Melt Blown Filter Cartridge Market Report

Published Date: 22 January 2026 | Report Code: melt-blown-filter-cartridge

Melt Blown Filter Cartridge Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Melt Blown Filter Cartridge market, including insights on market size, growth prospects, trends, and regional dynamics from 2023 to 2033. It offers critical information for stakeholders and decision-makers in the industry.

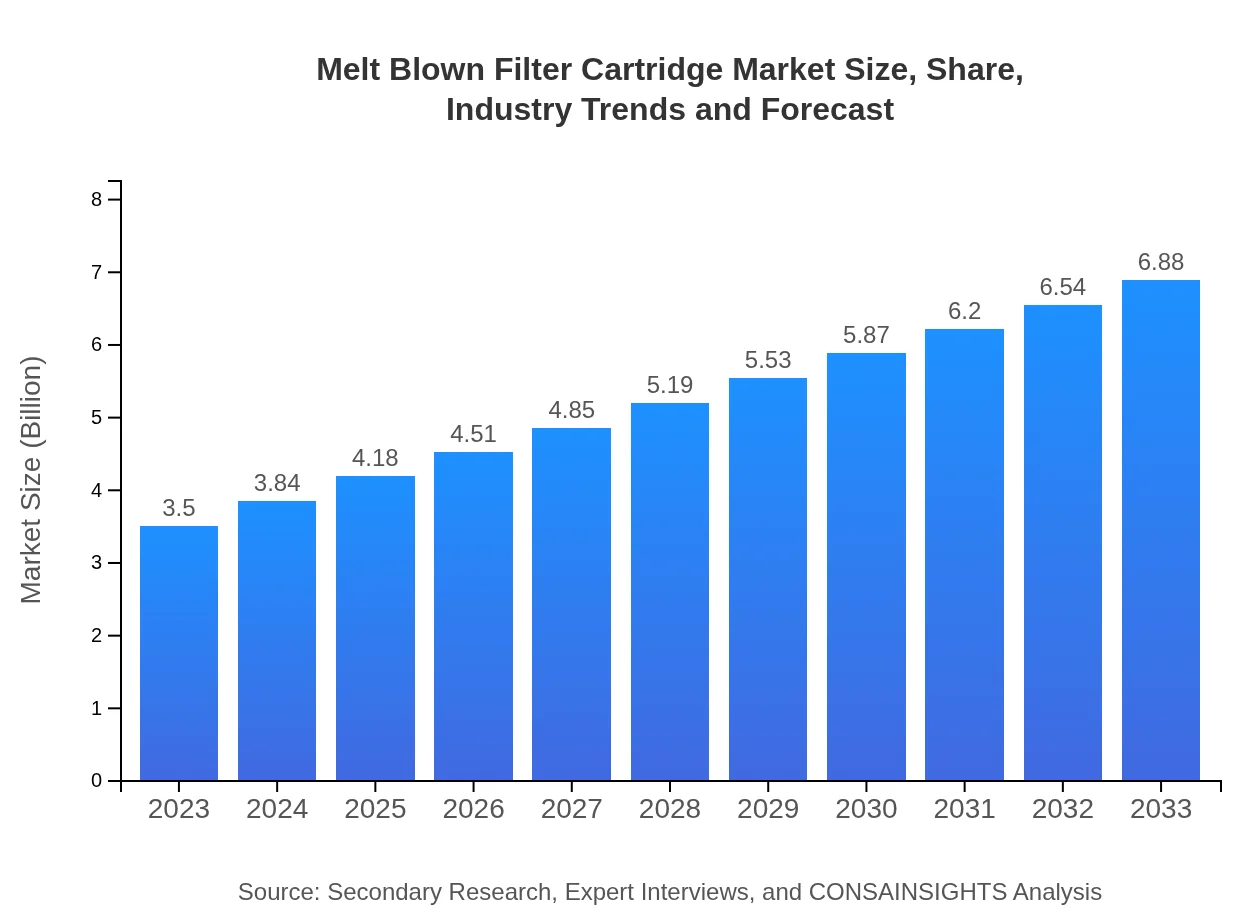

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $6.88 Billion |

| Top Companies | Parker Hannifin Corporation, 3M Company, Donaldson Company, Inc., Filtration Group Corporation |

| Last Modified Date | 22 January 2026 |

Melt Blown Filter Cartridge Market Overview

Customize Melt Blown Filter Cartridge Market Report market research report

- ✔ Get in-depth analysis of Melt Blown Filter Cartridge market size, growth, and forecasts.

