Linear Motion Market Report

Published Date: 22 January 2026 | Report Code: linear-motion

Linear Motion Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Linear Motion market from 2023 to 2033, highlighting market trends, segmentation, regional insights, and industry leaders. Insights include projected market size, growth rates, and technological advancements shaping the industry.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

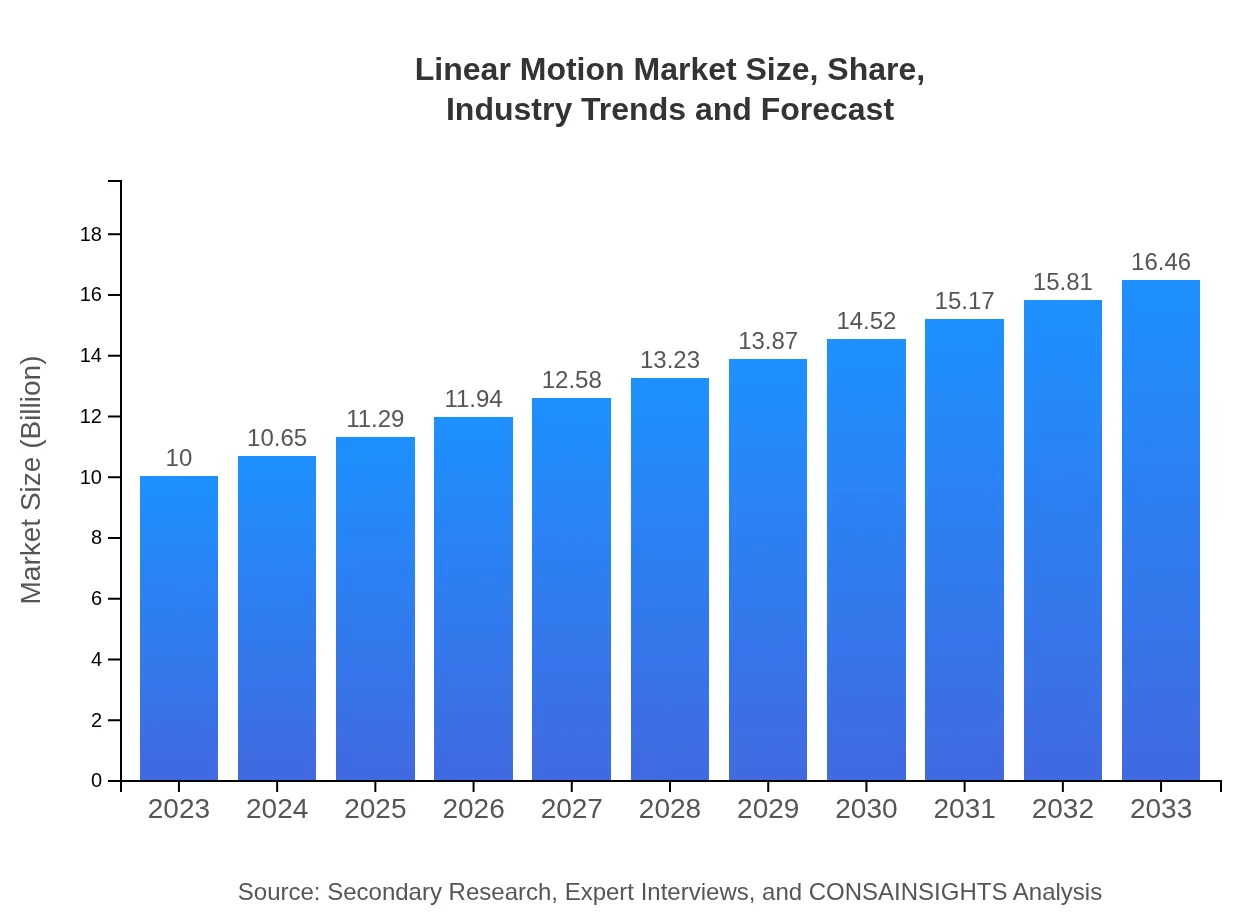

| 2023 Market Size | $10.00 Billion |

| CAGR (2023-2033) | 5% |

| 2033 Market Size | $16.46 Billion |

| Top Companies | Parker Hannifin, Bosch Rexroth, THK Co., Ltd., SKF Group |

| Last Modified Date | 22 January 2026 |

Linear Motion Market Overview

Customize Linear Motion Market Report market research report

- ✔ Get in-depth analysis of Linear Motion market size, growth, and forecasts.

