Magnesia Chrome Brick Market Report

Published Date: 22 January 2026 | Report Code: magnesia-chrome-brick

Magnesia Chrome Brick Market Size, Share, Industry Trends and Forecast to 2033

This report offers a comprehensive analysis of the Magnesia Chrome Brick market, providing insights into market size, growth rate, and trends from 2023 to 2033. It covers various segments, regional performance, and industry dynamics to inform strategic decision-making.

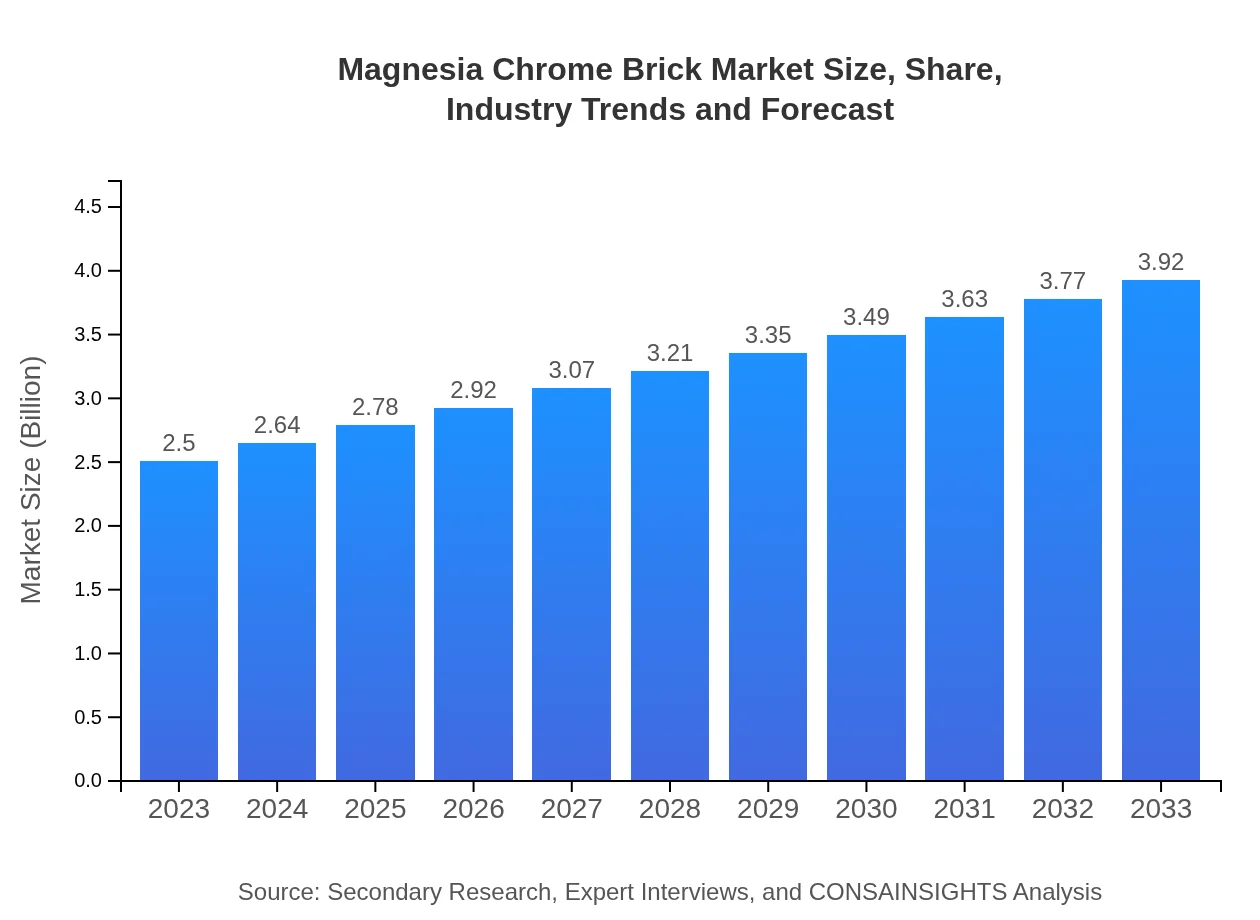

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 4.5% |

| 2033 Market Size | $3.92 Billion |

| Top Companies | RHI Magnesita, Vesuvius, Krosaki Harima Corporation, Morgan Advanced Materials |

| Last Modified Date | 22 January 2026 |

Magnesia Chrome Brick Market Overview

Customize Magnesia Chrome Brick Market Report market research report

- ✔ Get in-depth analysis of Magnesia Chrome Brick market size, growth, and forecasts.

