Mass Flow Sensor Market Report

Published Date: 31 January 2026 | Report Code: mass-flow-sensor

Mass Flow Sensor Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Mass Flow Sensor market, covering current trends, industry insights, regional performance, and forecasts from 2023 to 2033. It examines market size, growth rates, technology advancements, and key players shaping the industry.

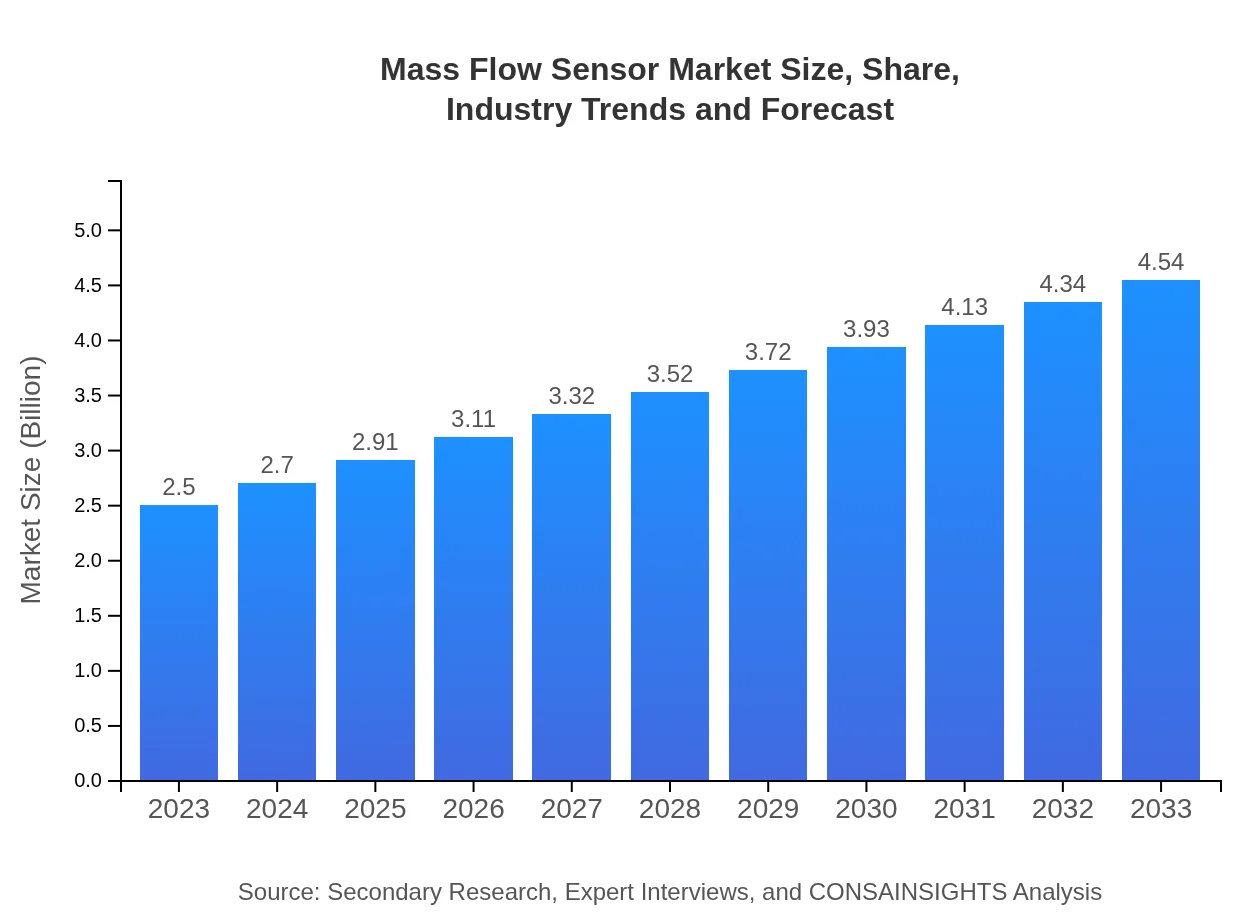

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 6% |

| 2033 Market Size | $4.54 Billion |

| Top Companies | Emerson Electric Co., Siemens AG, Endress+Hauser, Honeywell International Inc. |

| Last Modified Date | 31 January 2026 |

Mass Flow Sensor Market Overview

Customize Mass Flow Sensor Market Report market research report

- ✔ Get in-depth analysis of Mass Flow Sensor market size, growth, and forecasts.

