Machine Control System Market Report

Published Date: 22 January 2026 | Report Code: machine-control-system

Machine Control System Market Size, Share, Industry Trends and Forecast to 2033

This report analyzes the Machine Control System market from 2023 to 2033, providing insights on market size, growth rates, trends, and dynamics across various segments and regions.

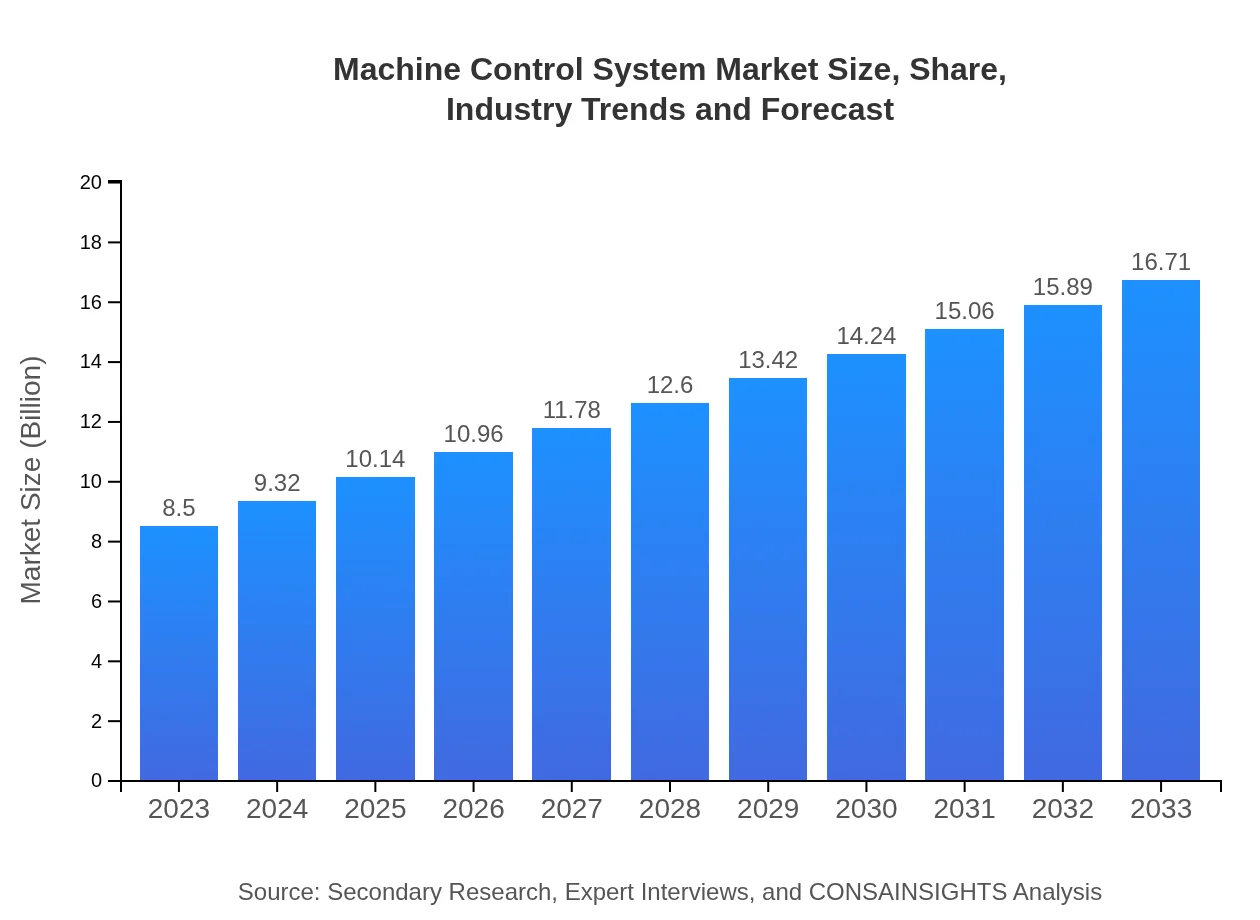

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $8.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $16.71 Billion |

| Top Companies | Siemens AG, Rockwell Automation, Honeywell International Inc., Schneider Electric |

| Last Modified Date | 22 January 2026 |

Machine Control System Market Overview

Customize Machine Control System Market Report market research report

- ✔ Get in-depth analysis of Machine Control System market size, growth, and forecasts.