- ✔ Understand Magnesia Chrome Brick's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Magnesia Chrome Brick

What is the Market Size & CAGR of Magnesia Chrome Brick market in 2023 and 2033?

Magnesia Chrome Brick Industry Analysis

Magnesia Chrome Brick Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Magnesia Chrome Brick Market Analysis Report by Region

Europe Magnesia Chrome Brick Market Report:

The European market for Magnesia Chrome Brick held a size of $0.61 billion in 2023 and is expected to increase to $0.96 billion by 2033, owing to stringent regulations promoting quality refractories and the demand for advanced technologies in industrial processes.Asia Pacific Magnesia Chrome Brick Market Report:

The Asia Pacific region held a market size of approximately $0.54 billion in 2023 and is expected to grow to $0.84 billion by 2033, driven by the increasing industrial activities in countries like China and India, coupled with the growing steel production capacity.North America Magnesia Chrome Brick Market Report:

The North American market was valued at about $0.94 billion in 2023, with a forecast to expand to $1.47 billion by 2033. This growth is fueled by the revival of manufacturing and construction industries post-pandemic.South America Magnesia Chrome Brick Market Report:

In South America, the Magnesia Chrome Brick market size was around $0.10 billion in 2023, projected to reach $0.16 billion by 2033. The growth is primarily supported by increased investments in the mining and metallurgy sectors.Middle East & Africa Magnesia Chrome Brick Market Report:

In the Middle East and Africa, the market size for Magnesia Chrome Brick was approximately $0.31 billion in 2023, anticipated to grow to $0.49 billion by 2033, driven by expanding industrial bases and rising investments in infrastructure.Tell us your focus area and get a customized research report.

