Nanomechanical Testing Market Report

Published Date: 31 January 2026 | Report Code: nanomechanical-testing

Nanomechanical Testing Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Nanomechanical Testing market from 2023 to 2033. It covers market dynamics, size estimations, trends, and insights into various segments, ensuring a comprehensive understanding of the industry's growth prospects and challenges.

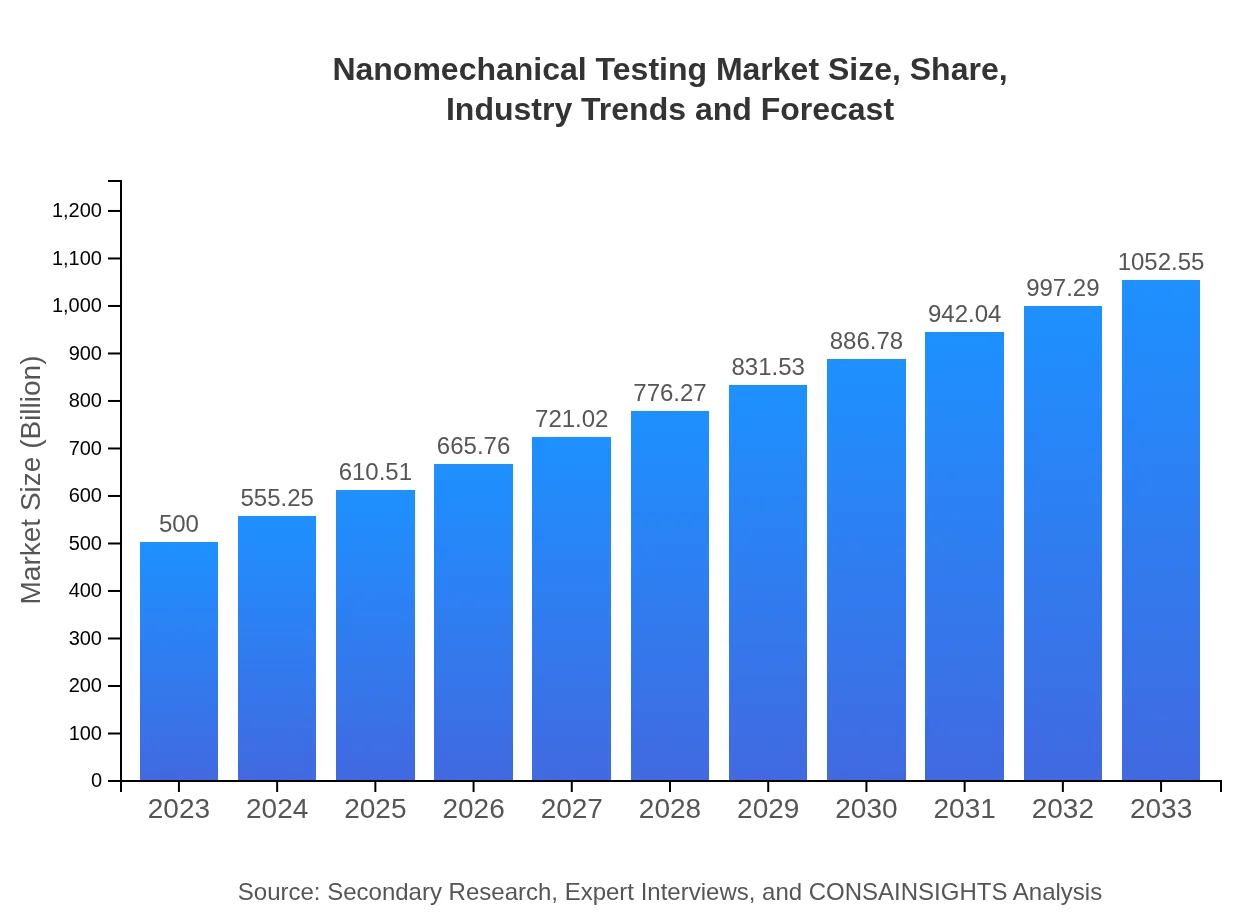

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $500.00 Million |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $1052.55 Million |

| Top Companies | Agilent Technologies, Hysitron (part of Bruker), Anton Paar, Micro Materials Ltd. |

| Last Modified Date | 31 January 2026 |

Nanomechanical Testing Market Overview

Customize Nanomechanical Testing Market Report market research report

- ✔ Get in-depth analysis of Nanomechanical Testing market size, growth, and forecasts.