- ✔ Understand Melt Blown Filter Cartridge's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Melt Blown Filter Cartridge

What is the Market Size & CAGR of Melt Blown Filter Cartridge market in 2023?

Melt Blown Filter Cartridge Industry Analysis

Melt Blown Filter Cartridge Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Melt Blown Filter Cartridge Market Analysis Report by Region

Europe Melt Blown Filter Cartridge Market Report:

The European market, valued at $1.17 billion in 2023, is projected to reach $2.30 billion by 2033. The region benefits from a strong regulatory framework emphasizing advanced filtration technologies to meet health standards, propelling market expansion.Asia Pacific Melt Blown Filter Cartridge Market Report:

In the Asia Pacific region, the market is valued at $0.67 billion in 2023 and is expected to grow to $1.31 billion by 2033. The surge in industrial activities and a rising focus on water quality improvement are driving this growth. Countries like China and India are seeing substantial investments in water treatment infrastructure.North America Melt Blown Filter Cartridge Market Report:

North America holds a significant share of the market, valued at $1.13 billion in 2023, with anticipated growth to $2.22 billion by 2033. This is attributed to stringent regulations and increasing investments in wastewater treatment technologies bolstered by various public health initiatives.South America Melt Blown Filter Cartridge Market Report:

The South American market is currently valued at $0.07 billion and projected to double to $0.14 billion by 2033. The demand is driven by the growing awareness of water purity and health standards, albeit at a slower pace compared to other regions.Middle East & Africa Melt Blown Filter Cartridge Market Report:

The Middle East and Africa are gearing up for substantial growth with a market size of $0.46 billion in 2023, expected to reach $0.91 billion by 2033. Governments in this region are aggressively initiating projects to bolster water purification efforts, significantly contributing to market growth.Tell us your focus area and get a customized research report.