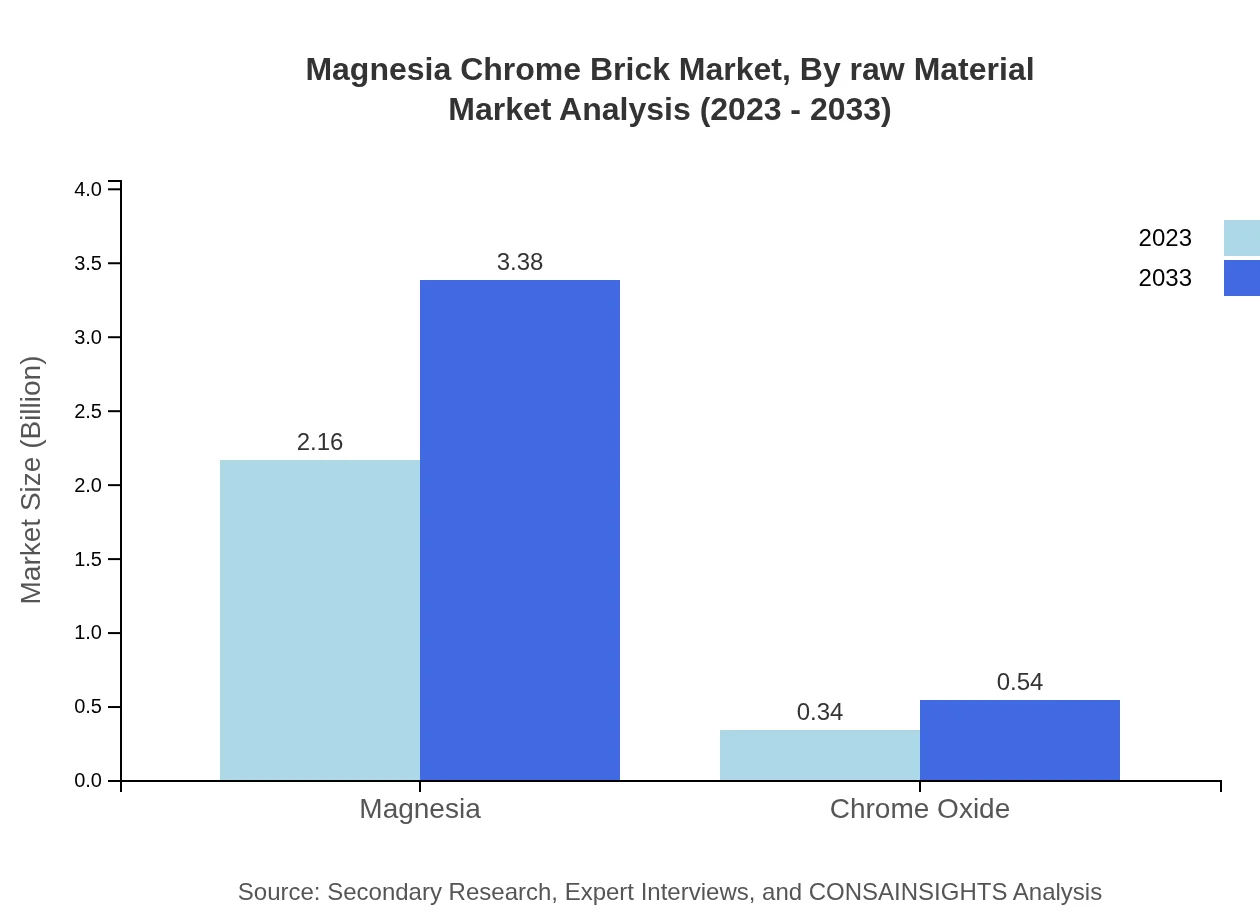

Magnesia Chrome Brick Market Analysis By Raw Material

As of 2023, the Magnesia segment constitutes the majority share with a market size of $2.16 billion and is projected to maintain a steady share until 2033. Chrome Oxide, while smaller, remains essential due to its unique properties enhancing thermal stability, contributing to the overall sector viability.

