Machine Tools Market Report

Published Date: 22 January 2026 | Report Code: machine-tools

Machine Tools Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Machine Tools market from 2023 to 2033, covering insights on market size, growth trends, segmentation, regional analysis, and the impact of technological advancements.

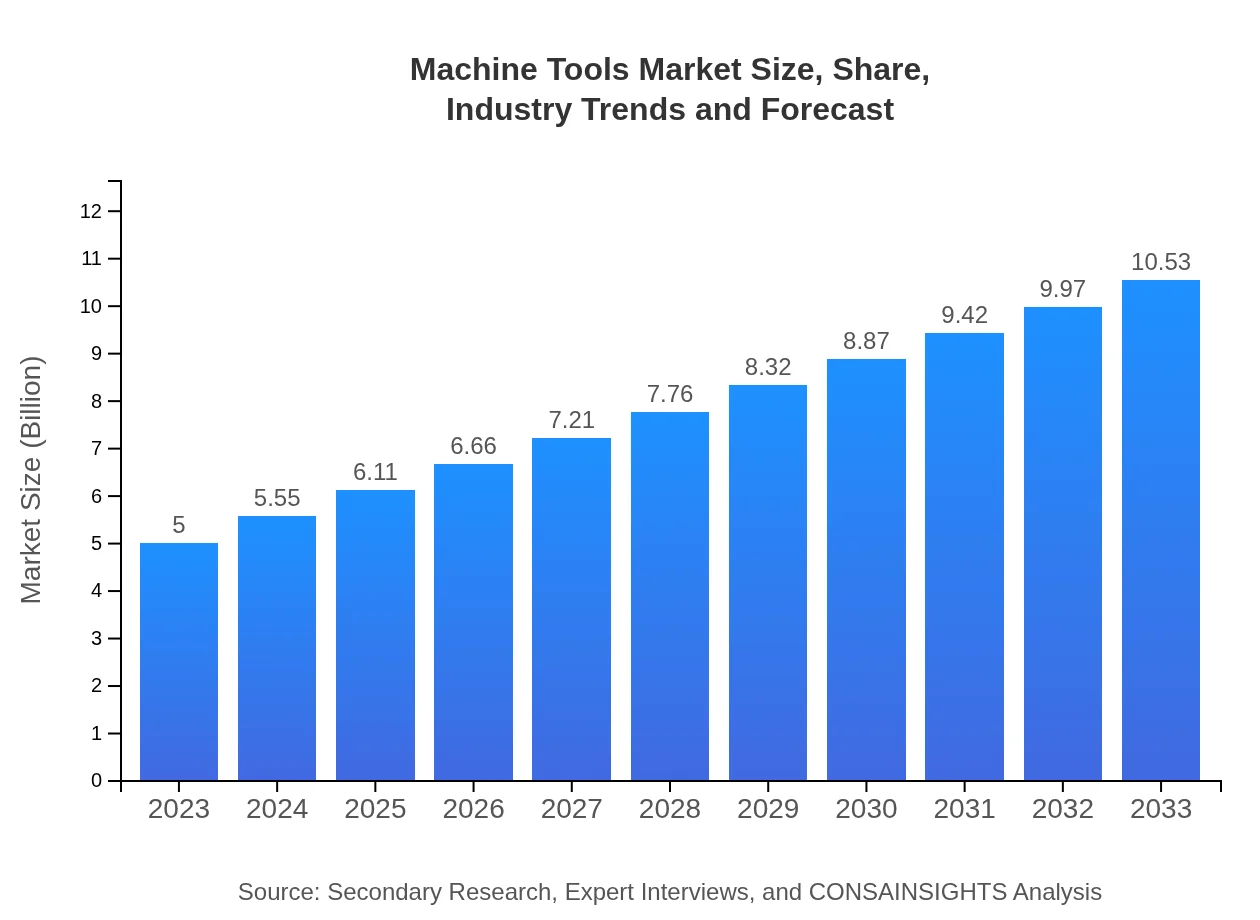

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | DMG Mori, Makino, Mazak, Haas Automation |

| Last Modified Date | 22 January 2026 |

Machine Tools Market Overview

Customize Machine Tools Market Report market research report

- ✔ Get in-depth analysis of Machine Tools market size, growth, and forecasts.