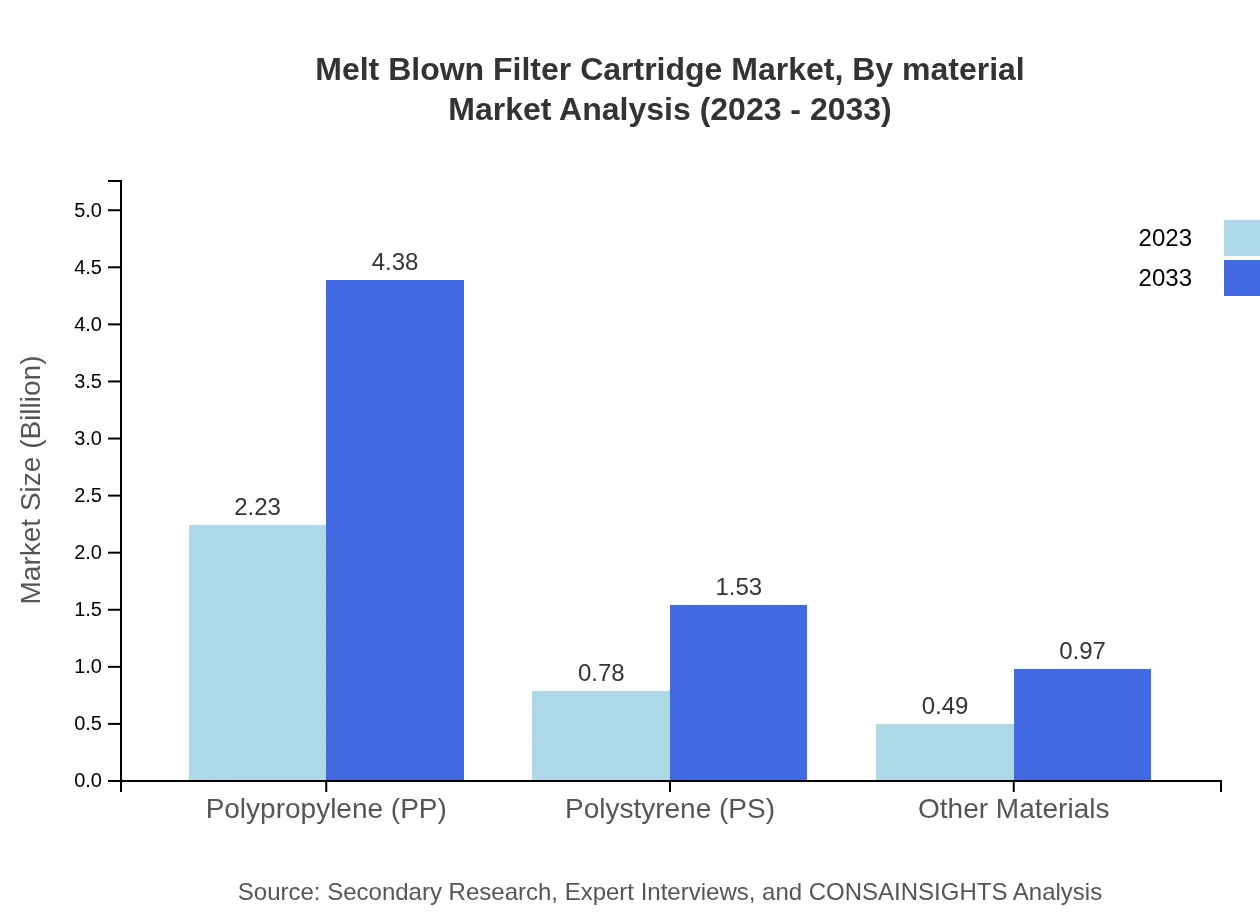

Melt Blown Filter Cartridge Market Analysis By Material

The predominant material in the Melt Blown Filter Cartridge market is polypropylene, making up a market size of $2.23 billion, expected to grow to $4.38 billion by 2033. Other materials like polystyrene and various formulations are showing incremental growth, catering to niche applications.