- ✔ Understand Linear Motion's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Linear Motion

What is the Market Size & CAGR of Linear Motion market in 2023?

Linear Motion Industry Analysis

Linear Motion Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Linear Motion Market Analysis Report by Region

Europe Linear Motion Market Report:

Europe is another key player, with a market size of $2.66 billion in 2023, anticipated to grow to $4.38 billion by 2033. The increasing focus on renewable energy and automation in industries such as aerospace and automotive drives this growth.Asia Pacific Linear Motion Market Report:

The Asia Pacific region shows substantial growth potential, with a market size of $2.04 billion in 2023, projected to reach $3.36 billion by 2033. The boom in industrial automation in countries such as China and Japan significantly contributes to this growth, alongside rising investments in technological advancements.North America Linear Motion Market Report:

North America leads the market with a robust valuation of $3.31 billion in 2023, expected to reach $5.45 billion by 2033. This dominance is attributed to advanced manufacturing technologies and a strong automotive sector, which continually seek innovative linear motion solutions.South America Linear Motion Market Report:

In South America, the Linear Motion market is comparatively smaller, with a valuation of $0.91 billion projected to grow to $1.49 billion by 2033. Growth is supported by increasing investment in infrastructure and manufacturing processes, despite regional economic challenges.Middle East & Africa Linear Motion Market Report:

The Middle East and Africa show a market size of $1.08 billion in 2023, growing to $1.77 billion by 2033. The growth is primarily driven by the expanding manufacturing sector, despite various regional economic fluctuations.Tell us your focus area and get a customized research report.

