Mass Flow Controller Market Report

Published Date: 22 January 2026 | Report Code: mass-flow-controller

Mass Flow Controller Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Mass Flow Controller market, detailing market size, segmentation, industry dynamics, and regional insights from 2023 to 2033. It covers trends, forecasts, and competitive landscapes to offer valuable insights for stakeholders.

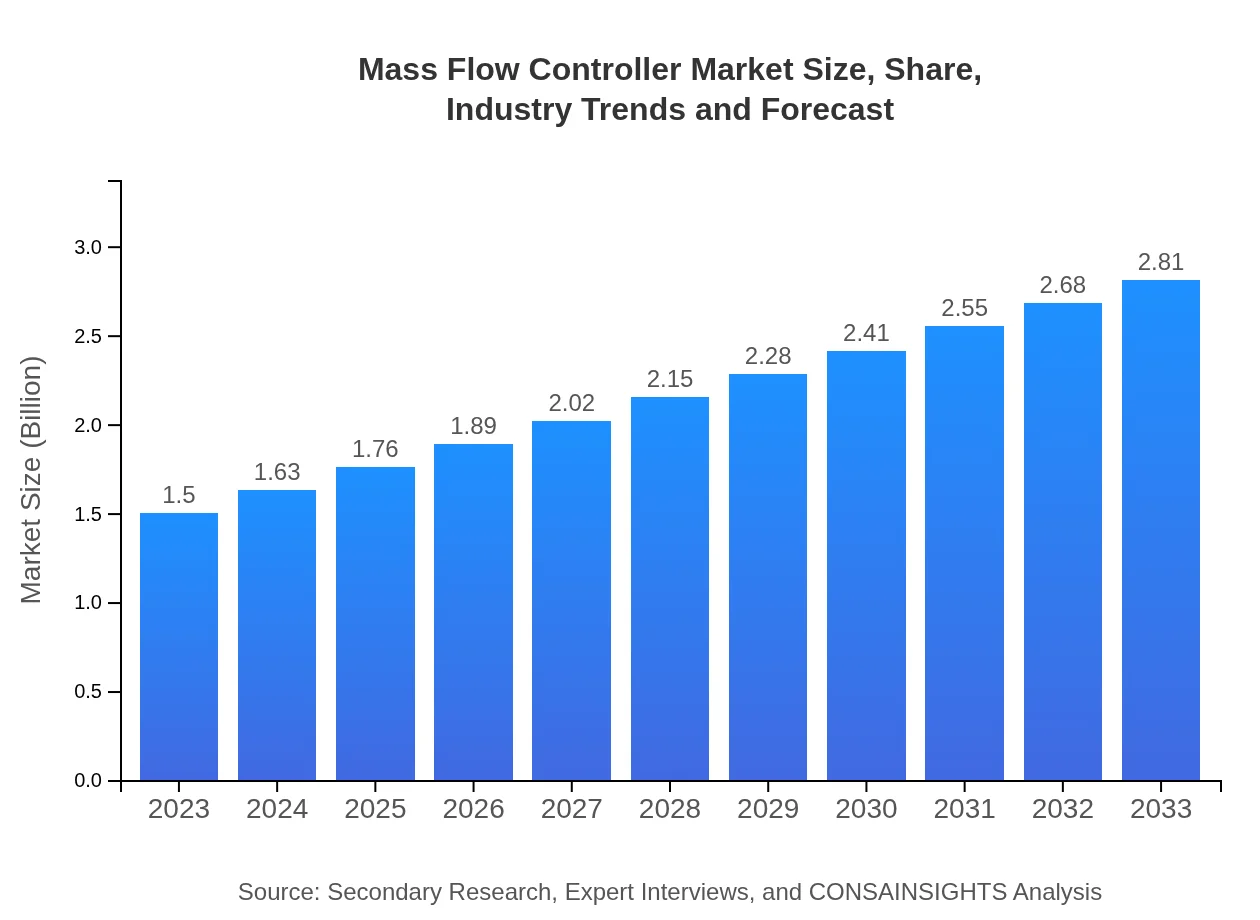

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 6.3% |

| 2033 Market Size | $2.81 Billion |

| Top Companies | Brooks Instrument, Emerson Electric Co., Omega Engineering Ltd., Horiba Ltd. |

| Last Modified Date | 22 January 2026 |

Mass Flow Controller Market Overview

Customize Mass Flow Controller Market Report market research report

- ✔ Get in-depth analysis of Mass Flow Controller market size, growth, and forecasts.