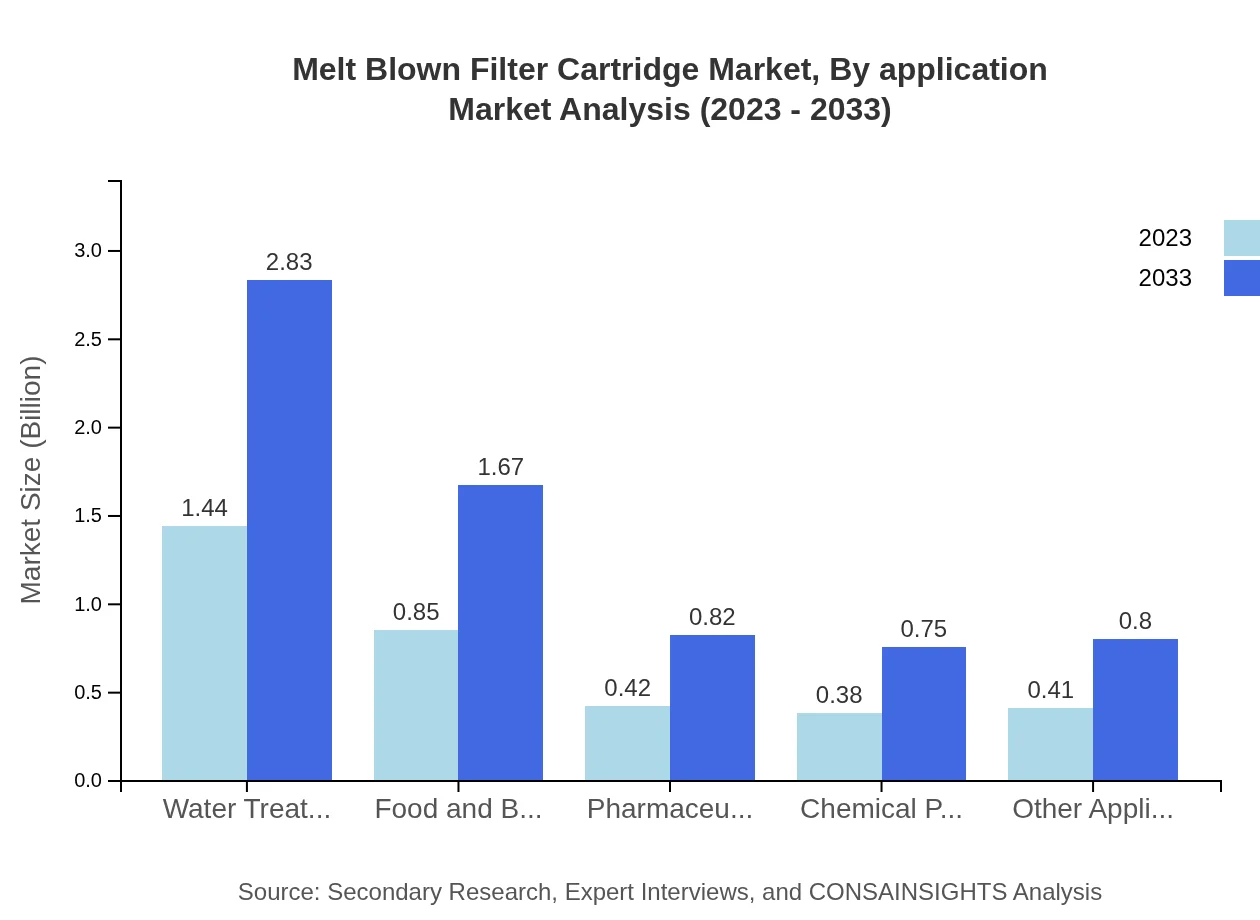

Melt Blown Filter Cartridge Market Analysis By Application

Key applications in the Melt Blown Filter Cartridge market include water treatment (dominating at $1.44 billion in 2023), food and beverage, pharmaceuticals, and chemical processing. The water treatment sector will grow significantly as sanitation standards tighten globally.

