Machine Safety Market Report

Published Date: 22 January 2026 | Report Code: machine-safety

Machine Safety Market Size, Share, Industry Trends and Forecast to 2033

This report offers a comprehensive analysis of the Machine Safety market, focusing on current trends, projections from 2023 to 2033, and insights into regional growth, segmentation, and technological advancements.

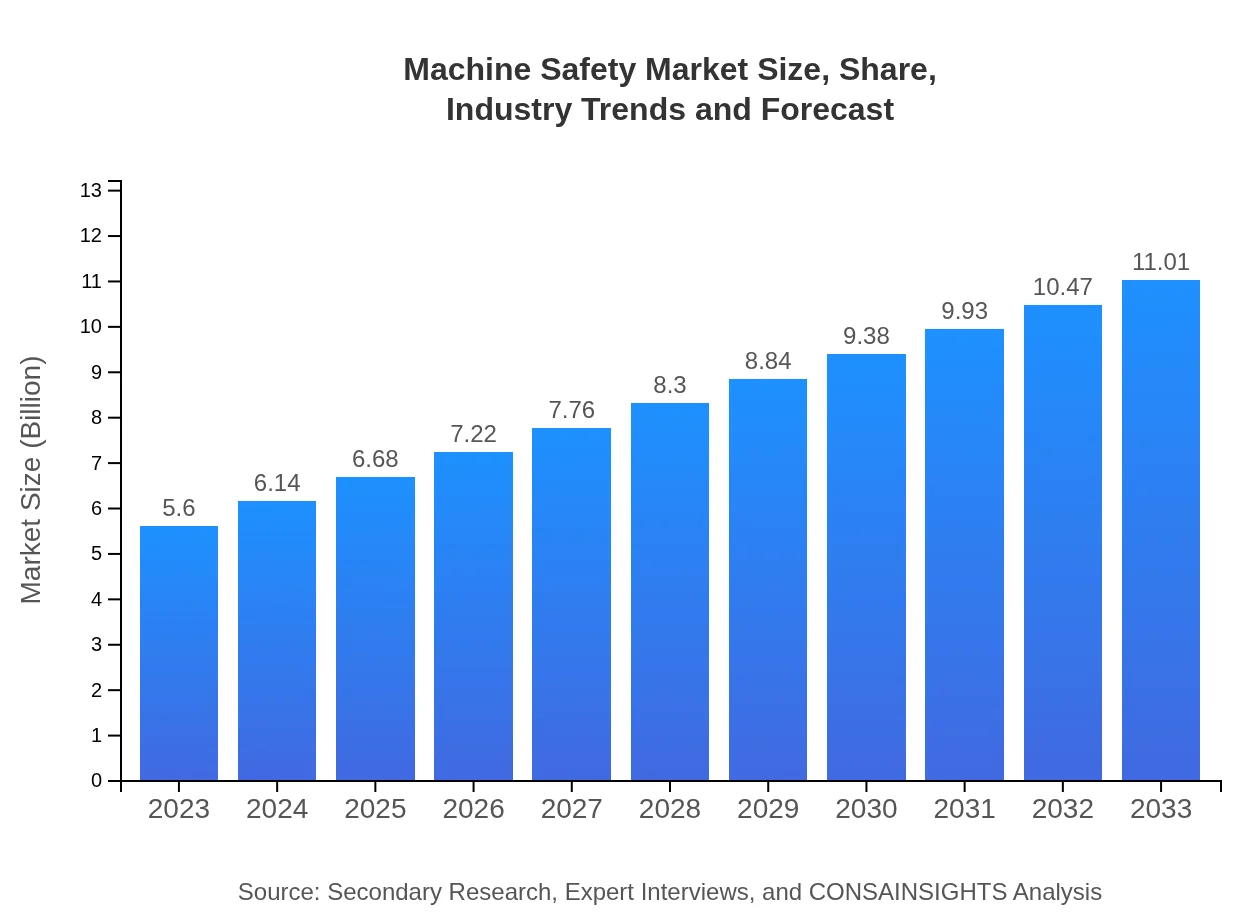

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $11.01 Billion |

| Top Companies | Rockwell Automation, Siemens AG, Honeywell International Inc., Schneider Electric |

| Last Modified Date | 22 January 2026 |

Machine Safety Market Overview

Customize Machine Safety Market Report market research report

- ✔ Get in-depth analysis of Machine Safety market size, growth, and forecasts.

