Mems Pressure Sensors Market Report

Published Date: 31 January 2026 | Report Code: mems-pressure-sensors

Mems Pressure Sensors Market Size, Share, Industry Trends and Forecast to 2033

This report provides an extensive analysis of the MEMS pressure sensors market from 2023 to 2033, covering market dynamics, size, segmentation, regional insights, and trends that will shape the future of this industry.

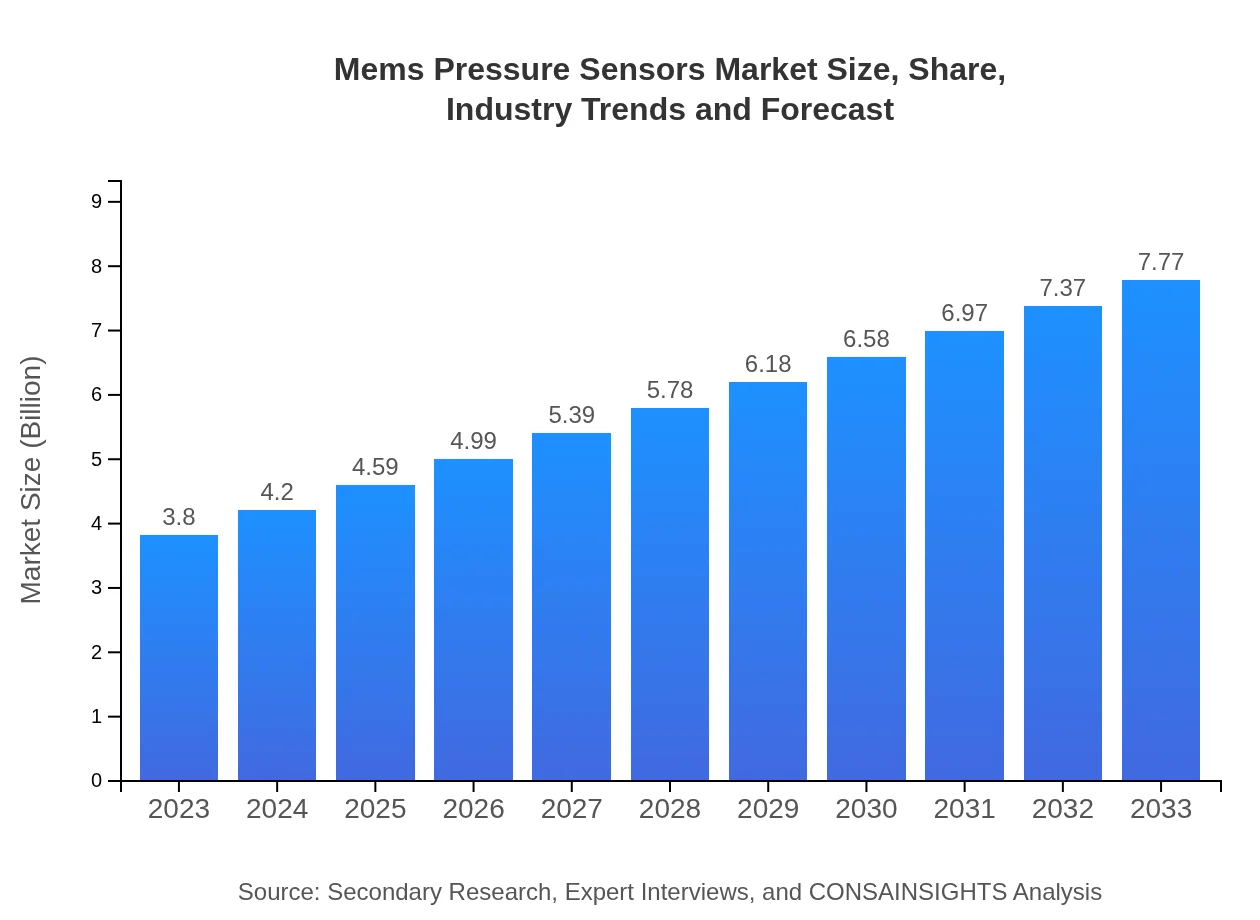

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.80 Billion |

| CAGR (2023-2033) | 7.2% |

| 2033 Market Size | $7.77 Billion |

| Top Companies | Honeywell International Inc., Bosch Sensortec, TE Connectivity, NXP Semiconductors, Murata Manufacturing Co. Ltd. |

| Last Modified Date | 31 January 2026 |

MEMS Pressure Sensors Market Overview

Customize Mems Pressure Sensors Market Report market research report

- ✔ Get in-depth analysis of Mems Pressure Sensors market size, growth, and forecasts.

