Machine Automation Controller Market Report

Published Date: 22 January 2026 | Report Code: machine-automation-controller

Machine Automation Controller Market Size, Share, Industry Trends and Forecast to 2033

This report explores the Machine Automation Controller market, providing insights into market trends, segmentation, regional performance, and future forecasts from 2023 to 2033.

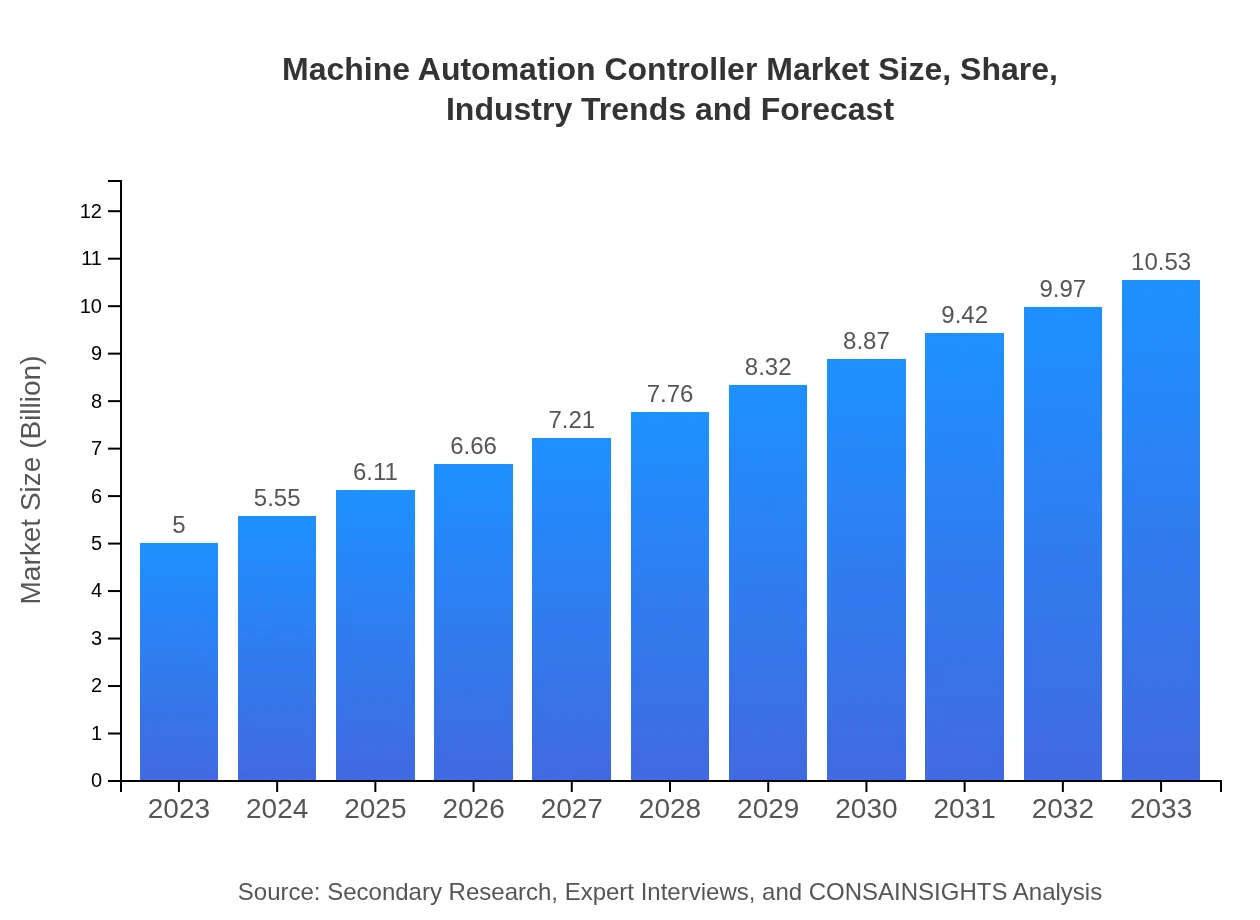

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | Siemens AG, Rockwell Automation, Inc., Schneider Electric, ABB Ltd., Honeywell International Inc. |

| Last Modified Date | 22 January 2026 |

Machine Automation Controller Market Overview

Customize Machine Automation Controller Market Report market research report

- ✔ Get in-depth analysis of Machine Automation Controller market size, growth, and forecasts.