- ✔ Understand Machine Control System's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Machine Control System

What is the Market Size & CAGR of Machine Control System market in 2023?

Machine Control System Industry Analysis

Machine Control System Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Machine Control System Market Analysis Report by Region

Europe Machine Control System Market Report:

Europe's market is set to increase from $3.03 billion in 2023 to about $5.95 billion by 2033. The region's maturity in automation and favorable regulatory frameworks contribute to the robust demand for machine control systems, especially in manufacturing and automotive sectors.Asia Pacific Machine Control System Market Report:

The Asia Pacific region is expected to witness substantial growth in the Machine Control System market, increasing from $1.50 billion in 2023 to approximately $2.94 billion by 2033. This growth is driven by rapid industrialization, increased investments in automation technologies, and a rising middle-class population demanding higher efficiency in production processes.North America Machine Control System Market Report:

North America is anticipated to expand significantly, growing from $2.92 billion in 2023 to $5.74 billion by 2033. A strong emphasis on technological advancement and a robust industrial base facilitate rapid adoption of sophisticated machine control systems, supported by proactive government initiatives.South America Machine Control System Market Report:

In South America, the Machine Control System market is projected to grow from $0.05 billion in 2023 to $0.09 billion by 2033. The gradual adoption of advanced manufacturing technologies and improvements in infrastructure are key drivers for this growth despite economic challenges.Middle East & Africa Machine Control System Market Report:

The Middle East and Africa market is predicted to grow from $1.01 billion in 2023 to $1.98 billion by 2033. Key drivers include the rising investments in infrastructure projects and a growing emphasis on sustainability and energy efficiency.Tell us your focus area and get a customized research report.

