Mechanical Explosion Proof Equipment Market Report

Published Date: 22 January 2026 | Report Code: mechanical-explosion-proof-equipment

Mechanical Explosion Proof Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Mechanical Explosion Proof Equipment market, highlighting key insights, market trends, and growth projections from 2023 to 2033. It includes data on market size, segmentation by technology and application, regional analysis, and forecasts for the industry's future.

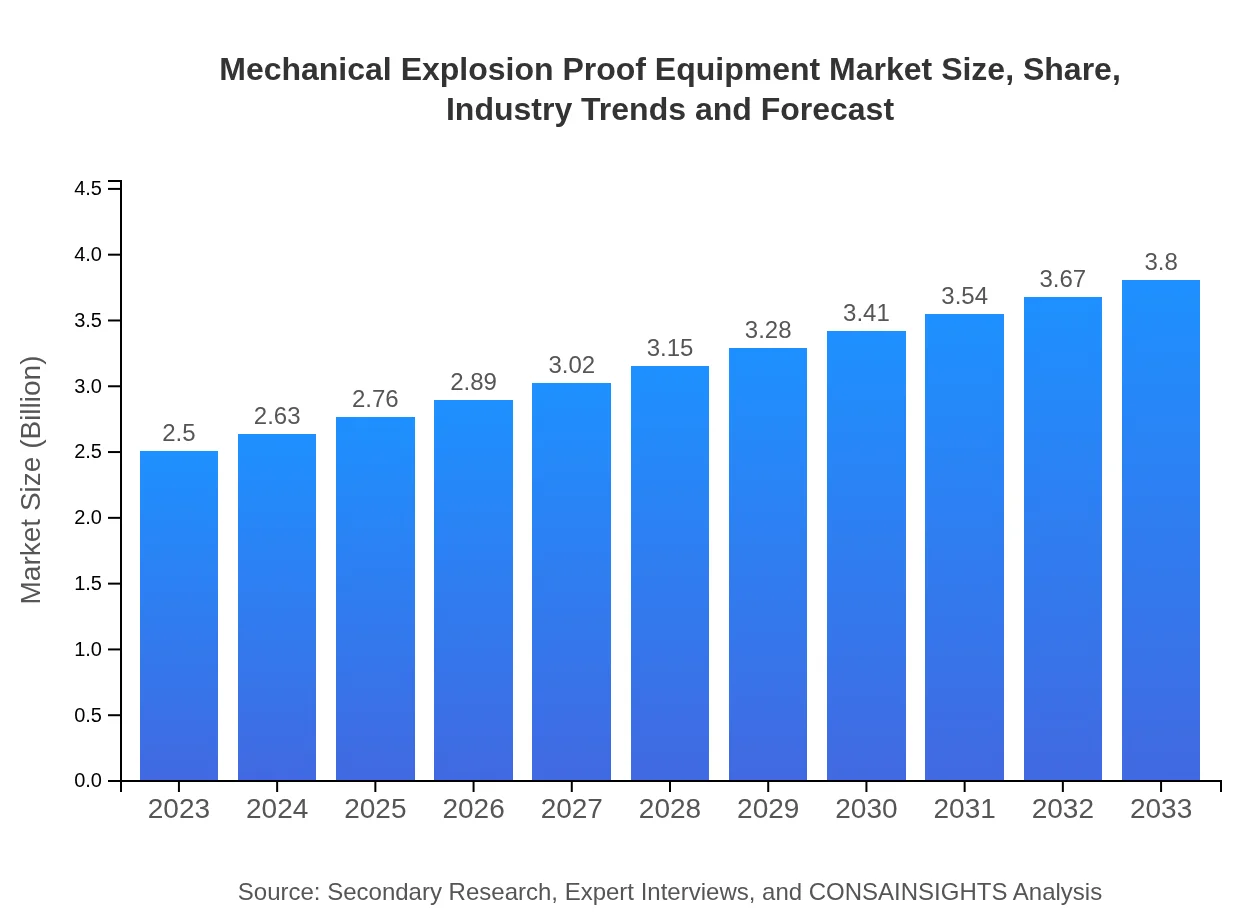

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 4.2% |

| 2033 Market Size | $3.80 Billion |

| Top Companies | Eaton Corporation, Schneider Electric, Honeywell International Inc., Siemens AG, Adobe Systems |

| Last Modified Date | 22 January 2026 |

Mechanical Explosion Proof Equipment Market Overview

Customize Mechanical Explosion Proof Equipment Market Report market research report

- ✔ Get in-depth analysis of Mechanical Explosion Proof Equipment market size, growth, and forecasts.