- ✔ Understand Machine Tools's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Machine Tools

What is the Market Size & CAGR of Machine Tools market in 2023?

Machine Tools Industry Analysis

Machine Tools Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Machine Tools Market Analysis Report by Region

Europe Machine Tools Market Report:

Europe's machine tools market is projected to grow from USD 1.50 billion in 2023 to USD 3.15 billion by 2033. Countries like Germany and Italy are renowned for their engineering expertise and innovation in manufacturing processes, significantly contributing to the region's market expansion.Asia Pacific Machine Tools Market Report:

The Asia Pacific is the largest regional market for machine tools, with a market size of USD 0.83 billion in 2023, expected to grow to USD 1.75 billion by 2033. Countries like China, Japan, and India are leading the charge due to their robust manufacturing sectors. The region's growth is further supported by government initiatives aimed at enhancing technological adoption in factories.North America Machine Tools Market Report:

North America exhibits a strong machine tools market, set to rise from USD 1.95 billion in 2023 to USD 4.10 billion by 2033. The United States leads the charge with significant investments in advanced manufacturing technologies, particularly in the automotive and aerospace sectors.South America Machine Tools Market Report:

In South America, the machine tools market is anticipated to increase from USD 0.25 billion in 2023 to USD 0.53 billion by 2033. Brazil and Argentina are the primary contributors, focusing on improving infrastructure and manufacturing capabilities to boost economic growth.Middle East & Africa Machine Tools Market Report:

The Middle East and Africa are expected to see market growth from USD 0.48 billion in 2023 to USD 1.00 billion by 2033, driven primarily by investments in manufacturing and construction projects aimed at economic development.Tell us your focus area and get a customized research report.

