Machine Vision Market Report

Published Date: 22 January 2026 | Report Code: machine-vision

Machine Vision Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Machine Vision market, focusing on market trends, size, segmentation, and insights from 2023 to 2033. It offers data-driven forecasts and discusses the impact of technological innovations on industry growth.

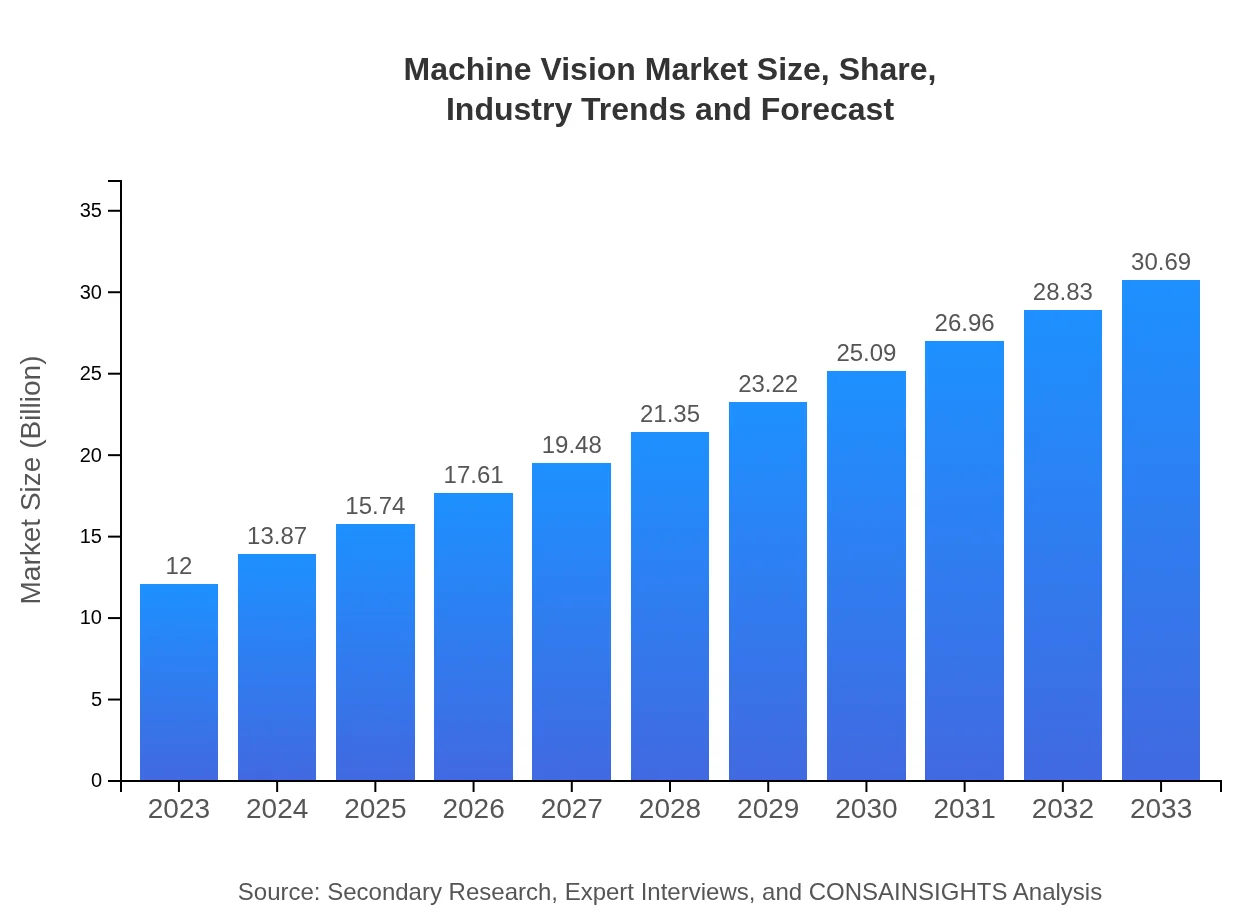

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $12.00 Billion |

| CAGR (2023-2033) | 9.5% |

| 2033 Market Size | $30.69 Billion |

| Top Companies | Cognex Corporation, Keyence Corporation, Basler AG, Omron Corporation, Teledyne Technologies |

| Last Modified Date | 22 January 2026 |

Machine Vision Market Overview

Customize Machine Vision Market Report market research report

- ✔ Get in-depth analysis of Machine Vision market size, growth, and forecasts.