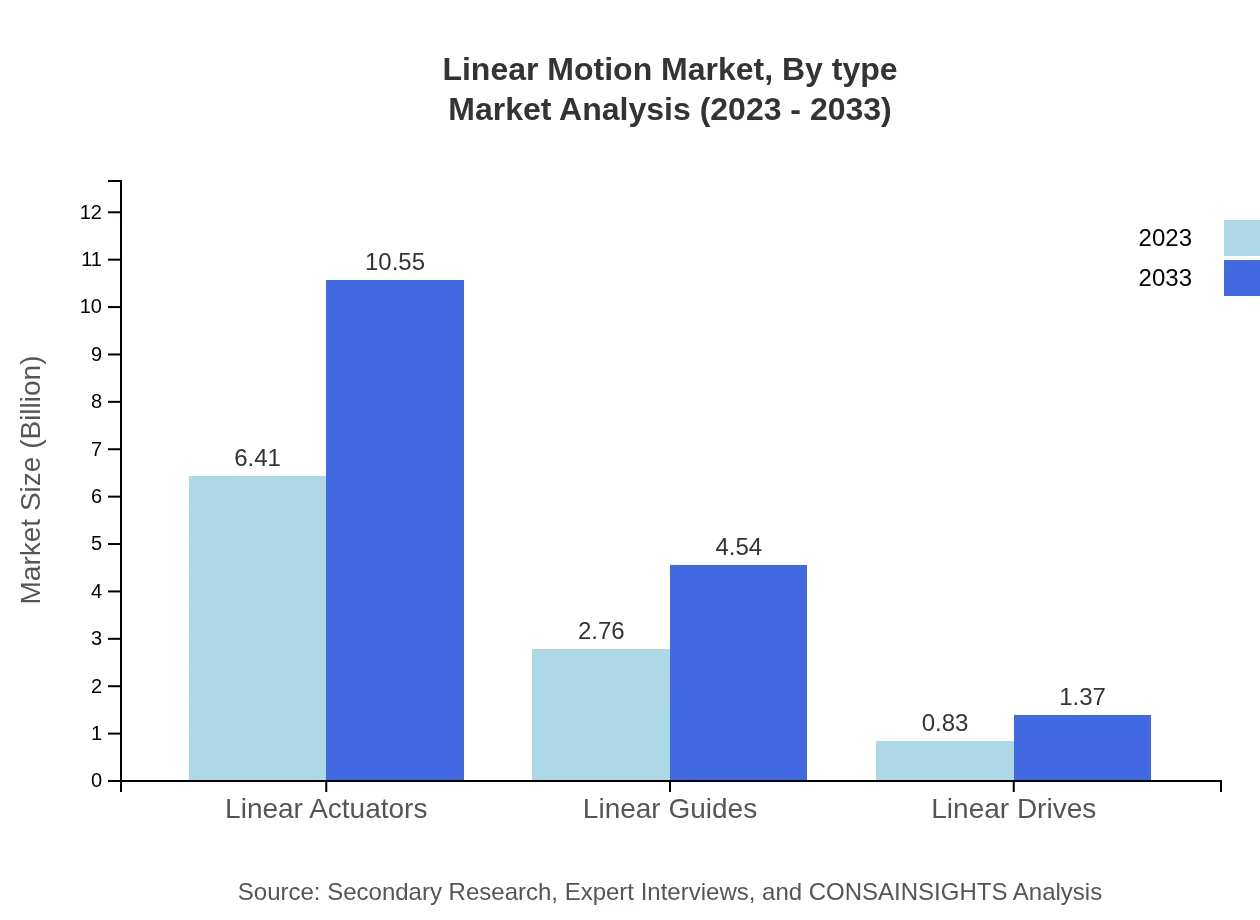

Linear Motion Market Analysis By Type

The Linear Motion market shows significant performance across different product categories. Linear Actuators are projected to dominate the market, with a size of $6.41 billion in 2023, growing to $10.55 billion by 2033. Other categories include Linear Guides, valued at $2.76 billion in 2023, expected to grow to $4.54 billion by 2033, and Linear Drives, projected to rise from $0.83 billion to $1.37 billion during the same period.