- ✔ Understand Machine Safety's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Machine Safety

What is the Market Size & CAGR of Machine Safety market in 2033?

Machine Safety Industry Analysis

Machine Safety Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Machine Safety Market Analysis Report by Region

Europe Machine Safety Market Report:

The European market is anticipated to grow from $2.01 billion in 2023 to $3.95 billion by 2033. This region displays strong adherence to safety standards and innovative practices in areas such as smart manufacturing and automation.Asia Pacific Machine Safety Market Report:

The Asia Pacific region hosted a market size of $0.98 billion in 2023, projected to reach $1.92 billion by 2033. Growth is driven by swift industrialization, the rise of manufacturing hubs, and increasing governmental safety mandates across countries like China and India.North America Machine Safety Market Report:

North America remains a significant player, with a market size of $1.89 billion in 2023 set to increase to $3.71 billion by 2033. The robust regulatory framework and high adoption of advanced manufacturing technologies support this growth.South America Machine Safety Market Report:

South America is expected to grow from $0.32 billion in 2023 to $0.63 billion by 2033. Economic development and improved industrial safety regulations are key factors contributing to this growth, particularly in Brazil and Argentina.Middle East & Africa Machine Safety Market Report:

With a market size of $0.40 billion in 2023 expected to grow to $0.79 billion by 2033, the Middle East and Africa depict emerging prospects driven by infrastructural development and increased attention to worker safety.Tell us your focus area and get a customized research report.