- ✔ Understand Mems Pressure Sensors's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Mems Pressure Sensors

What is the Market Size & CAGR of MEMS Pressure Sensors market in 2023?

MEMS Pressure Sensors Industry Analysis

MEMS Pressure Sensors Market Segmentation and Scope

Tell us your focus area and get a customized research report.

MEMS Pressure Sensors Market Analysis Report by Region

Europe Mems Pressure Sensors Market Report:

The European market for MEMS pressure sensors is forecasted to grow from $1.03 billion in 2023 to $2.10 billion by 2033. This growth is underpinned by regulatory support for automotive technologies and a flourish of innovation in the healthcare sector.Asia Pacific Mems Pressure Sensors Market Report:

In the Asia Pacific region, the MEMS pressure sensors market is anticipated to grow from $0.77 billion in 2023 to $1.58 billion by 2033. This growth can be attributed to rising adoption in automotive and industrial applications, along with increasing investments in IoT technologies and smart sensors.North America Mems Pressure Sensors Market Report:

North America holds a significant share of the MEMS pressure sensors market, with a projected increase from $1.27 billion in 2023 to $2.60 billion in 2033. The growth is driven by technological advancements, a strong automotive sector, and increasing investments in medical devices, pushing demand for precision sensors.South America Mems Pressure Sensors Market Report:

The South American MEMS pressure sensors market is expected to grow from $0.36 billion in 2023 to $0.73 billion in 2033. Market growth in this region is fueled by increasing industrial activities and the adoption of modern technology in healthcare and automotive sectors.Middle East & Africa Mems Pressure Sensors Market Report:

The MEMS pressure sensors market in the Middle East and Africa is projected to expand from $0.37 billion in 2023 to $0.76 billion by 2033, as infrastructure development and industrialization initiatives gain momentum, attracting investments in sensor technologies.Tell us your focus area and get a customized research report.