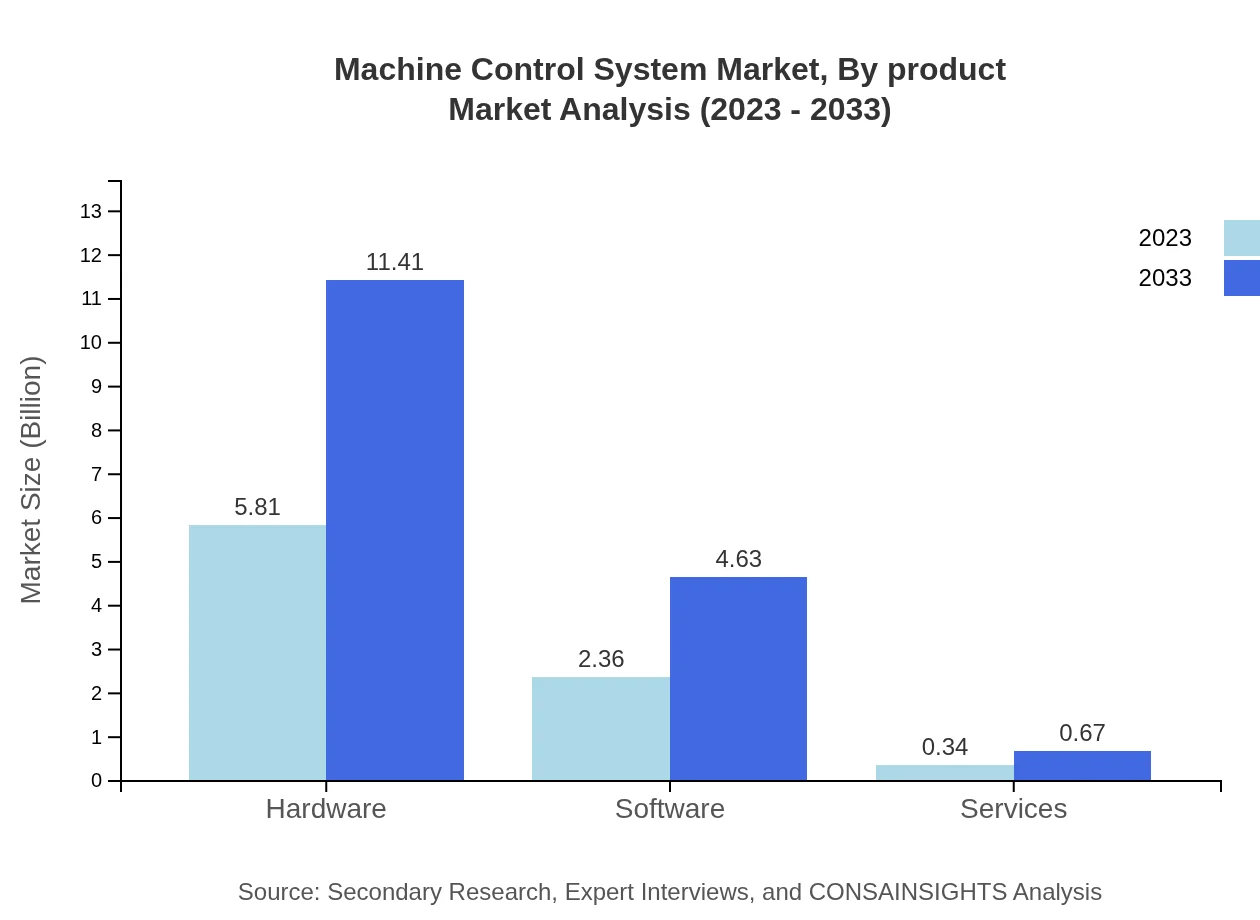

Machine Control System Market Analysis By Product

The segmentation by product type reveals that Hardware dominates the market, contributing significantly to the overall size. With a market size of $5.81 billion in 2023 expected to grow to $11.41 billion by 2033, hardware is crucial for implementing effective control systems. Software follows, indicating a growth from $2.36 billion to $4.63 billion due to the increasing reliance on digital solutions. Lastly, Services represent the smallest segment but are critical for maintaining system performance, expected to grow from $0.34 billion in 2023 to $0.67 billion in 2033.