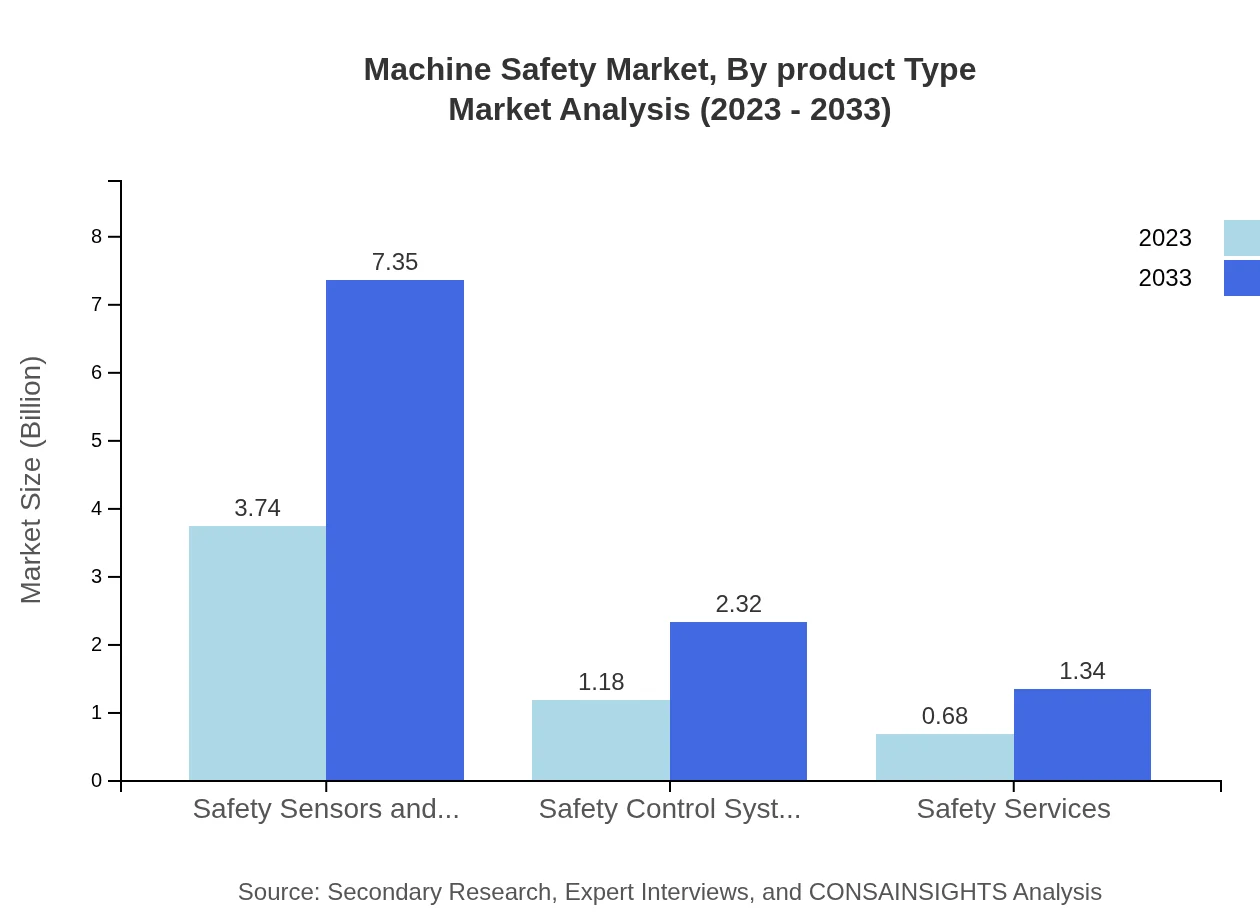

Machine Safety Market Analysis By Product Type

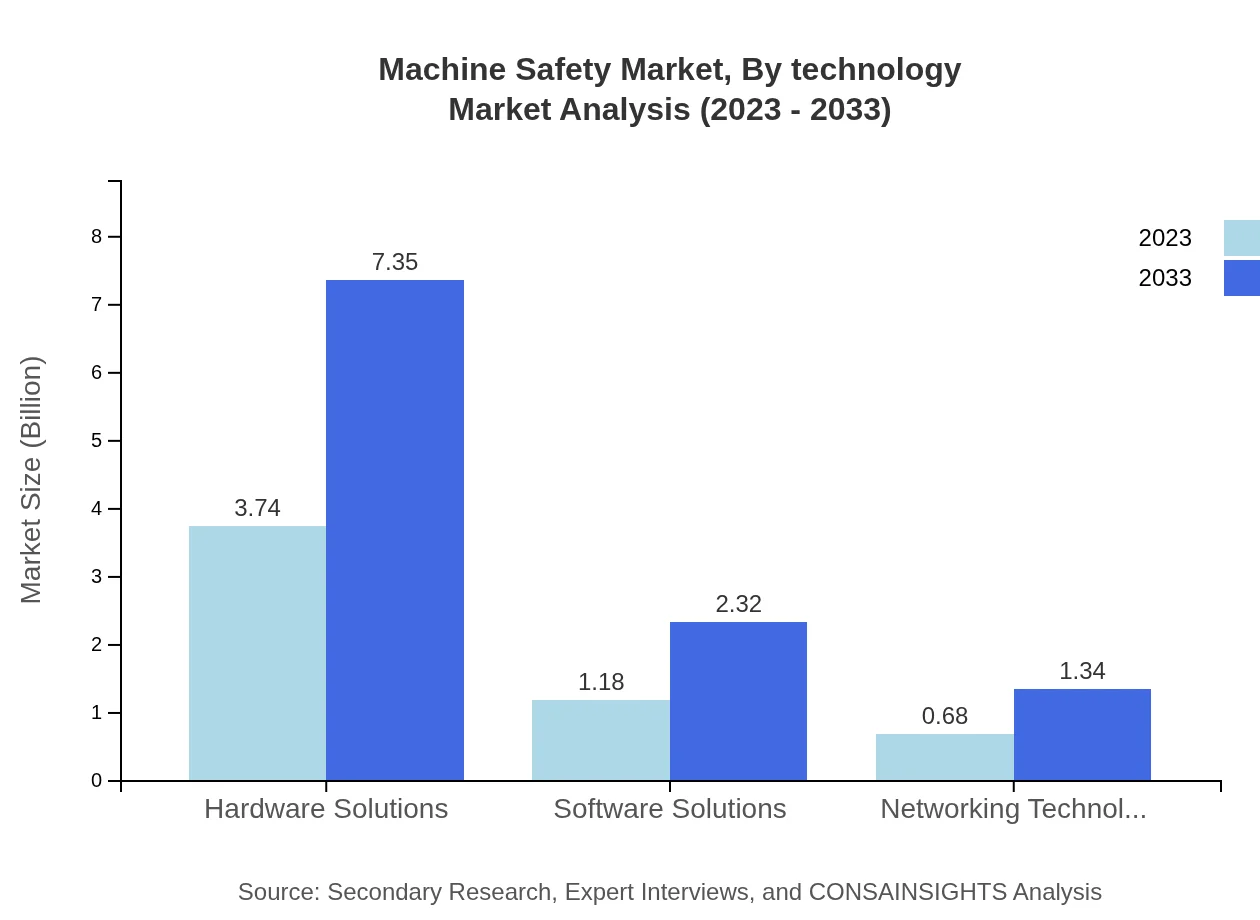

The product types within the Machine Safety market include Hardware Solutions, which accounted for $3.74 billion in 2023 and will trend toward $7.35 billion by 2033, capture 66.75% market share. Software Solutions generated $1.18 billion in 2023, projected to reach $2.32 billion by 2033, holding a steady 21.12% market share.