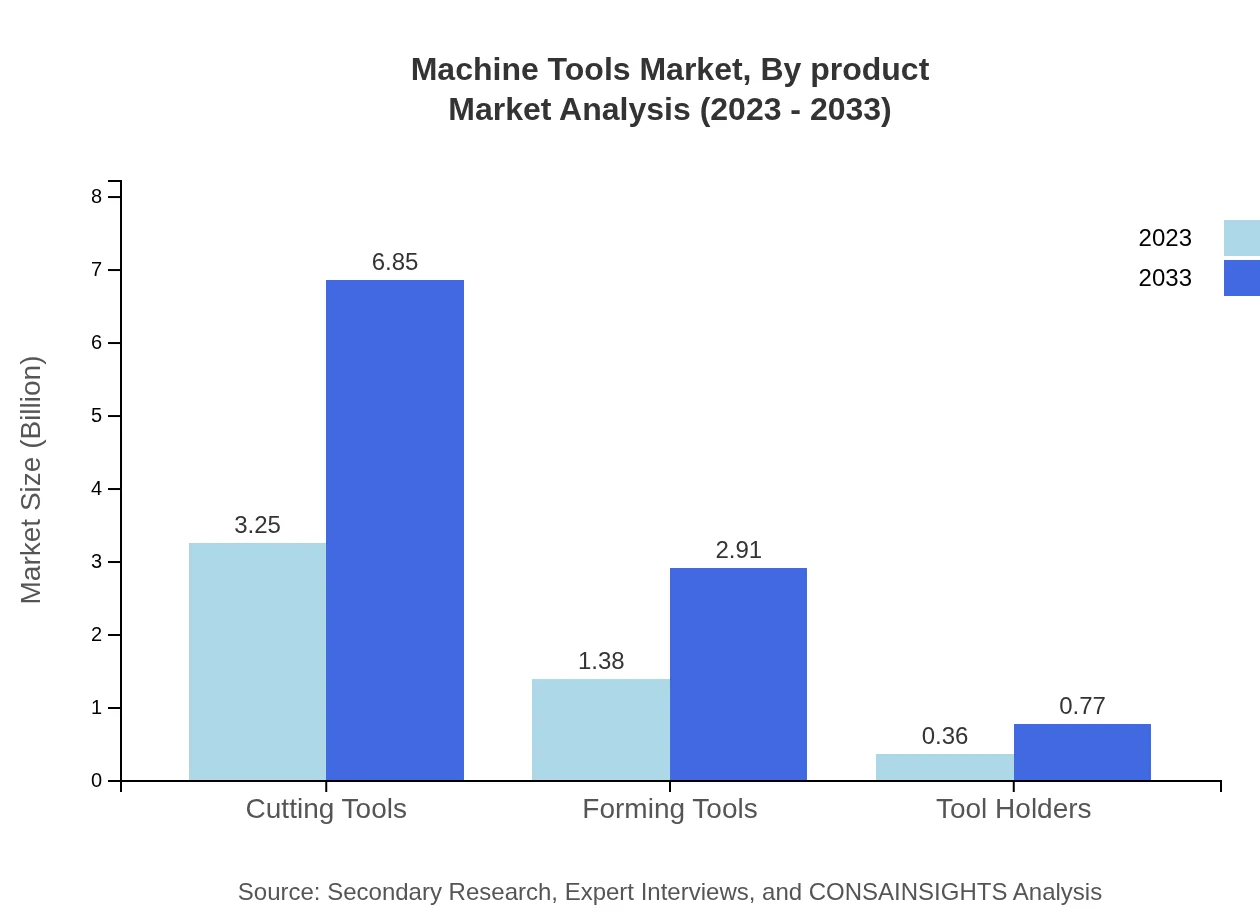

Machine Tools Market Analysis By Product

The product segment of the Machine Tools market includes Cutting Tools, Forming Tools, and Tool Holders. In 2023, Cutting Tools dominate the market with a size of USD 3.25 billion (65.09% market share) and are expected to grow significantly to USD 6.85 billion by 2033. Forming Tools, holding a 27.64% market share in 2023 (USD 1.38 billion), are also anticipated to expand considerably. Tool Holders, while smaller, represent 7.27% of the market at USD 0.36 billion and are projected to grow as well.

