Motor Control Centers Market Report

Published Date: 22 January 2026 | Report Code: motor-control-centers

Motor Control Centers Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Motor Control Centers market, including market size, growth forecasts, segment analysis, and regional insights from 2023 to 2033.

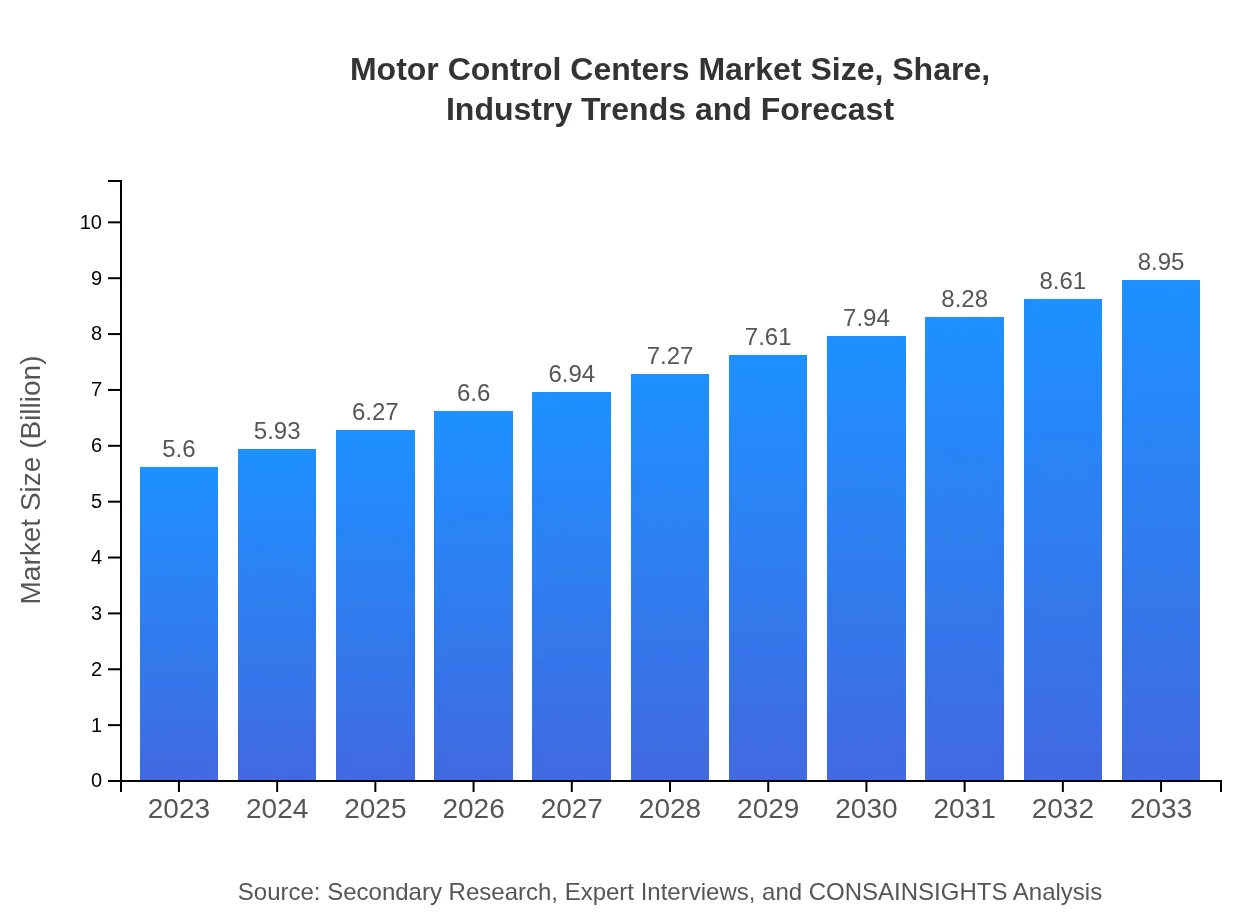

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 4.7% |

| 2033 Market Size | $8.95 Billion |

| Top Companies | Schneider Electric, Siemens , General Electric, Rockwell Automation, Mitsubishi Electric |

| Last Modified Date | 22 January 2026 |

Motor Control Centers Market Overview

Customize Motor Control Centers Market Report market research report

- ✔ Get in-depth analysis of Motor Control Centers market size, growth, and forecasts.