- ✔ Understand Machine Automation Controller's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Machine Automation Controller

What is the Market Size & CAGR of Machine Automation Controller market in 2023 and 2033?

Machine Automation Controller Industry Analysis

Machine Automation Controller Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Machine Automation Controller Market Analysis Report by Region

Europe Machine Automation Controller Market Report:

The European market for Machine Automation Controllers is set to grow from 1.41 billion USD in 2023 to 2.96 billion USD by 2033. The region's focus on automation in manufacturing processes is a key driver of this growth.Asia Pacific Machine Automation Controller Market Report:

The Asia Pacific region, valued at 0.93 billion USD in 2023, is anticipated to experience significant growth, reaching 1.97 billion USD by 2033. This growth is propelled by rapid industrialization and increased investments in automation technologies in countries like China, Japan, and India.North America Machine Automation Controller Market Report:

North America is expected to dominate the market, with a valuation of 1.92 billion USD in 2023, projected to double to 4.05 billion USD by 2033, fueled by advancements in IoT and robotics technology.South America Machine Automation Controller Market Report:

In South America, the Machine Automation Controller market is projected to grow from 0.31 billion USD in 2023 to 0.65 billion USD by 2033. Factors such as the growing manufacturing sector and the need for modernized equipment are driving this growth.Middle East & Africa Machine Automation Controller Market Report:

In the Middle East and Africa, the market is anticipated to increase from 0.43 billion USD in 2023 to 0.90 billion USD by 2033 due to increasing industrial investments and the push for digital transformation.Tell us your focus area and get a customized research report.