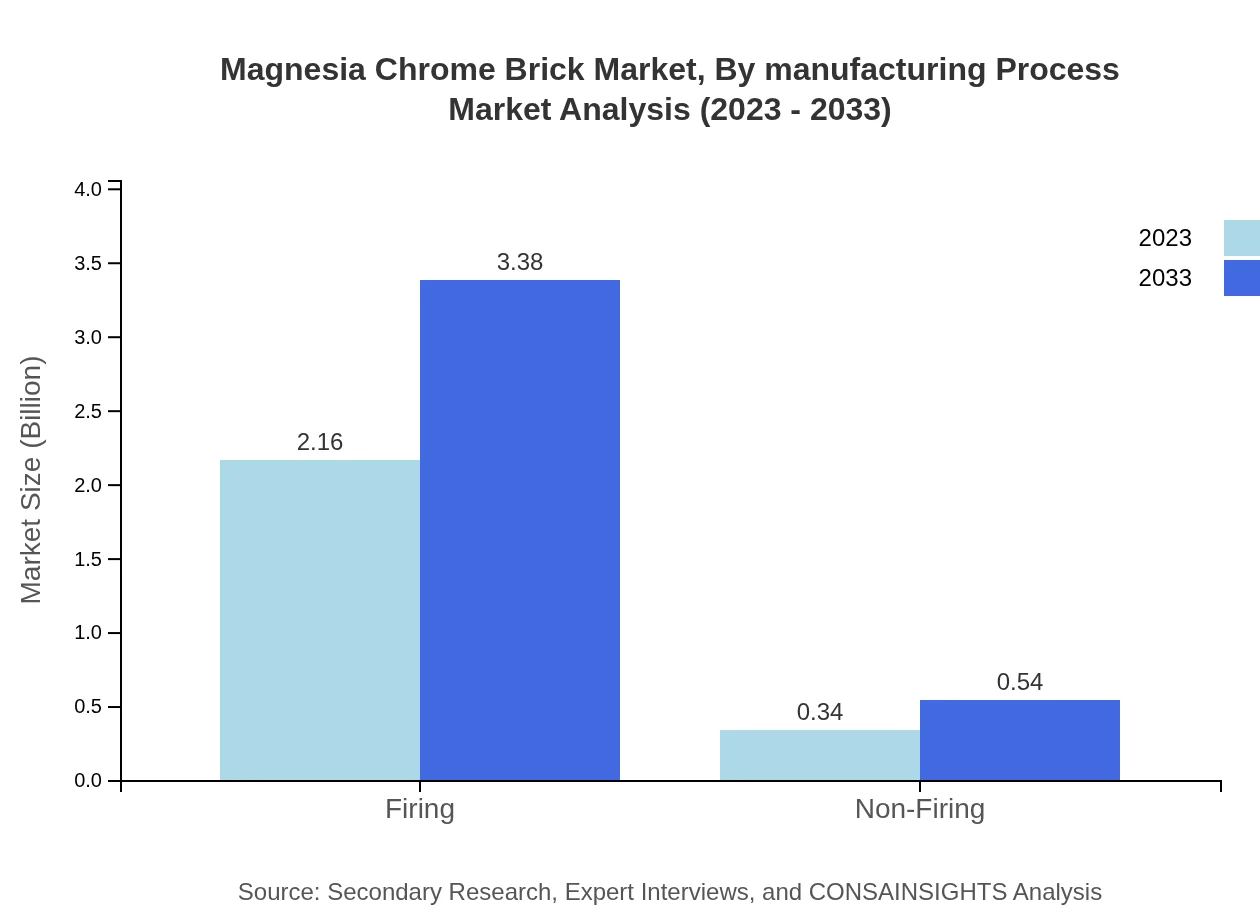

Magnesia Chrome Brick Market Analysis By Manufacturing Process

The Firing process dominates the production of Magnesia Chrome Bricks, securing an 86.22% share in 2023. Non-Firing methods, though smaller at 13.78%, are growing due to advancements in material processing techniques.