- ✔ Understand Mechanical Explosion Proof Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Mechanical Explosion Proof Equipment

What is the Market Size & CAGR of Mechanical Explosion Proof Equipment market in 2023 and 2033?

Mechanical Explosion Proof Equipment Industry Analysis

Mechanical Explosion Proof Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Mechanical Explosion Proof Equipment Market Analysis Report by Region

Europe Mechanical Explosion Proof Equipment Market Report:

In Europe, the market size is estimated at $0.74 billion in 2023, projected to expand to $1.12 billion by 2033, reflecting stronger focus on safety standards and technological advancements.Asia Pacific Mechanical Explosion Proof Equipment Market Report:

In the Asia-Pacific region, the Mechanical Explosion Proof Equipment market is valued at $0.46 billion in 2023, projected to increase to $0.70 billion by 2033. This growth is fueled by expanding industrial activities and increasing investments in infrastructure.North America Mechanical Explosion Proof Equipment Market Report:

North America is a significant market for Mechanical Explosion Proof Equipment, with a projected value of $0.93 billion in 2023 and an expected increase to $1.42 billion by 2033, driven by stringent safety regulations and a mature industrial base.South America Mechanical Explosion Proof Equipment Market Report:

South America holds a market size of $0.16 billion in 2023, expected to grow to $0.24 billion by 2033. The region's growth is driven by its mining and oil & gas sectors that demand explosion-proof solutions.Middle East & Africa Mechanical Explosion Proof Equipment Market Report:

The Middle East and Africa exhibit a niche market with values of $0.21 billion in 2023 and increasing to $0.32 billion by 2033, primarily driven by the oil & gas industry and rising safety concerns.Tell us your focus area and get a customized research report.