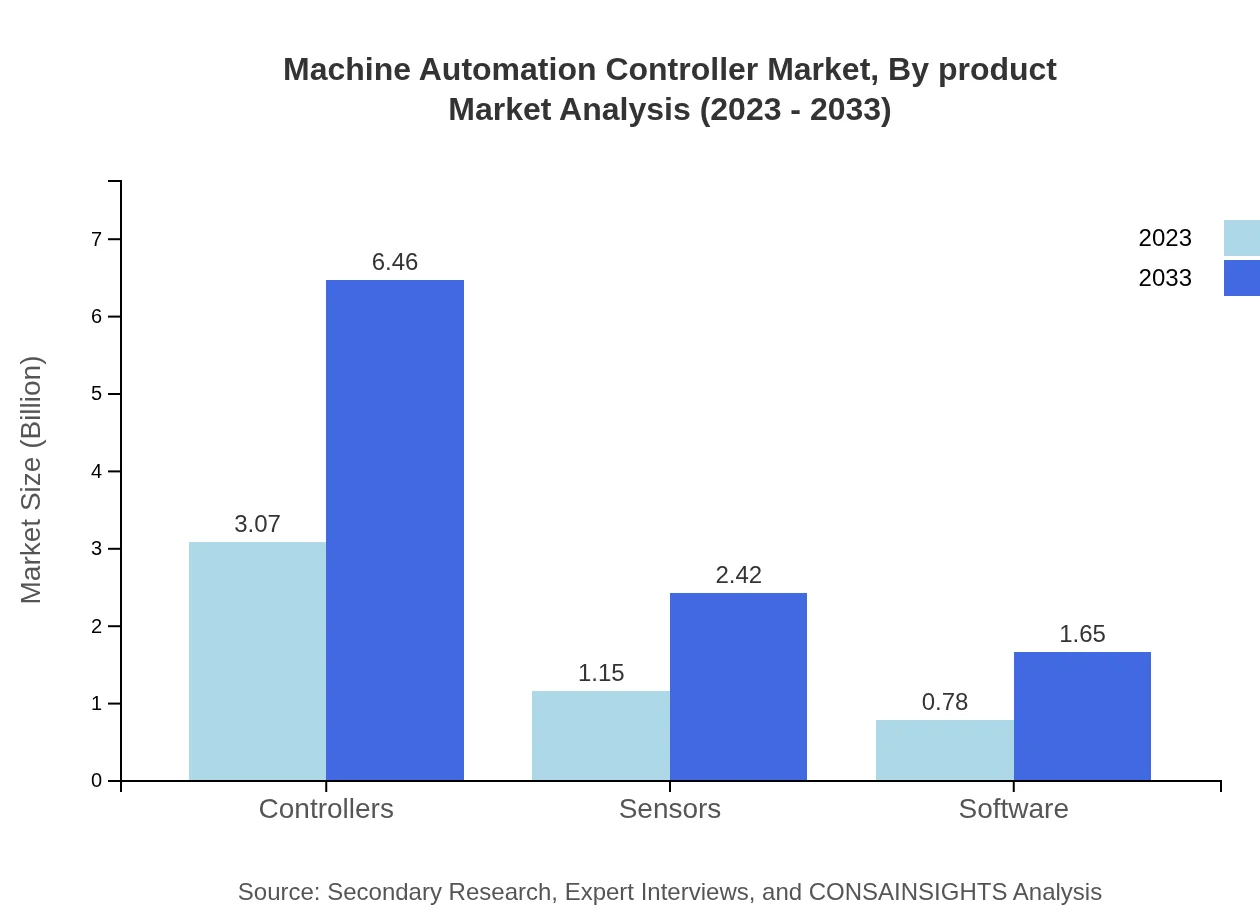

Machine Automation Controller Market Analysis By Product

In 2023, the Controllers segment is valued at 3.07 billion USD and is expected to reach 6.46 billion USD by 2033, maintaining a dominant share of approximately 61.39%. The Sensors segment will increase from 1.15 billion USD to 2.42 billion USD, holding a 22.98% market share, while Software solutions will grow from 0.78 billion USD to 1.65 billion USD, accounting for 15.63% market share.