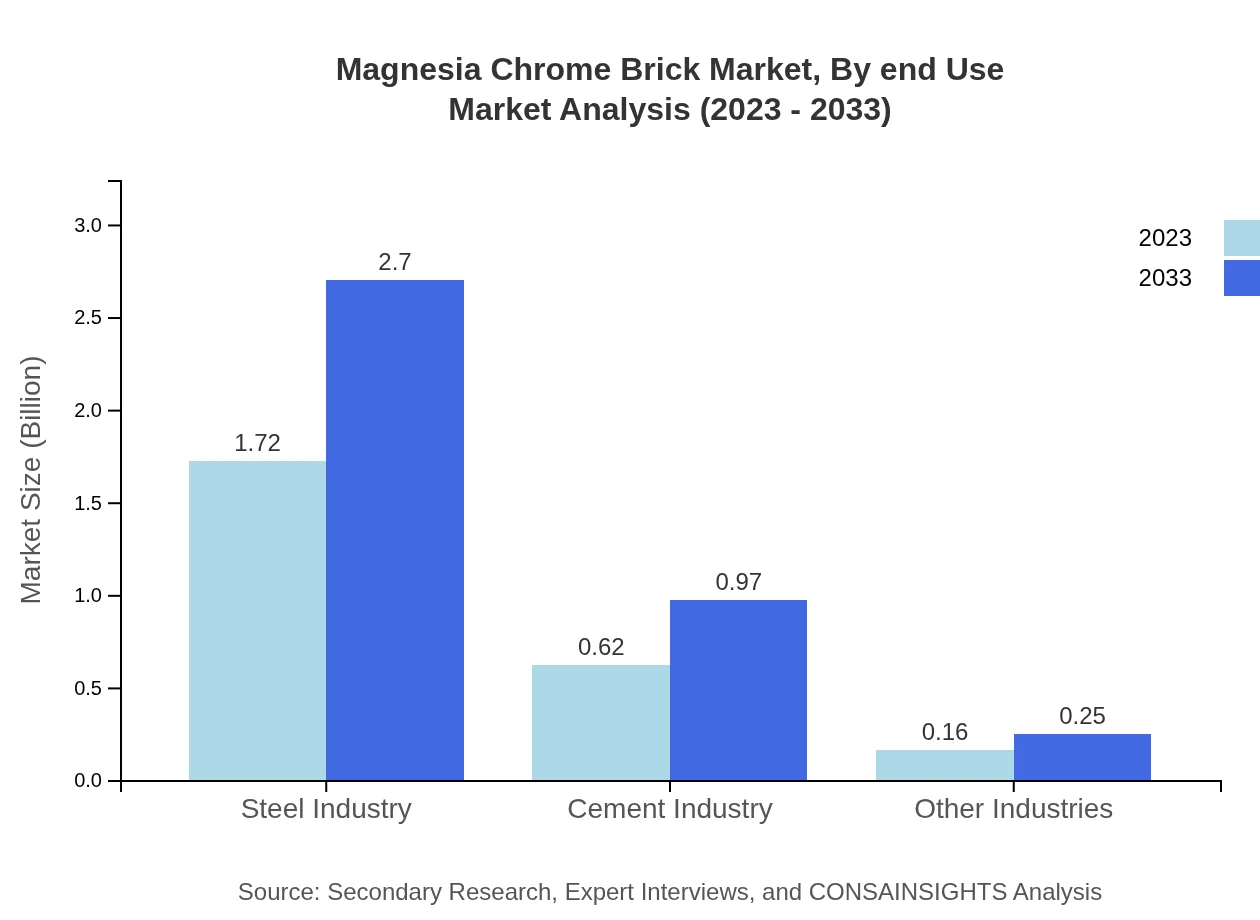

Magnesia Chrome Brick Market Analysis By End Use

The steel industry remains the largest end-user, with a market size of $1.72 billion in 2023, projected to reach $2.70 billion by 2033. Significant demands also arise from cement manufacturing and other industrial applications, which continue to expand their adoption of these refractories.