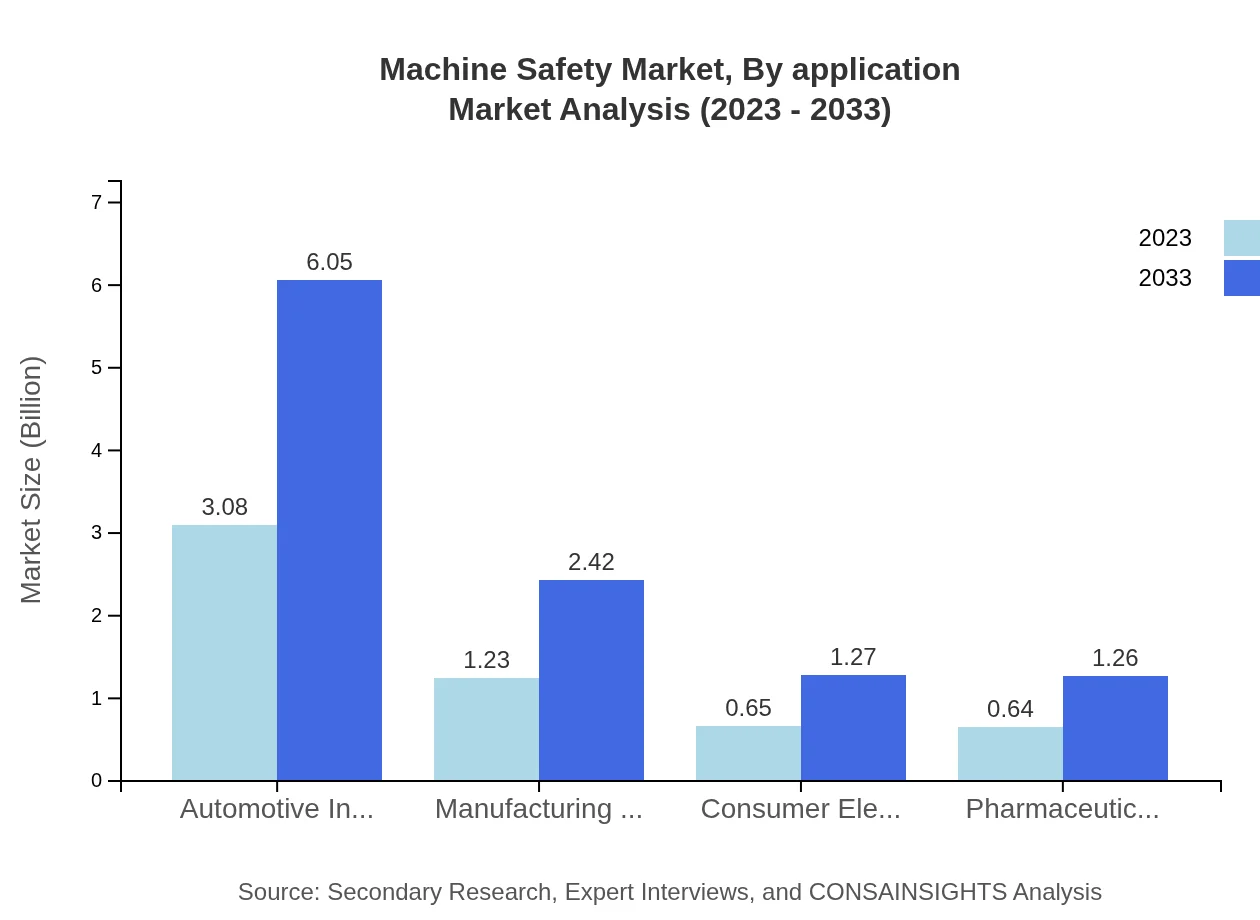

Machine Safety Market Analysis By Application

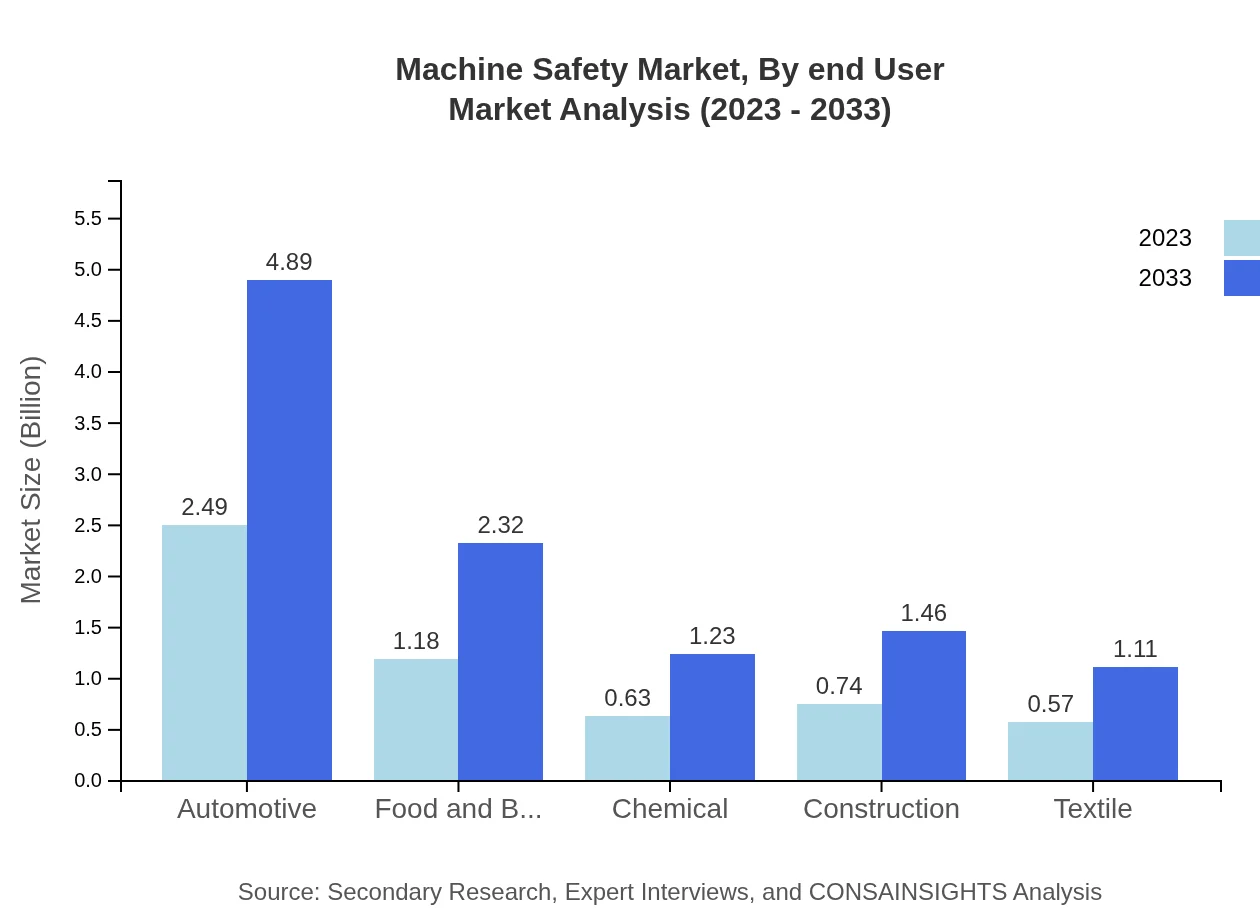

Key applications span automotive, food and beverage, pharmaceuticals, and manufacturing. The automotive industry alone is projected to grow from $2.49 billion in 2023 to $4.89 billion by 2033, representing 44.44% share in the market.

Machine Safety Market Analysis By End User

End-user industries such as automotive, manufacturing, and food processing significantly contribute to market growth. For instance, the automotive sector is expected to witness substantial growth from $3.08 billion in 2023 to $6.05 billion by 2033.