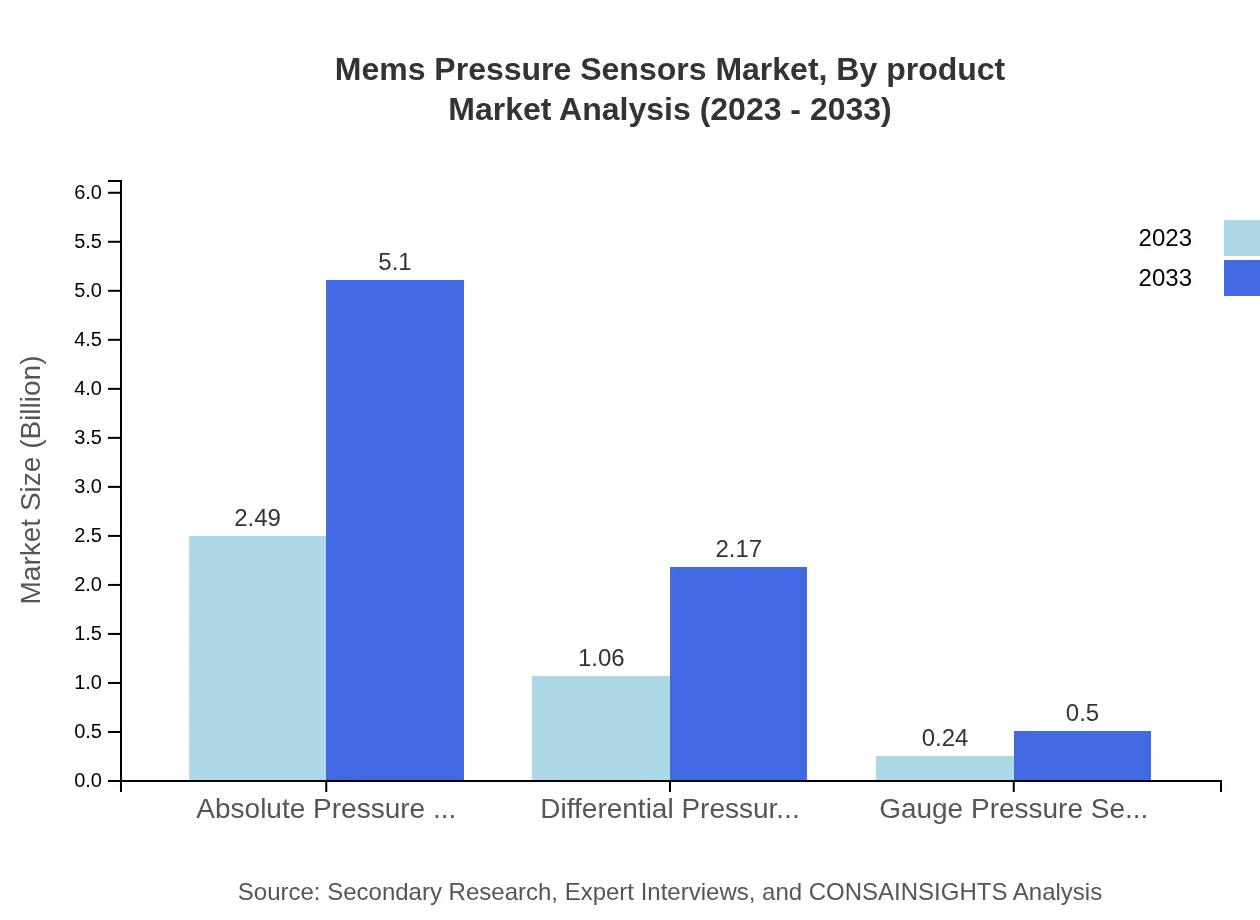

Mems Pressure Sensors Market Analysis By Product

In 2023, the MEMS pressure sensors market is primarily dominated by Absolute Pressure Sensors, projected to reach $2.49 billion, representing a 65.61% share. Differential Pressure Sensors are significant as well, with a market size of $1.06 billion. Gauge Pressure Sensors, while smaller at $0.24 billion, also contribute notably to market dynamics. This illustrates a distinct demand across product categories, with absolute sensors leading due to their accuracy and reliability.