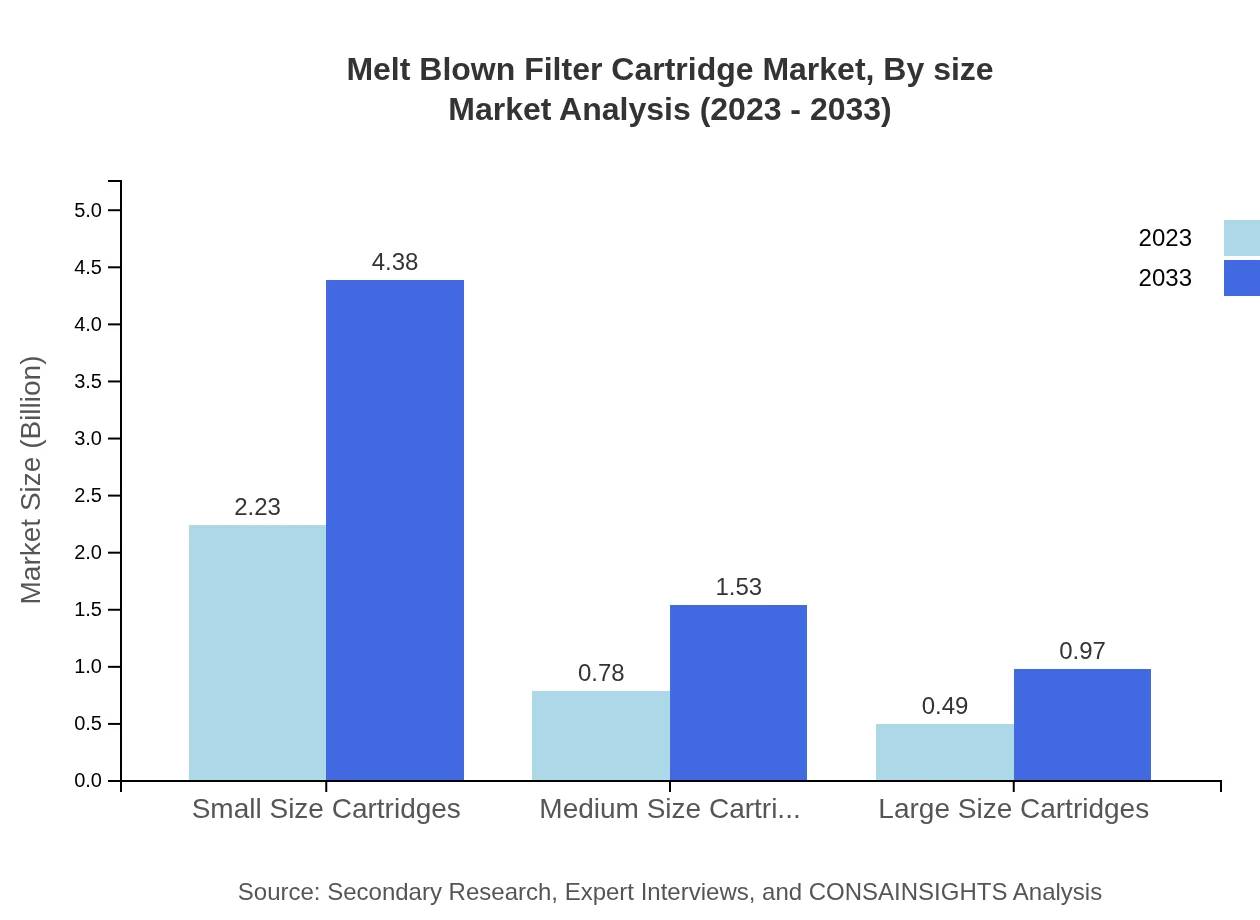

Melt Blown Filter Cartridge Market Analysis By Size

Market performance is notable in small-size cartridges with an expected $2.23 billion growing to $4.38 billion by 2033. Medium-size cartridges follow with growth predictions from $0.78 billion to $1.53 billion, while large-size cartridges are less prominent but critical for industrial applications.