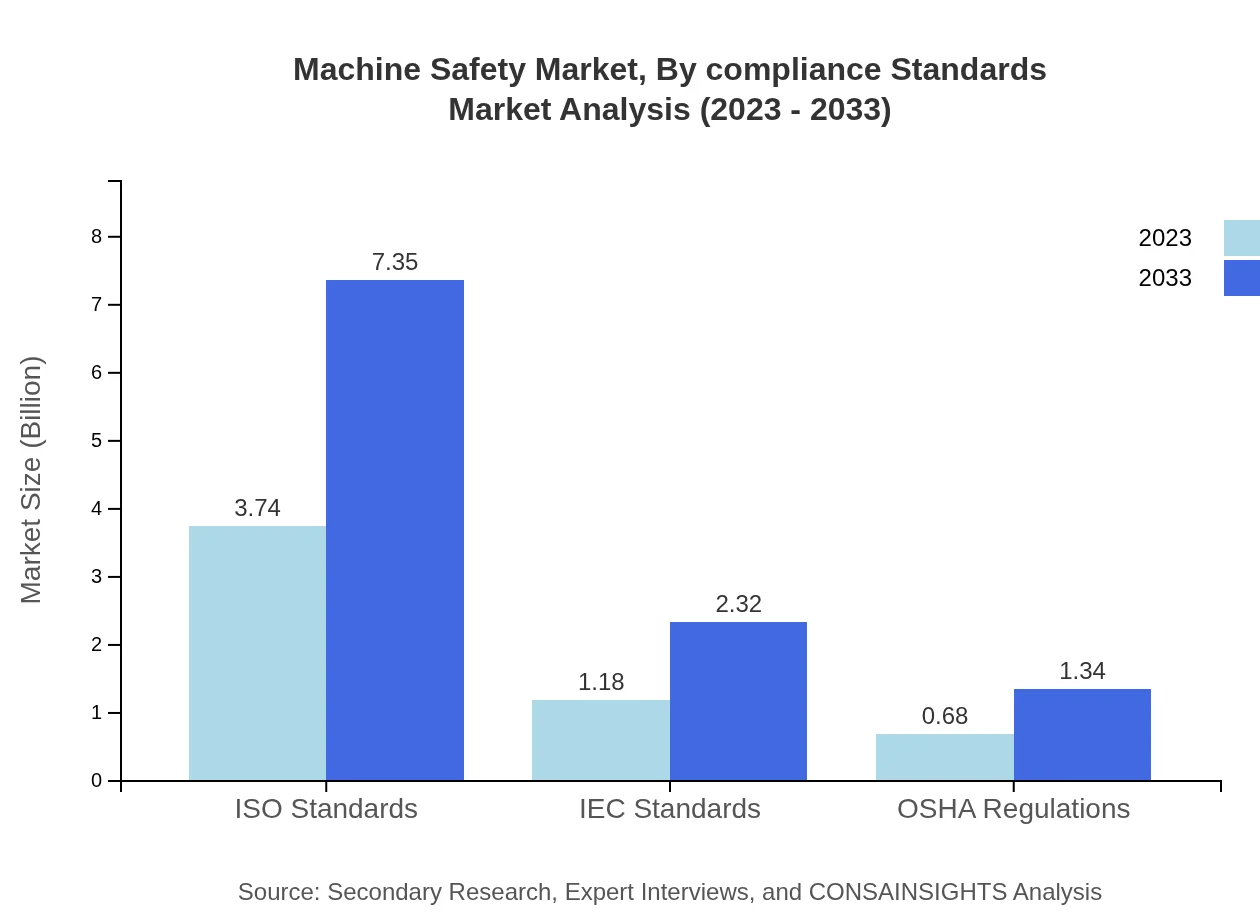

Machine Safety Market Analysis By Compliance Standards

Compliance with ISO, IEC, and OSHA standards is crucial for market growth. Solutions adhering to ISO standards are expected to reach a size of $3.74 billion by 2033, maintaining a market share of 66.75%.

Machine Safety Market Analysis By Technology

Advancements in networking technologies and AI are transforming the Machine Safety landscape. Networking technologies are projected to grow from $0.68 billion in 2023 to $1.34 billion by 2033, accounting for 12.13% share.

Machine Safety Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Machine Safety Industry

Rockwell Automation:

A leader in industrial automation and information, Rockwell Automation provides integrated safety solutions to enhance productivity while minimizing risks.Siemens AG:

Siemens offers a comprehensive range of safety systems and services that are integrated tightly with their automation solutions.Honeywell International Inc.:

Specializing in safety technology, Honeywell delivers innovative solutions that help improve worker safety across various industries.Schneider Electric:

As a global specialist in energy management and automation, Schneider Electric provides safety solutions aimed at reducing machine downtime and ensuring compliance.We're grateful to work with incredible clients.

FAQs

What is the market size of machine safety?

The machine safety market is projected to reach a size of $5.6 billion in 2023, with a robust CAGR of 6.8% expected through 2033. This growth indicates an ongoing emphasis on safety protocols and technologies across industries.

What are the key market players or companies in the machine safety industry?

Key players in the machine safety market include Siemens, Honeywell, Rockwell Automation, and ABB. These companies are known for developing innovative safety solutions, ensuring compliance with regulations, and enhancing operational safety.

What are the primary factors driving the growth in the machine safety industry?

The growth in the machine safety industry is driven by increased safety awareness, stringent regulatory standards, and technological advancements. Additionally, the rise in automation and the need for efficient safety systems also contribute significantly.

Which region is the fastest Growing in the machine safety market?

The fastest-growing region in the machine safety market is Europe, expected to grow from $2.01 billion in 2023 to $3.95 billion by 2033. This growth is driven by strong regulatory frameworks and advancements in safety technologies.

Does ConsaInsights provide customized market report data for the machine safety industry?

Yes, ConsaInsights offers customized market report data for the machine safety industry, allowing clients to access tailored insights based on specific needs, regional focuses, and market segments.

What deliverables can I expect from this machine safety market research project?

From the machine safety market research project, you can expect comprehensive reports, detailed market analysis, segmentation insights, regional trends, and strategic recommendations tailored to specific industry needs.

What are the market trends of machine safety?

Current trends in the machine safety market include the integration of IoT technologies, increasing automation in industrial sectors, and a focus on real-time monitoring systems. There's also a growing demand for compliant safety solutions.