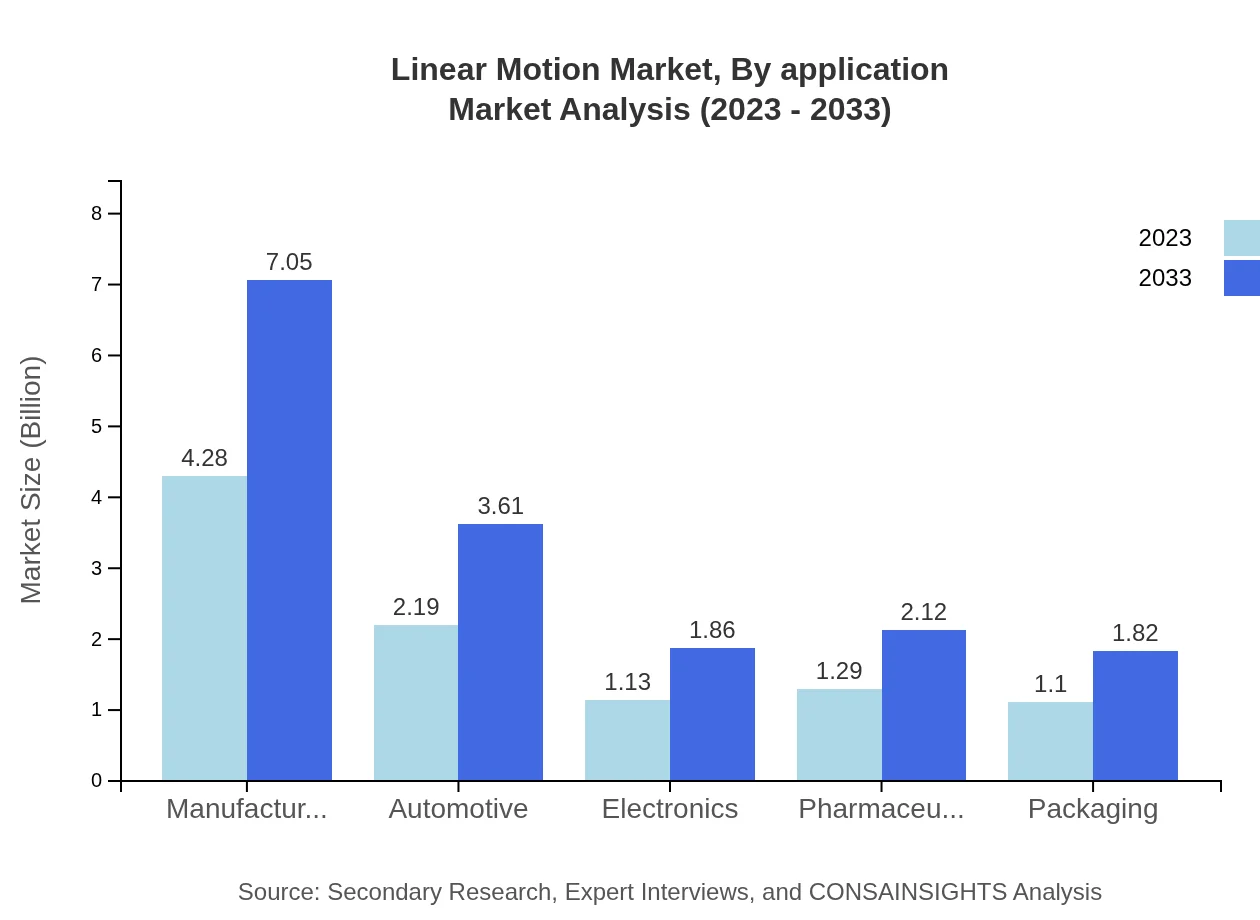

Linear Motion Market Analysis By Application

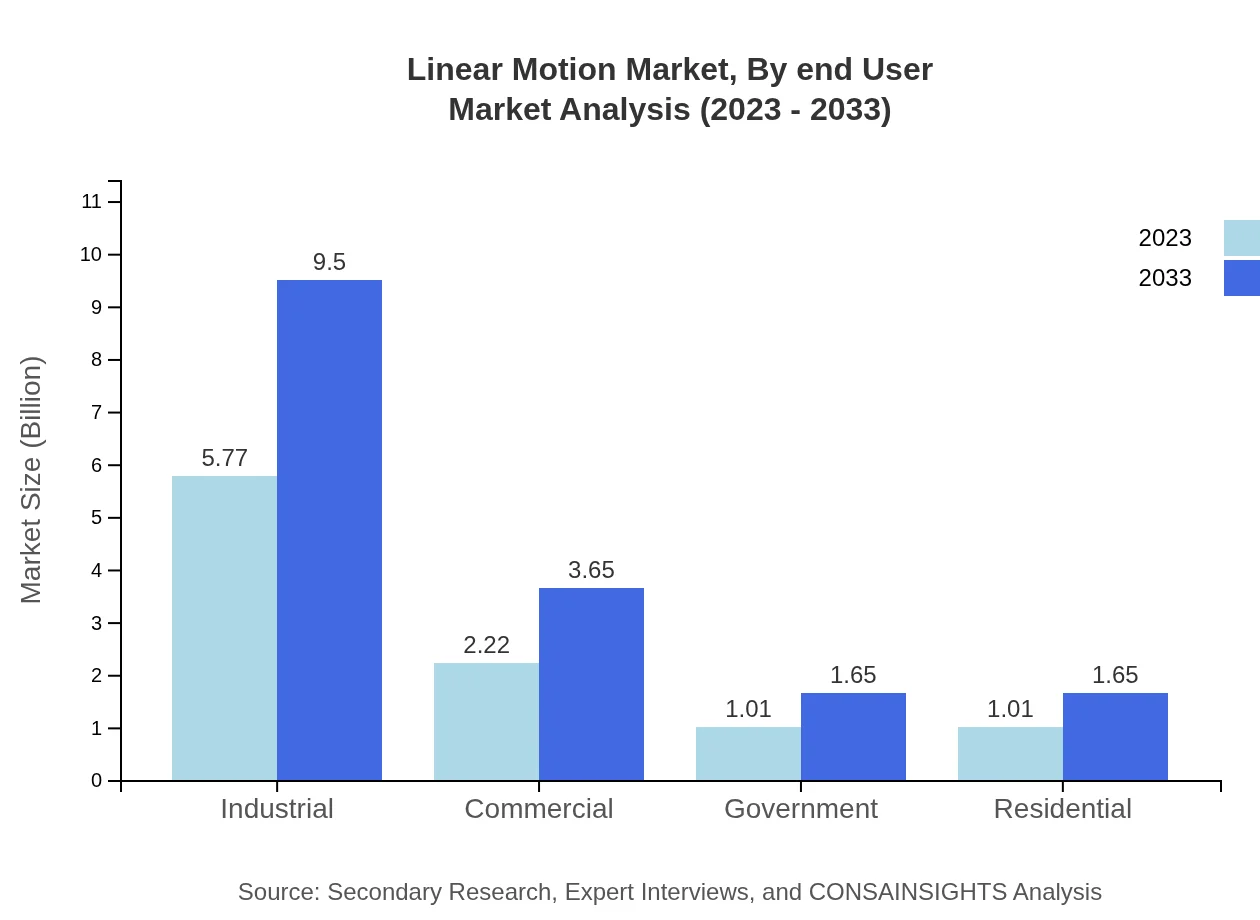

In terms of applications, the Industrial sector accounts for roughly $5.77 billion in 2023 and is expected to grow to $9.50 billion by 2033. The commercial and government sectors also contribute significantly, with expected growth stemming from an increase in automation and process improvements.