- ✔ Understand Mass Flow Controller's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Mass Flow Controller

What is the Market Size & CAGR of Mass Flow Controller market in 2023?

Mass Flow Controller Industry Analysis

Mass Flow Controller Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Mass Flow Controller Market Analysis Report by Region

Europe Mass Flow Controller Market Report:

The European market, valued at $0.51 billion in 2023, is set to reach $0.96 billion by 2033. The stringent environmental regulations and a push towards sustainability in manufacturing are key drivers of growth in this region.Asia Pacific Mass Flow Controller Market Report:

The Asia Pacific region, estimated at $0.28 billion in 2023, is projected to grow to $0.52 billion by 2033. This growth is driven by the booming manufacturing sector in countries like China and Japan, where semiconductor and automotive industries are primary consumers of MFCs. The rapid industrialization and adoption of advanced technologies contribute to the rising market demand.North America Mass Flow Controller Market Report:

North America holds a significant share, with a market size of $0.50 billion in 2023, expected to grow to $0.93 billion by 2033. Strong demand from the semiconductor and biotechnology sectors, combined with technological innovations and regulatory compliance requirements, drives this expansion.South America Mass Flow Controller Market Report:

In South America, the Mass Flow Controller market is valued at approximately $0.13 billion in 2023 and is expected to reach $0.24 billion by 2033. The growth is attributed to expanding industries such as fuel production and renewable energy projects aiming to improve efficiency and reduce emissions.Middle East & Africa Mass Flow Controller Market Report:

The Middle East and Africa represent a smaller segment of the market with a current value of $0.08 billion expected to grow to $0.16 billion by 2033, largely fueled by investments in energy production and environmental monitoring applications.Tell us your focus area and get a customized research report.