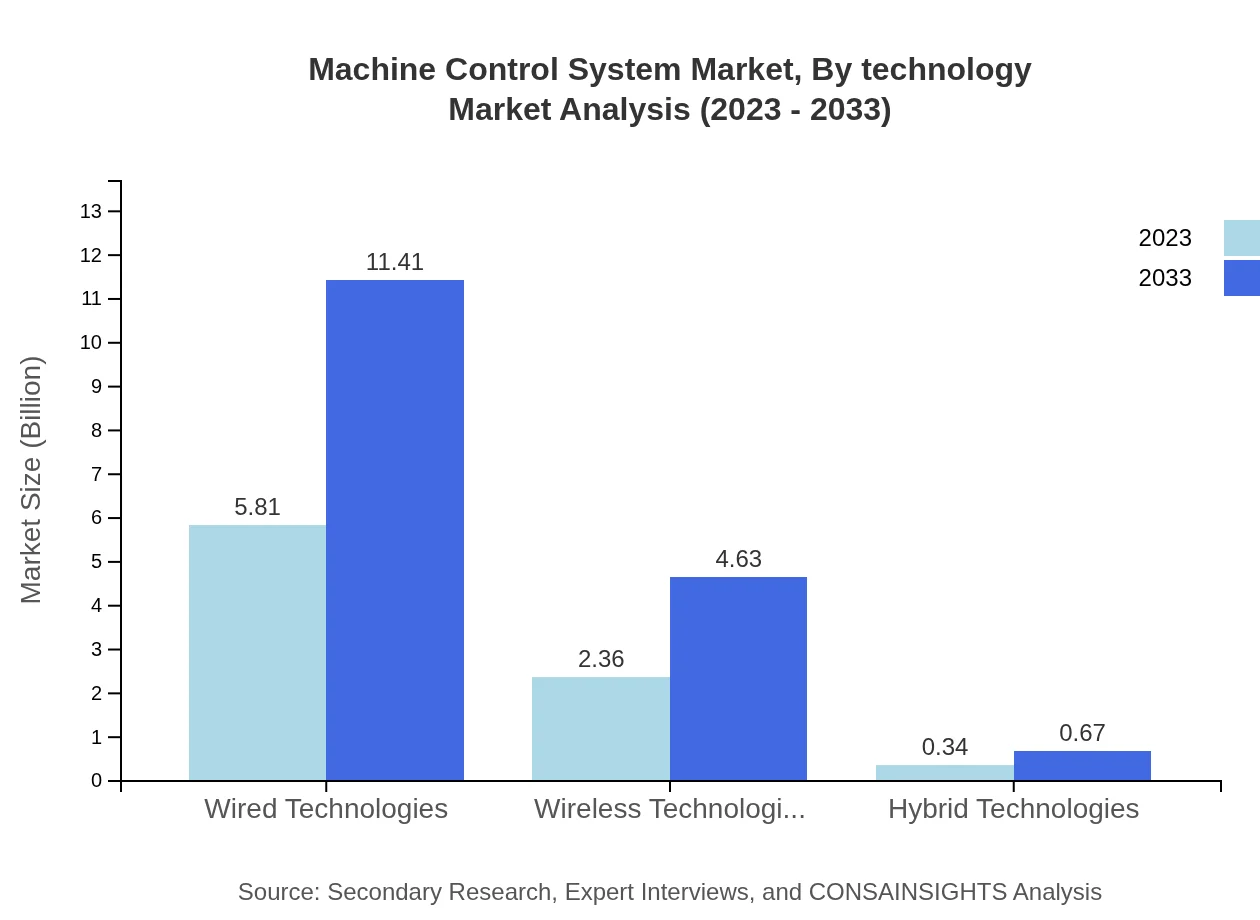

Machine Control System Market Analysis By Technology

The market is classified into Wired, Wireless, and Hybrid technologies. Wired technologies dominate the landscape with a size of $5.81 billion in 2023, maintaining a steady share of 68.3% due to reliability and stability in communication. Wireless technologies, significant for enhancing mobility, are projected to grow from $2.36 billion to $4.63 billion. Hybrid technologies, although smaller, are expected to double from $0.34 billion to $0.67 billion as industries look for adaptable solutions.

