Main Automation Contractor Mac Market Report

Published Date: 22 January 2026 | Report Code: main-automation-contractor-mac

Main Automation Contractor Mac Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Main Automation Contractor (MAC) market, exploring insights and data from 2023 to 2033. It covers market trends, segmentation, regional performance, and forecasts, allowing stakeholders to understand the evolving landscape of automation contracting.

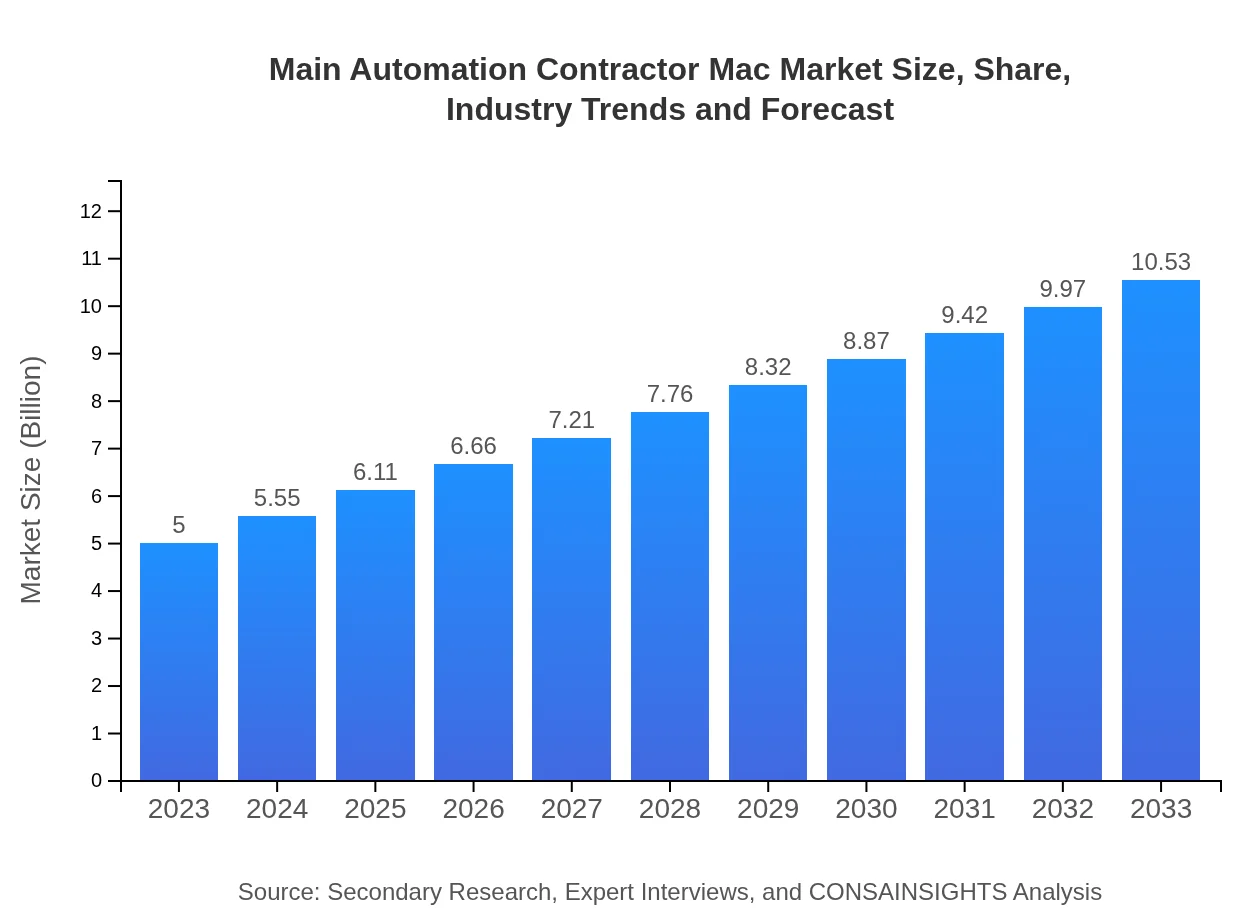

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | Siemens AG, Honeywell International Inc., Emerson Electric Co., Schneider Electric |

| Last Modified Date | 22 January 2026 |

Main Automation Contractor Mac Market Overview

Customize Main Automation Contractor Mac Market Report market research report

- ✔ Get in-depth analysis of Main Automation Contractor Mac market size, growth, and forecasts.