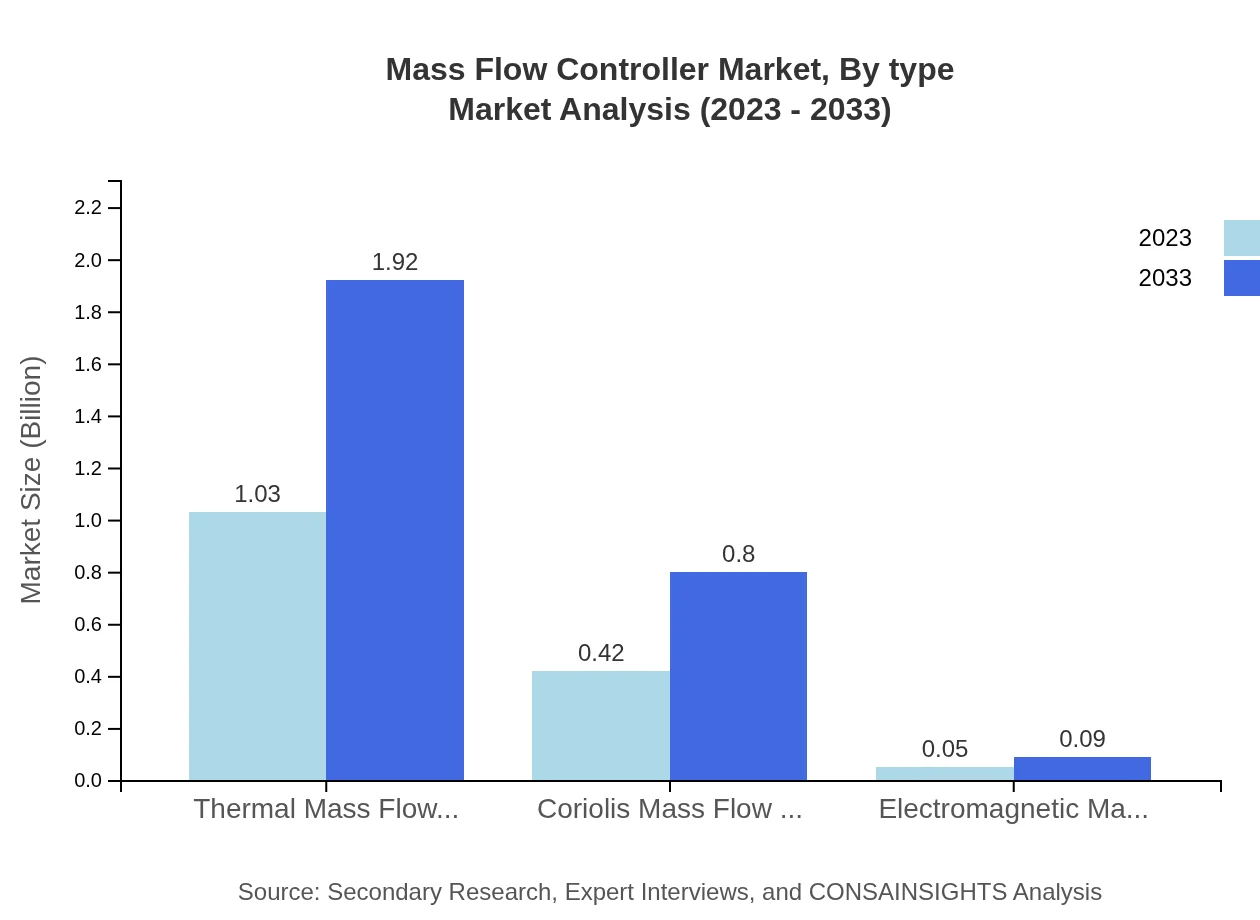

Mass Flow Controller Market Analysis By Type

The segmentation reveals that Thermal Mass Flow Controllers dominate the market, with a size of $1.03 billion in 2023, growing to $1.92 billion by 2033, capturing 68.48% market share. Coriolis Mass Flow Controllers follow with a size of $0.42 billion in 2023, expected to reach $0.80 billion in 2033, holding a market share of 28.33%. Electromagnetic Mass Flow Controllers represent a smaller segment, with $0.05 billion in 2023 and an anticipated $0.09 billion by 2033, equating to a 3.19% market share.