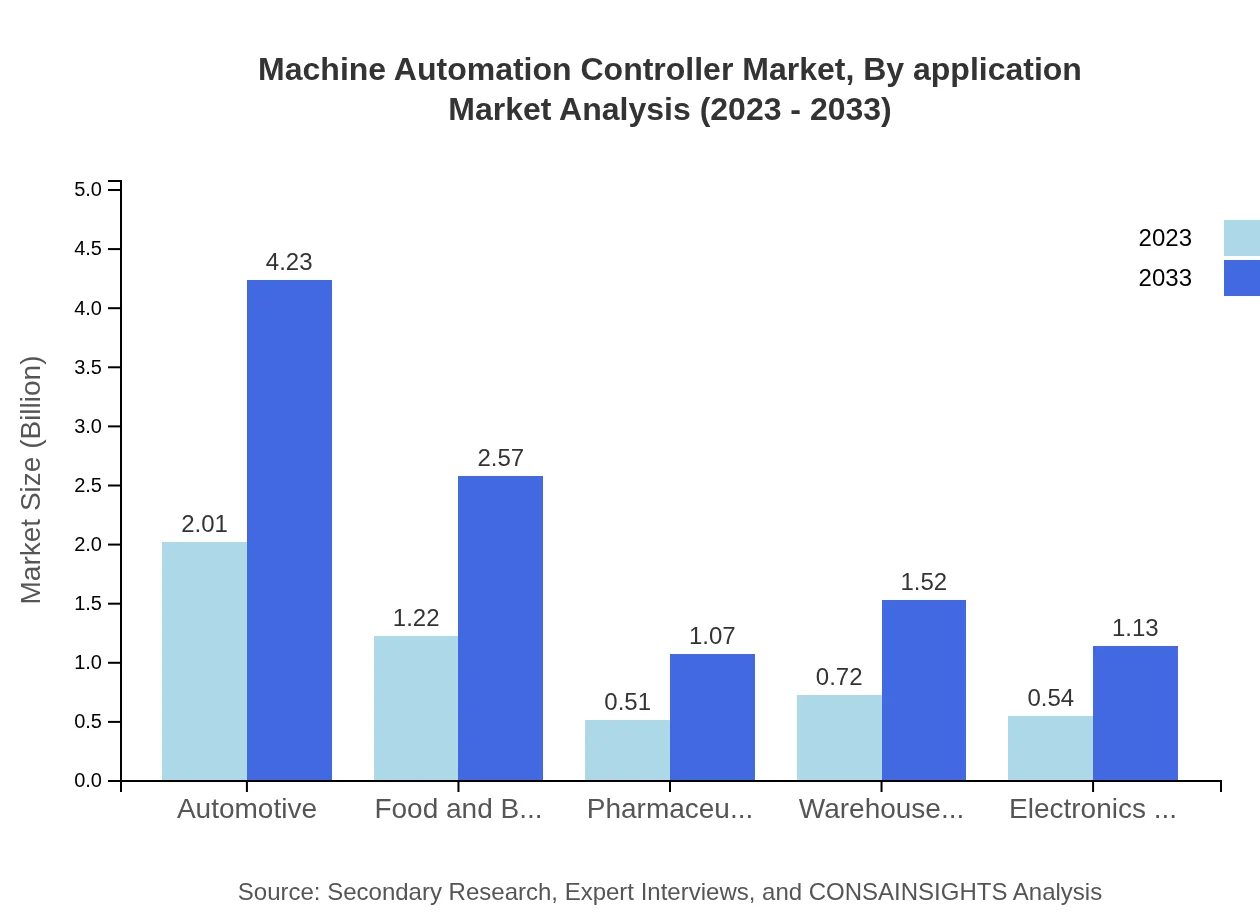

Machine Automation Controller Market Analysis By Application

Applications in industries such as Automotive, Aerospace, and Oil & Gas significantly impact the market. For instance, the Automotive sector is currently valued at 2.01 billion USD and expected to grow to 4.23 billion USD by 2033, reflecting a trend towards automation in vehicle manufacturing.