- ✔ Understand Motor Control Centers's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Motor Control Centers

What is the Market Size & CAGR of Motor Control Centers market in 2023?

Motor Control Centers Industry Analysis

Motor Control Centers Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Motor Control Centers Market Analysis Report by Region

Europe Motor Control Centers Market Report:

The European Motor Control Centers market is projected to grow from 1.69 billion USD in 2023 to 2.70 billion USD by 2033, driven by advancements in technology and the adoption of sustainable practices across numerous sectors.Asia Pacific Motor Control Centers Market Report:

In the Asia Pacific region, the Motor Control Centers market is projected to expand from 1.07 billion USD in 2023 to 1.71 billion USD by 2033. The growth is fueled by rapid industrialization, increasing investments in infrastructure, and advancements in smart grid technologies.North America Motor Control Centers Market Report:

North America is set to witness substantial growth as the market is anticipated to grow from 1.80 billion USD in 2023 to 2.88 billion USD by 2033. This surge can be attributed to the increasing adoption of automation in various industries and stringent energy efficiency regulations.South America Motor Control Centers Market Report:

The South American market for Motor Control Centers is expected to grow from 0.41 billion USD in 2023 to 0.65 billion USD in 2033. Factors contributing to this growth include rising urbanization and increased focus on renewable energy sources.Middle East & Africa Motor Control Centers Market Report:

In the Middle East and Africa, the Motor Control Centers market is expected to rise from 0.63 billion USD in 2023 to 1.00 billion USD by 2033. This growth is supported by increasing energy demands and investments in infrastructure development.Tell us your focus area and get a customized research report.