- ✔ Understand Mass Flow Sensor's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Mass Flow Sensor

What is the Market Size & CAGR of Mass Flow Sensor market in 2023?

Mass Flow Sensor Industry Analysis

Mass Flow Sensor Market Segmentation and Scope

Tell us your focus area and get a customized research report.

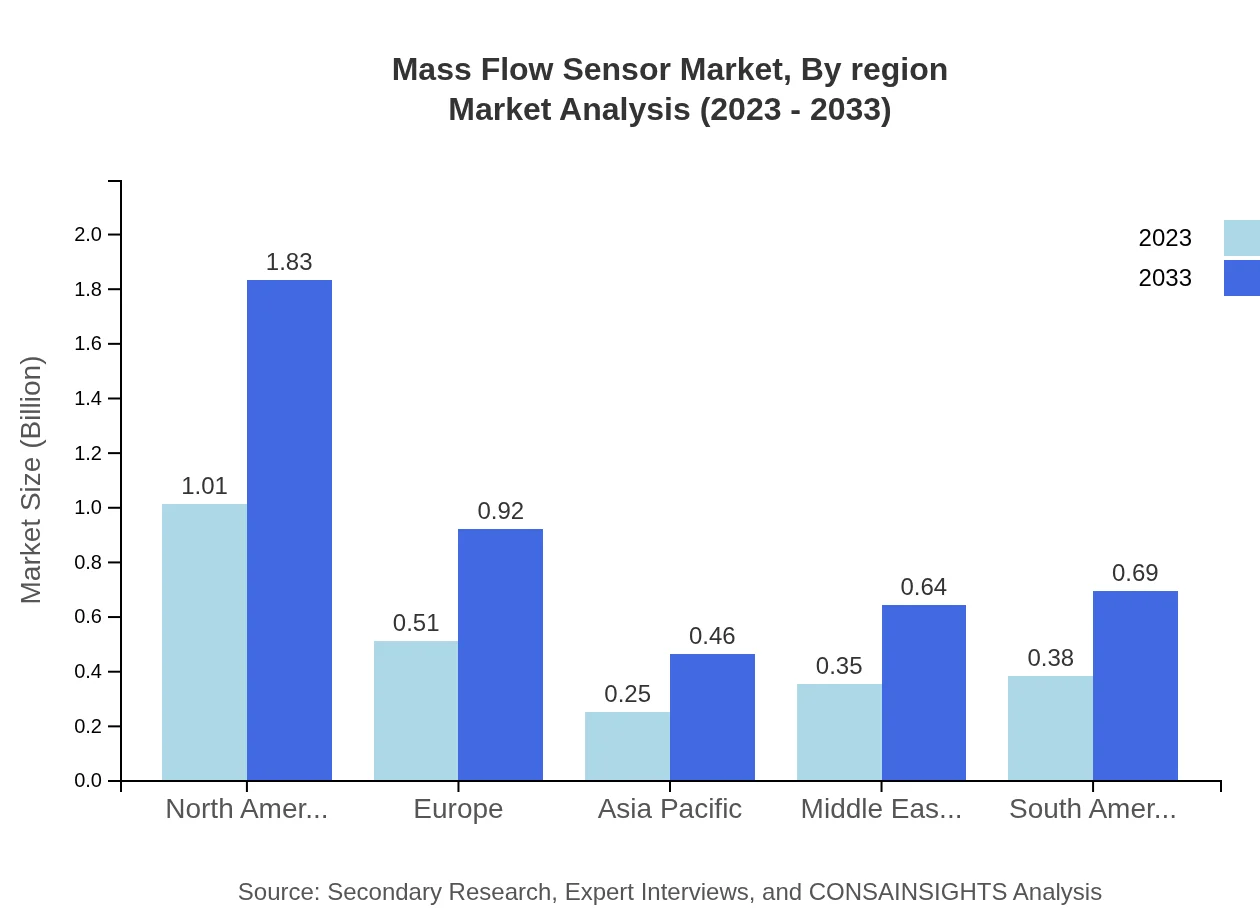

Mass Flow Sensor Market Analysis Report by Region

Europe Mass Flow Sensor Market Report:

Europe’s Mass Flow Sensor market is anticipated to grow from $0.79 billion in 2023 to $1.44 billion by 2033. The increasing focus on energy efficiency and strict environmental regulations mandate the use of sophisticated flow measurement devices, contributing to market expansion across various industries.Asia Pacific Mass Flow Sensor Market Report:

In 2023, the Mass Flow Sensor market in the Asia Pacific region is valued at approximately $0.48 billion, with projections indicating growth to $0.87 billion by 2033. The region's rapid industrialization, particularly in manufacturing and energy sectors, significantly enhances the demand for sensors in applications such as environmental monitoring and process control.North America Mass Flow Sensor Market Report:

In North America, the Mass Flow Sensor market is projected to expand from $0.85 billion in 2023 to $1.54 billion by 2033. The U.S. and Canada lead with substantial investments in automation and process control within oil and gas, healthcare, and automotive sectors, driving further adoption of advanced flow measurement solutions.South America Mass Flow Sensor Market Report:

The South American Mass Flow Sensor market, valued at $0.13 billion in 2023, is expected to grow to $0.24 billion by 2033. Increased investment in mining and oil extraction activities in the region fuels market growth, alongside the rising demand for precise flow measurement technologies.Middle East & Africa Mass Flow Sensor Market Report:

In the Middle East and Africa, the Mass Flow Sensor market is expected to grow from $0.25 billion in 2023 to $0.45 billion by 2033. The growth stems from the region's developments in oil and gas sectors, combined with the rising need for advanced monitoring systems to optimize production processes.Tell us your focus area and get a customized research report.