- ✔ Understand Nanomechanical Testing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Nanomechanical Testing

What is the Market Size & CAGR of Nanomechanical Testing market in 2023?

Nanomechanical Testing Industry Analysis

Nanomechanical Testing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Nanomechanical Testing Market Analysis Report by Region

Europe Nanomechanical Testing Market Report:

Europe's Nanomechanical Testing market is predicted to expand from $162.10 million in 2023 to $341.24 million by 2033, with a CAGR of 8.0%. The presence of leading universities and research institutions fosters innovation, while stringent regulations regarding material quality in various sectors support consistent growth.Asia Pacific Nanomechanical Testing Market Report:

In the Asia Pacific region, the Nanomechanical Testing market is projected to grow from $87.80 million in 2023 to $184.83 million by 2033, indicating a steady increase of approximately 8.1% CAGR. Factors contributing to this growth include the rise of manufacturing hubs, increased investment in R&D, and growing applications in the semiconductor and electronics industries.North America Nanomechanical Testing Market Report:

North America commands a significant portion of the market with an expected increase from $175.95 million to $370.39 million from 2023 to 2033. The region's CAGR stands at about 8.5%, fueled by strong governmental support for advanced materials research and the presence of major players in the nanotechnology field.South America Nanomechanical Testing Market Report:

The South American market, although smaller, is expected to grow from $24.05 million in 2023 to $50.63 million in 2033, achieving a CAGR of around 8.0%. The growth is primarily driven by increasing industrialization and a rising focus on academic research initiatives in the region.Middle East & Africa Nanomechanical Testing Market Report:

In the Middle East and Africa, the market will grow from $50.10 million to $105.47 million, registering approximately 8.0% CAGR. The rising demand for high-quality materials in construction and manufacturing plays a key role in this region's growing market dynamics.Tell us your focus area and get a customized research report.