- ✔ Understand Main Automation Contractor Mac's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Main Automation Contractor Mac

What is the Market Size & CAGR of Main Automation Contractor Mac market in 2023?

Main Automation Contractor Mac Industry Analysis

Main Automation Contractor Mac Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Main Automation Contractor Mac Market Analysis Report by Region

Europe Main Automation Contractor Mac Market Report:

Europe's market for MAC is projected to grow from $1.52 billion in 2023 to $3.21 billion by 2033. The European Union's focus on green technologies and industry decarbonization is fostering an environment for automation services that enhance sustainability and efficiency.Asia Pacific Main Automation Contractor Mac Market Report:

In the Asia-Pacific region, the market is expected to grow from $0.93 billion in 2023 to $1.95 billion by 2033, driven by rapid industrial growth, increasing urbanization, and heightened investment in smart manufacturing initiatives. Countries like China and India are leading the demand for automation solutions to improve production capabilities and operational efficiencies.North America Main Automation Contractor Mac Market Report:

North America is anticipated to expand significantly, escalating from $1.90 billion in 2023 to $4.01 billion by 2033. The region's emphasis on advanced manufacturing technologies, coupled with high expenditure in research and development, drives robust demand for MAC services, particularly in the oil and gas and automotive sectors.South America Main Automation Contractor Mac Market Report:

The South American MAC market is projected to increase from $0.46 billion in 2023 to $0.96 billion in 2033. The growth in this region focuses on enhancing the performance of industries such as mining and agriculture, thereby prompting investments in automation technologies to optimize processes and reduce costs.Middle East & Africa Main Automation Contractor Mac Market Report:

The Middle East and Africa region shows modest growth, increasing from $0.19 billion in 2023 to $0.40 billion by 2033. The market's dynamics are influenced by oil and gas sector developments, alongside rising demand for automation in construction and mining industries.Tell us your focus area and get a customized research report.