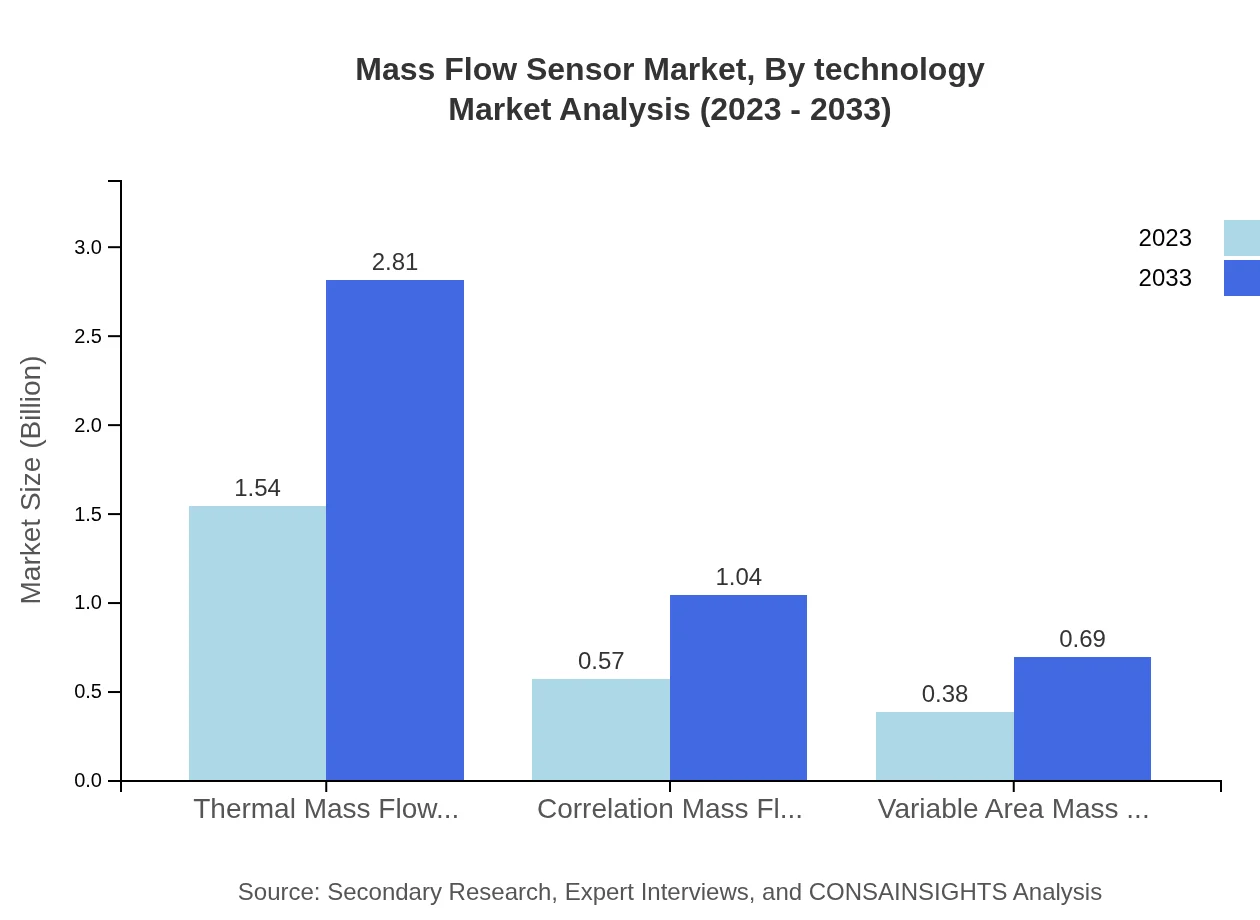

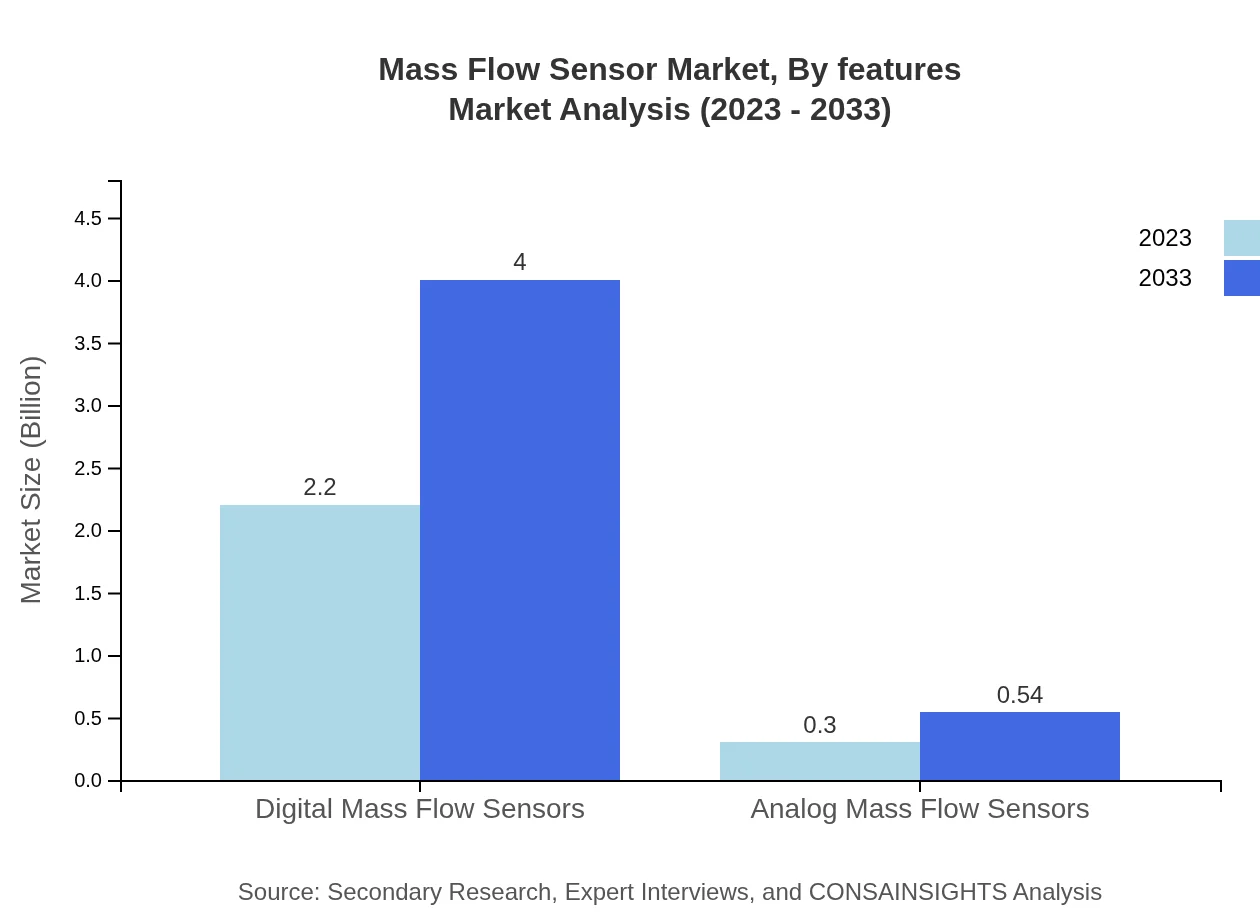

Mass Flow Sensor Market Analysis By Technology

The Mass Flow Sensor market by technology is dominated by Digital Mass Flow Sensors, accounting for approximately 88% of the market share in 2023, growing steadily to 88% by 2033. Other segments, such as Thermal Mass Flow Sensors and Correlation Mass Flow Sensors, also play vital roles, comprising substantial market shares contributing to overall industry growth. This diversification in technology enables broader application reach across various industries, ensuring robust performance and operational efficiency.