- ✔ Understand Machine Vision's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Machine Vision

What is the Market Size & CAGR of Machine Vision market in 2023?

Machine Vision Industry Analysis

Machine Vision Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Machine Vision Market Analysis Report by Region

Europe Machine Vision Market Report:

The European Machine Vision market, with a size of $3.54 billion in 2023, is anticipated to expand to $9.04 billion by 2033. This growth is fueled by stringent quality standards and a greater focus on enhancing manufacturing efficiencies.Asia Pacific Machine Vision Market Report:

In 2023, the Asia Pacific Machine Vision market is valued at $2.34 billion and is projected to grow to $5.98 billion by 2033. The region's growth is driven by rapid industrialization, and increasing investments in manufacturing technologies, particularly in countries like China and Japan.North America Machine Vision Market Report:

North America holds a market value of $3.94 billion in 2023 with a forecasted rise to $10.09 billion by 2033. The region benefits from a robust presence of leading technology firms and increased adoption of automation across manufacturing sectors.South America Machine Vision Market Report:

The South American Machine Vision market, valued at $1.16 billion in 2023, is expected to reach $2.97 billion by 2033. The growth is majorly supported by a rising push toward automation in various sectors including food and beverage and pharmaceuticals.Middle East & Africa Machine Vision Market Report:

In the Middle East and Africa, the Machine Vision market is expected to grow from $1.02 billion in 2023 to $2.61 billion by 2033, driven by investments in smart manufacturing and infrastructural development.Tell us your focus area and get a customized research report.

