Metering Pump Dosing Chemical Injection Market Report

Published Date: 22 January 2026 | Report Code: metering-pump-dosing-chemical-injection

Metering Pump Dosing Chemical Injection Market Size, Share, Industry Trends and Forecast to 2033

This report offers a comprehensive analysis of the Metering Pump Dosing Chemical Injection market, covering key market insights, trends, and forecasts for the period 2023-2033. It includes detailed information on market size, industry analysis, regional breakdowns, and competitive landscape.

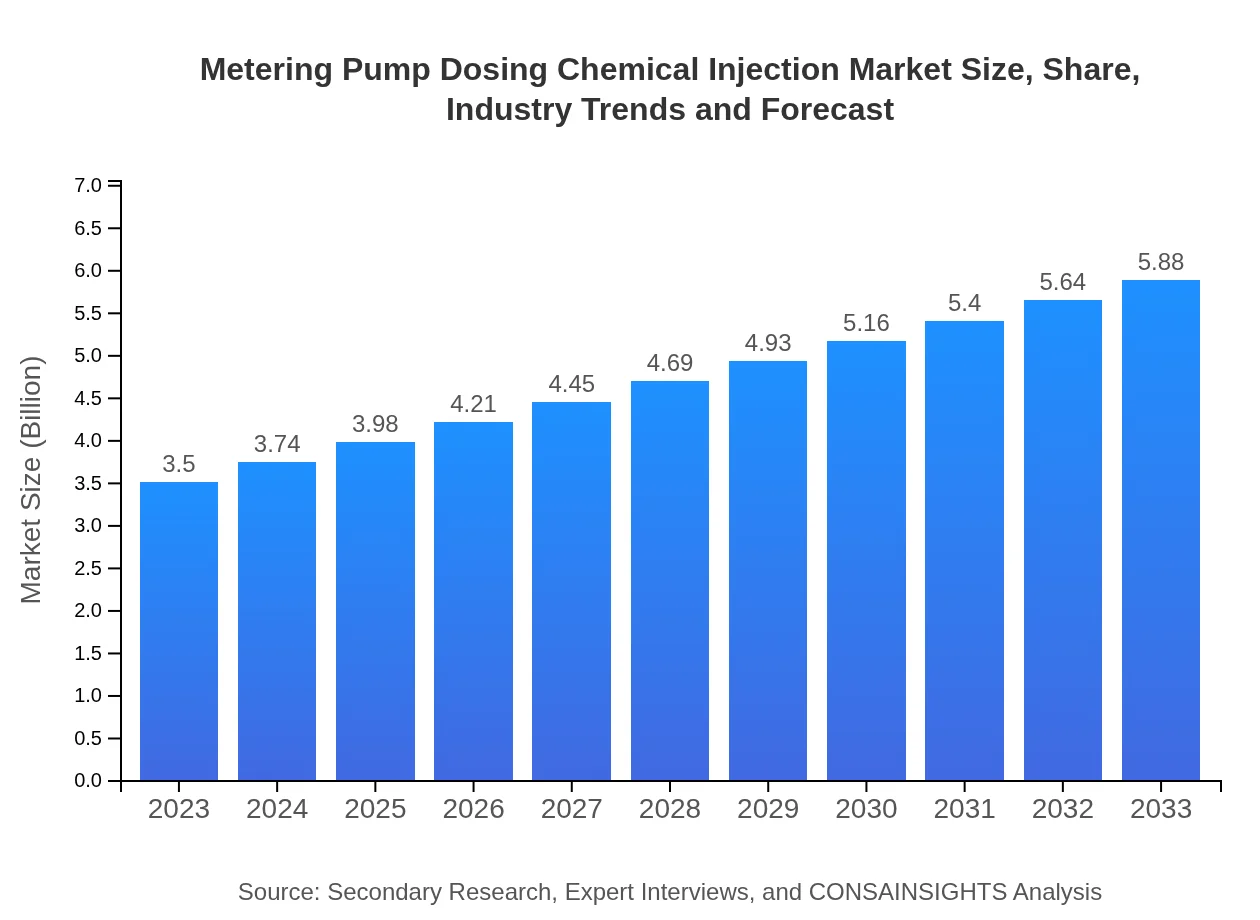

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 5.2% |

| 2033 Market Size | $5.88 Billion |

| Top Companies | Graco Inc., Flowserve Corporation, Hermetic Pumpen GmbH |

| Last Modified Date | 22 January 2026 |

Metering Pump Dosing Chemical Injection Market Overview

Customize Metering Pump Dosing Chemical Injection Market Report market research report

- ✔ Get in-depth analysis of Metering Pump Dosing Chemical Injection market size, growth, and forecasts.