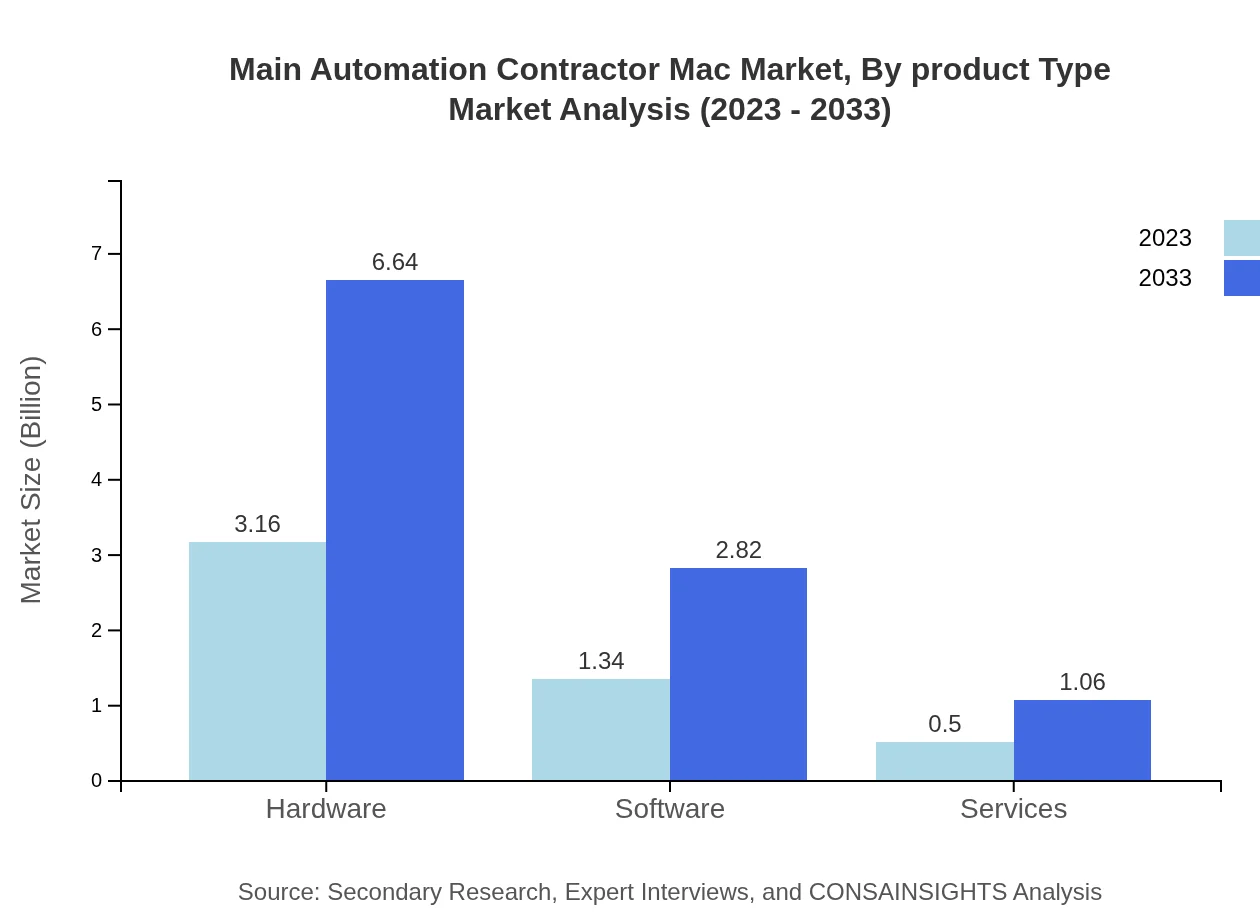

Main Automation Contractor Mac Market Analysis By Product Type

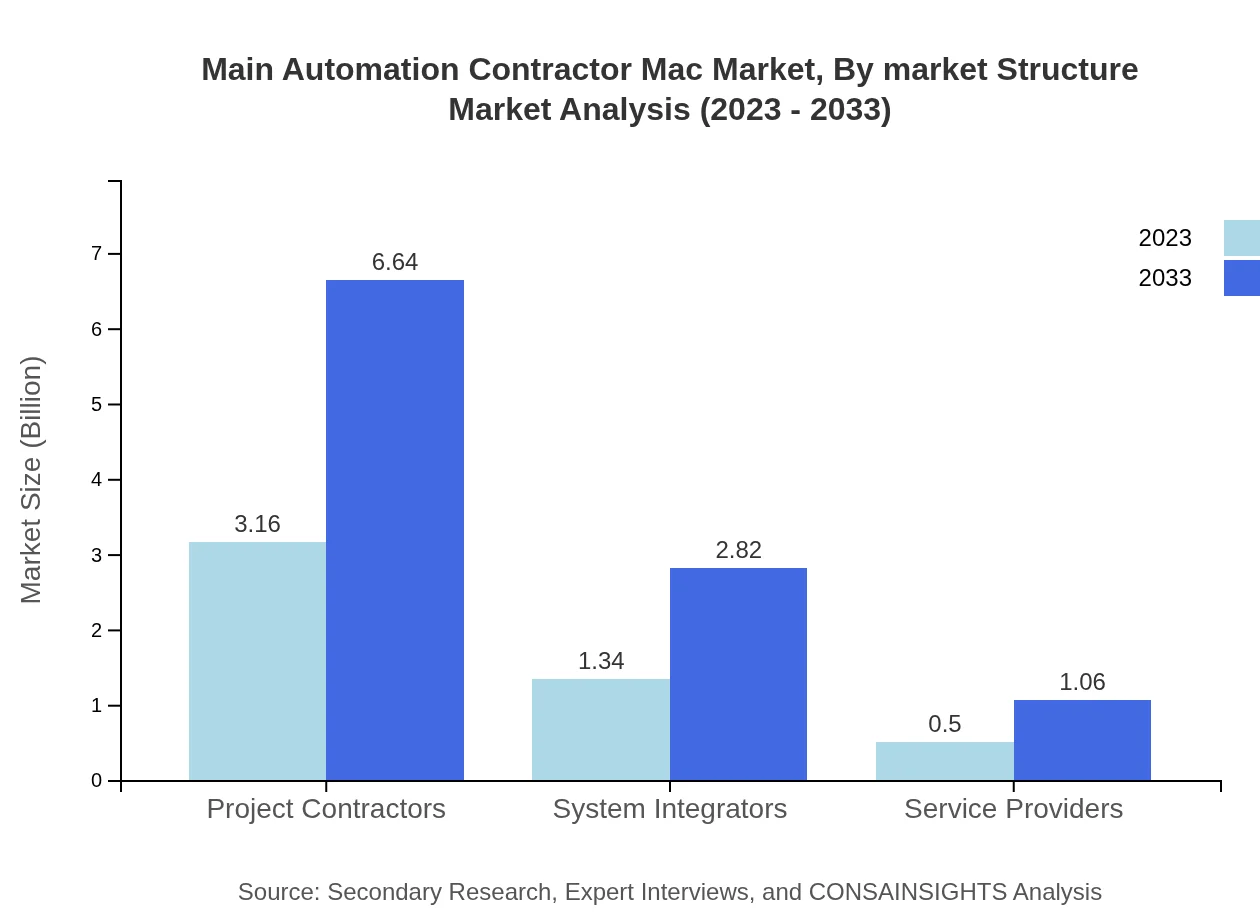

The analysis reveals that in 2023, hardware dominates the MAC market with a size of $3.16 billion, accounting for 63.12% market share. This is followed by software solutions ($1.34 billion) at 26.8% share and services at $0.50 billion with a 10.08% share. By 2033, hardware is projected to reach $6.64 billion; software could grow to $2.82 billion; and services may increase to $1.06 billion.