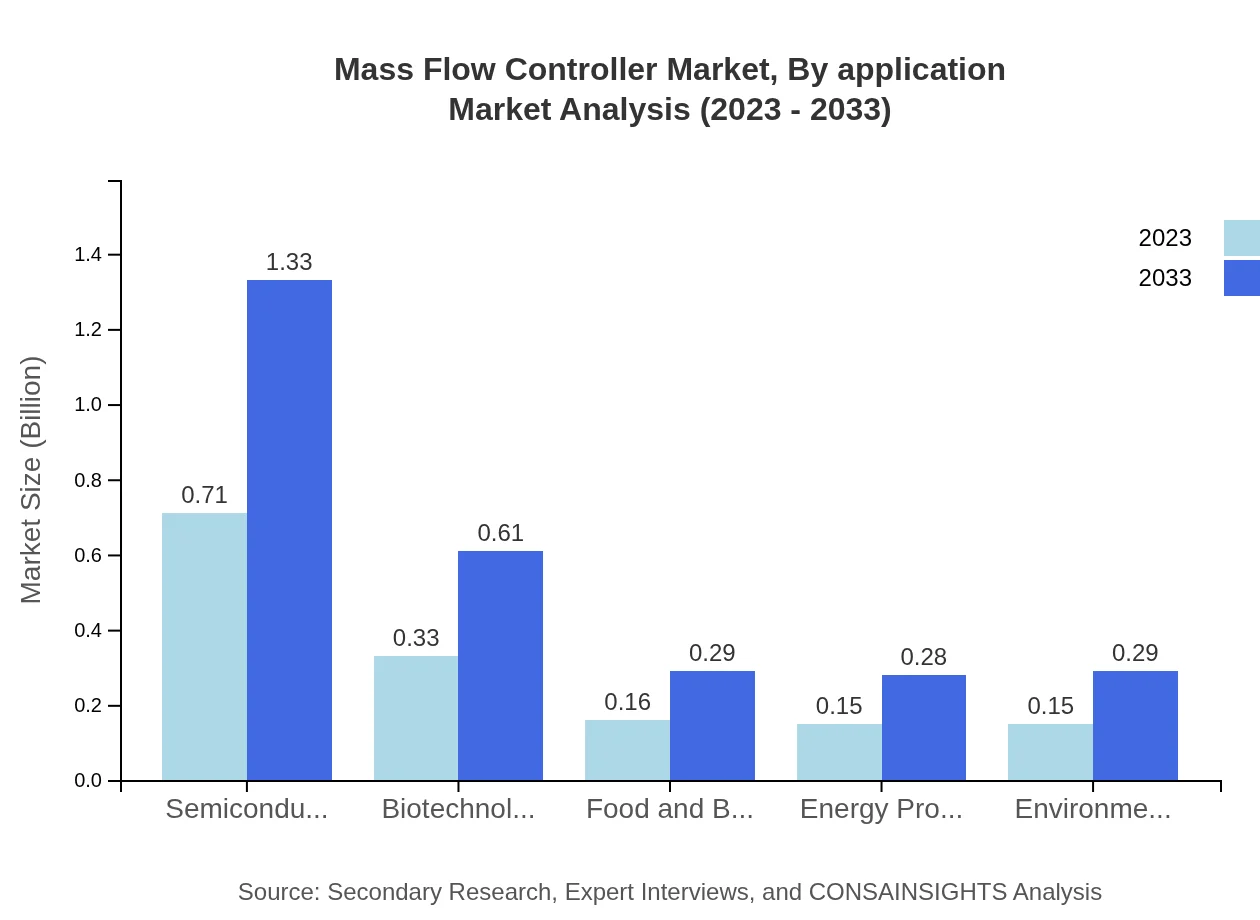

Mass Flow Controller Market Analysis By Application

In terms of application, Semiconductor Manufacturing leads with a size of $0.71 billion in 2023, projected to grow to $1.33 billion by 2033, holding a 47.48% share. Biotechnology and Pharmaceuticals follow closely with $0.33 billion in 2023 and a growth forecast to $0.61 billion by 2033, capturing a 21.86% market share. Environmental Monitoring and Energy Production also represent significant application areas, being critical for compliance and efficiency.