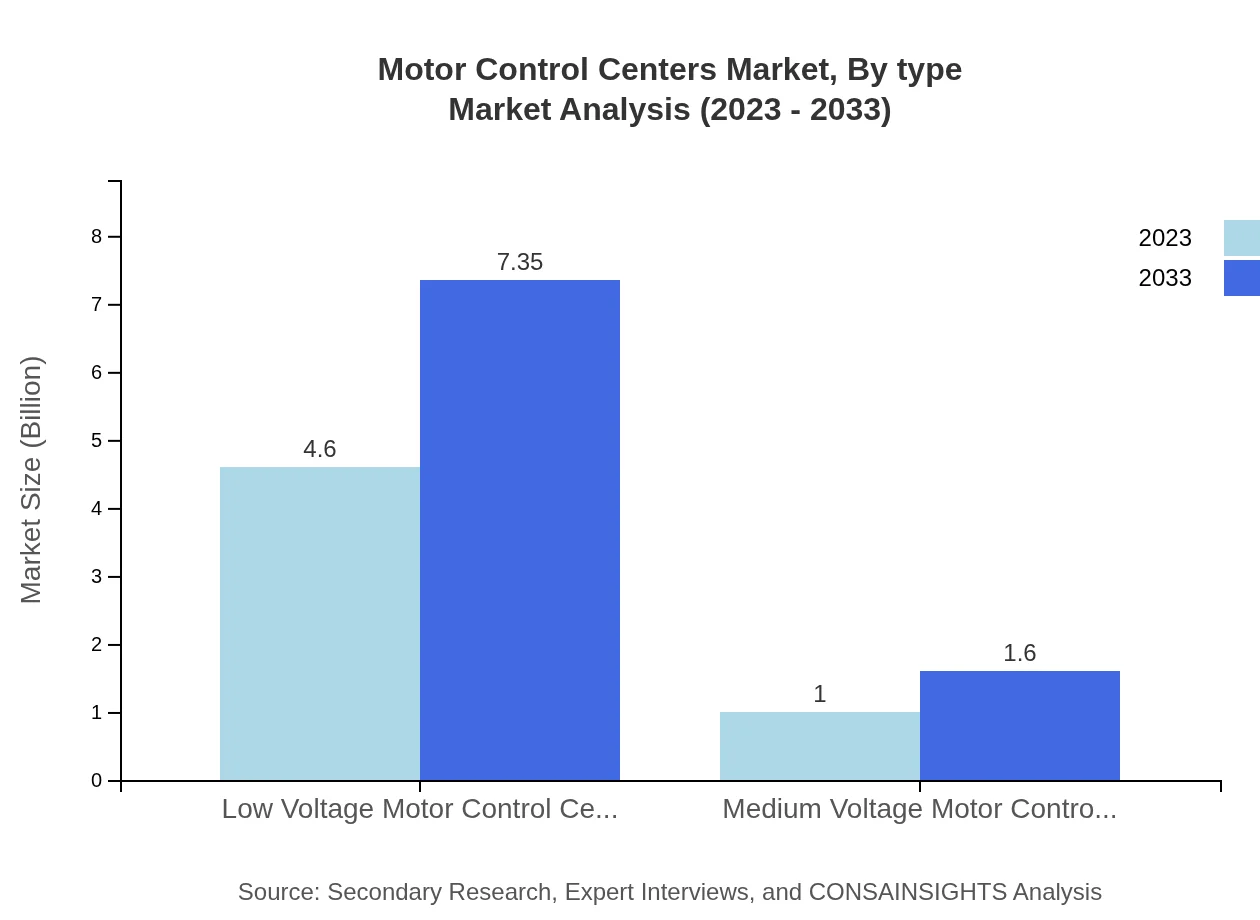

Motor Control Centers Market Analysis By Type

The Motor Control Centers market can be bifurcated into Low Voltage and Medium Voltage categories. The Low Voltage Motor Control Centers market is expected to burgeon from 4.60 billion USD in 2023 to 7.35 billion USD in 2033, indicating its dominating share of approximately 82.12% in the market. Meanwhile, the Medium Voltage Motor Control Centers market is projected to increase from 1.00 billion USD in 2023 to 1.60 billion USD by 2033, possessing 17.88% of the market share.