- ✔ Understand Metering Pump Dosing Chemical Injection's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Metering Pump Dosing Chemical Injection

What is the Market Size & CAGR of Metering Pump Dosing Chemical Injection market in 2023?

Metering Pump Dosing Chemical Injection Industry Analysis

Metering Pump Dosing Chemical Injection Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Metering Pump Dosing Chemical Injection Market Analysis Report by Region

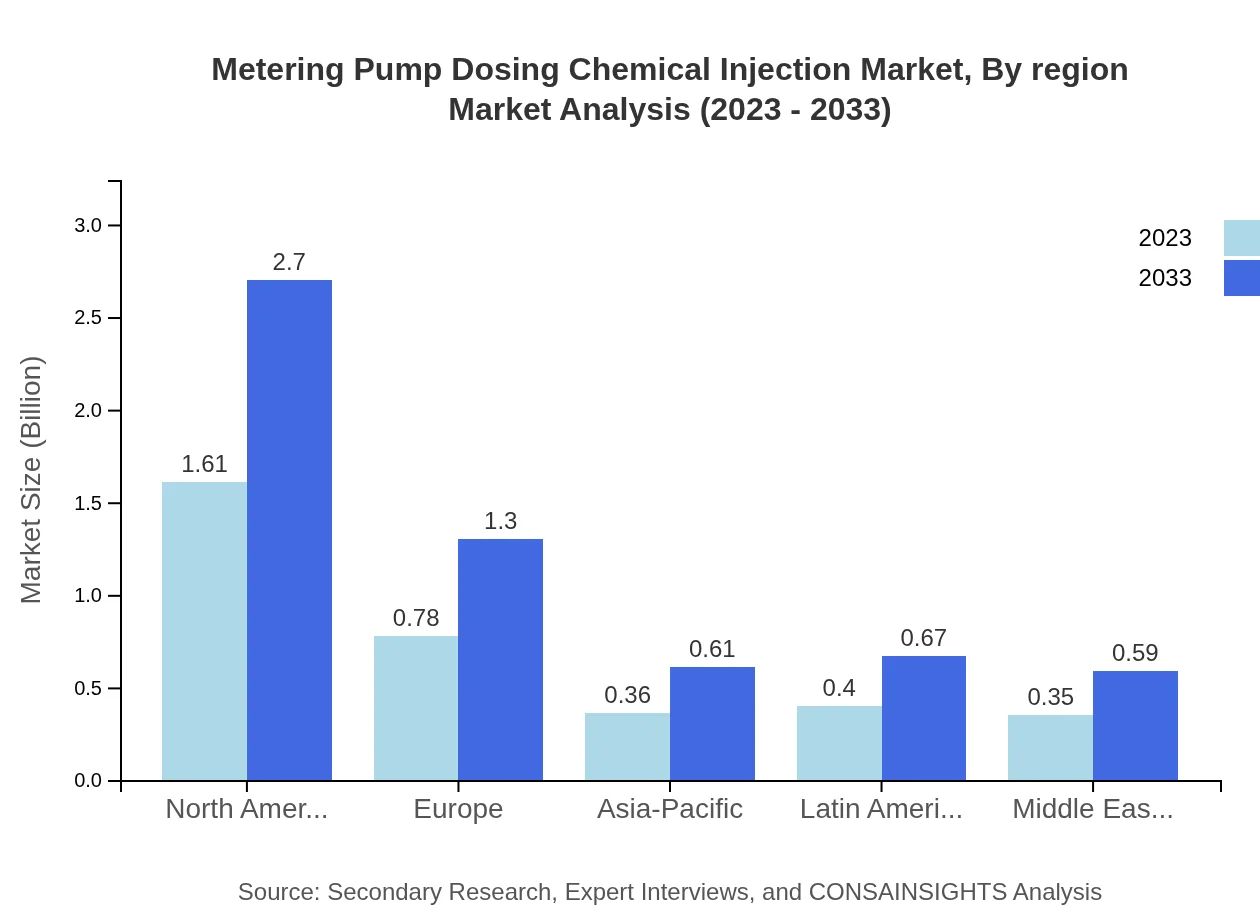

Europe Metering Pump Dosing Chemical Injection Market Report:

Europe's metering pump market is expected to grow from $1.02 billion in 2023 to $1.71 billion by 2033, driven by stringent environmental regulations and a shift towards smart metering technologies. The focus on green chemistry and sustainability enhances opportunities for market players.Asia Pacific Metering Pump Dosing Chemical Injection Market Report:

The Asia Pacific region currently holds a market size of $0.66 billion in 2023 and is expected to reach $1.11 billion by 2033, fueled by rising industrialization and urbanization. Countries such as India and China are implementing stringent water quality regulations, which further enhances the market potential for dosing pumps in water treatment.North America Metering Pump Dosing Chemical Injection Market Report:

North America dominates the market with a size of $1.30 billion in 2023, expected to reach $2.19 billion by 2033. The surge is driven by significant investments in infrastructure development and a growing focus on sustainable practices in industries such as chemicals and oil and gas.South America Metering Pump Dosing Chemical Injection Market Report:

In South America, the metering pump market size is relatively smaller at $0.06 billion in 2023, projected to grow to $0.10 billion by 2033. Investments in agriculture and brewing industries will drive growth, particularly in Brazil and Argentina, focusing on improving chemical handling and efficiency.Middle East & Africa Metering Pump Dosing Chemical Injection Market Report:

In the Middle East and Africa, the market is valued at $0.46 billion in 2023, anticipated to grow to $0.77 billion by 2033. Growing oil & gas exploration and the demand for water treatment technologies are the primary growth drivers in this region.Tell us your focus area and get a customized research report.