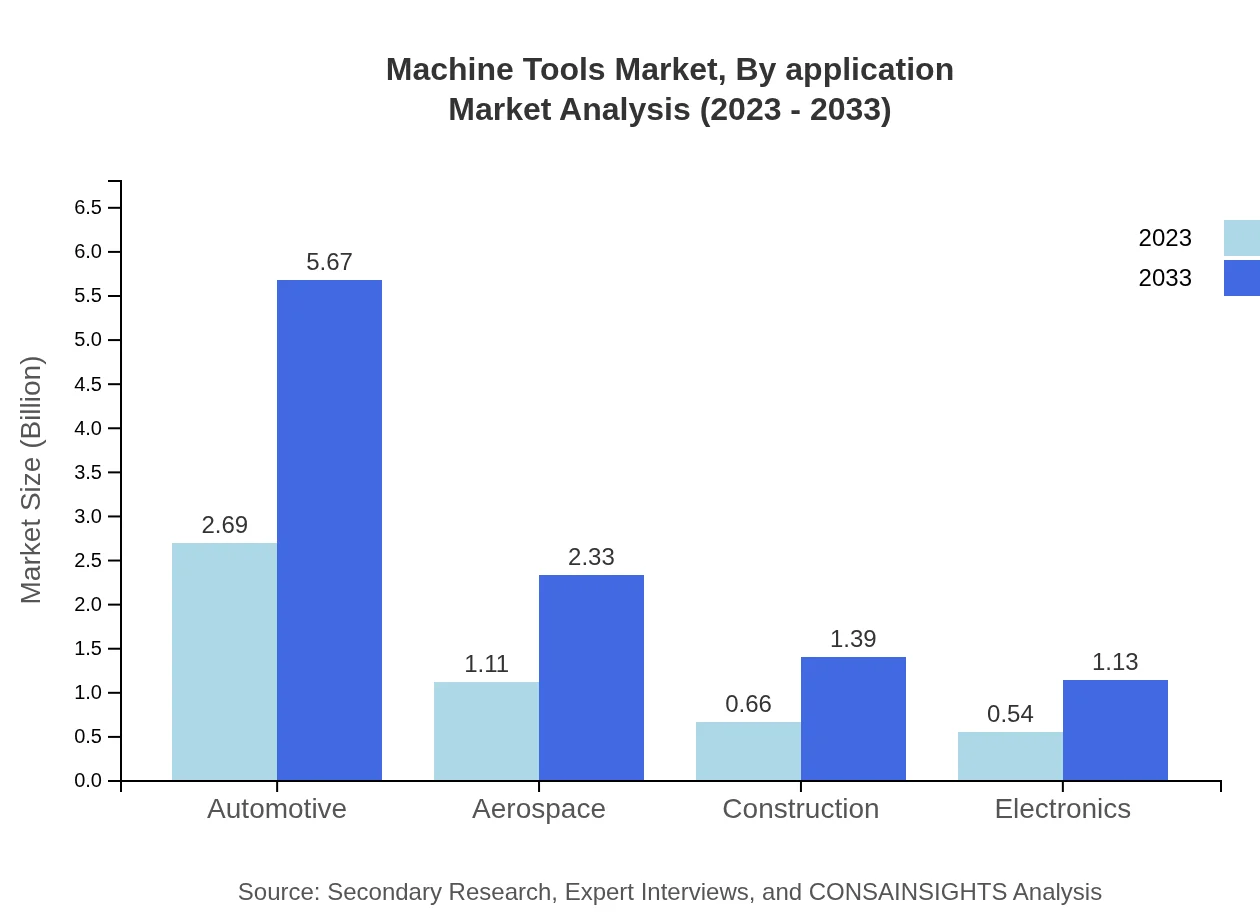

Machine Tools Market Analysis By Application

In analyzing by application, the Machine Tools industry shows a strong presence in the automotive (USD 2.69 billion, 53.87% share) and aerospace (USD 1.11 billion, 22.12% share) sectors. The construction and electronics applications also constitute significant portions of the market, with USD 0.66 billion and USD 0.54 billion in 2023, respectively, showcasing the versatility of machine tools.