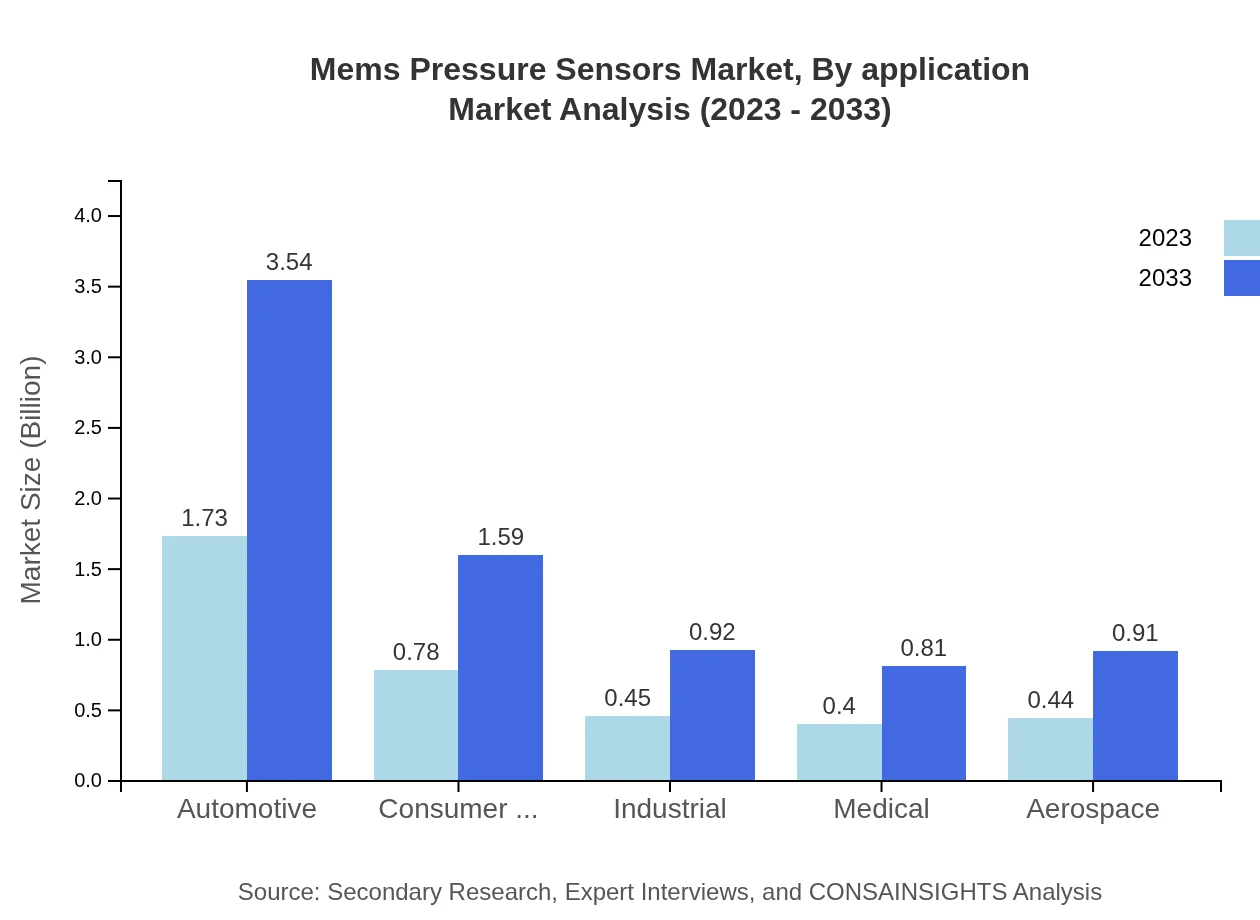

Mems Pressure Sensors Market Analysis By Application

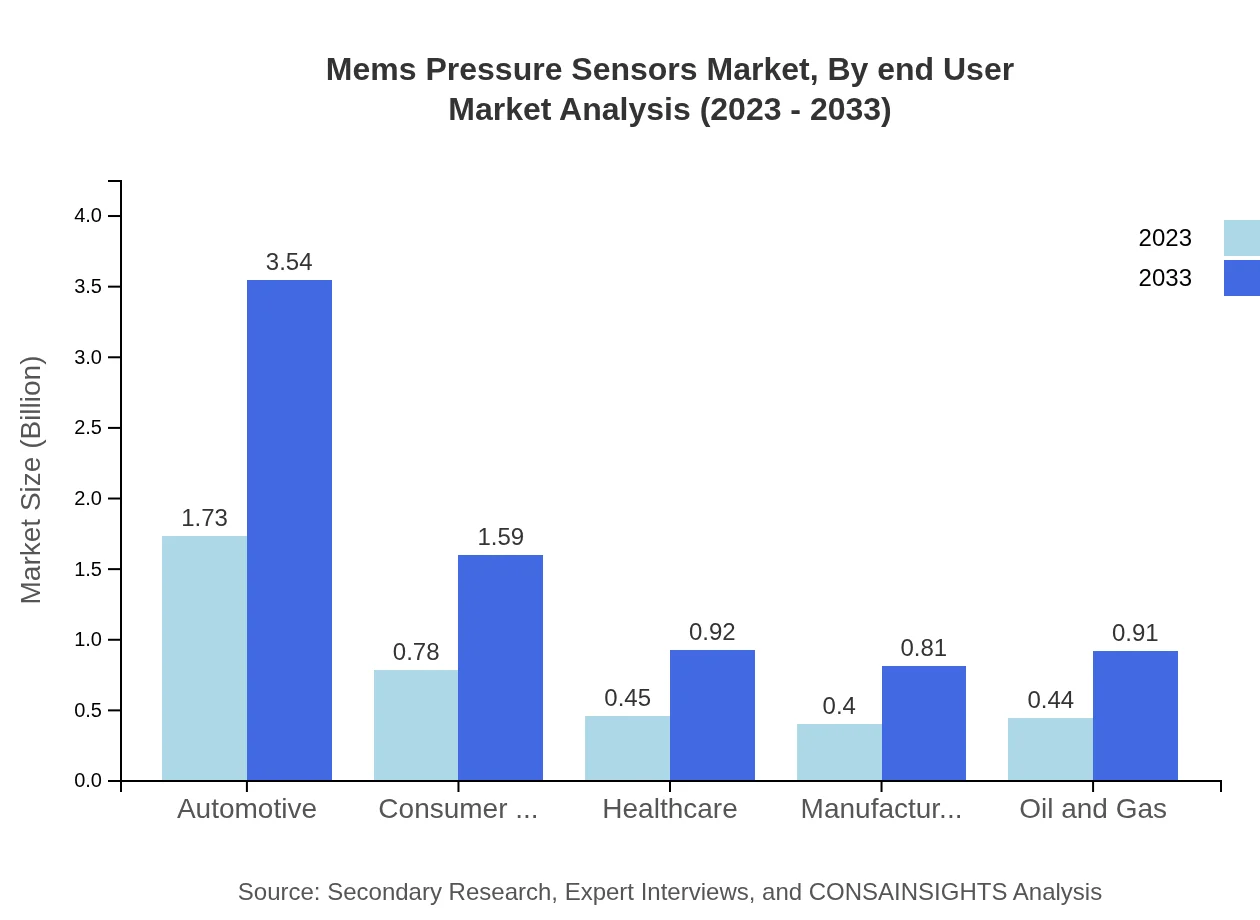

In terms of application, the automotive sector leads with a market size of $1.73 billion in 2023, constituting 45.55% of the share, followed closely by consumer goods at $0.78 billion. Healthcare applications, valued at $0.45 billion, are on an upward trend due to the increasing need for precise measurements in medical devices. Each application area emphasizes the necessity for MEMS pressure sensors in enhancing performance and user functionalities across diverse sectors.