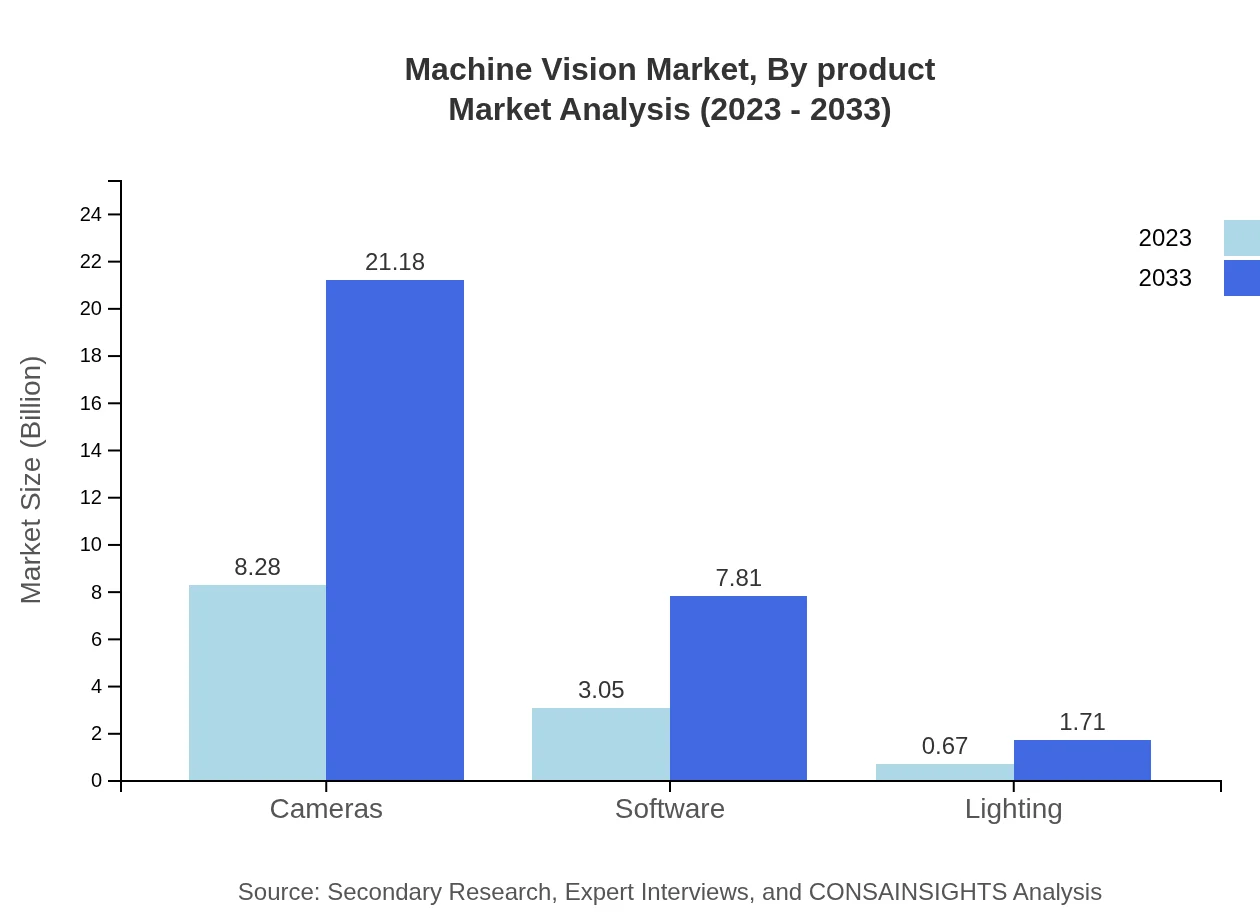

Machine Vision Market Analysis By Product

The Machine Vision market comprises various product segments primarily including Cameras, Software, and Lighting. In 2023, the Cameras segment leads with a market value of $8.28 billion, growing to $21.18 billion by 2033, representing a stable market share of 69%. Software follows with a current market size of $3.05 billion and is projected to reach $7.81 billion within the forecast period, maintaining a consistent share of around 25%. Lighting, while smaller, shows potential growth from $0.67 billion to $1.71 billion, indicating an increase in applications requiring high-quality illumination.