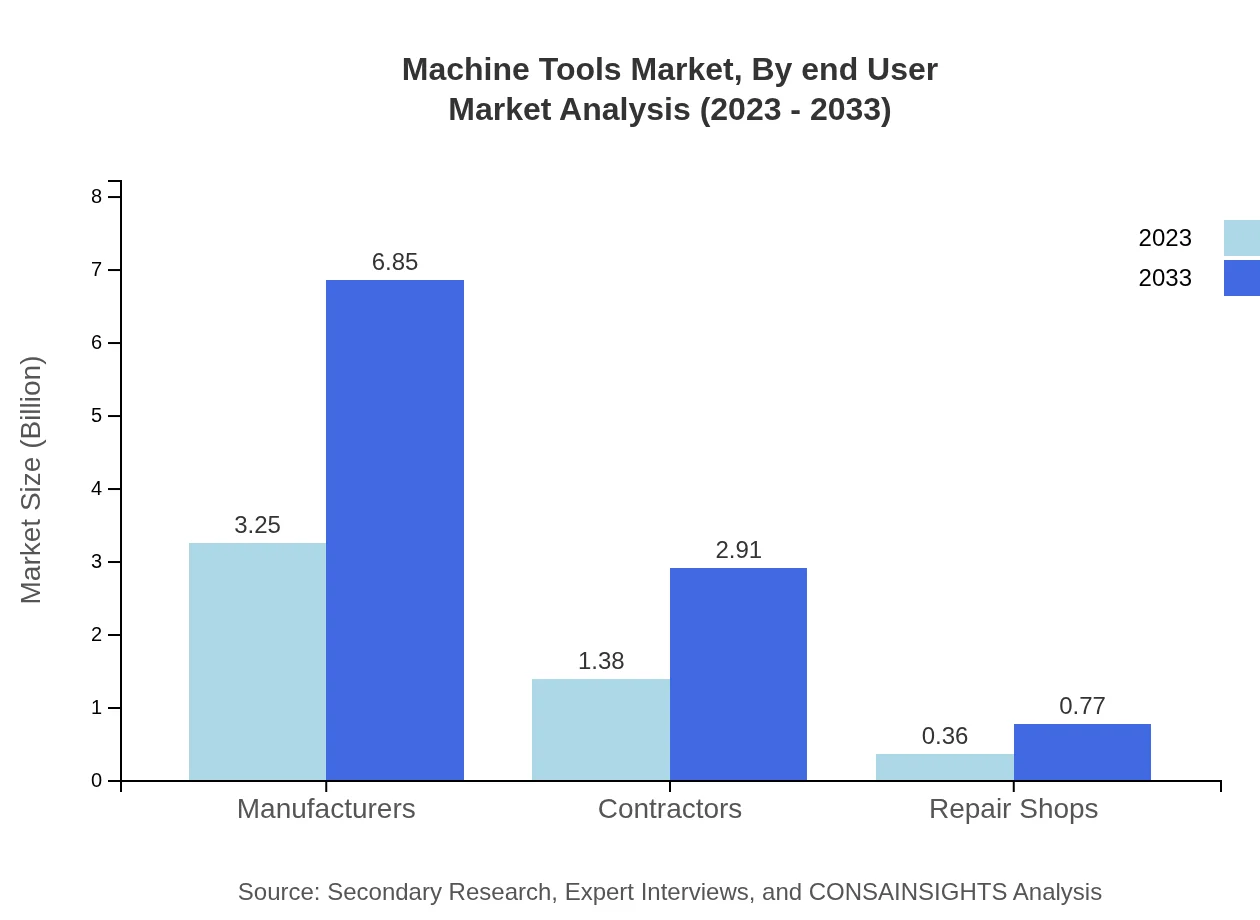

Machine Tools Market Analysis By End User

End-users are crucial to market dynamics, with the automotive sector leading at USD 2.69 billion in 2023, reflecting 53.87% of the total market. Aerospace follows closely, hinting at the growing demand for precision engineering tools, while the construction (USD 0.66 billion, 13.25%) and electronics (USD 0.54 billion, 10.76%) sectors represent significant opportunities for market expansion.