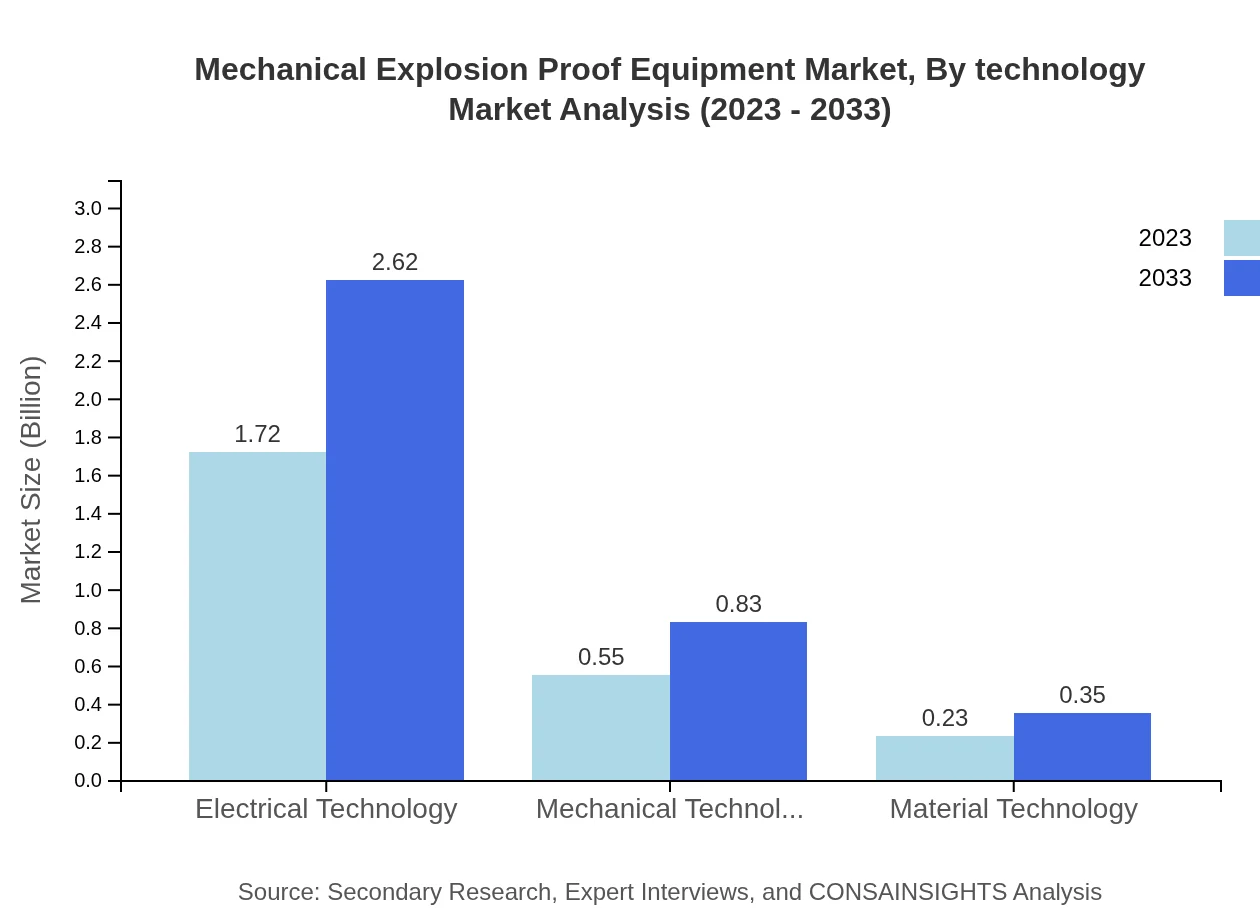

Mechanical Explosion Proof Equipment Market Analysis By Technology

The market consists of various technologies, including electrical, mechanical, and material technologies. The electrical technology segment dominates the market with a size of $1.72 billion in 2023, growing to $2.62 billion by 2033, holding a market share of 68.9%. Mechanical technology also plays a significant role, with a market size of $0.55 billion in 2023, reaching $0.83 billion by 2033, accounting for 21.88% of the market. Material technology, while smaller, contributes with a size of $0.23 billion in 2023 and an expected increase to $0.35 billion by 2033, comprising 9.22% share.