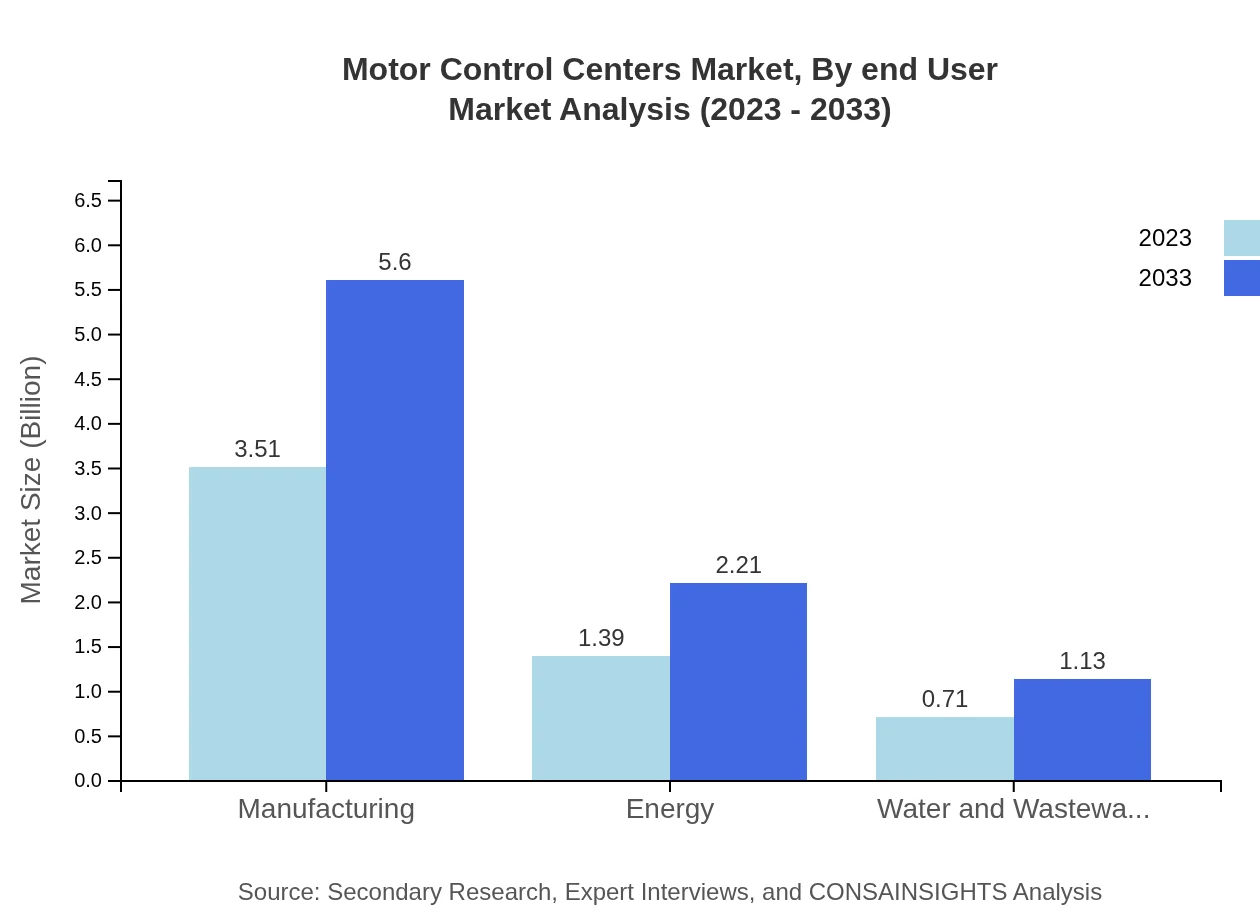

Motor Control Centers Market Analysis By Application

The primary applications for Motor Control Centers include sectors such as Manufacturing, Energy, Water and Wastewater Management, and Commercial usage. The manufacturing sector leads with a share of 62.62%, growing from 3.51 billion USD in 2023 to 5.60 billion USD by 2033, while the energy sector captures around 24.75% of the market with significant growth projected from 1.39 billion USD in 2023 to 2.21 billion USD by 2033.

