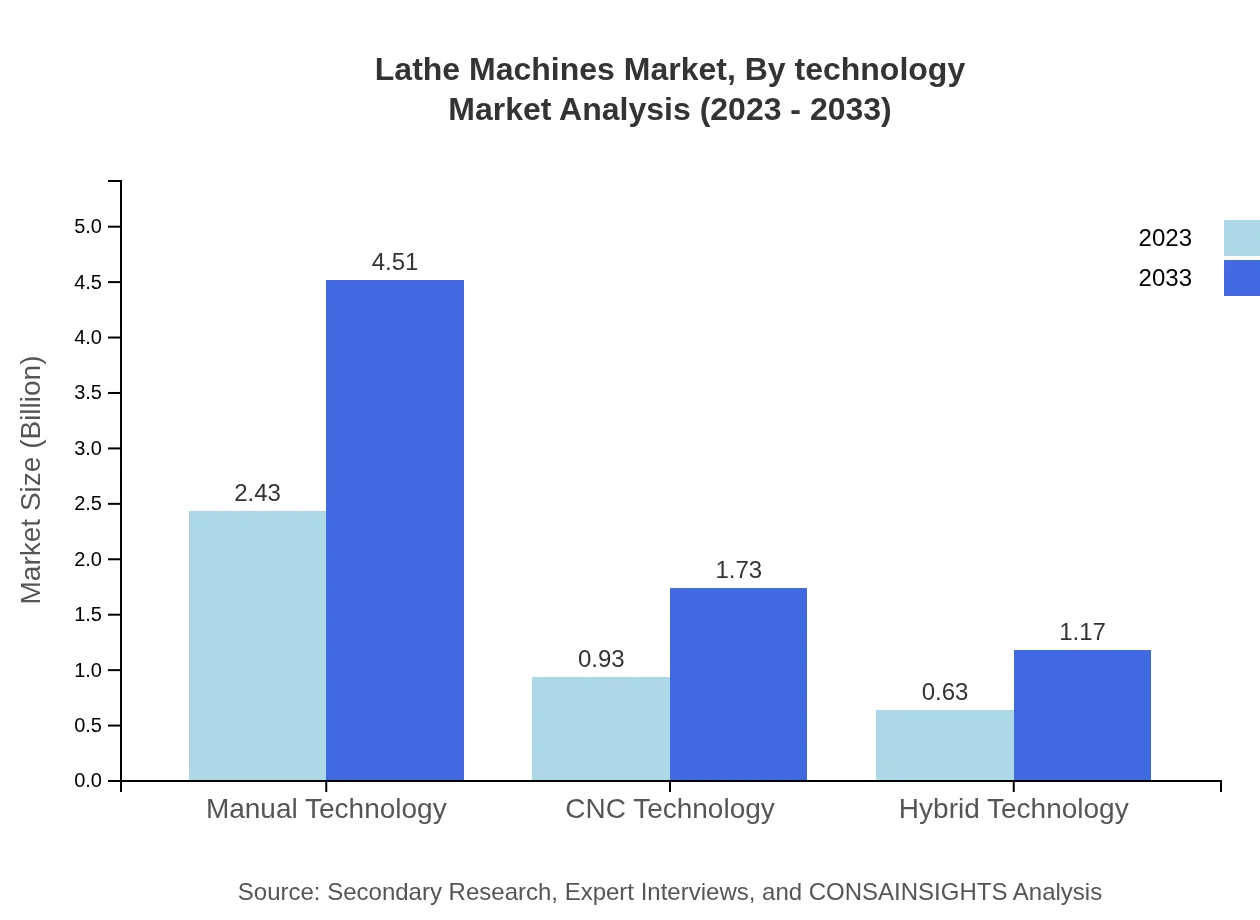

Lathe Machines Market Analysis By Technology

The lathe machines market is segmented into manual, CNC, and hybrid technologies. CNC technology leads with a market size of $0.93 billion in 2023, expected to reach $1.73 billion by 2033, constituting a 23.30% market share. Manual technology remains prominent with a significant share of 60.85%, while hybrid technology, although smaller, reflects growing interest with a forecast growth from $0.63 billion to $1.17 billion.