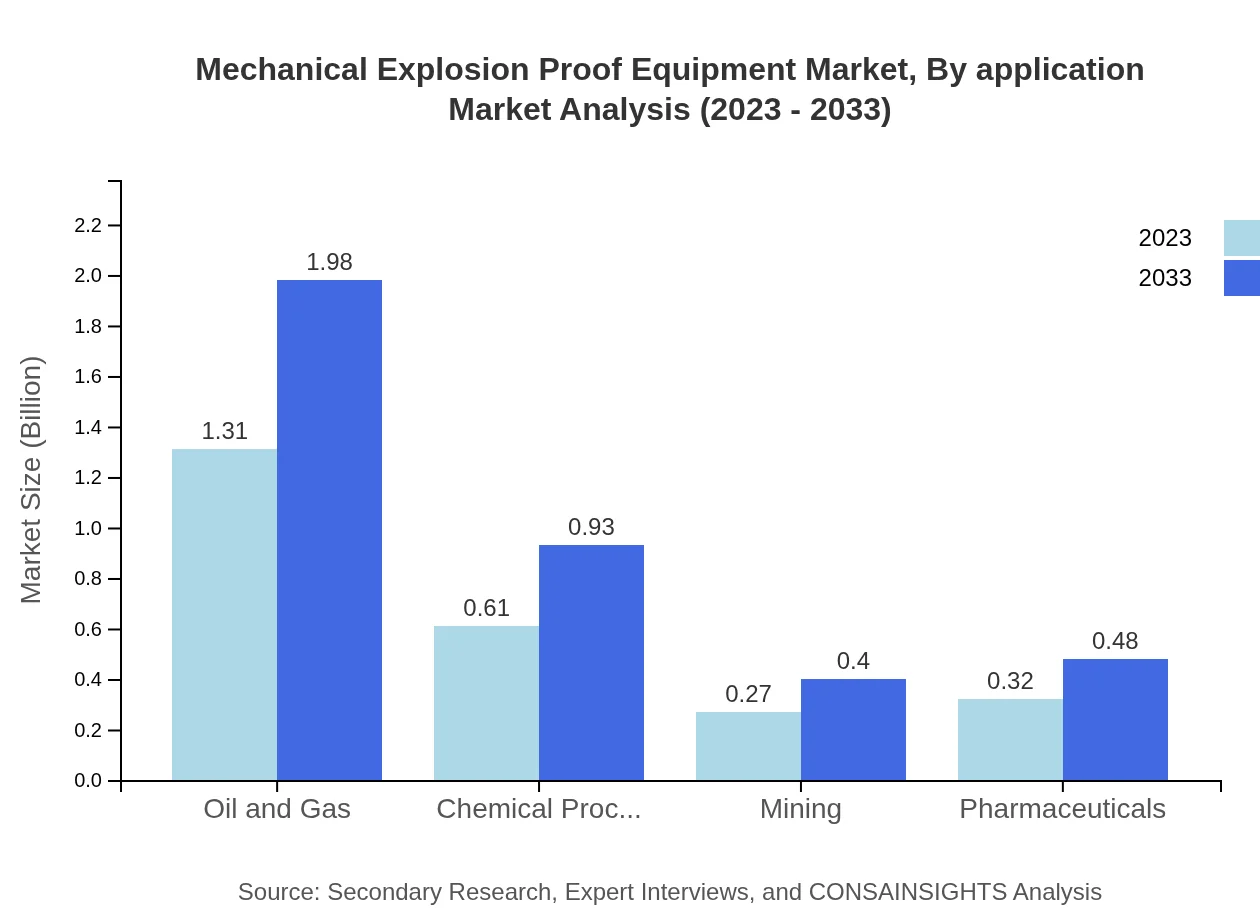

Mechanical Explosion Proof Equipment Market Analysis By Application

Key applications include oil and gas (size: $1.31 billion in 2023 to $1.98 billion in 2033, 52.21%), chemical processing ($0.61 billion to $0.93 billion, 24.44%), mining ($0.27 billion to $0.40 billion, 10.65%), pharmaceuticals ($0.32 billion to $0.48 billion, 12.7%). Each application segment highlights the critical need for safety in hazardous working conditions dictated by industry requirements.