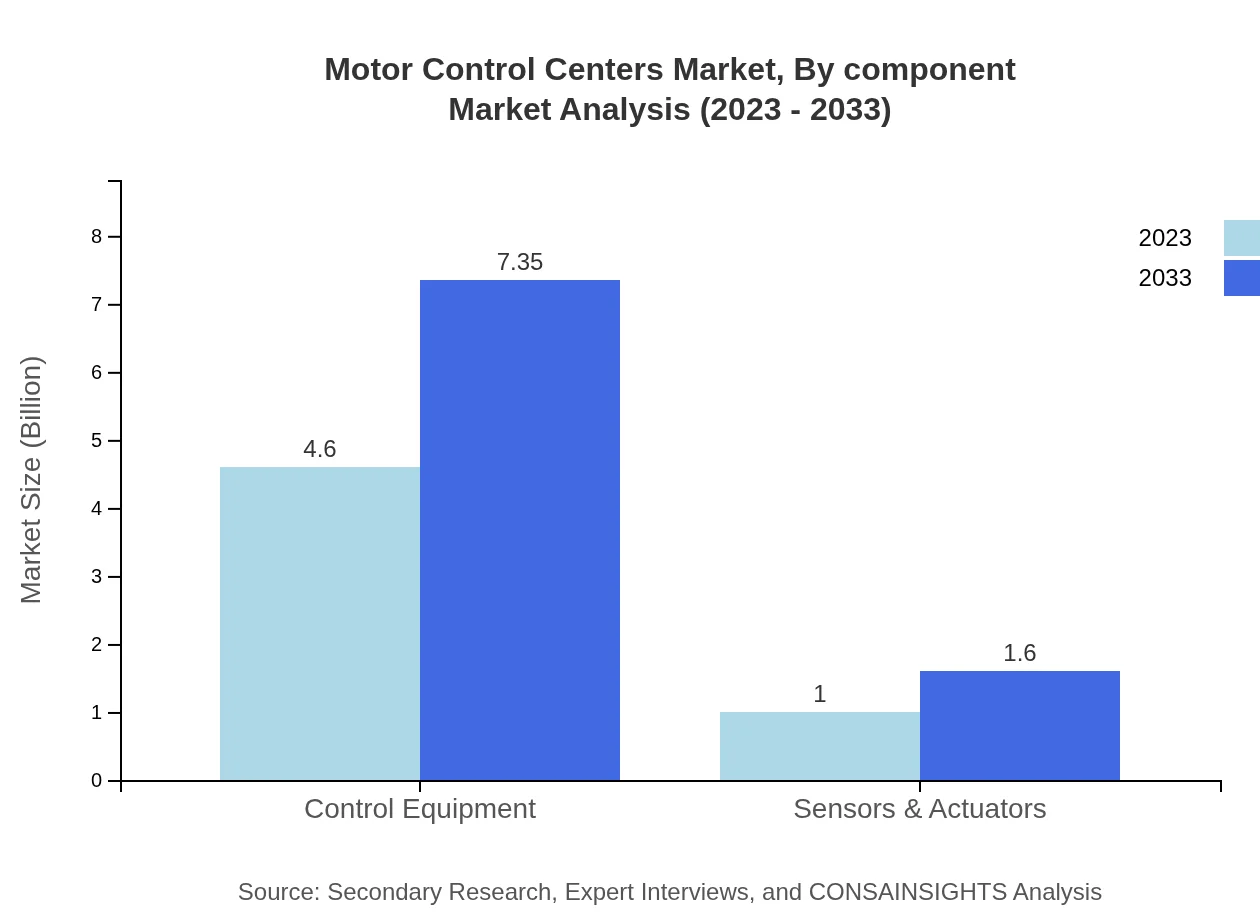

Motor Control Centers Market Analysis By Component

Key components of Motor Control Centers include Control Equipment, Sensors & Actuators, Digital and Analog Motor Control Technology. Control Equipment is expected to comprise the largest segment with a revenue forecast rising from 4.60 billion USD in 2023 to 7.35 billion USD in 2033, staying at 82.12% market dominance. Sensors & Actuators will also become increasingly vital, expanding from 1.00 billion USD in 2023 to 1.60 billion USD by 2033.