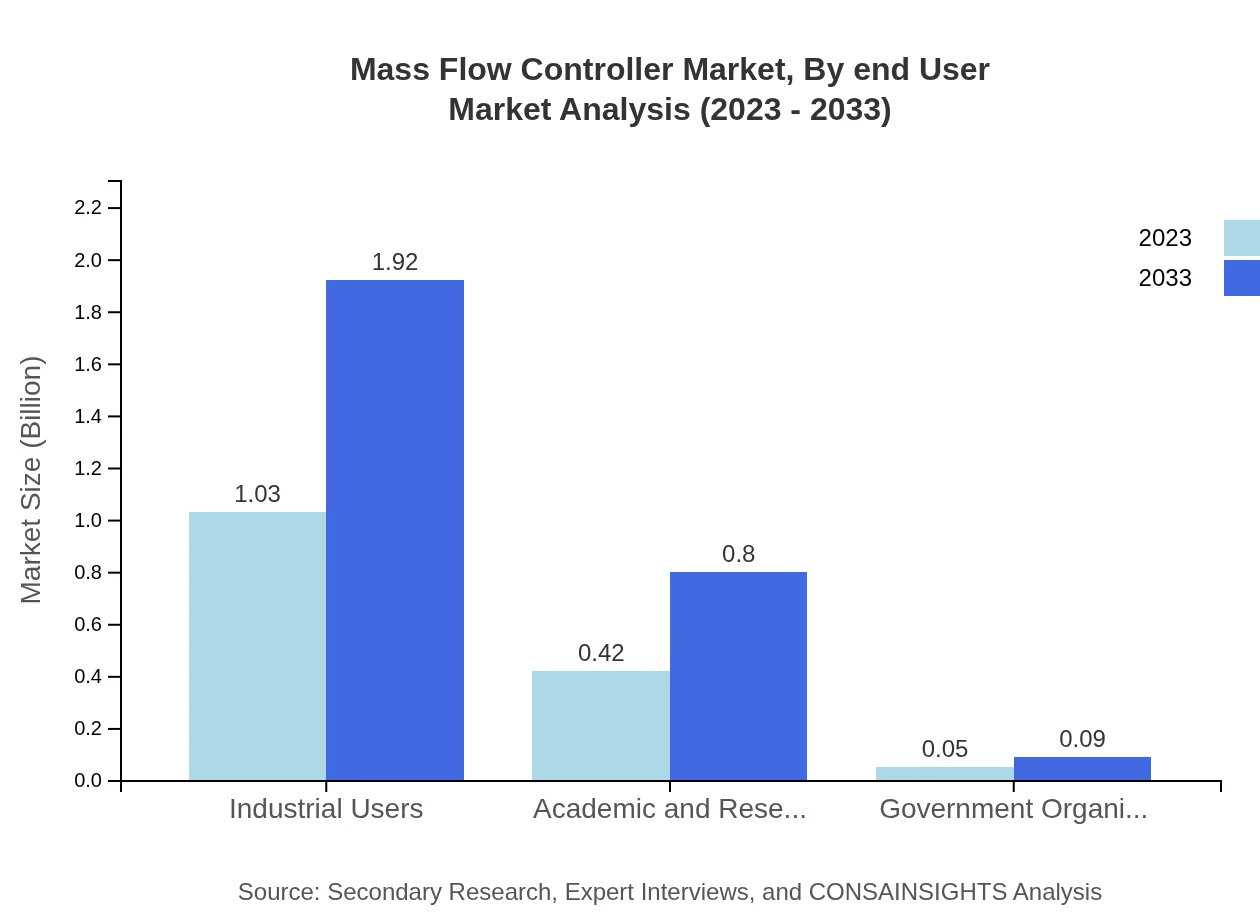

Mass Flow Controller Market Analysis By End User

The end-user segmentation shows Industrial Users dominating with sizes of $1.03 billion in 2023, expected to double to $1.92 billion by 2033, maintaining a 68.48% share. Academic and Research Institutions, while smaller in comparison, are significant, growing from $0.42 billion to $0.80 billion over the same period, representing a 28.33% share. Government Organizations account for a smaller segment as well, projected to grow and reach $0.09 billion.