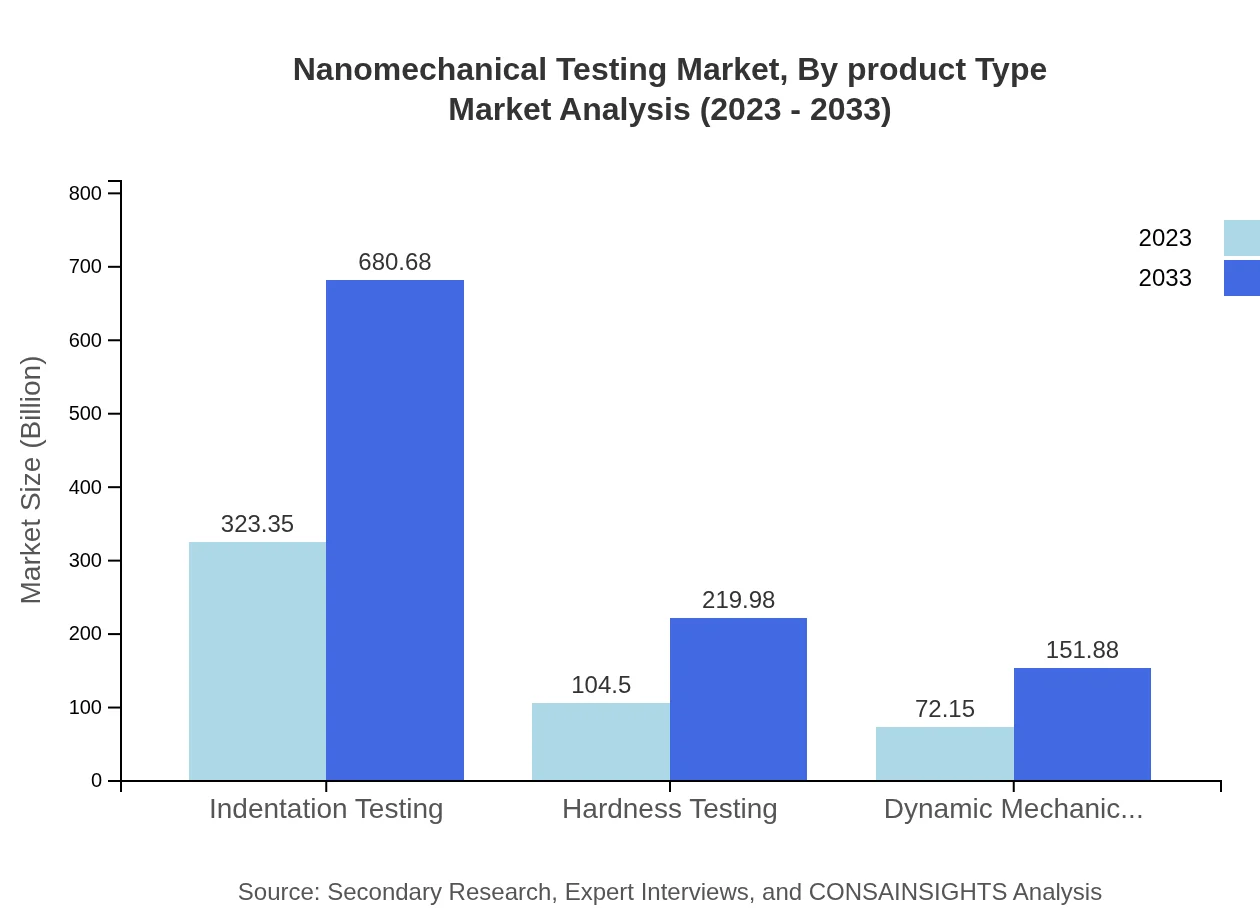

Nanomechanical Testing Market Analysis By Product Type

The Nanomechanical Testing market, segmented by product type, shows that nanoindentation testing dominates with substantial contributions to the overall market size, projected to grow from $323.35 million in 2023 to $680.68 million by 2033. Other types like hardness testing and dynamic mechanical testing also witness significant growth, driven by their applications in various industries including materials science and aerospace.