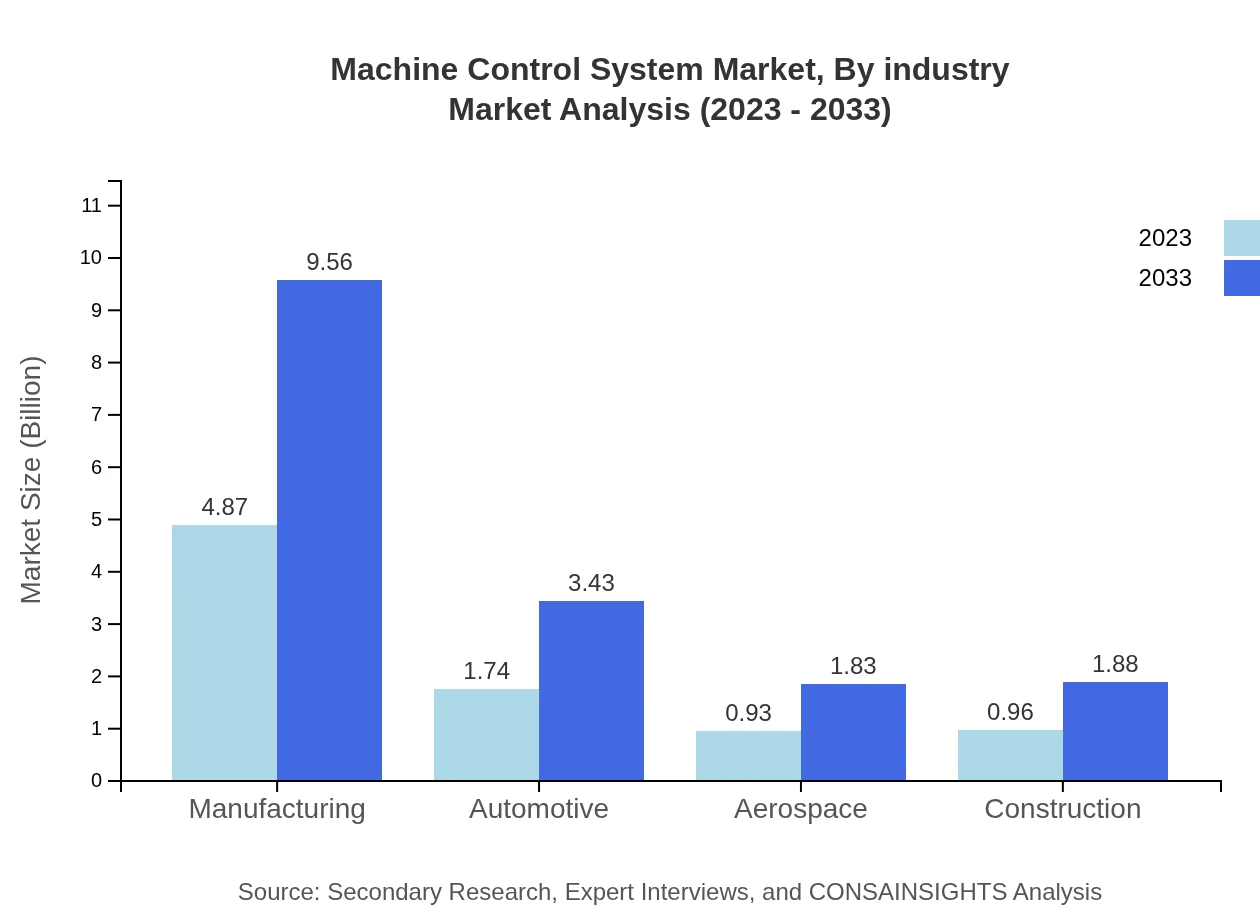

Machine Control System Market Analysis By Industry

When segmented by industry, Manufacturing captures the largest share, valued at $4.87 billion in 2023 and forecast to grow to $9.56 billion. The Automotive sector, while smaller, shows promising growth potential, moving from $1.74 billion to $3.43 billion. Likewise, Aerospace and Construction present niche markets that are gradually adopting MCS, projected to grow by similar percentages as the overall market.