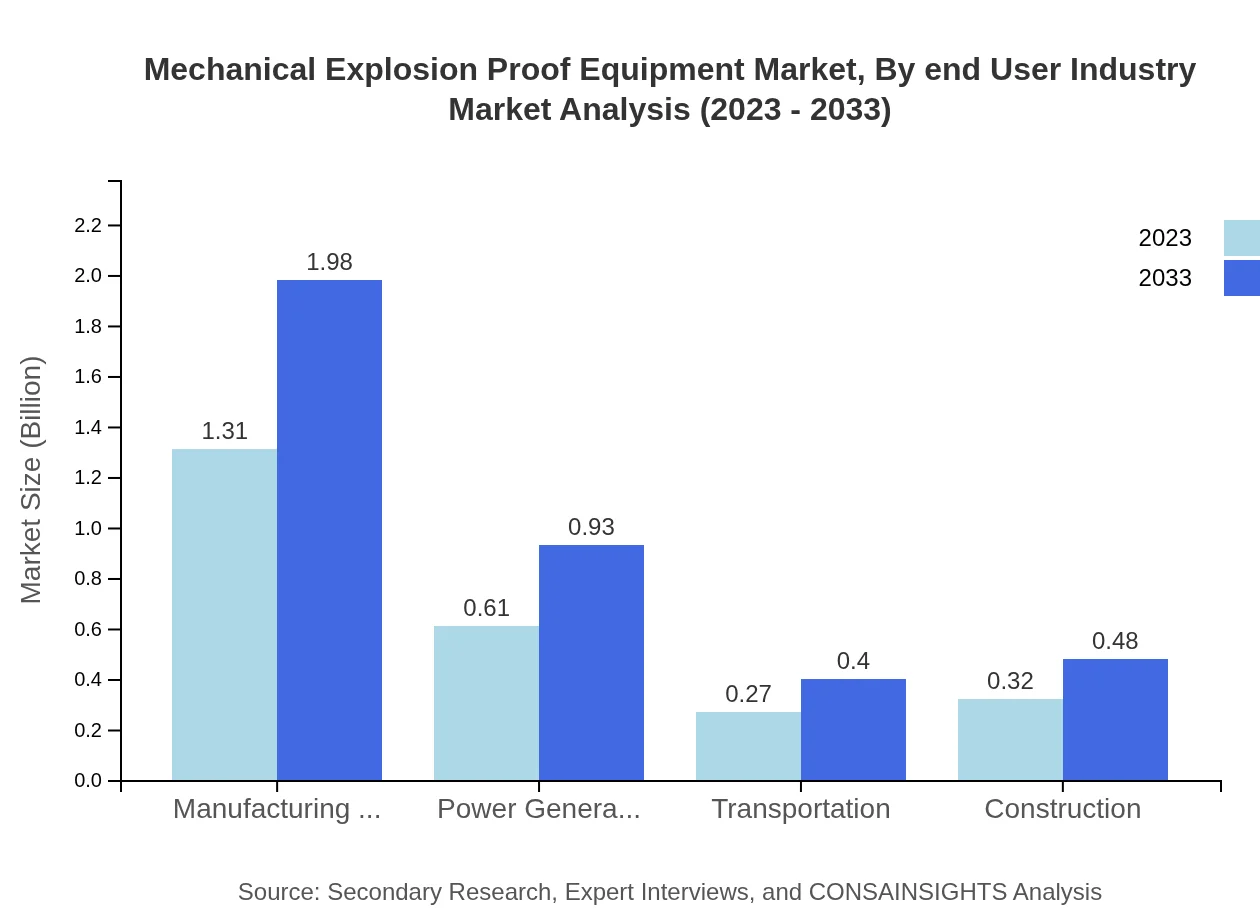

Mechanical Explosion Proof Equipment Market Analysis By End User Industry

The end-user industries are varied, with manufacturing industries leading the market (size: $1.31 billion to $1.98 billion, 52.21%), followed by power generation ($0.61 billion to $0.93 billion, 24.44%) and transportation ($0.27 billion to $0.40 billion, 10.65%). These sectors showcase a consistent demand for reliable equipment that can operate safely in hazardous environments.