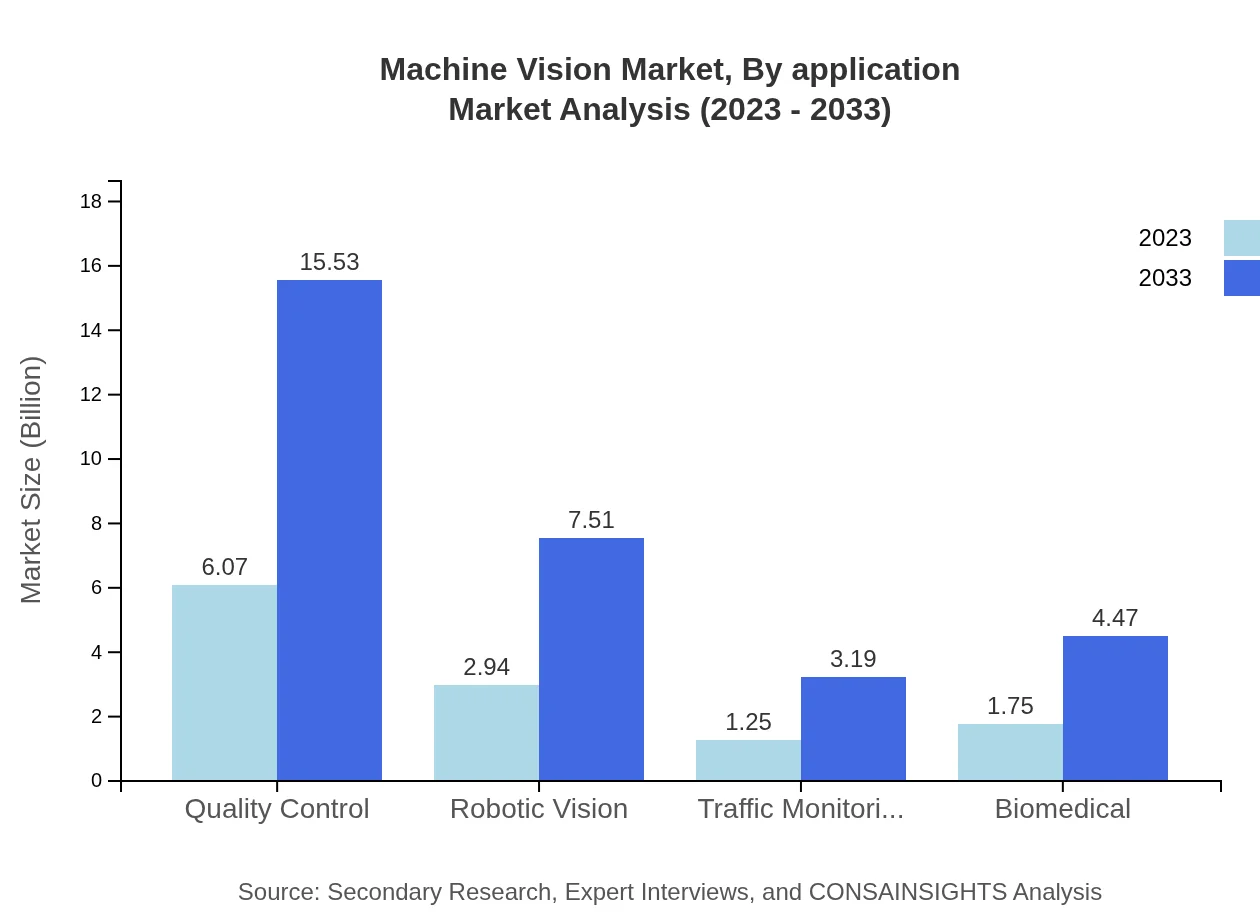

Machine Vision Market Analysis By Application

Applications of Machine Vision systems are vast and include Quality Control, Robotic Vision, Traffic Monitoring, and Biomedical applications among others. Quality Control dominates this segment with an estimated size of $6.07 billion in 2023, expanding to $15.53 billion by 2033, reflecting the critical importance of quality assurance in industrial processes with a share of 50.6%. Robotic Vision applications are also significant, projected to grow from $2.94 billion to $7.51 billion, indicating increased automation in manufacturing.