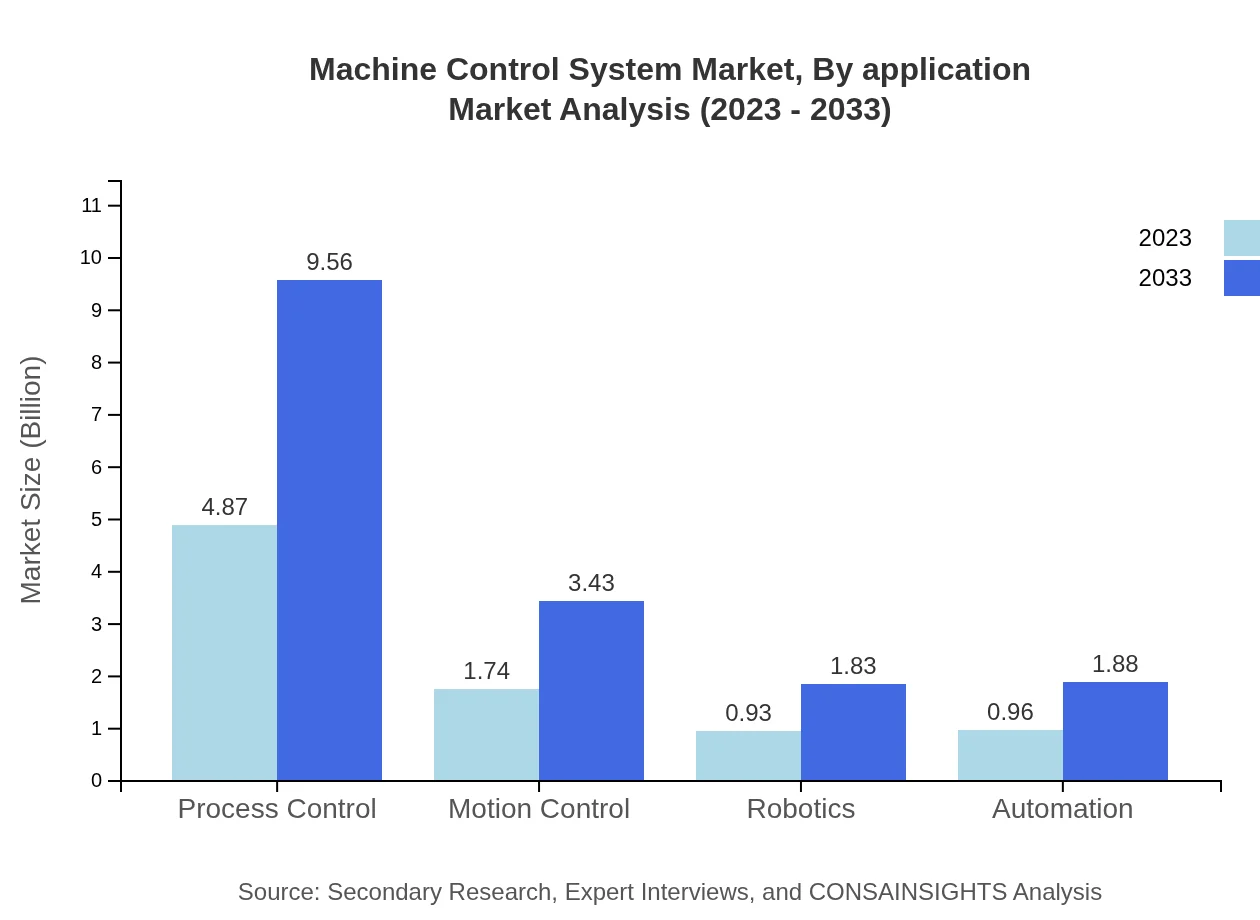

Machine Control System Market Analysis By Application

Application-wise, the emphasis on Process Control arises from industrial needs for consistent quality and efficiency, showing significant growth. Motion Control and Robotics, while smaller, are also critical sectors reflecting increased investment in automation.