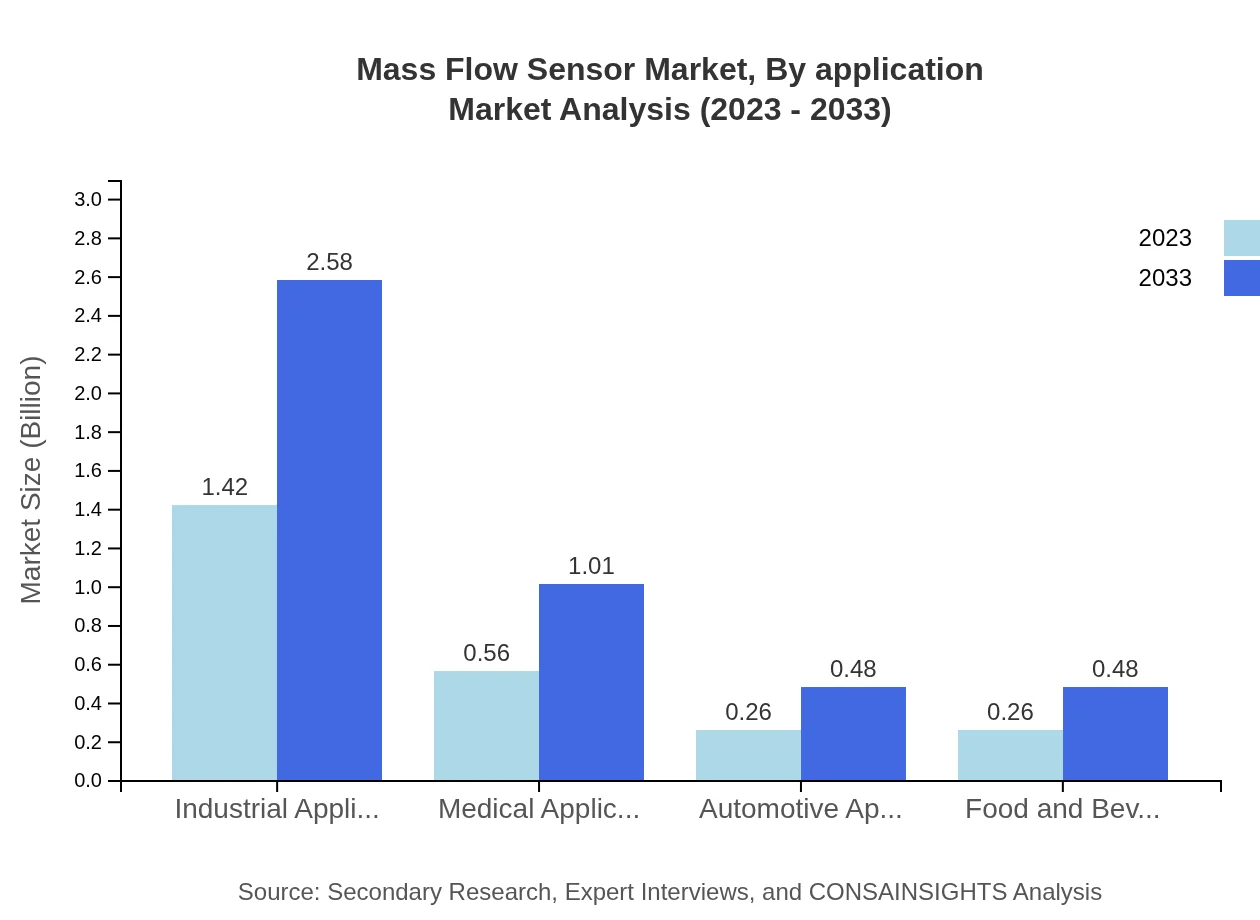

Mass Flow Sensor Market Analysis By Application

The applications of Mass Flow Sensors include sectors such as oil and gas, chemical processing, and industrial applications, accounting for significant market shares. The oil and gas segment alone earned a market share of 61.78% in 2023. The growing emphasis on precision and efficiency in these industries fundamentally drives demand for reliable measurement solutions, highlighting the critical role of flow sensors in ensuring operational integrity.