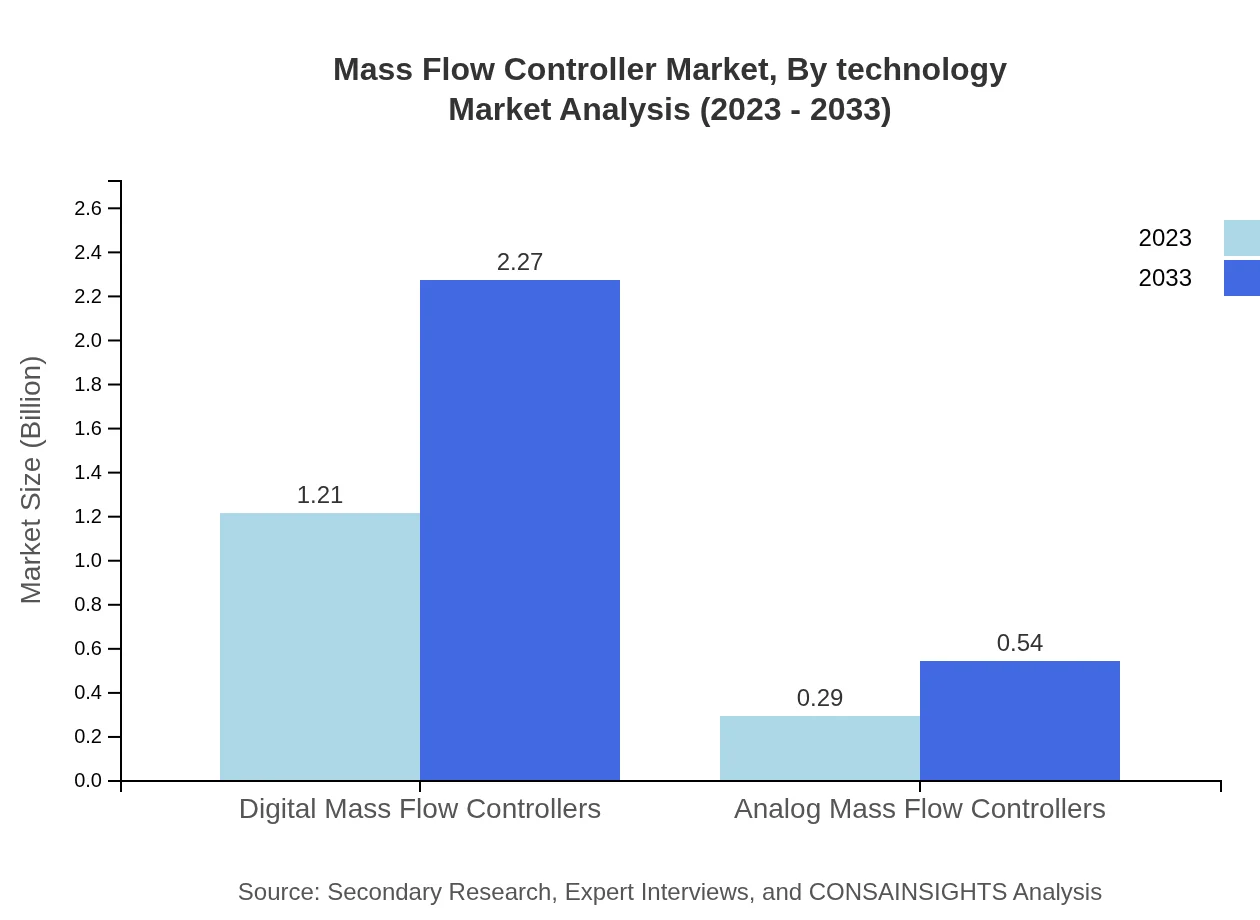

Mass Flow Controller Market Analysis By Technology

Digital Mass Flow Controllers dominate with a market size of $1.21 billion in 2023, projected to grow significantly to $2.27 billion by 2033, commanding an 80.93% share. Analog Mass Flow Controllers are anticipated to grow from $0.29 billion to $0.54 billion, maintaining a 19.07% share, as industries transition more toward digital solutions for improved monitoring and control.