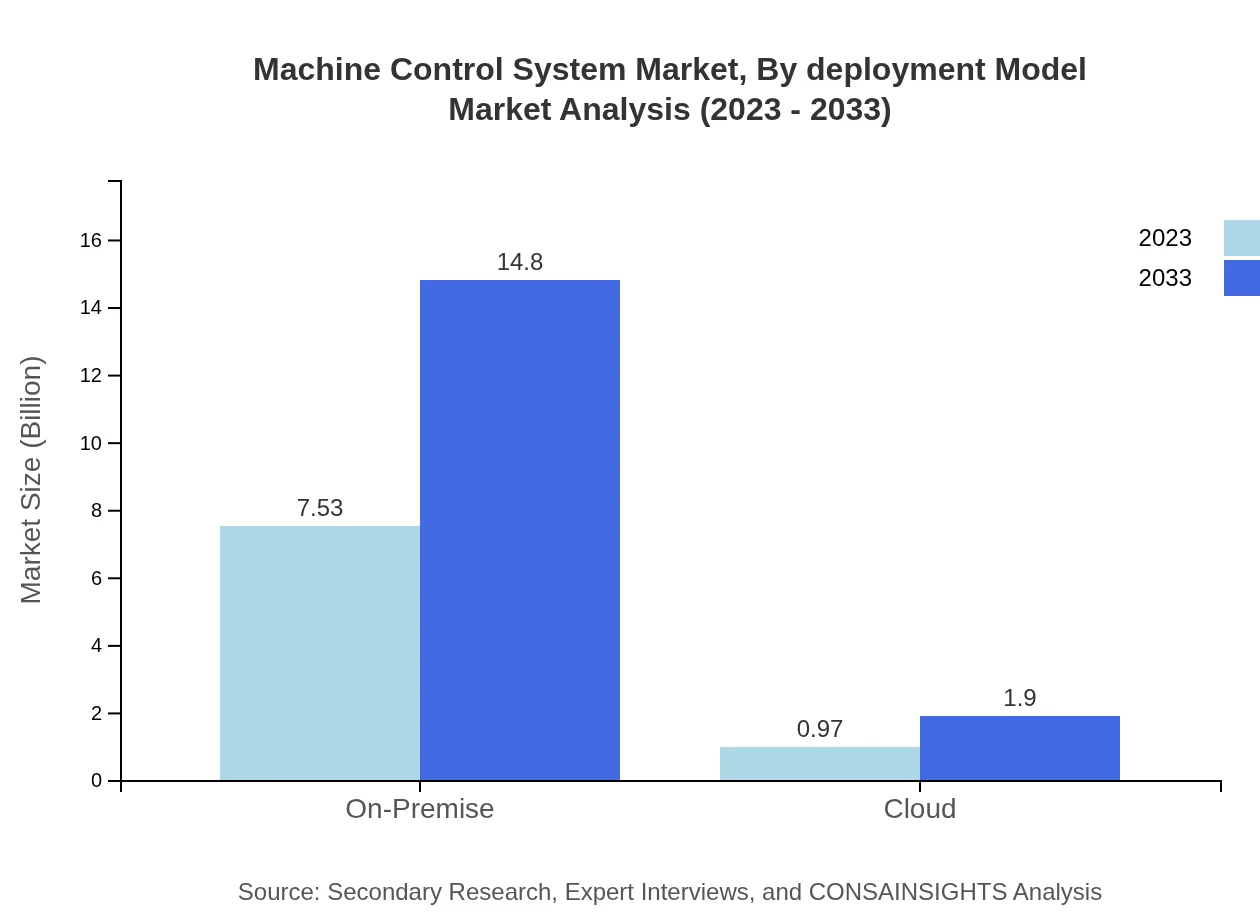

Machine Control System Market Analysis By Deployment Model

In the deployment model, On-Premise solutions dominate the market size, expected to grow from $7.53 billion to $14.80 billion due to widespread enterprise adoption. Meanwhile, Cloud-based solutions show potential, growing from $0.97 billion to $1.90 billion, appealing to companies seeking scalability and reduced IT costs.

Machine Control System Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Machine Control System Industry

Siemens AG:

Siemens AG is a global leader in automation technology, providing comprehensive solutions in machine control systems to enhance operational efficiency in diverse industries.Rockwell Automation:

Rockwell Automation focuses on industrial automation and information technology, delivering machine control systems that optimize productivity and streamline operations.Honeywell International Inc.:

Honeywell provides advanced machine control systems and services, enabling smart operations and a safer working environment across several sectors.Schneider Electric:

Schneider Electric specializes in digital transformation and energy management, offering cutting-edge machine control solutions tailored for industrial applications.We're grateful to work with incredible clients.

FAQs

What is the market size of machine Control System?

The global machine control system market is projected to reach approximately $8.5 billion by 2033, with a CAGR of 6.8% during the forecast period. The market is expected to grow significantly as technology evolves.

What are the key market players or companies in this machine Control System industry?

Key players in the machine control system industry include Trimble Inc., Topcon Positioning Systems, Leica Geosystems, and Hexagon AB, among others. These companies lead through innovations in hardware, software, and services.

What are the primary factors driving the growth in the machine Control System industry?

Factors driving growth in the machine control system industry include increasing construction activities, the demand for automation in manufacturing, technological advancements, and the need for precise control in various industries.

Which region is the fastest Growing in the machine Control System?

The fastest-growing region in the machine control system market is Europe, projected to grow from $3.03 billion in 2023 to $5.95 billion by 2033. North America and Asia Pacific also show strong growth trajectories.

Does ConsaInsights provide customized market report data for the machine Control System industry?

Yes, ConsaInsights offers tailored market report data for the machine control system industry, allowing clients to obtain specific insights, trends, and projections based on their unique requirements.

What deliverables can I expect from this machine Control System market research project?

Expect comprehensive market analysis reports, including market size, trends, competitive landscape assessments, and strategic recommendations tailored to the machine control system sector.

What are the market trends of machine Control System?

Key trends include increasing adoption of AI and IoT technologies, the shift towards cloud-based solutions, and expanding applications in sectors such as manufacturing, construction, and agriculture.