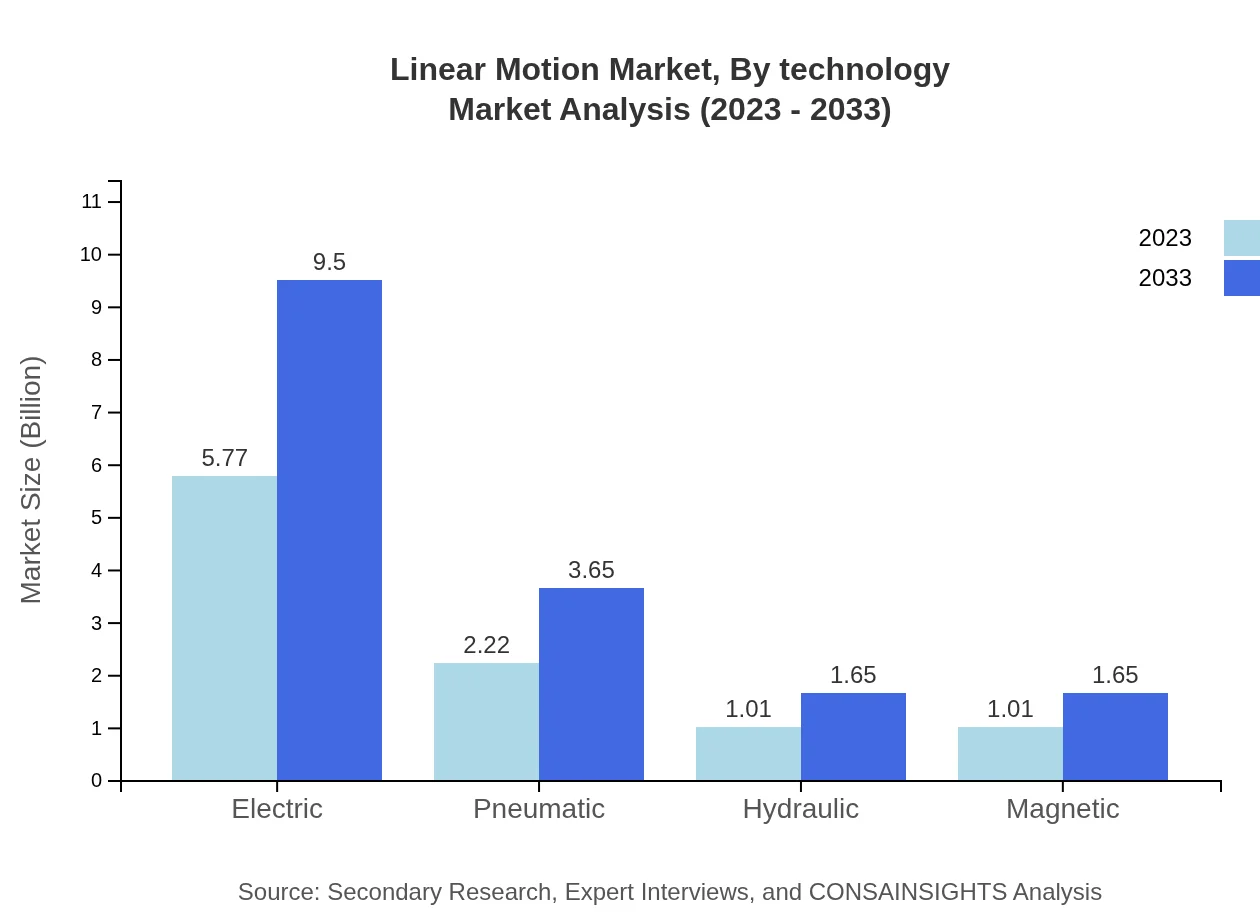

Linear Motion Market Analysis By Technology

The technology segment is growing rapidly, with Electric systems leading the way, expected to maintain a market share of 57.74% through 2033. Pneumatic and Hydraulic systems also show a steady performance, retaining essential market shares due to their specific utility in various applications.

Linear Motion Market Analysis By End User

Key end-user industries include Manufacturing, Automotive, and Pharmaceuticals, accounting collectively for a large portion of the Linear Motion market. The Manufacturing industry's projected size from $4.28 billion in 2023 to $7.05 billion by 2033 tells a remarkable growth story, reflecting the sector's shift toward automation and precision engineering.

Linear Motion Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Linear Motion Industry

Parker Hannifin:

A leading provider of motion control technologies, providing a broad range of linear motion solutions suitable for various industrial applications.Bosch Rexroth:

Known for high-quality drive and control technologies, Bosch Rexroth significantly contributes to the market through innovative linear motion systems.THK Co., Ltd.:

A pioneer in linear motion products, THK develops innovative components designed to improve efficiency and precision in diverse industries.SKF Group:

Specializing in bearings and seals, SKF also provides efficient and advanced linear motion solutions, enhancing operational reliability.We're grateful to work with incredible clients.

FAQs

What is the market size of linear motion?

The global linear motion market was valued at approximately $10 billion in 2023 and is projected to grow at a CAGR of 5%, reaching around $16.3 billion by 2033.

What are the key market players or companies in this linear motion industry?

Key players in the linear motion industry include major manufacturers and suppliers such as THK, Bosch Rexroth, Siemens, and Schneider Electric, who are critical in driving innovation and delivering high-quality products.

What are the primary factors driving the growth in the linear motion industry?

Key factors driving growth in the linear motion market include the increasing demand for automation in manufacturing processes, advancements in technology, and the growing use of electric actuators in various applications.

Which region is the fastest Growing in the linear motion market?

The Asia Pacific region is anticipated to be the fastest-growing market for linear motion, with its market size projected to increase from $2.04 billion in 2023 to $3.36 billion by 2033.

Does ConsaInsights provide customized market report data for the linear motion industry?

Yes, ConsaInsights offers customized market report data for the linear motion industry, enabling clients to obtain tailored insights and analyses based on specific needs and market dynamics.

What deliverables can I expect from this linear motion market research project?

From this linear motion market research project, you can expect comprehensive reports, detailed market analysis, segment evaluations, forecasts, and customized data tailored to your specific business needs.

What are the market trends of linear motion?

Current trends in the linear motion market include a shift towards electric systems, increased demand in automation sectors, and a growing emphasis on sustainable and energy-efficient solutions.