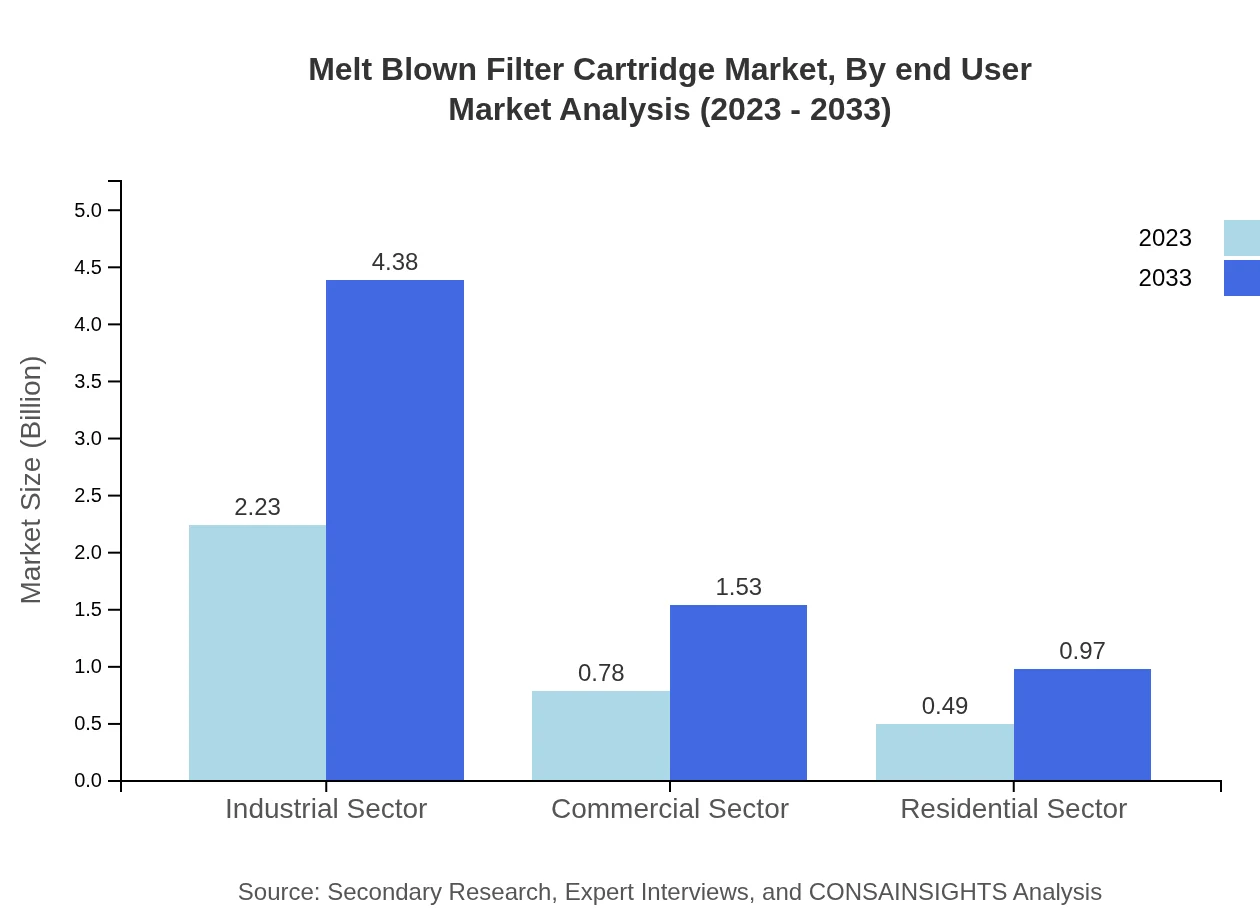

Melt Blown Filter Cartridge Market Analysis By End User

Industrial applications represent the largest end-user segment, with a size of $2.23 billion poised to reach $4.38 billion by 2033. The commercial sector's share is anticipated to grow steadily alongside residential uses focusing on water purification systems.