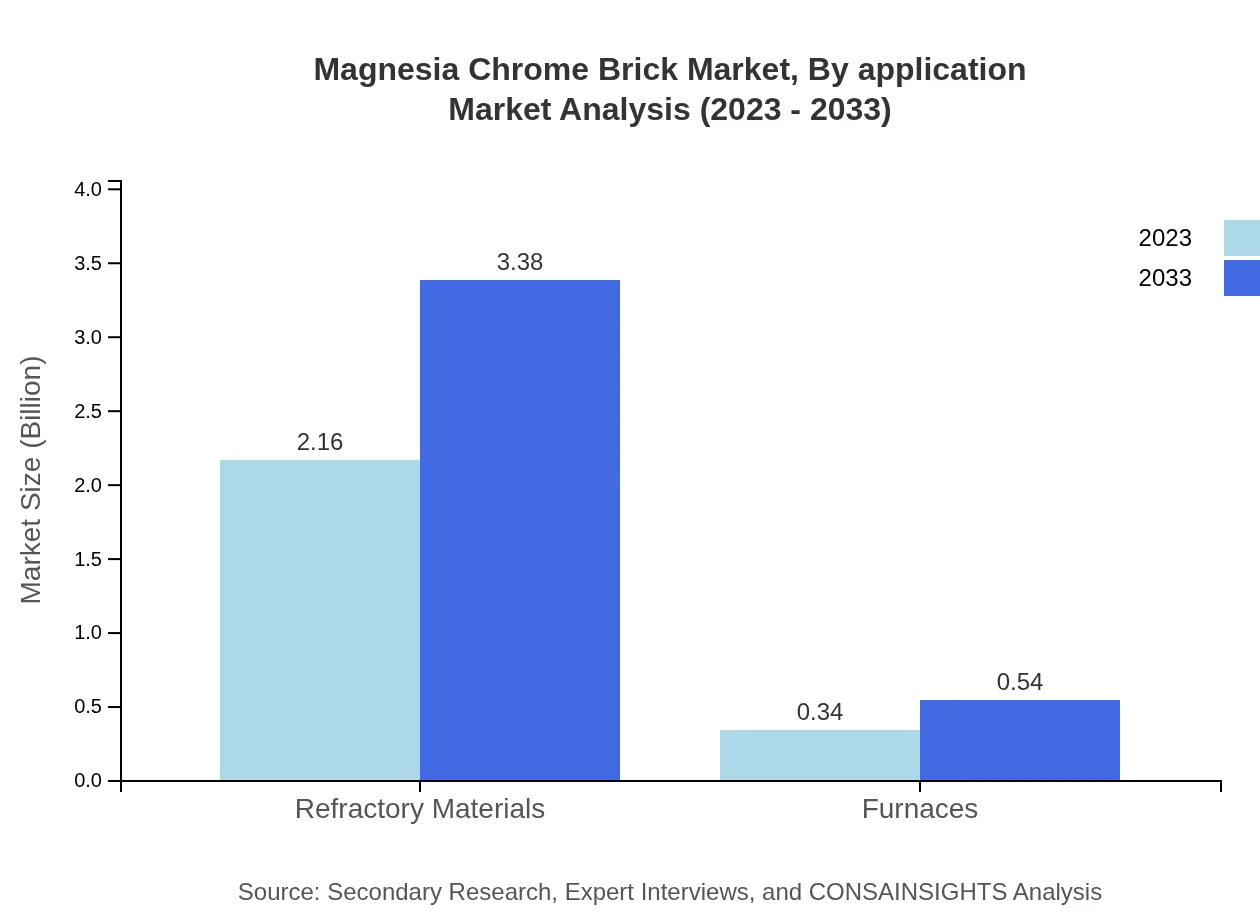

Magnesia Chrome Brick Market Analysis By Application

Applications in furnaces account for a substantial share due to the high operational temperatures required in steel production. This segment will see consistent demand growth, ensuring high market relevance through 2033.