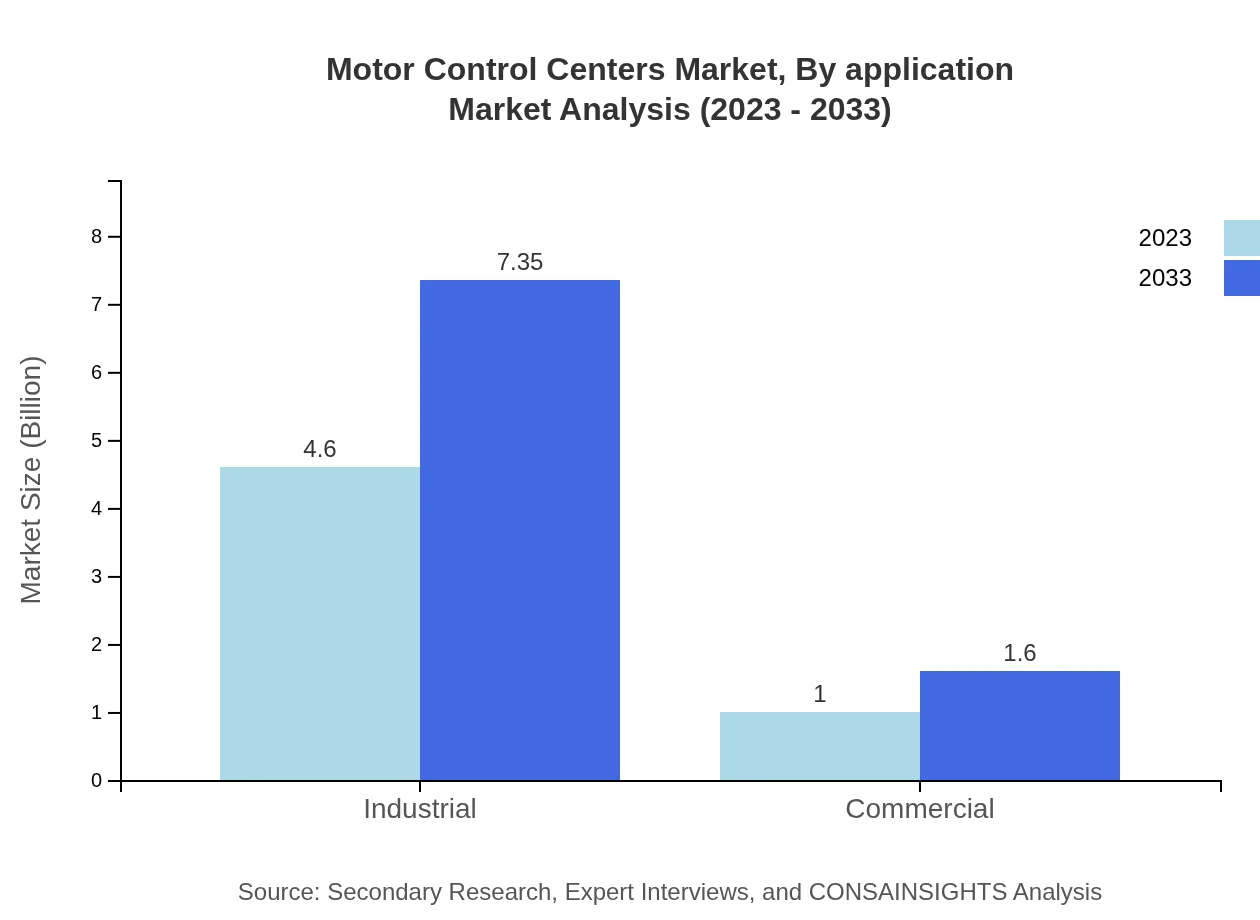

Motor Control Centers Market Analysis By End User

The end-user industry segmentation highlights the role of Industrial and Commercial sectors, with the Industrial segment representing approximately 82.12% of the market, escalating from 4.60 billion USD in 2023 to 7.35 billion USD by 2033. The Commercial sector, while smaller, is also on an upward trajectory, projected to grow from 1.00 billion USD in 2023 to 1.60 billion USD by 2033.