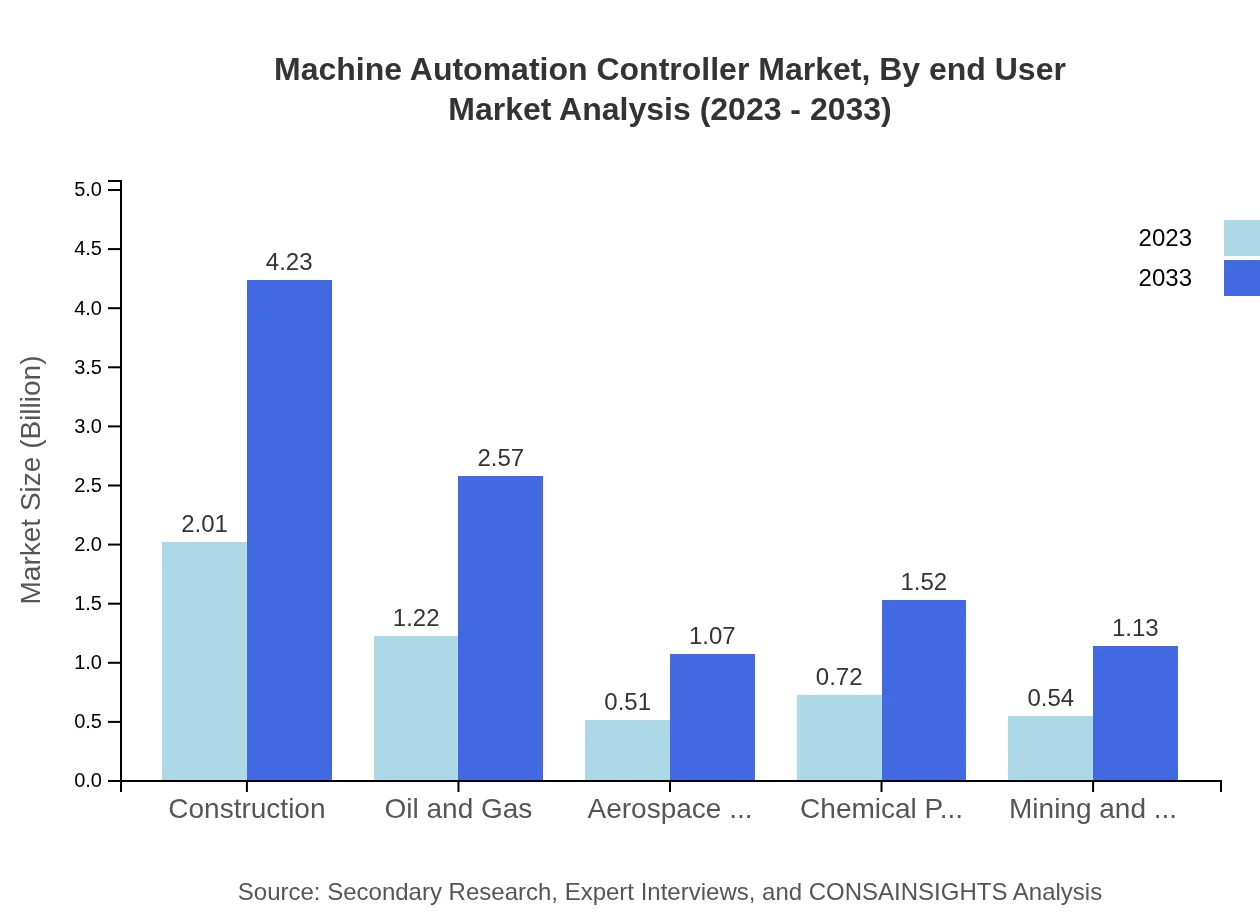

Machine Automation Controller Market Analysis By End User

End-users span several industries, including Pharmaceuticals, Chemicals, and Electronics Manufacturing. The Pharmaceuticals sector notably saw growth from 0.51 billion USD to 1.07 billion USD by 2033, highlighting the rise in automated quality control systems.