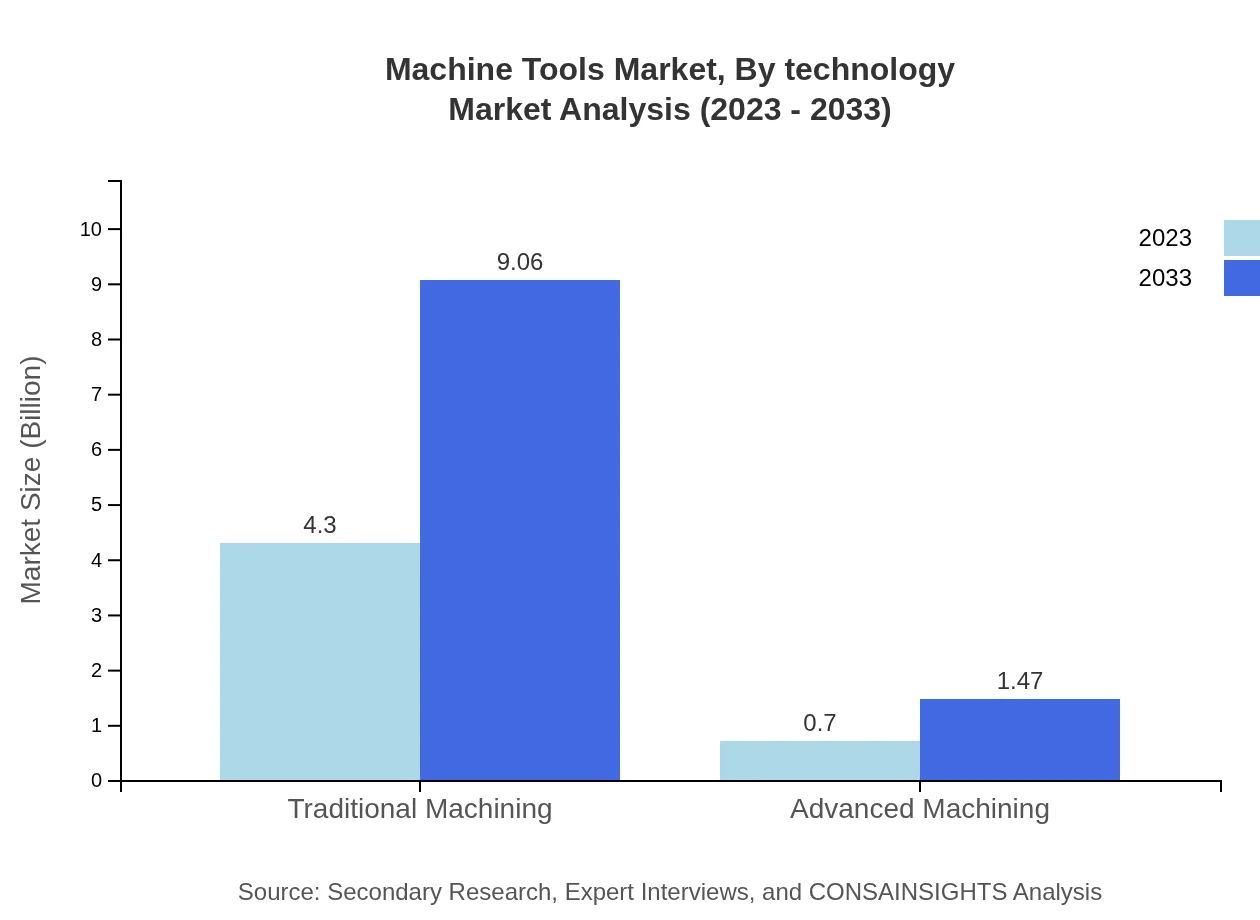

Machine Tools Market Analysis By Technology

The Machine Tools market can be classified by technology types into traditional machining and advanced machining. Traditional machining, valued at USD 4.30 billion and dominating the market at 86.05% share, is expected to gradually evolve with advancements that integrate more automated solutions, pushing the advanced machining segment to growth from USD 0.70 billion (13.95% share) to USD 1.47 billion by 2033.