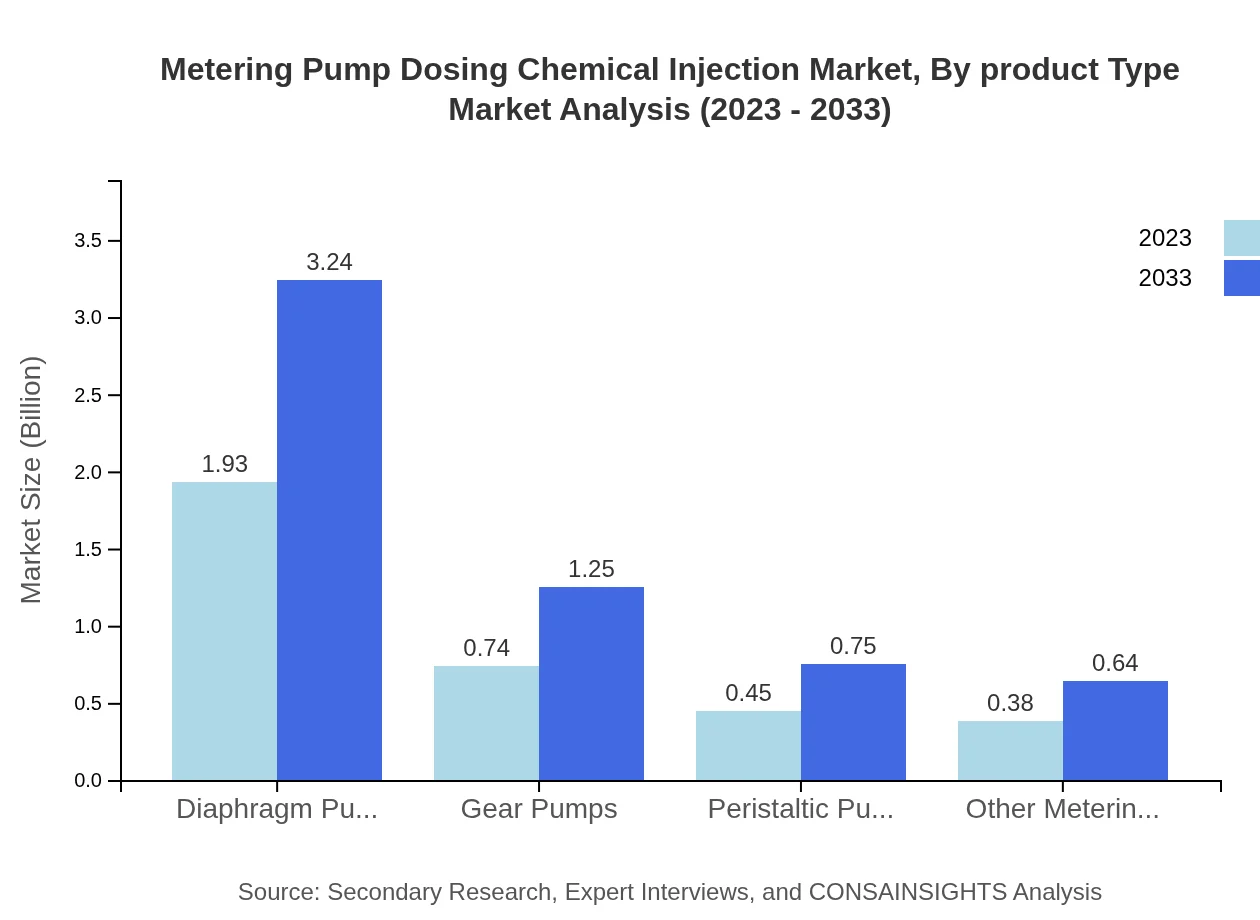

Metering Pump Dosing Chemical Injection Market Analysis By Product Type

Diaphragm pumps, with a market size of $1.93 billion in 2023, lead the product segment due to their reliability and efficiency in handling harsh chemicals. Gear pumps and peristaltic pumps also have significant shares, demonstrating advanced capabilities in various applications.