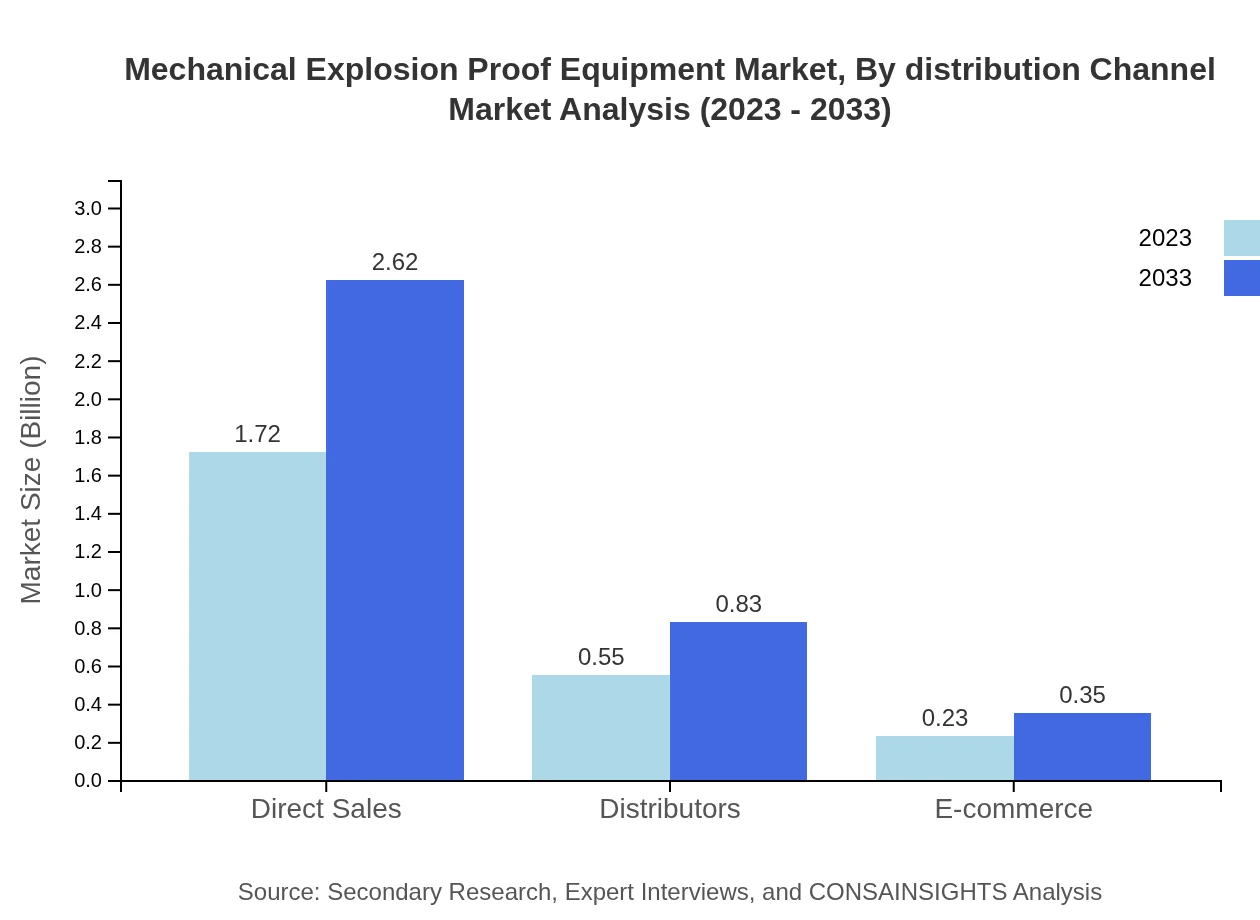

Mechanical Explosion Proof Equipment Market Analysis By Distribution Channel

Distribution channels encompass direct sales ($1.72 billion to $2.62 billion, 68.9%), distributors ($0.55 billion to $0.83 billion, 21.88%), and e-commerce ($0.23 billion to $0.35 billion, 9.22%). Direct sales remain prevalent due to the specialized nature of the equipment and the need for direct engagement with industrial clients.