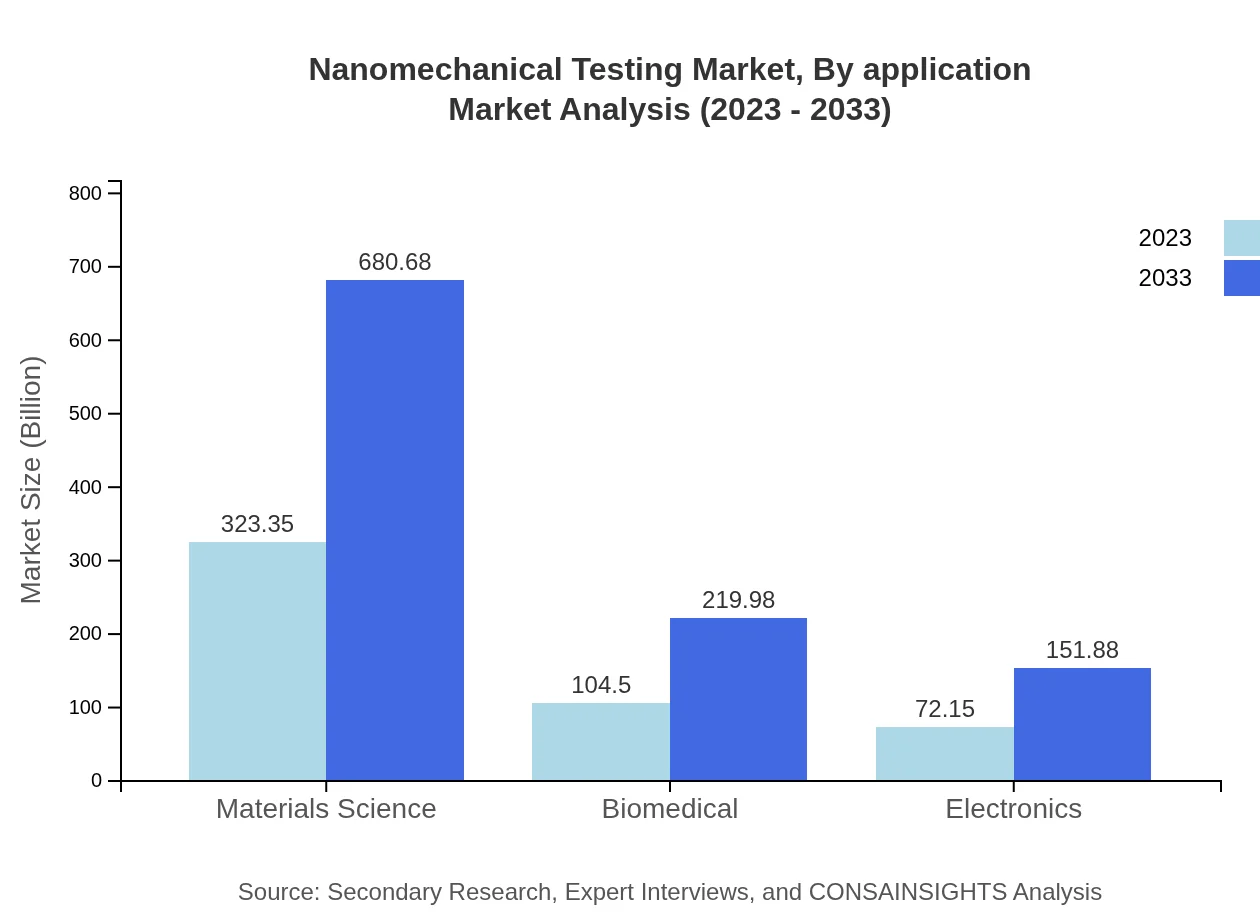

Nanomechanical Testing Market Analysis By Application

Key applications of the Nanomechanical Testing market encompass materials science, biomedical applications, and electronics. The materials science segment is crucial, with a market size forecast to grow from $323.35 million to $680.68 million from 2023 to 2033. As industries seek to innovate and enhance material properties, this segment's demand is pivotal for overall market expansion.

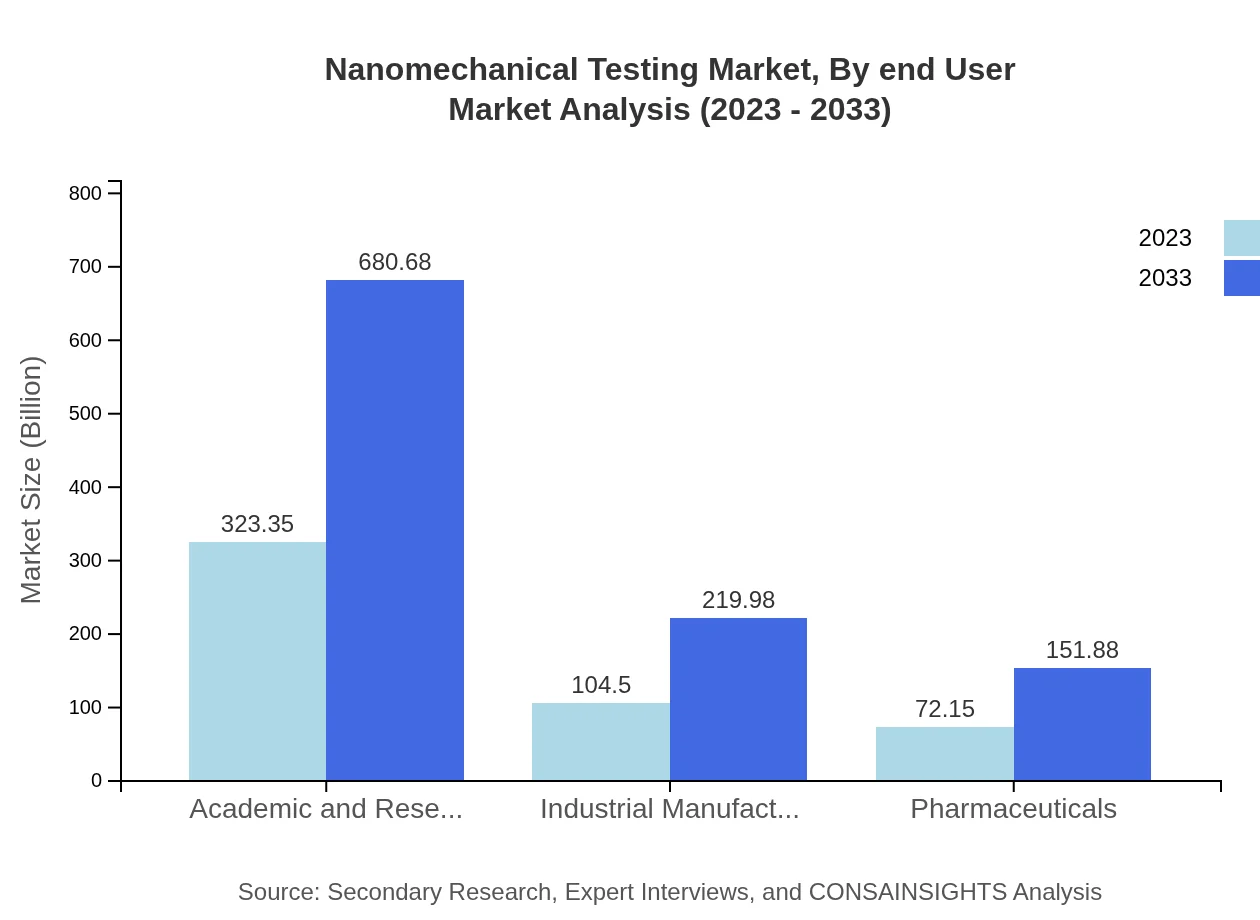

Nanomechanical Testing Market Analysis By End User

The end-user segments show dominant contributions from academic and research institutions, with a market size expected to escalate from $323.35 million in 2023 to $680.68 million by 2033. Industrial manufacturing follows, with its market share poised to grow significantly as industries integrate advanced testing for quality assurance.