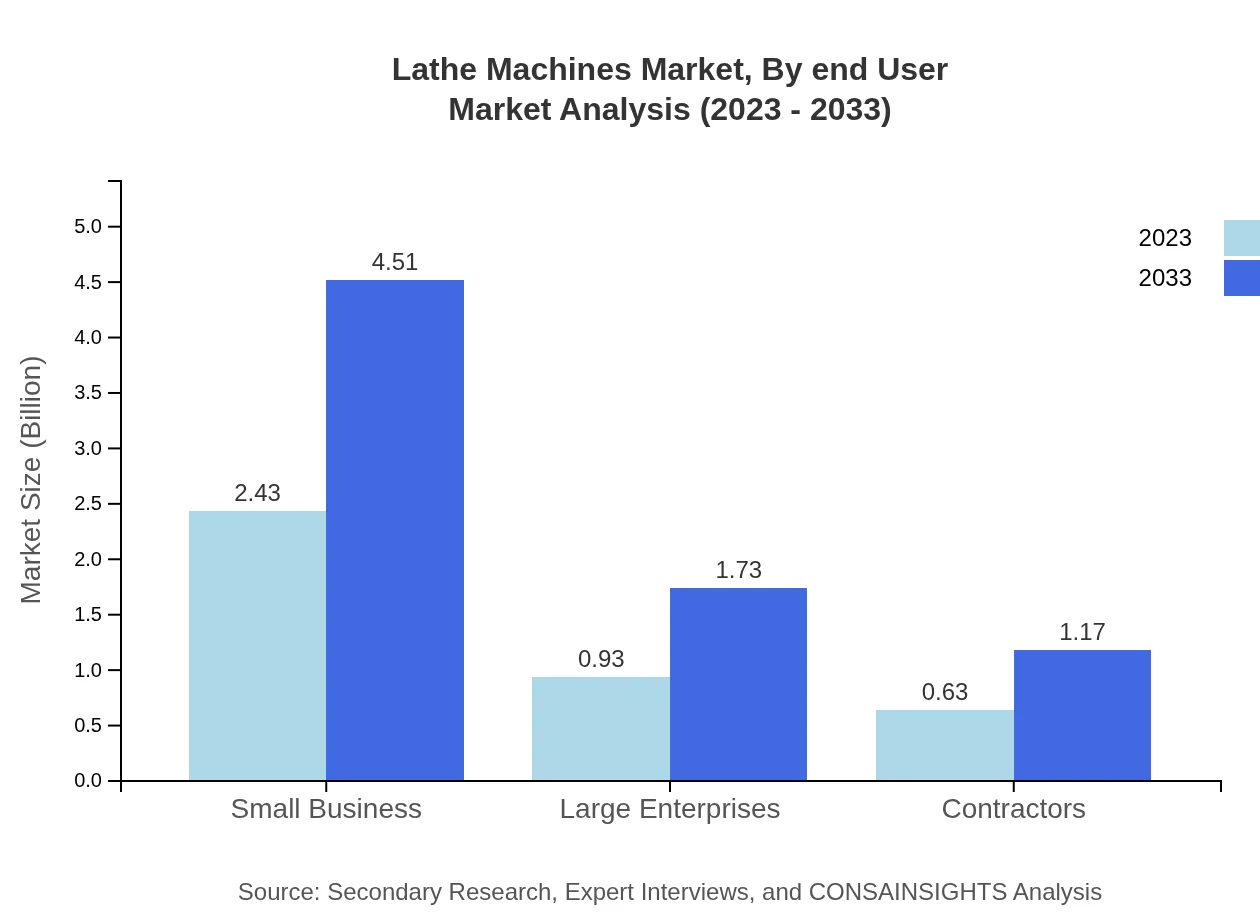

Lathe Machines Market Analysis By End User

The end-user segment comprises small businesses, large enterprises, and contractors. Small businesses dominated the market with a size of $2.43 billion in 2023, projected to grow to $4.51 billion by 2033, accounting for a 60.85% share. Large enterprises and contractors hold 23.30% and 15.85% shares, respectively, illustrating their diverse demands for lathe machines.

Lathe Machines Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Lathe Machines Industry

Haas Automation, Inc.:

Haas Automation is one of the prominent manufacturers of CNC equipment, known for its advanced lathes and machining centers. The company emphasizes a high level of reliability and service, catering to various industries including aerospace and automotive.Mazak Corporation:

Mazak is a pioneering company in the machine tool industry, providing solutions for the precise machining of complex parts. The company focuses on innovation through advanced technology, significantly impacting the lathe machines market.DMG MORI:

DMG MORI is a leading manufacturer of CNC machine tools, specializing in lathes and milling machines. The company is renowned for its commitment to quality and cutting-edge manufacturing solutions that meet evolving customer needs.Okuma Corporation:

Okuma is recognized for its high-quality CNC lathes, offering versatile solutions that cater to various sectors. The company aims to enhance performance through automation and innovative designs.Yamazaki Mazak:

Yamazaki Mazak stands out for producing advanced CNC lathes that deliver exceptional precision and efficiency. The company continually invests in research and development to enhance manufacturing performance.We're grateful to work with incredible clients.

FAQs

What is the market size of lathe Machines?

The global market size for lathe machines is projected to reach $4 billion by 2033, with a CAGR of 6.2%. This growth reflects increased demand across various industries and advancements in machining technologies.

What are the key market players or companies in this lathe Machines industry?

Key players in the lathe machines market include major manufacturers specializing in CNC technology, manual lathes, and automated solutions. They drive innovation and competition, impacting market dynamics significantly.

What are the primary factors driving the growth in the lathe Machines industry?

The growth of the lathe machines market is driven by advancements in manufacturing technology, increased automation, and rising demand from end-user industries for precision machining and efficiency in production.

Which region is the fastest Growing in the lathe Machines?

The fastest-growing regions include Europe, projected to grow from $1.23 billion in 2023 to $2.28 billion by 2033, followed closely by North America, from $1.42 billion to $2.64 billion during the same period.

Does ConsaInsights provide customized market report data for the lathe Machines industry?

Yes, ConsaInsights offers customized market report data tailored specifically to the lathe machines industry, allowing clients to receive insights that are relevant and focused on their unique business needs.

What deliverables can I expect from this lathe Machines market research project?

Clients can expect comprehensive deliverables including detailed market analyses, forecasts, competitive landscape assessments, and actionable insights tailored for strategic decision-making in the lathe machines sector.

What are the market trends of lathe Machines?

Current trends in the lathe machines market encompass increased adoption of CNC technology, a shift towards hybrid machines, and advancements in automation, revolutionizing production capabilities and efficiency.