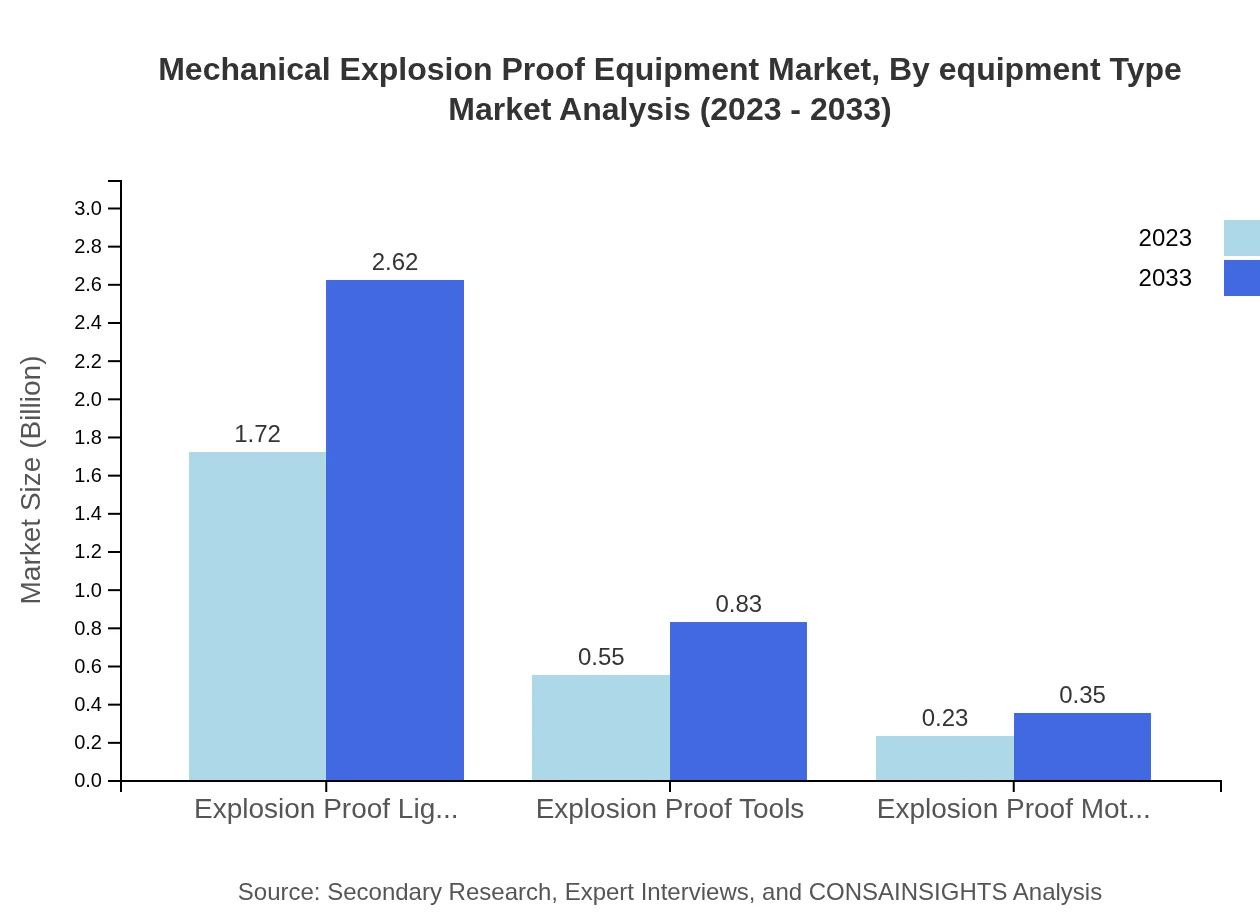

Mechanical Explosion Proof Equipment Market Analysis By Equipment Type

Major equipment types include explosion-proof lighting, tools ($0.55 billion to $0.83 billion, 21.88%), and motors ($0.23 billion to $0.35 billion, 9.22%). Lighting technology continues to lead with its significant market share driven by a higher volume of installations across various sectors.

Mechanical Explosion Proof Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Mechanical Explosion Proof Equipment Industry

Eaton Corporation:

A leading global provider of electrical components and solutions designing a wide range of explosion-proof equipment used in industrial settings.Schneider Electric:

Known for its commitment to safety and innovation, Schneider Electric offers numerous explosion-proof solutions for various industries.Honeywell International Inc.:

A major player in providing advanced technology solutions, including explosion-proof equipment tailored for hazardous environments.Siemens AG:

Siemens delivers comprehensive solutions, including top-tier explosion-proof equipment, supported by years of industry experience.Adobe Systems:

Although not traditionally associated with heavy industry, Adobe contributes through advanced software solutions for design and safety assessment in explosive environments.We're grateful to work with incredible clients.

FAQs

What is the market size of mechanical Explosion Proof Equipment?

The market size of mechanical explosion-proof equipment is currently estimated at $2.5 billion in 2023, with a compound annual growth rate (CAGR) of 4.2% projected for the next decade, indicating a steady increase in demand.

What are the key market players or companies in this mechanical Explosion Proof Equipment industry?

Key players in the mechanical explosion-proof equipment market include established companies and innovators, focusing on safety, efficiency, and technological advancements in their products to meet stringent industry standards.

What are the primary factors driving the growth in the mechanical Explosion Proof Equipment industry?

The growth in the mechanical explosion-proof equipment industry is primarily driven by increasing safety regulations, growth in industries such as oil and gas, chemical processing, and the rising demand for explosion-resistant technologies in hazardous environments.

Which region is the fastest Growing in the mechanical Explosion Proof Equipment?

The fastest-growing region in the mechanical explosion-proof equipment market is projected to be North America, with market growth from $0.93 billion in 2023 to $1.42 billion by 2033, reflecting a robust industrial sector.

Does ConsaInsights provide customized market report data for the mechanical Explosion Proof Equipment industry?

Yes, ConsaInsights offers customized market report data tailored to the mechanical explosion-proof equipment industry, allowing clients to obtain specific insights, analyses, and trends that align with their strategic needs.

What deliverables can I expect from this mechanical Explosion Proof Equipment market research project?

Expect comprehensive deliverables including detailed market analysis, growth forecasts, segmentation insights, competitive landscape assessments, and regional market evaluations, enabling strategic decision-making for stakeholders.

What are the market trends of mechanical Explosion Proof Equipment?

Current market trends for mechanical explosion-proof equipment include a shift towards advanced technologies, increased emphasis on durability and reliability, and a rise in automation across industries requiring compliant safety equipment.