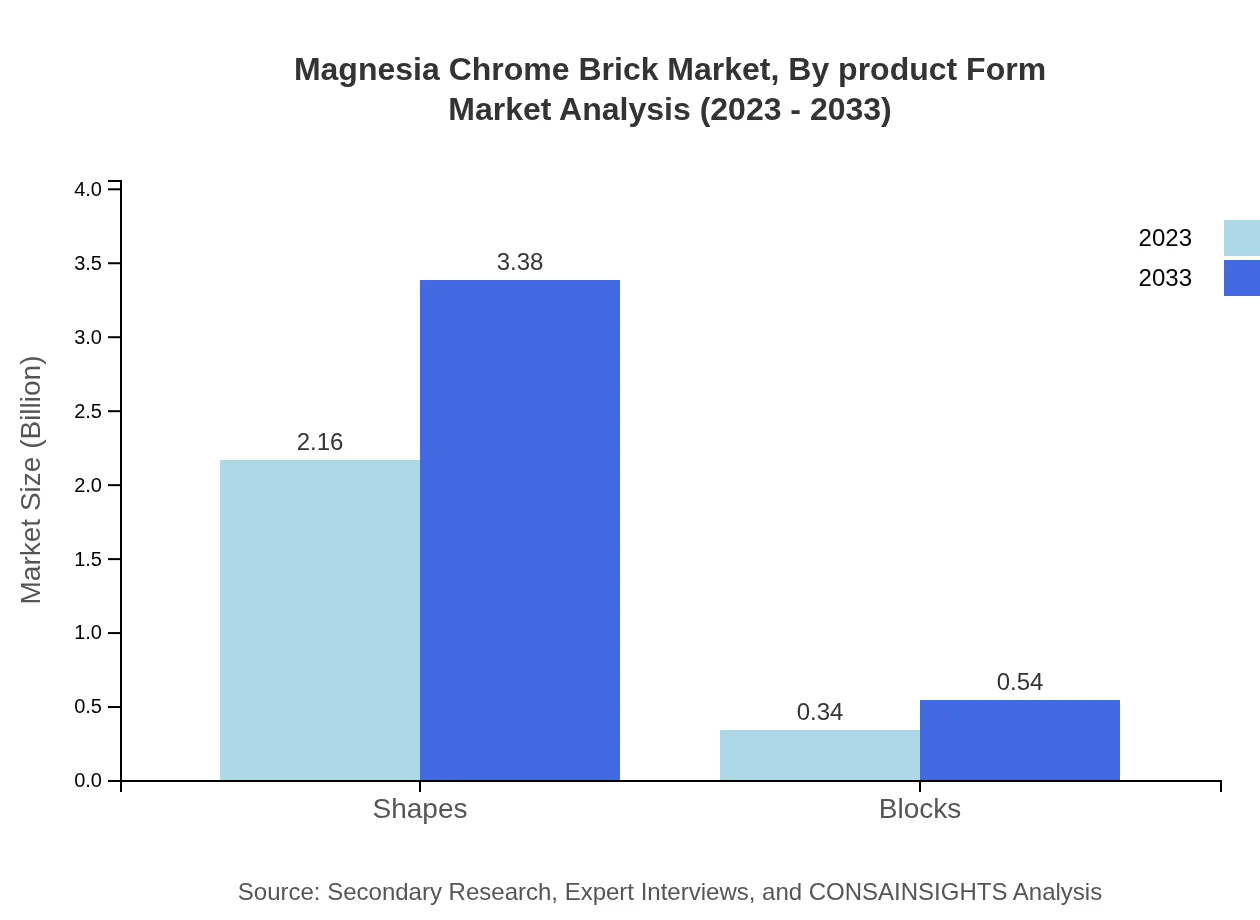

Magnesia Chrome Brick Market Analysis By Product Form

Shapes and Blocks produce the majority of market revenues, with a share of approximately 86.22% in 2023. This trend will likely persist due to growing preferences for custom forms in high-temperature applications.

Magnesia Chrome Brick Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Magnesia Chrome Brick Industry

RHI Magnesita:

RHI Magnesita is a global leader in refractories, providing innovative solutions characterized by comprehensive capabilities across the entire value chain from raw material sourcing to manufacturing.Vesuvius:

Vesuvius specializes in molten metal flow engineering and refractories, delivering high-performance products tailored for the steel and foundry industry.Krosaki Harima Corporation:

Krosaki Harima, a significant player in the refractory sector, focuses on manufacturing refractories specifically for high-temperature applications in the steel and cement industries.Morgan Advanced Materials:

Morgan Advanced Materials offers high-quality silicon carbide and refractory materials, focusing on innovation and sustainability in product development.We're grateful to work with incredible clients.

FAQs

What is the market size of magnesia Chrome Brick?

The magnesia-chrome-brick market is projected to reach approximately $2.5 billion by 2033, growing at a CAGR of 4.5%. This steady growth is driven by increasing demand in steel and cement industries.

What are the key market players or companies in this magnesia Chrome Brick industry?

The key players in the magnesia-chrome-brick industry include major refractory manufacturers, focusing on quality and innovation. Companies are investing in R&D to enhance product performance and sustainability across sectors.

What are the primary factors driving the growth in the magnesia Chrome Brick industry?

The growth of the magnesia-chrome-brick market is primarily driven by increased production in the steel and cement industries, along with growing infrastructure projects globally, enhancing overall demand for refractory materials.

Which region is the fastest Growing in the magnesia Chrome Brick?

The Asia Pacific region is the fastest-growing market for magnesia-chrome-brick, expected to grow from $0.54 billion in 2023 to $0.84 billion by 2033, reflecting robust industrial activity and demand.

Does ConsaInsights provide customized market report data for the magnesia Chrome Brick industry?

Yes, ConsaInsights offers customized market research reports tailored to specific needs in the magnesia-chrome-brick industry, ensuring detailed insights and analysis to support strategic decision-making.

What deliverables can I expect from this magnesia Chrome Brick market research project?

Deliverables from the magnesia-chrome-brick market research project include comprehensive market analysis, segmentation data, regional insights, competitive landscape overview, and strategic recommendations.

What are the market trends of magnesia Chrome Brick?

Current trends in the magnesia-chrome-brick market include increasing demand for high-performance refractories and sustainable manufacturing practices, along with innovative applications in various industrial processes.