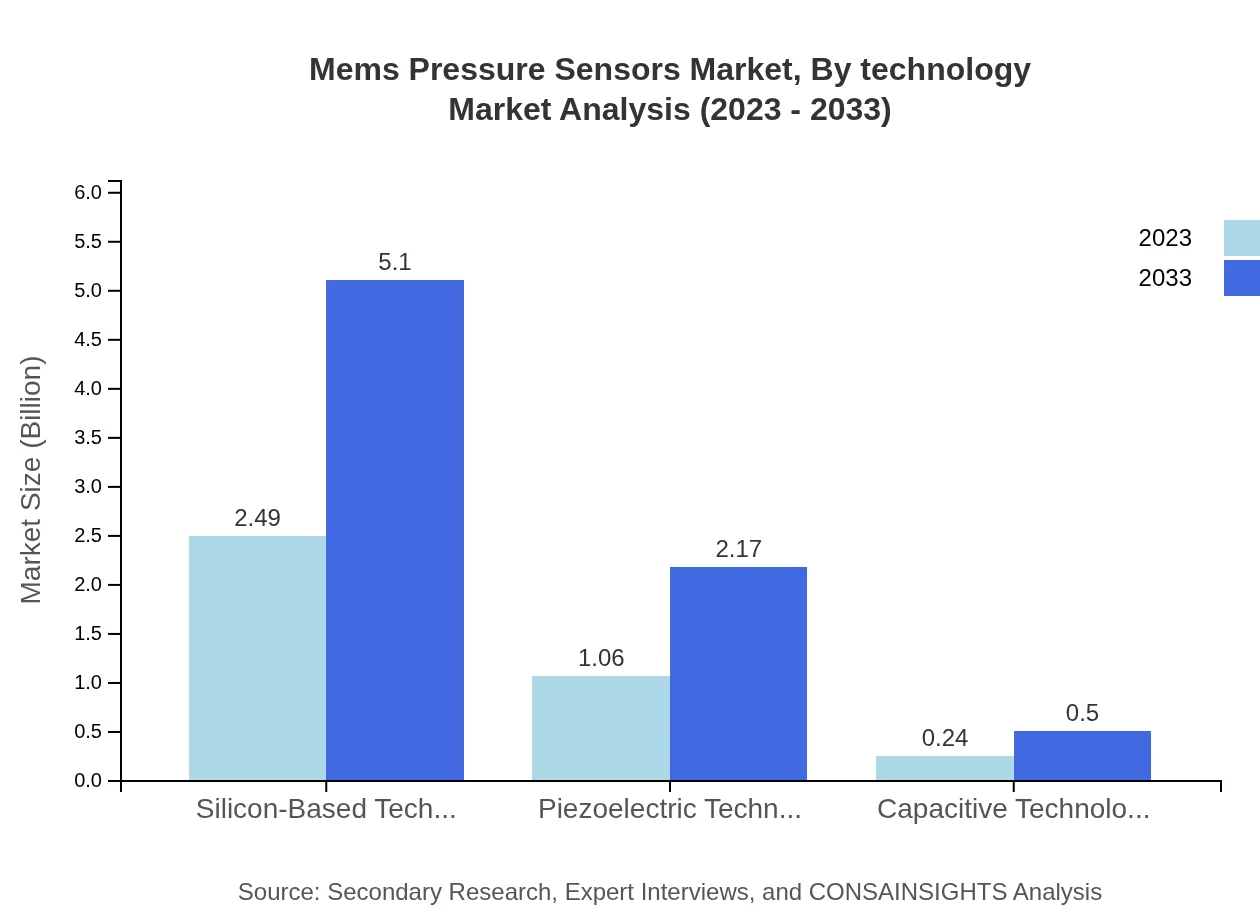

Mems Pressure Sensors Market Analysis By Technology

Silicon-based technology accounts for the largest segment of the MEMS pressure sensors market in 2023, valued at $2.49 billion, maintaining a 65.61% market share. Piezoelectric and capacitive technologies are growing segments, with market sizes of $1.06 billion and $0.24 billion, respectively. The evolution of MEMS technology continues to drive innovation, improving sensor performance and expanding application areas, leading to greater adoption.

Mems Pressure Sensors Market Analysis By End User

In 2023, automotive applications dominate the MEMS pressure sensor market with revenues of $1.73 billion and a substantial market share of 45.55%. Other significant industries such as Consumer Electronics, Industrial, and Aerospace also contribute, pushing for refined sensor technologies to improve operations in different sectors. This diversity in end users demonstrates the versatility of MEMS pressure sensors across industries.

MEMS Pressure Sensors Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in MEMS Pressure Sensors Industry

Honeywell International Inc.:

Honeywell is a leading manufacturer of MEMS pressure sensors providing solutions across automotive, aerospace, and healthcare markets with innovative sensor technologies.Bosch Sensortec:

Bosch Sensortec is a pioneer in MEMS sensor technology, focusing on high-performance and energy-efficient solutions for consumer electronics and automotive industry.TE Connectivity:

TE Connectivity specializes in sensor solutions, including MEMS pressure sensors for industrial and automotive applications, known for their reliability and performance.NXP Semiconductors:

NXP Semiconductors offers advanced MEMS pressure sensors suitable for automotive applications, delivering accuracy and wireless capabilities.Murata Manufacturing Co. Ltd.:

Murata Manufacturing is renowned for innovations in MEMS sensors, focusing on compact, high-performance devices suitable for various applications.We're grateful to work with incredible clients.

FAQs

What is the market size of MEMS pressure sensors?

The MEMS pressure sensors market is valued at approximately $3.8 billion in 2023, with a projected CAGR of 7.2%, indicating significant growth potential in the coming years as demand for advanced sensing technologies rises.

What are the key market players or companies in this MEMS pressure sensors industry?

Key players in the MEMS pressure sensors industry include leaders such as Bosch Sensortec, Honeywell International Inc., and TE Connectivity, which drive innovation and market share through advanced technologies and strategic partnerships.

What are the primary factors driving the growth in the MEMS pressure sensors industry?

The growth of the MEMS pressure sensors industry is driven by increasing demand for automation, advancements in sensor technologies, and the rising adoption of MEMS in automotive applications and consumer electronics.

Which region is the fastest Growing in the MEMS pressure sensors market?

In the MEMS pressure sensors market, Europe is the fastest-growing region, projected to grow from $1.03 billion in 2023 to $2.10 billion by 2033, driven by robust industrial and automotive sectors.

Does ConsaInsights provide customized market report data for the MEMS pressure sensors industry?

Yes, ConsaInsights offers customized market report data tailored to the specific needs of clients in the MEMS pressure sensors industry, providing detailed insights and analysis.

What deliverables can I expect from this MEMS pressure sensors market research project?

Expect comprehensive deliverables including detailed market analysis, segment data, competitive landscape overview, and future projections, all tailored to address specific inquiries about the MEMS pressure sensors market.

What are the market trends of MEMS pressure sensors?

Current market trends for MEMS pressure sensors include the growing adoption of IoT devices, increased focus on miniaturization, and advancements in sensing technologies, enhancing performance and application scope.

Which segments dominate the MEMS pressure sensors market?

The MEMS pressure sensors market is dominated by absolute pressure sensors, which capture 65.61% market share in 2023. Automotive segment leads applications, contributing 45.55% share, showcasing significant market influence.