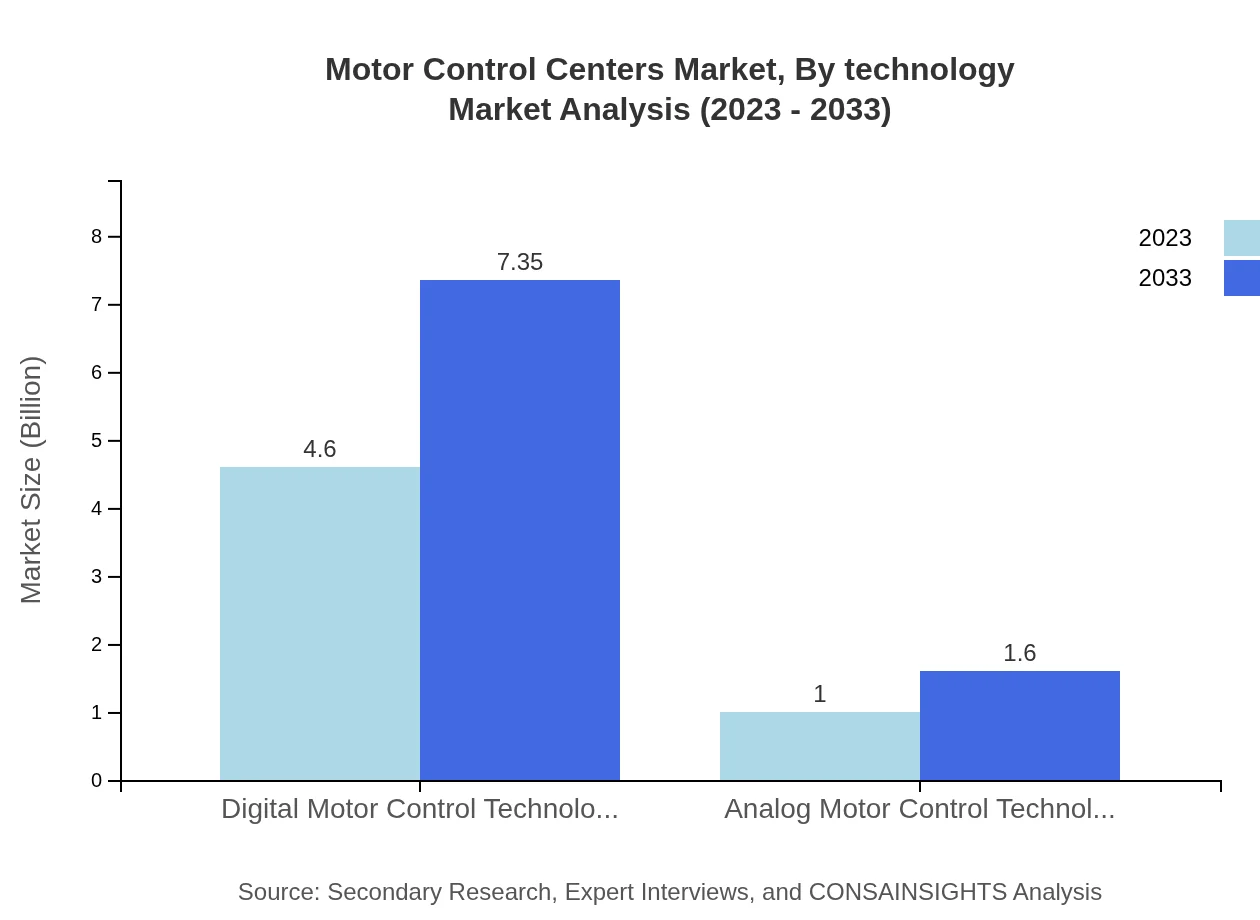

Motor Control Centers Market Analysis By Technology

Technological advancements in the Motor Control Centers market center around Digital and Analog Motor Control Technologies. The market for Digital technologies is poised for considerable growth from 4.60 billion USD in 2023 to 7.35 billion USD by 2033, while Analog technologies maintain relevance with growth expected from 1.00 billion USD to 1.60 billion USD in the same timeframe.

Motor Control Centers Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Motor Control Centers Industry

Schneider Electric:

Schneider Electric is a global leader in digital transformation of energy management and automation in homes, buildings, data centers, infrastructure, and industries.Siemens :

Siemens is a leading innovator in automation and digitalization, playing a vital role in developing and producing advanced Motor Control Centers.General Electric:

General Electric (GE) provides a variety of industrial and electrical solutions, including advanced Motor Control Centers, enhancing operational efficiencies.Rockwell Automation:

Rockwell Automation specializes in industrial automation and information solutions, offering a comprehensive range of Motor Control solutions.Mitsubishi Electric:

Mitsubishi Electric is recognized for its efficient energy solutions and innovative approaches in the Motor Control Centers market.We're grateful to work with incredible clients.

FAQs

What is the market size of the Motor Control Centers?

The global motor control centers market is valued at approximately $5.6 billion in 2023, with an expected compound annual growth rate (CAGR) of 4.7% over the next decade, indicating significant growth potential in the industry.

What are the key market players or companies in the Motor Control Centers industry?

Key players in the motor control centers market include industry leaders such as Siemens, Schneider Electric, ABB, Eaton, and Mitsubishi Electric. These companies play a crucial role in innovation, quality production, and global distribution.

What are the primary factors driving the growth in the Motor Control Centers industry?

Growth in the motor control centers industry is driven by increased industrial automation, rising demand for energy efficiency, advancements in technology, and a growing need for reliable motor control solutions across various sectors.

Which region is the fastest Growing in the Motor Control Centers market?

Asia Pacific is the fastest-growing region in the motor control centers market, projected to expand from $1.07 billion in 2023 to $1.71 billion by 2033, fueled by industrial growth and urbanization.

Does ConsaInsights provide customized market report data for the Motor Control Centers industry?

Yes, ConsaInsights offers customized market report data tailored to specific client needs in the motor control centers industry, ensuring relevant insights and actionable information for strategic decision-making.

What deliverables can I expect from this Motor Control Centers market research project?

Deliverables from a motor control centers market research project typically include in-depth market analysis, detailed reports on trends & forecasts, competitive landscape overviews, and actionable recommendations based on findings.

What are the market trends of Motor Control Centers?

Current market trends in the motor control centers segment include increasing adoption of digital technology, emphasis on sustainability, integration of IoT for enhanced monitoring, and growth in low voltage control centers, indicating a shift towards smarter solutions.