Mass Flow Controller Market Analysis By Sales Channel

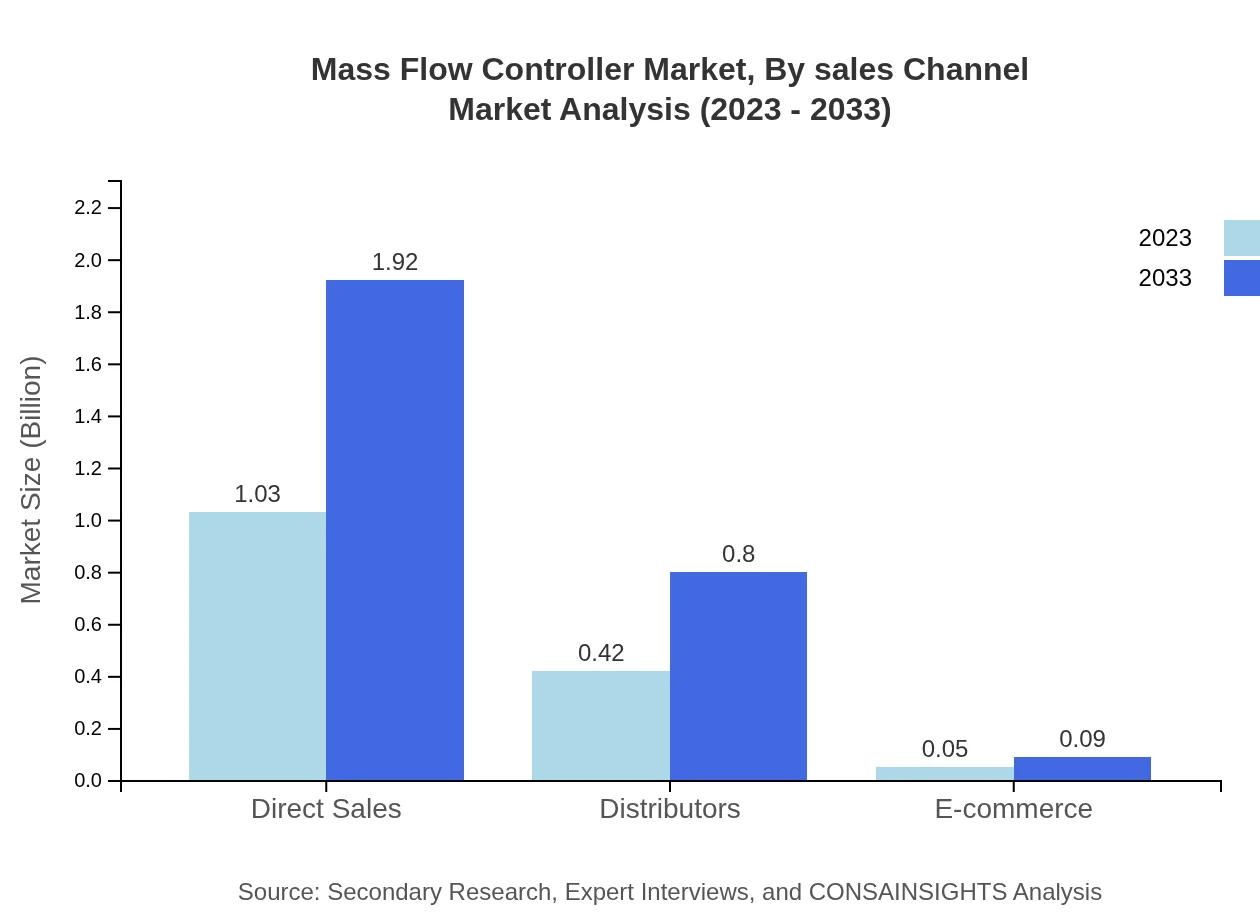

Direct Sales remain the leading sales channel with a size of $1.03 billion in 2023, growing to $1.92 billion by 2033, maintaining a 68.48% share. Distributors and E-commerce represent smaller channels at $0.42 billion and $0.05 billion respectively in 2023, with projections to grow to $0.80 billion and $0.09 billion by 2033, reflecting evolving purchasing behaviors in the market.

Mass Flow Controller Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Mass Flow Controller Industry

Brooks Instrument:

Brooks Instrument is a leader in the design and delivery of precision fluid measurement and control solutions, recognized for its innovative technologies in MFCs and strong customer focus.Emerson Electric Co.:

Emerson Electric Co. specializes in automation solutions including MFCs, leveraging advanced technology and extensive industry expertise to deliver reliable and efficient products.Omega Engineering Ltd.:

Omega Engineering offers a wide range of MFC solutions that cater to different industries, known for its commitment to quality and robust engineering.Horiba Ltd.:

Horiba is renowned for its high-quality measurement and control equipment in the Mass Flow Controller arena, serving the automotive, environmental and semiconductor markets.We're grateful to work with incredible clients.

FAQs

What is the market size of Mass Flow Controllers?

The global mass flow controller market is valued at approximately $1.5 billion in 2023, with a projected CAGR of 6.3% anticipated throughout the forecast period.

What are the key market players or companies in the Mass Flow Controllers industry?

Key players in the mass flow controllers industry include Brooks Instrument, Bronkhorst High-Tech, and Hitachi High-Technologies. These companies are pivotal in technological advancements and market expansion.

What are the primary factors driving the growth in the Mass Flow Controllers industry?

Key drivers for the mass flow controllers market include the rising demand in biotechnology, semiconductor manufacturing, and increased automation in industrial applications enhancing precision in fluid measurement.

Which region is the fastest Growing in the Mass Flow Controller market?

The Asia Pacific region shows the fastest growth rate, expected to increase from $0.28 billion in 2023 to $0.52 billion by 2033, mainly driven by industrialization and technological advancements.

Does ConsaInsights provide customized market report data for the Mass Flow Controllers industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs, providing in-depth insights and analytics to fit unique business requirements.

What deliverables can I expect from this Mass Flow Controllers market research project?

Deliverables include detailed market analysis reports, segment insights, regional forecasts, competitive landscape assessments, and customization options for specific strategic needs.

What are the market trends of Mass Flow Controllers?

Current trends indicate a shift towards digital mass flow controllers, integration of IoT technology, and increased adoption across various sectors like semiconductor and healthcare.