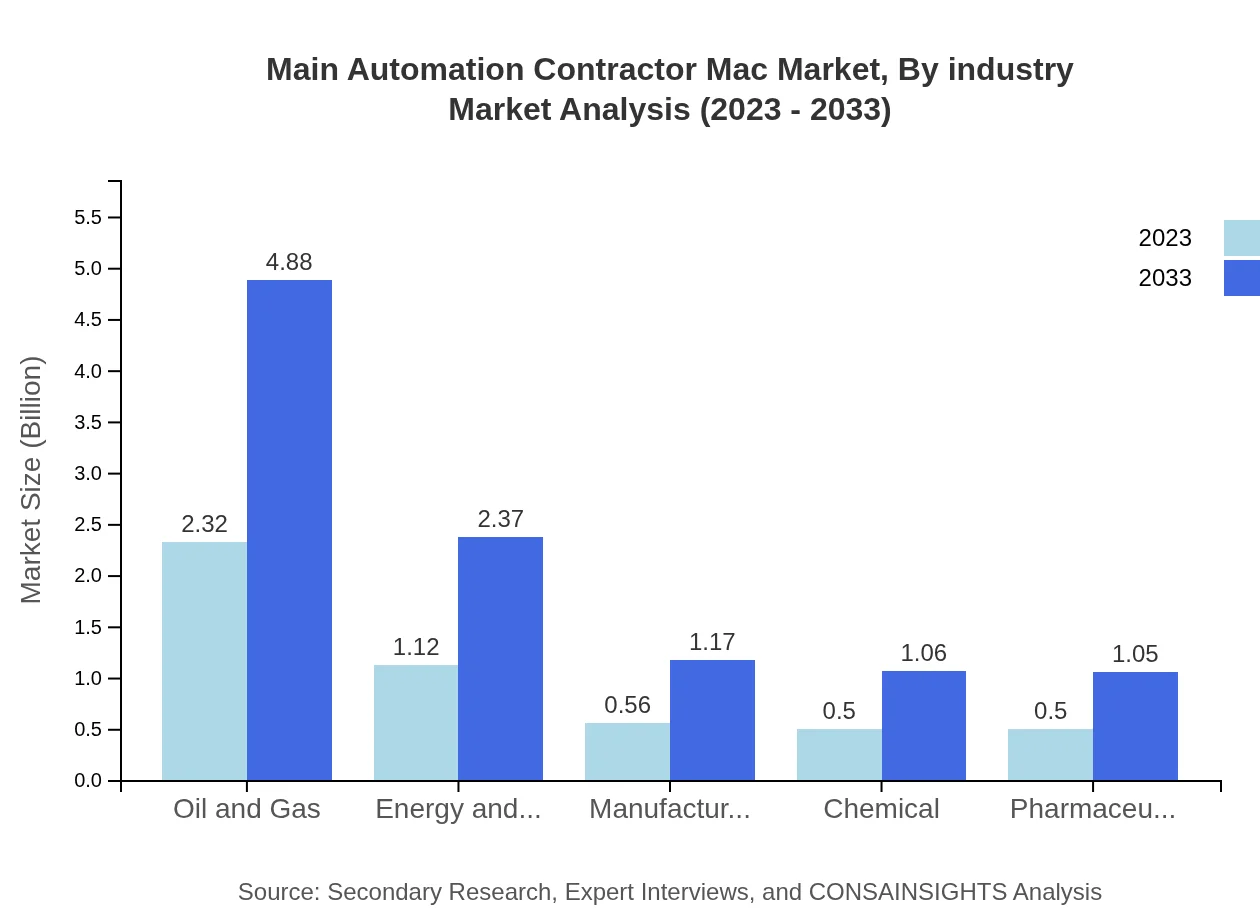

Main Automation Contractor Mac Market Analysis By Industry

Key industries utilizing MAC services include oil and gas, with a market size of $2.32 billion in 2023 (46.35% share), and energy and utilities, at $1.12 billion (22.49% share). Other notable sectors are manufacturing ($0.56 billion, 11.11% share) and chemicals ($0.50 billion, 10.03% share). This segmentation showcases the demand for automation across varied operational landscapes.