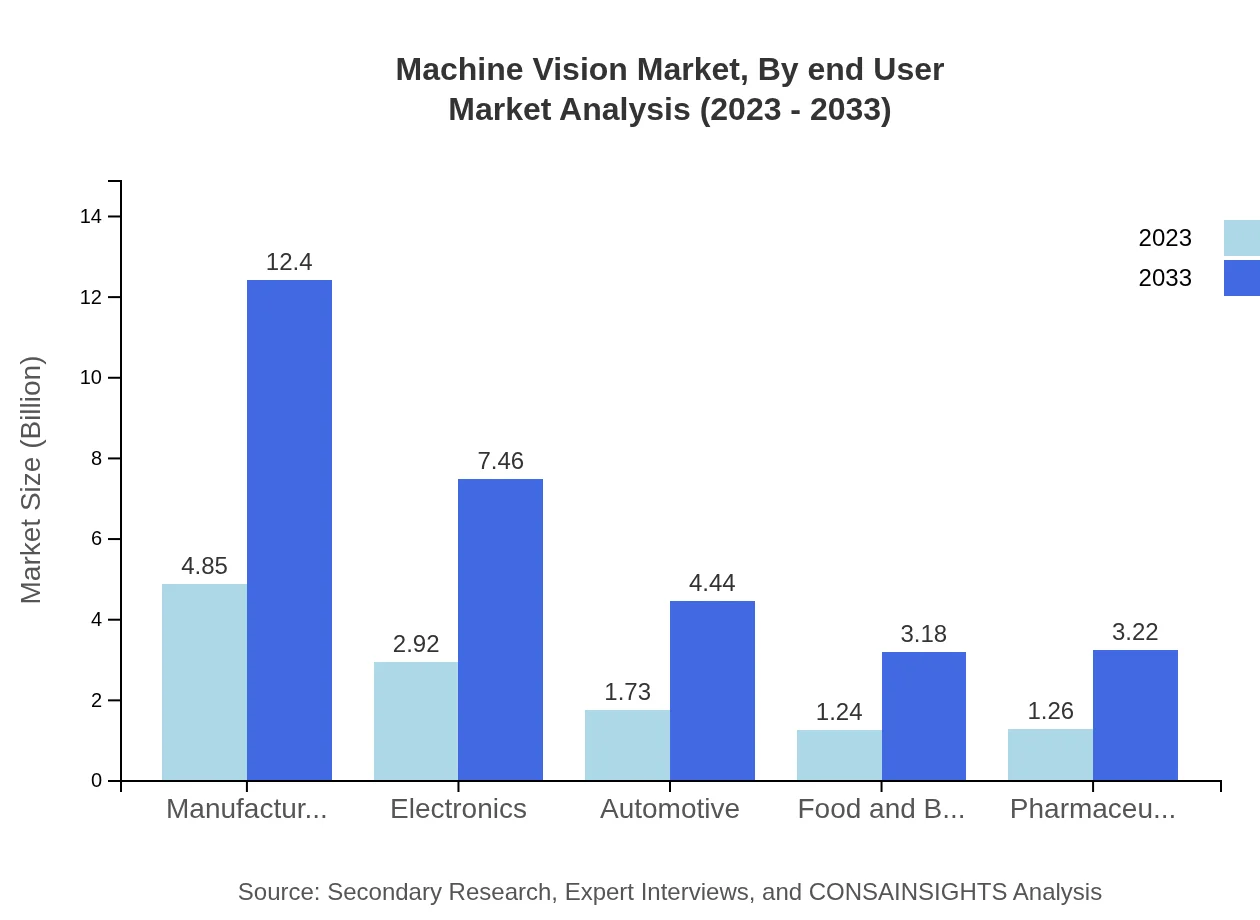

Machine Vision Market Analysis By End User

Key end-user industries for Machine Vision systems include Manufacturing, Electronics, Automotive, Food and Beverage, and Pharmaceuticals. Manufacturing commands a substantial share, contributing $4.85 billion in 2023, projected to reach $12.40 billion by 2033, accounting for 40.39% of the market. Each sector utilizes Machine Vision in distinctive ways – for instance, in Automotive for quality assurance or Food and Beverage for product inspection.