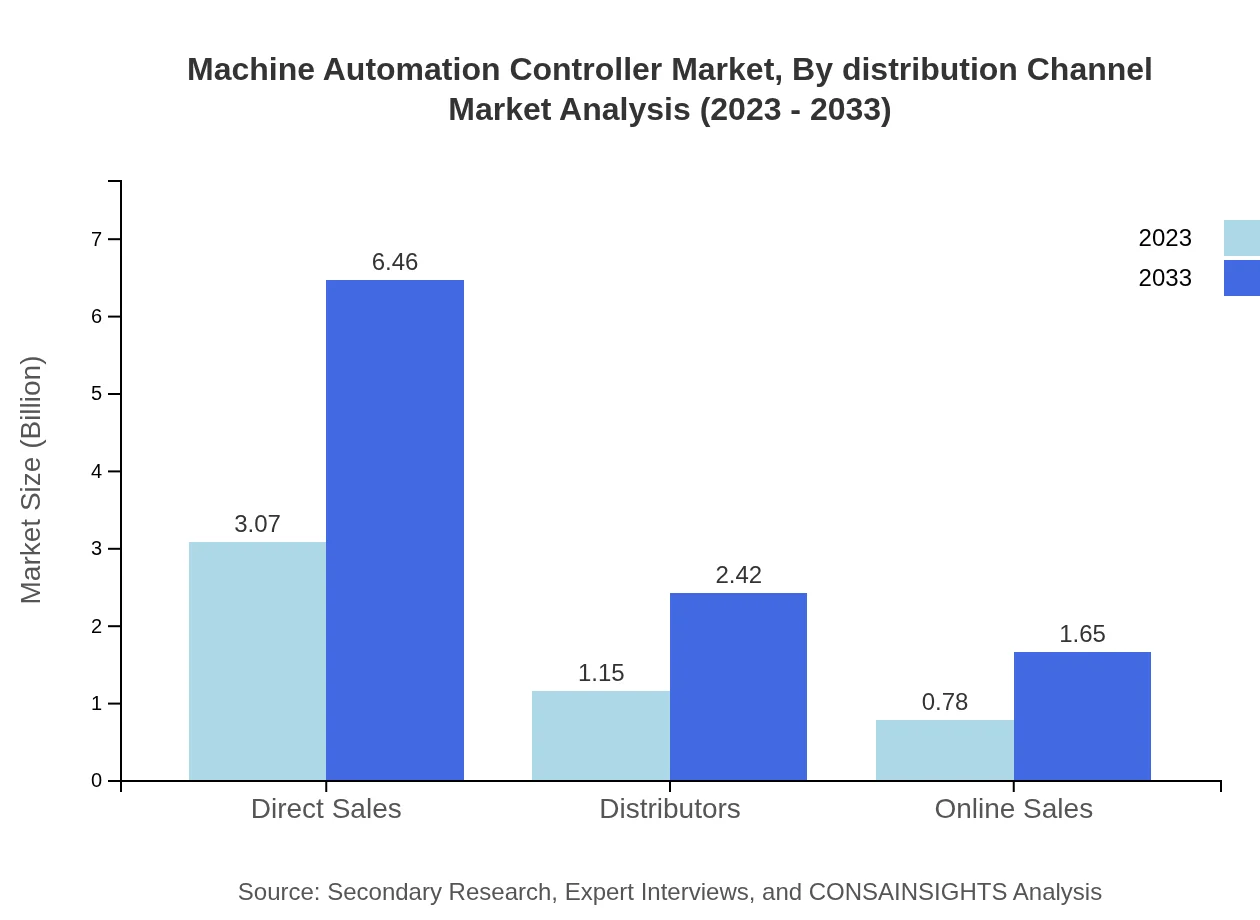

Machine Automation Controller Market Analysis By Distribution Channel

Distribution through Direct Sales holds a substantial market share of 61.39%, valued at 3.07 billion USD and expected to reach 6.46 billion USD by 2033. Meanwhile, Online Sales and Distributor channels are also gaining traction with expected growth rates of 15.63% and 22.98% respectively.