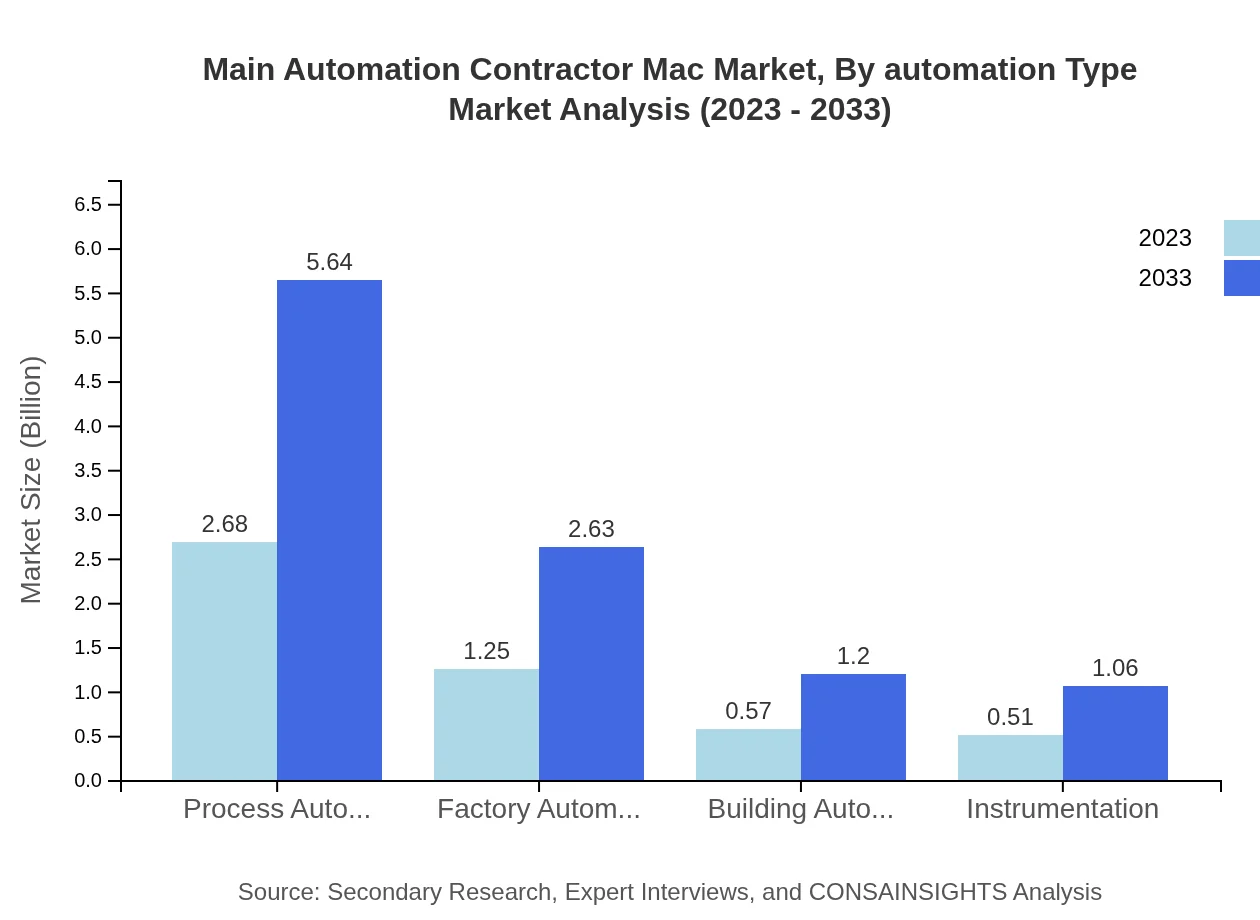

Main Automation Contractor Mac Market Analysis By Automation Type

Process automation leads with a market size of $2.68 billion (53.54% share) in 2023, followed by factory automation at $1.25 billion (24.94% share). Building automation represents a specialized subset with a market of $0.57 billion (11.41% share). Innovations in these types significantly enhance operational efficiency in numerous sectors.