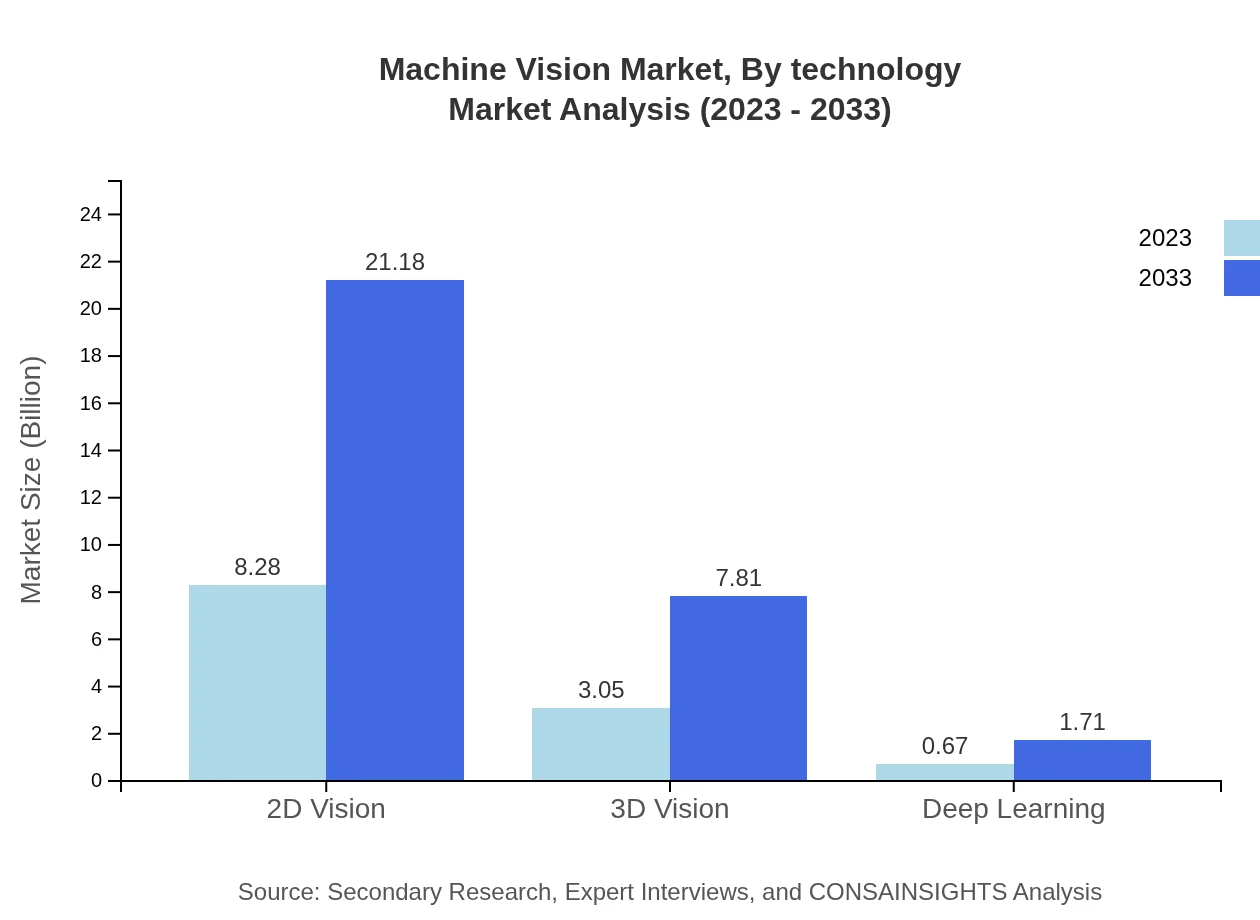

Machine Vision Market Analysis By Technology

The Machine Vision technology landscape includes various approaches such as 2D Vision, 3D Vision, Deep Learning, and more. The 2D Vision segment leads with a market value of $8.28 billion in 2023, expected to reach $21.18 billion by 2033. Meanwhile, 3D Vision technology, gaining traction due to its ability to add depth and detail, expands from $3.05 billion to $7.81 billion. The Deep Learning segment, while currently smaller at $0.67 billion, showcases promising growth potential.

Machine Vision Market Analysis By Region

Global Machine Vision Market, By Region Market Analysis (2023 - 2033)

Regional analysis reveals distinct growth trajectories influenced by technological adoption and industrial advancements. Each region presents unique opportunities, such as the strong demand in Asia Pacific primarily driven by manufacturing sectors, while North America benefits from early adoption of automated solutions.

Machine Vision Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Machine Vision Industry

Cognex Corporation:

A pioneer in the vision systems sector, Cognex develops image-based barcode readers and machine vision solutions that enhance production processes and quality control.Keyence Corporation:

Keyence provides a diverse range of automation products, including sensors, vision systems, and measurement tools, catering extensively to the manufacturing sector.Basler AG:

Specializing in machine vision cameras, Basler emphasizes high-quality imaging solutions that are integral to various industrial applications.Omron Corporation:

Omron delivers innovative automation products and solutions, focusing on enhancing productivity through advanced machine vision technologies.Teledyne Technologies:

Teledyne’s diverse portfolio includes imaging and machine vision solutions aimed at providing reliable and advanced technologies across industries.We're grateful to work with incredible clients.

FAQs

What is the market size of machine vision?

The global machine vision market is currently valued at approximately $12 billion, with an expected CAGR of 9.5% from 2023 to 2033, reflecting robust growth as industries increasingly adopt automated inspection and quality assurance systems.

What are the key market players or companies in the machine vision industry?

Key players in the machine vision industry include Cognex Corporation, National Instruments, Basler AG, Teledyne Technologies, and Hikrobot among others, all of which significantly contribute to innovations and market expansion.

What are the primary factors driving the growth in the machine vision industry?

Driving factors for growth include rapid automation in manufacturing, increased demand for quality assurance, advancements in AI and deep learning, and the rising need for enhanced safety and security in various sectors.

Which region is the fastest Growing in the machine vision market?

North America is the fastest-growing region in the machine vision market, projected to rise from $3.94 billion in 2023 to $10.09 billion by 2033, followed closely by Europe due to high industrial automation levels.

Does Consainsights provide customized market report data for the machine vision industry?

Yes, Consainsights offers customized market reports tailored to specific needs, ensuring that clients receive relevant data, insights, and analysis to support strategic decision-making in the machine vision industry.

What deliverables can I expect from this machine vision market research project?

Clients can expect comprehensive deliverables including detailed market analysis, segment data, competitive landscape assessments, and tailored insights based on specific research objectives and queries.

What are the market trends of machine vision?

Current trends in the machine vision market include increased adoption of 3D vision systems, integration of AI technologies, expanded application in quality control, and a growing focus on robotic vision in automation processes.