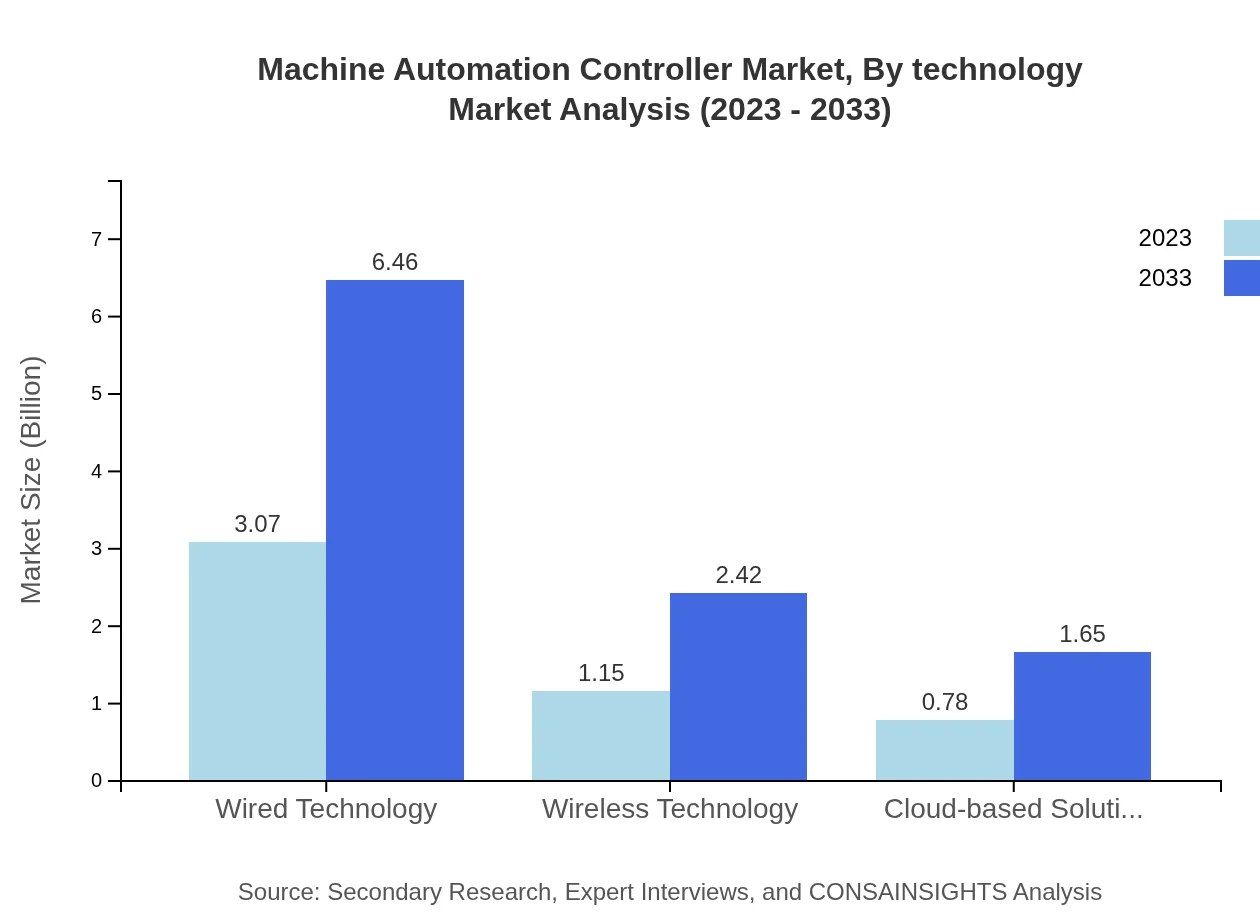

Machine Automation Controller Market Analysis By Technology

The market's technological landscape is evolving, with Wired Technology leading at 3.07 billion USD in 2023. Wireless Technology and Cloud-based Solutions also show potential growth, with market sizes projected to increase significantly by 2033, indicating a trend towards more flexible automation solutions.

Machine Automation Controller Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Machine Automation Controller Industry

Siemens AG:

Siemens AG is a leading global technology company specializing in the automation and digitalization of industries, offering a wide range of innovative products and solutions for automation controllers.Rockwell Automation, Inc.:

Rockwell Automation provides industrial automation solutions and information services, focusing on innovative controllers that enhance operational efficiency in various industries.Schneider Electric:

Schneider Electric is a multinational corporation engaged in the digital transformation of energy management and automation, delivering state-of-the-art automation controllers.ABB Ltd.:

ABB specializes in robotics, power, and automation technology, providing comprehensive automation solutions tailored for various sectors.Honeywell International Inc.:

Honeywell offers a range of automation and control solutions for various industries, leveraging advanced technologies to deliver efficient machine automation controllers.We're grateful to work with incredible clients.

FAQs

What is the market size of machine Automation Controller?

The machine automation controller market is projected to grow from $5 billion in 2023 to a significant size by 2033, with a CAGR of 7.5%. This growth reflects the increasing adoption of automation technologies across various industries.

What are the key market players or companies in the machine Automation Controller industry?

Key players in the machine automation controller market include major companies from the automation, robotics, and manufacturing sectors. These organizations lead in innovation, product development, and market share, shaping trends through advanced technologies.

What are the primary factors driving the growth in the machine Automation Controller industry?

The primary growth drivers for the machine automation controller industry include technological advancements, increasing demand for operational efficiency, heightened focus on automation in manufacturing, and the introduction of smart manufacturing solutions that leverage IoT.

Which region is the fastest Growing in the machine Automation Controller?

North America is the fastest-growing region in the machine automation controller market, expected to increase from $1.92 billion in 2023 to $4.05 billion by 2033. This growth is propelled by significant investments in automation technologies and smart manufacturing.

Does ConsaInsights provide customized market report data for the machine Automation Controller industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the machine automation controller industry. We provide detailed insights, allowing businesses to make informed decisions based on current market dynamics.

What deliverables can I expect from this machine Automation Controller market research project?

From the machine automation controller market research project, clients can expect comprehensive reports, market forecasts, regional analyses, competitive insights, and strategic recommendations that cater to specific business objectives.

What are the market trends of machine Automation Controller?

Current trends in the machine automation controller market include a surge in wireless technology adoption, integration of IoT solutions, and rising demand for cloud-based applications. These trends signify a shift towards smarter, more connected industrial solutions.