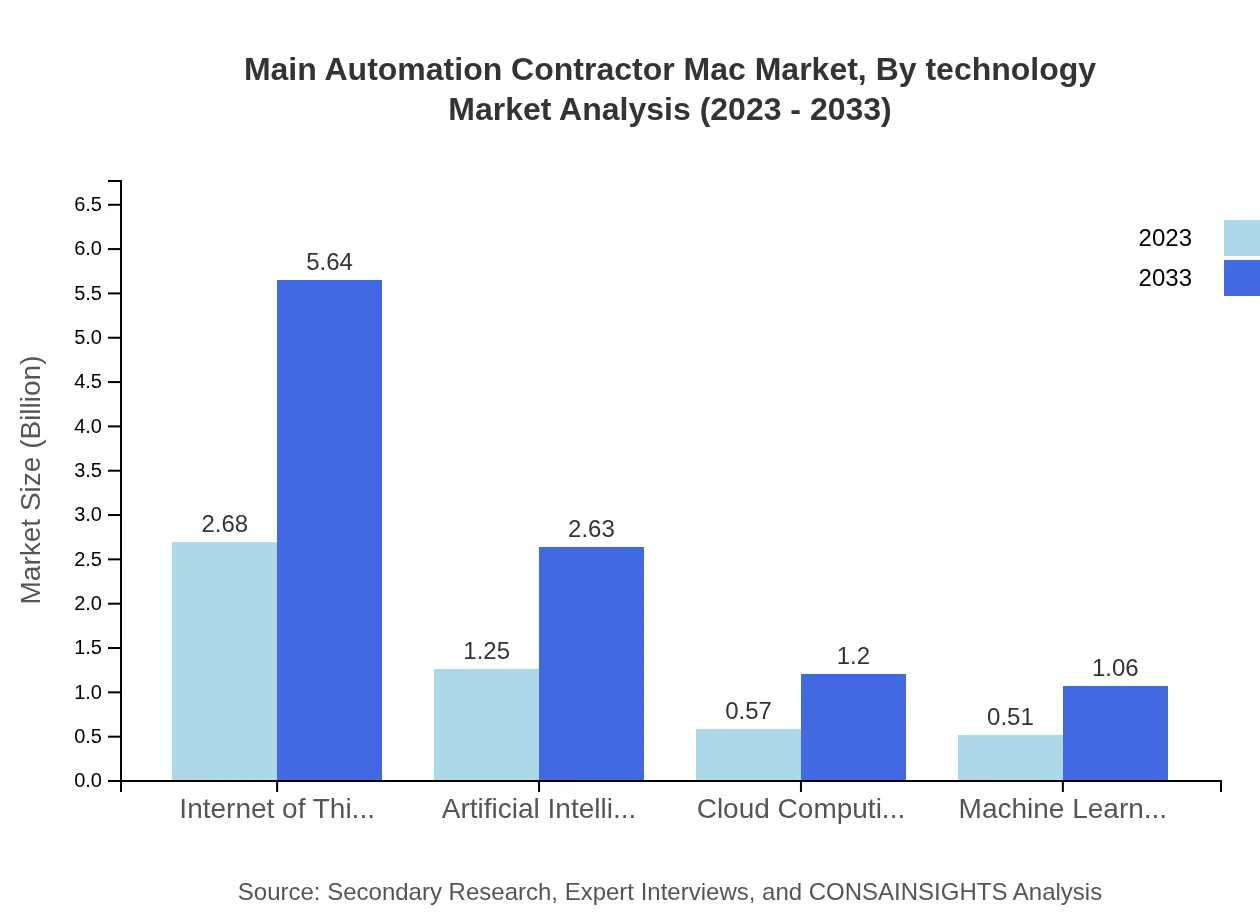

Main Automation Contractor Mac Market Analysis By Technology

The influence of Internet of Things (IoT) technology is evident, projected to reach $5.64 billion in 2033, accounting for a share of 53.54%. Other technologies like Artificial Intelligence ($2.63 billion, 24.94% share), Cloud Computing ($1.20 billion, 11.41% share), and Machine Learning ($1.06 billion, 10.11% share) are also emerging, indicating the shift towards smarter automation solutions.

Main Automation Contractor Mac Market Analysis By Market Structure

Project contractors hold a significant position in the MAC market, with a size of $3.16 billion (63.12% share) reported in 2023. This reflects the strategic role of contractors in implementing large-scale automation projects. System integrators, with $1.34 billion (26.8% share), and service providers at $0.50 billion (10.08% share), also contribute importantly to the market structure.

Main Automation Contractor Mac Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Main Automation Contractor Mac Industry

Siemens AG:

A global leader in automation and digitalization in the industry, Siemens provides comprehensive solutions that address the needs of the Main Automation Contractor market, emphasizing sustainability and efficiency across various applications.Honeywell International Inc.:

Honeywell is known for its advanced automation technologies and solutions, enabling organizations to optimize performance and mitigate risks across industrial operations through innovative MAC services.Emerson Electric Co.:

Emerson specializes in automation solutions that help clients achieve operational excellence. Their expertise in digital transformation and process management solidifies their status as a leader in the MAC landscape.Schneider Electric:

Focusing on energy management and industrial automation, Schneider Electric reinforces its position by integrating automation solutions that enhance efficiency and sustainability in industry sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of Main Automation Contractor (MAC)?

The global Main Automation Contractor (MAC) market was valued at approximately $5 billion in 2023, with a projected CAGR of 7.5%. By 2033, the market is expected to grow significantly, indicating robust investment and interest in automation services.

What are the key market players or companies in the Main Automation Contractor (MAC) industry?

Key players in the Main Automation Contractor (MAC) industry include major firms engaged in automation and control solutions. These companies focus on providing comprehensive integrated solutions that enhance process efficiency and safety across various sectors.

What are the primary factors driving the growth in the Main Automation Contractor (MAC) industry?

The growth in the Main Automation Contractor (MAC) industry is driven by the increasing need for operational efficiency, the rise of Industry 4.0 technologies, and the growing adoption of IoT and automation across sectors such as manufacturing, oil and gas, and utilities.

Which region is the fastest Growing in the Main Automation Contractor (MAC)?

The fastest-growing region in the Main Automation Contractor (MAC) market is North America, expected to grow from $1.90 billion in 2023 to $4.01 billion by 2033. Europe also shows significant growth, reaching $3.21 billion by 2033.

Does ConsaInsights provide customized market report data for the Main Automation Contractor (MAC) industry?

Yes, ConsaInsights offers customized market report data for the Main Automation Contractor (MAC) industry. Clients can obtain tailored reports focusing on specific segments, regions, or technologies to suit their unique business needs.

What deliverables can I expect from this Main Automation Contractor (MAC) market research project?

From this Main Automation Contractor (MAC) market research project, you can expect comprehensive reports detailing market size, growth forecasts, competitive analyses, regional insights, and trends with actionable recommendations for strategic planning.

What are the market trends of Main Automation Contractor (MAC)?

Current market trends in the Main Automation Contractor (MAC) sector include increased investment in IoT applications, digital twins, and advanced analytics. The focus is on enhancing efficiency, flexibility, and sustainability in automation solutions across various industries.