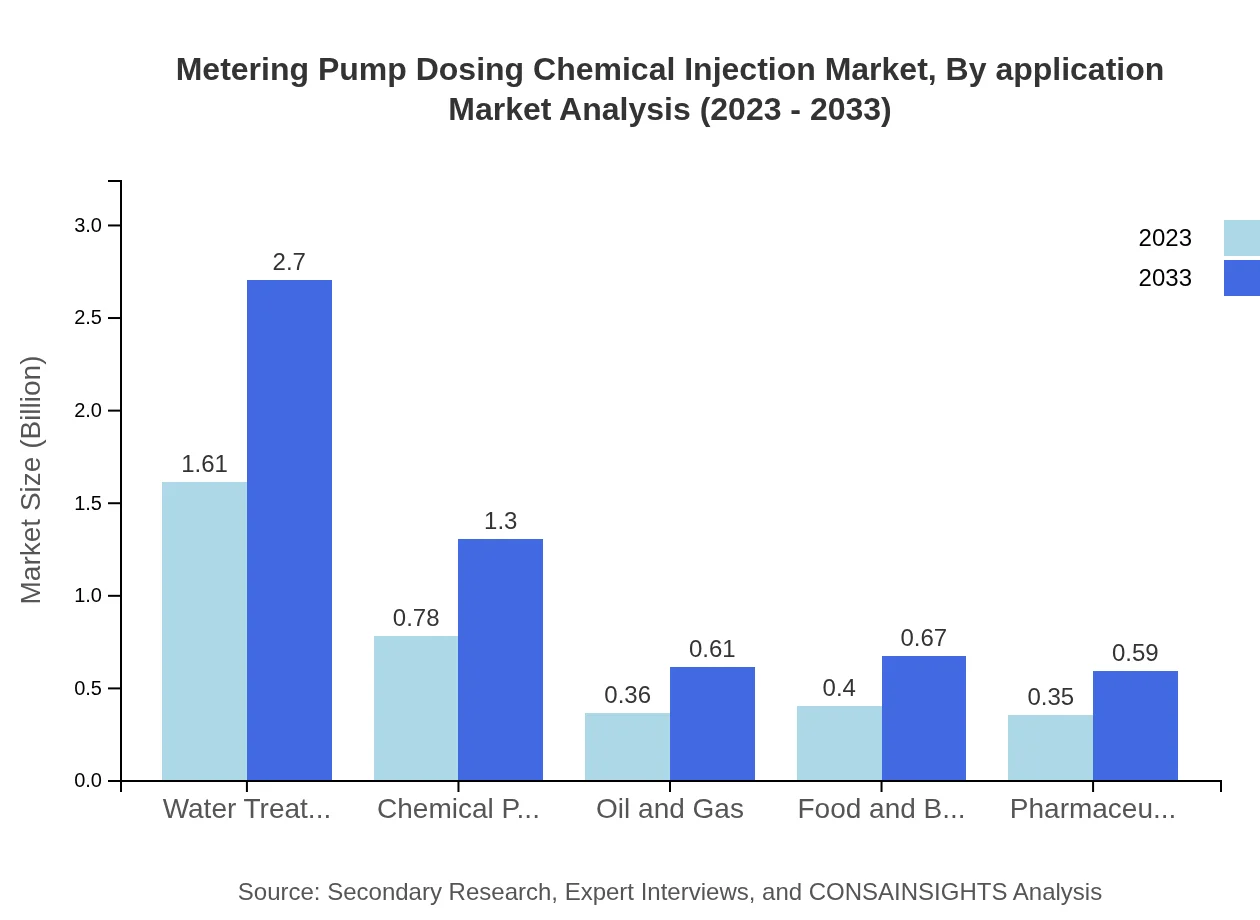

Metering Pump Dosing Chemical Injection Market Analysis By Application

The water treatment sector accounts for over 46% of the market share. Other substantial applications include pharmaceuticals (11.44%) and food and beverage (10.05%), each requiring precision in chemical dosing for quality control.