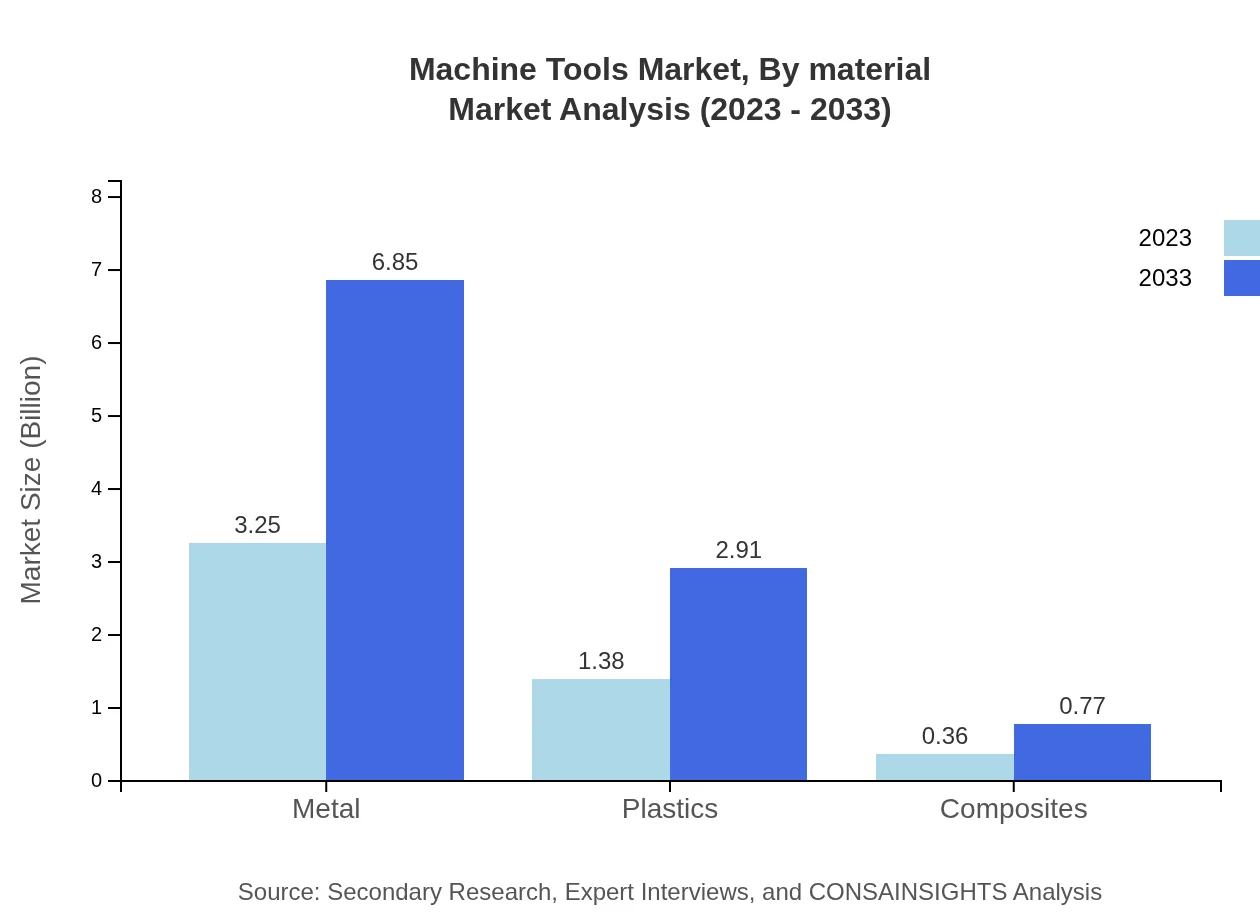

Machine Tools Market Analysis By Material

Analyzing the market by material highlights the significant usage of metals in machine tools, commanding a market size of USD 3.25 billion with a share of 65.09%. Plastics and composites also serve essential roles, with forecasts indicating growth as industries increasingly adopt machinable composites.

Machine Tools Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Machine Tools Industry

DMG Mori:

A leading manufacturer of cutting machine tools known for innovative designs and advanced technology solutions tailored for various sectors.Makino:

Specializes in high-performance machining solutions combining cutting-edge technology and automation for optimal manufacturing performance.Mazak:

Known for pioneering CNC machine technologies, Mazak provides comprehensive solutions for high volume and precision manufacturing.Haas Automation:

Drives innovation in machining systems, offering various machine tools ideal for a range of manufacturing sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of machine Tools?

The global machine-tools market is projected to reach $5 billion by 2033, growing at a CAGR of 7.5% from its current size. This growth is driven by increasing industrial automation and demand for precision engineering.

What are the key market players or companies in the machine Tools industry?

Key players in the machine-tools industry include major companies such as Siemens AG, Mazak Corporation, and DMG Mori Seiki AG. These firms lead in technology advancements and contribute significantly to market growth through innovative solutions.

What are the primary factors driving the growth in the machine Tools industry?

The growth in the machine-tools industry is driven by increasing automation, rising demand for high precision components, and advancements in manufacturing technologies such as additive manufacturing, which require sophisticated machine tools.

Which region is the fastest Growing in the machine Tools?

Asia Pacific is the fastest-growing region in the machine-tools market, expected to expand from $0.83 billion in 2023 to $1.75 billion by 2033, reflecting significant industrial development and demand for advanced manufacturing technologies.

Does ConsaInsights provide customized market report data for the machine Tools industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the machine-tools industry, enabling clients to obtain precise insights based on their unique business requirements.

What deliverables can I expect from this machine Tools market research project?

Deliverables from the machine-tools market research project typically include detailed market analysis reports, trend insights, competitive landscape overviews, and tailored recommendations for strategic planning.

What are the market trends of machine Tools?

Current trends in the machine-tools market include increasing adoption of smart manufacturing technologies, greater focus on sustainability, and the integration of IoT in machine tools to enhance productivity and efficiency.