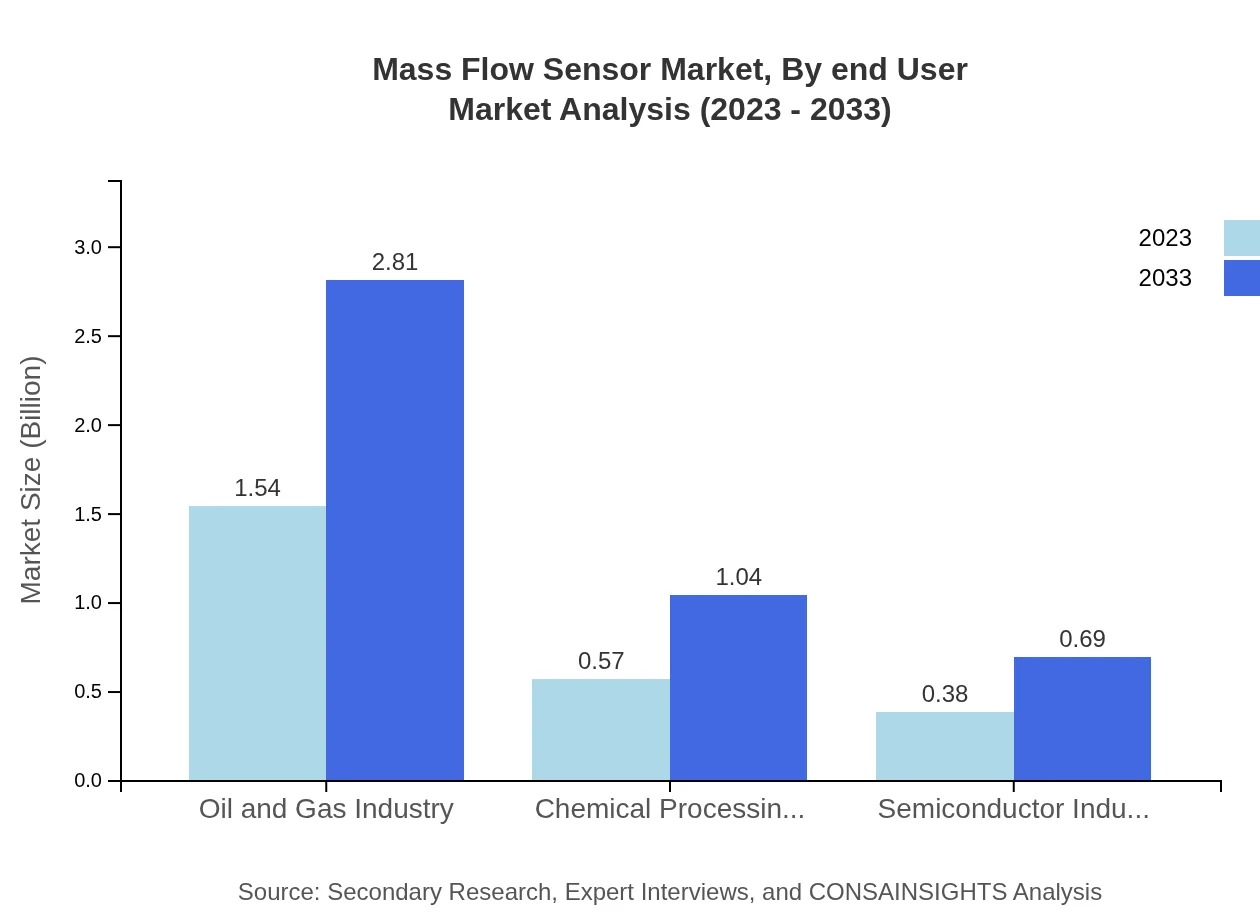

Mass Flow Sensor Market Analysis By End User

Key end-user industries include oil and gas, healthcare, automotive, and food and beverage sectors. The industrial application segment commands a major share, at 56.71% in 2023, indicative of ongoing advancements and requirements within manufacturing processes. These end-users increasingly rely on high-performance technologies to refine operations, maintain compliance, and enhance safety standards.

Mass Flow Sensor Market Analysis By Region

Regional analysis highlights the substantial growth opportunities in North America and Europe, where technological advancements and regulatory frameworks boost the Mass Flow Sensor adoption. Asia Pacific's rapid industrialization offers new avenues while South America and the Middle East present unique developments in resource extraction and processing that contribute to the overall market dynamics.

Mass Flow Sensor Market Analysis By Features

Features such as accuracy, reliability, and advanced connectivity significantly impact the selection of mass flow sensors. Innovations in sensor design, including thermal and digital technologies, enhance measurement accuracy and introduce new functionalities, such as real-time data monitoring. These advancements not only improve operational efficiency but also cater to evolving customer requirements across various industries.

Mass Flow Sensor Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Mass Flow Sensor Industry

Emerson Electric Co.:

Emerson is a global leader in automation solutions, providing a wide range of mass flow sensors known for their reliability and accuracy, and catering to industries such as oil, gas, and chemical processing.Siemens AG:

Siemens offers advanced mass flow measurement technologies, focusing on digital solutions that enhance manufacturing processes and environmental monitoring across diverse sectors.Endress+Hauser:

Endress+Hauser specializes in industrial process automation and offers advanced flow measurement solutions, playing a critical role in global mass flow sensor developments.Honeywell International Inc.:

Honeywell is known for its comprehensive range of process instrumentation, including mass flow sensors, impacting various industries with innovative technological advancements.We're grateful to work with incredible clients.

FAQs

What is the market size of mass Flow Sensor?

The global mass flow sensor market is valued at approximately $2.5 billion in 2023, projected to grow at a CAGR of 6%, leading to substantial growth by 2033.

What are the key market players or companies in this mass Flow Sensor industry?

Key players in the mass flow sensor market include companies like Bronkhorst, Emerson Electric, Endress+Hauser, Siemens, and Honeywell, all of which contribute significantly to market innovation and segment growth.

What are the primary factors driving the growth in the mass Flow Sensor industry?

Growth factors include rising demand across various sectors such as oil and gas, increasing automation in industrial processes, and technological advancements enhancing sensor performance and accuracy.

Which region is the fastest Growing in the mass Flow Sensor?

Among the regions analyzed, North America is forecasted to showcase the fastest growth in the mass flow sensor market, expanding from $0.85 billion in 2023 to $1.54 billion by 2033.

Does ConsaInsights provide customized market report data for the mass Flow Sensor industry?

Yes, ConsaInsights offers customized market reports tailored to specific needs, allowing clients to gain in-depth market analysis, forecasts, and trends specific to the mass flow sensor industry.

What deliverables can I expect from this mass Flow Sensor market research project?

Deliverables include comprehensive market analysis reports, trend forecasting, competitive landscape evaluations, and insights into regional and segment-specific data for the mass flow sensor market.

What are the market trends of mass Flow Sensor?

Key trends in the mass flow sensor market include increasing adoption of digital sensors, expansion in industrial applications, and the rising influence of IoT technologies enhancing sensor connectivity.