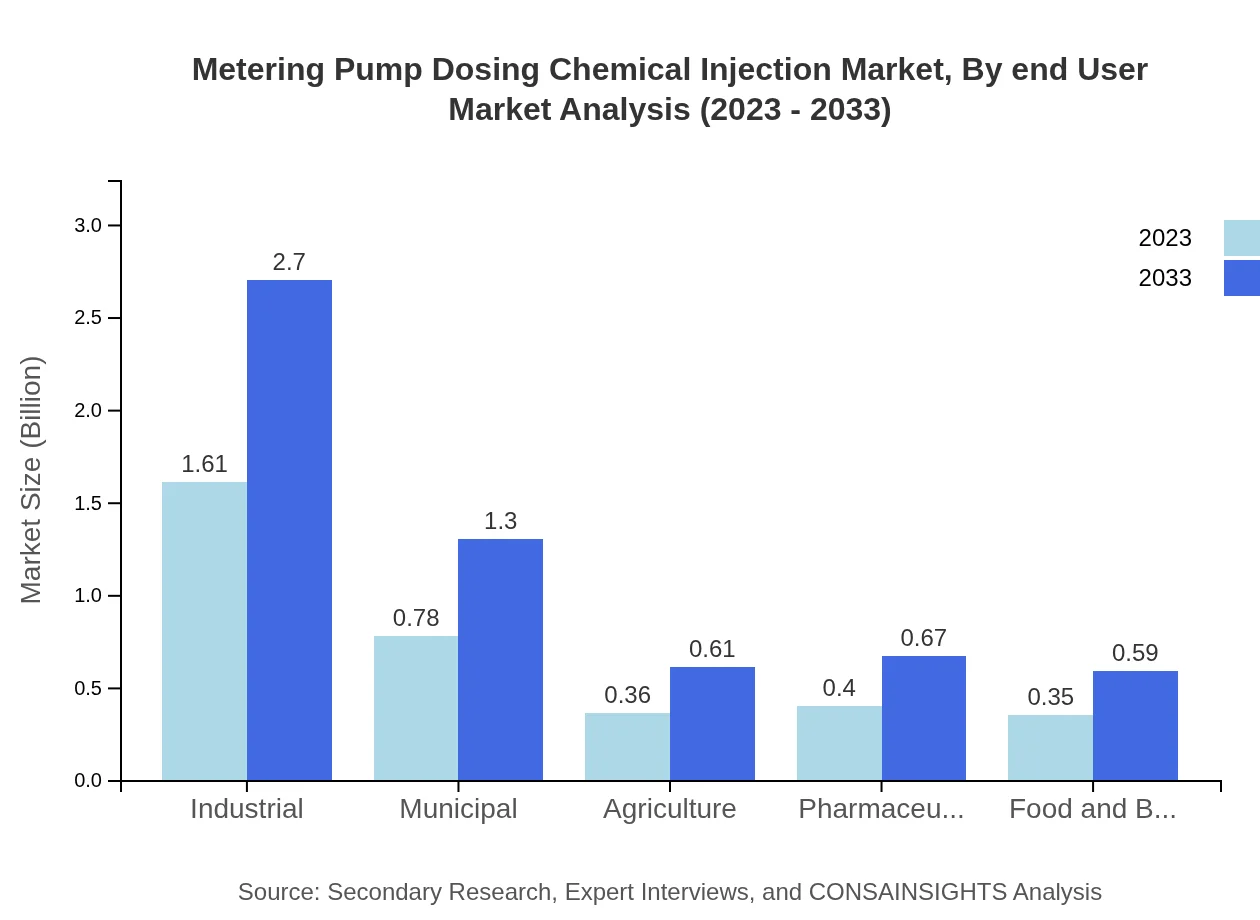

Metering Pump Dosing Chemical Injection Market Analysis By End User

The industrial sector holds the largest market share at 46.03%. Companies in oil and gas industries are increasingly adopting metering pumps to enhance efficiency and ensure precision in chemical applications.