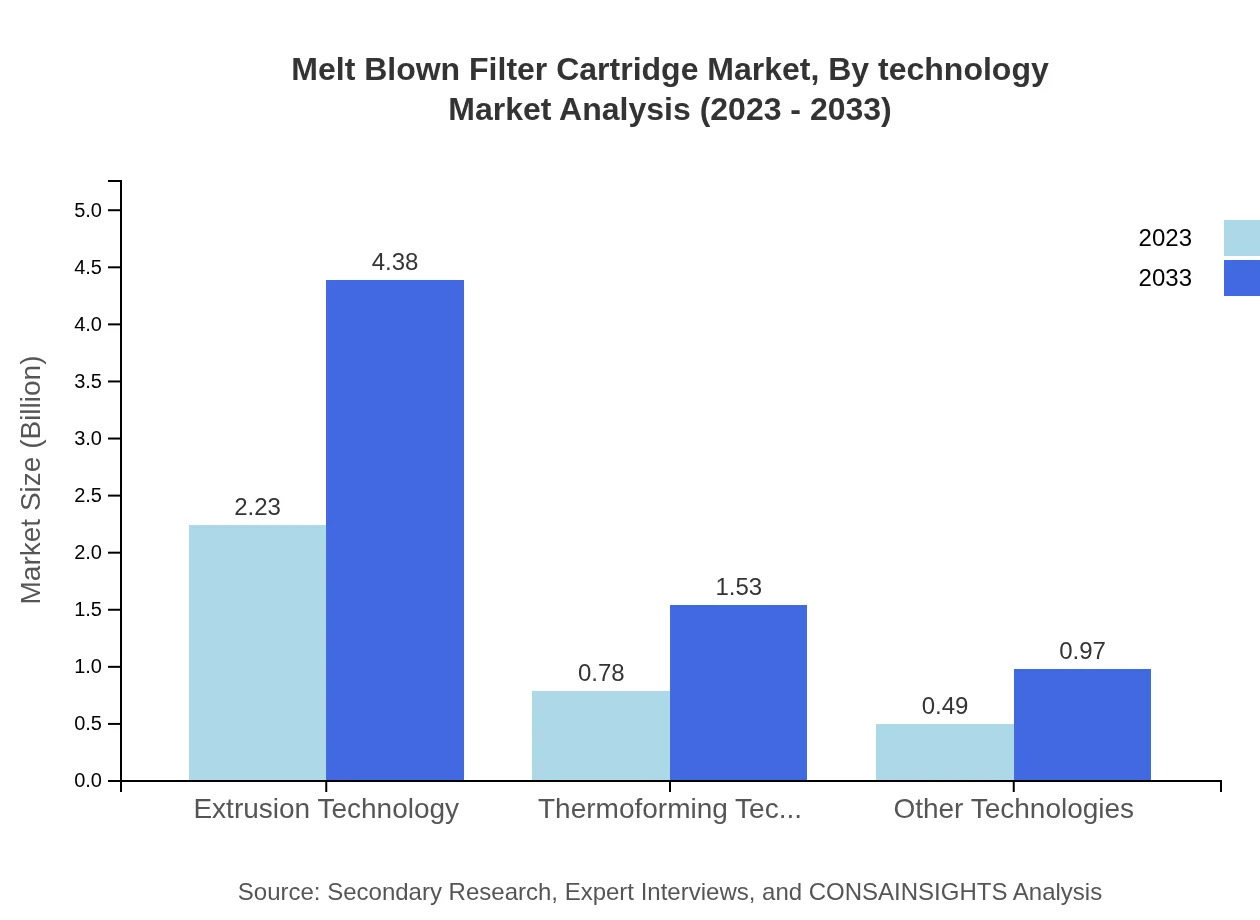

Melt Blown Filter Cartridge Market Analysis By Technology

Extrusion technology remains dominant in manufacturing melt blown filter cartridges, holding a market size of $2.23 billion with a growth trajectory towards $4.38 billion until 2033, while thermoforming technology contributes significantly with $0.78 billion to $1.53 billion in the same period.

Melt Blown Filter Cartridge Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Melt Blown Filter Cartridge Industry

Parker Hannifin Corporation:

A leading global provider of filtration solutions, Parker Hannifin designs and manufactures various melt blown filter products that enhance filtration efficiency across multiple sectors.3M Company:

Known for its innovative products, 3M is a key player in the melt blown filter cartridge market, offering advanced filtration technologies that meet stringent regulatory standards.Donaldson Company, Inc.:

Donaldson specializes in industrial filtration solutions, including high-performance melt blown filter cartridges designed for demanding applications in various industries.Filtration Group Corporation:

Filtration Group is focused on filtration products and services across multiple sectors, delivering reliable melt blown filter cartridges with innovative designs and advanced materials.We're grateful to work with incredible clients.

FAQs

What is the market size of melt Blown Filter Cartridge?

The melt-blown filter cartridge market is projected to reach approximately $3.5 billion by 2033, growing at a CAGR of 6.8%. This growth reflects the increased demand across various applications, especially in water treatment and industrial sectors.

What are the key market players or companies in this melt Blown Filter Cartridge industry?

Key players in the melt-blown filter cartridge market include major filtration companies that specialize in manufacturing innovative filtration solutions, particularly those focusing on environmental applications. These companies continuously invest in R&D to meet stringent quality standards.

What are the primary factors driving the growth in the melt Blown Filter Cartridge industry?

Growth is driven by rising environmental concerns, stringent regulations on water quality, and an increasing demand for efficient filtration systems in various sectors. The expansion of industries like pharmaceuticals and food processing also greatly influences market dynamics.

Which region is the fastest Growing in the melt Blown Filter Cartridge?

The fastest-growing region for melt-blown filter cartridges is Europe, expected to grow from $1.17 billion in 2023 to $2.3 billion by 2033. Asia Pacific also shows significant growth potential, with a forecasted increase from $0.67 billion to $1.31 billion.

Does ConsaInsights provide customized market report data for the melt Blown Filter Cartridge industry?

Yes, ConsaInsights specializes in providing customized market research reports, including tailored analyses of the melt-blown filter cartridge industry. Clients can expect insights aligned with specific strategic goals and market interests.

What deliverables can I expect from this melt Blown Filter Cartridge market research project?

From this market research project, you can expect comprehensive reports detailing market size, segmentation analysis, growth forecasts, competitive landscape, and tailored insights providing actionable strategies for market engagement.

What are the market trends of melt Blown Filter Cartridge?

Current market trends include an increasing adoption of eco-friendly materials, advancements in filtration technology, and growing applications in critical industries like water treatment and pharmaceuticals, driving innovation and market expansion.