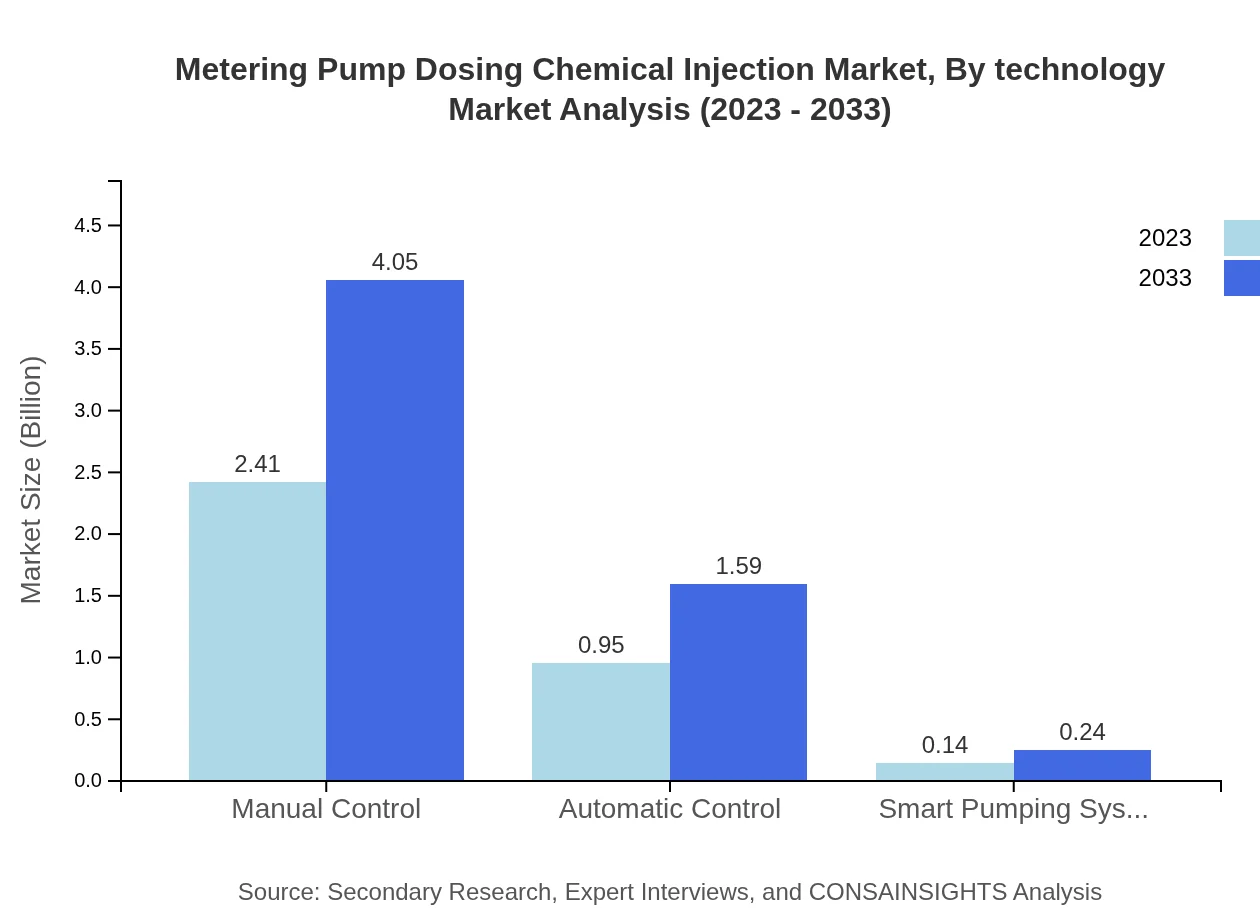

Metering Pump Dosing Chemical Injection Market Analysis By Technology

Manual control technology leads the market with a share of 68.94%, favored for its simplicity and cost-effectiveness. However, automatic control and smart pumping systems are gaining traction, driven by advances in IoT and automation.

Metering Pump Dosing Chemical Injection Market Analysis By Region

In-depth regional analysis reveals North America and Europe as key players, while Asia Pacific emerges as a future growth hub, particularly in industrial and agricultural applications.

Metering Pump Dosing Chemical Injection Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Metering Pump Dosing Chemical Injection Industry

Graco Inc.:

Graco Inc. specializes in fluid handling systems and is a leader in the manufacturing of metering pumps, notably enhancing application efficiency with innovative designs.Flowserve Corporation:

Flowserve offers a wide range of metering pumps, renowned for their reliability and advanced engineering capabilities tailored for various industrial applications.Hermetic Pumpen GmbH:

Hermetic is recognized for its high precision metering pumps designed for chemical and pharmaceutical applications, fostering quality and effectiveness in dosing processes.We're grateful to work with incredible clients.

FAQs

What is the market size of Metering Pump Dosing Chemical Injection?

The Metering Pump Dosing Chemical Injection market is valued at approximately $3.5 billion in 2023, with a projected CAGR of 5.2% through 2033, reflecting robust growth in demand across various industries.

What are the key market players or companies in this Metering Pump Dosing Chemical Injection industry?

Key players in the Metering Pump Dosing Chemical Injection market include leading manufacturers and suppliers that dominate the landscape. They typically focus on innovations, quality enhancement, and expanding their global footprint to cater to diverse applications.

What are the primary factors driving the growth in the Metering Pump Dosing Chemical Injection industry?

Growth in the Metering Pump Dosing Chemical Injection industry is driven by increasing industrial automation, rising demand for precise chemical dosing in various applications, and heightened regulatory focus on process efficiency and safety standards.

Which region is the fastest Growing in the Metering Pump Dosing Chemical Injection?

The fastest-growing region for Metering Pump Dosing Chemical Injection is North America, expected to expand from $1.30 billion in 2023 to $2.19 billion by 2033, showcasing significant demand in various industrial sectors.

Does ConsaInsights provide customized market report data for the Metering Pump Dosing Chemical Injection industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the Metering Pump Dosing Chemical Injection industry, helping stakeholders make informed strategic decisions based on comprehensive insights.

What deliverables can I expect from this Metering Pump Dosing Chemical Injection market research project?

Deliverables from the Metering Pump Dosing Chemical Injection market research project include detailed reports, analytical insights, market forecasts, and assessments across various segments and geographies, enabling informed decision-making.

What are the market trends of Metering Pump Dosing Chemical Injection?

Trends in the Metering Pump Dosing Chemical Injection market include the rise of smart pumping systems, increased automation in chemical dosing processes, and a growing emphasis on sustainability and efficiency across industrial applications.