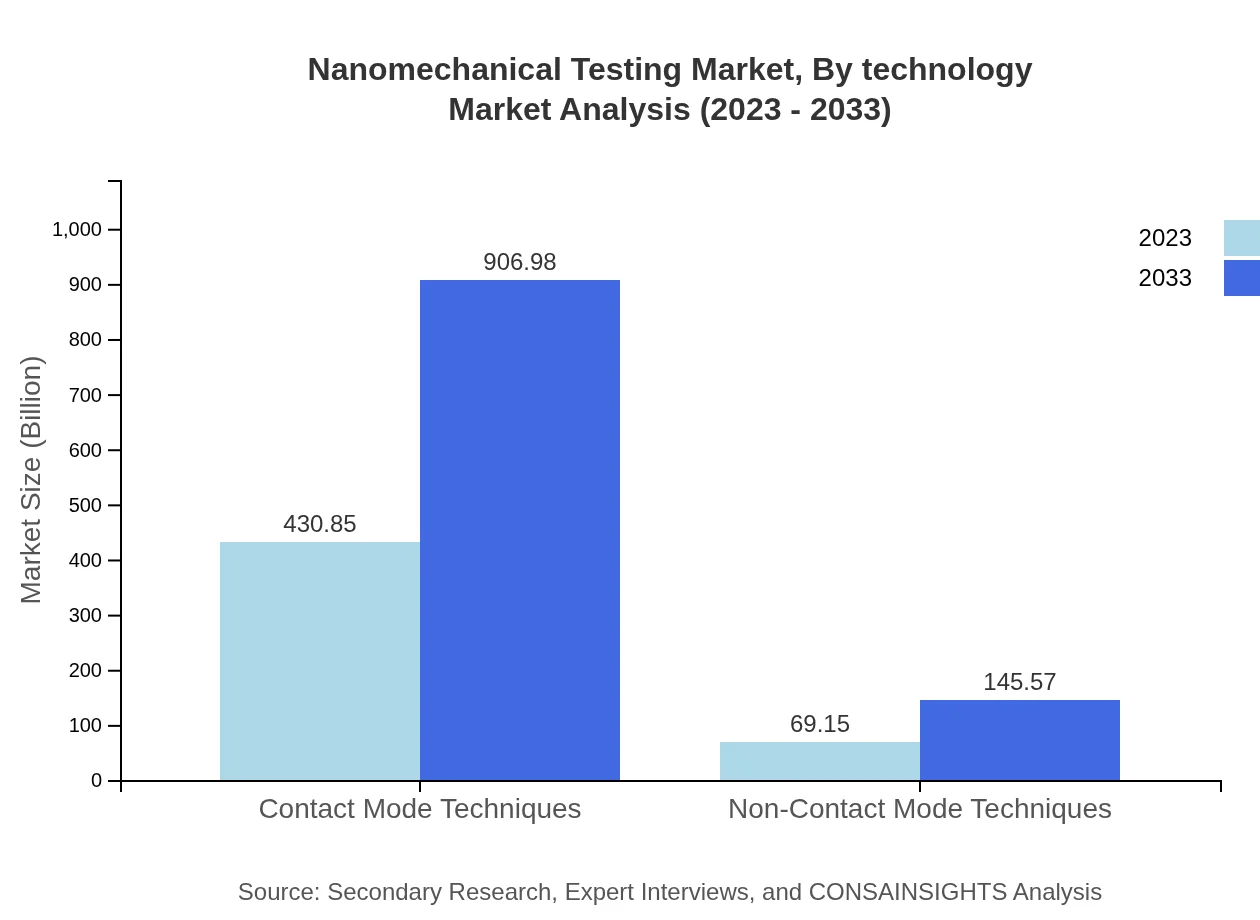

Nanomechanical Testing Market Analysis By Technology

Technological advancements are crucial for the Nanomechanical Testing market, especially in contact mode techniques which lead the market size from $430.85 million to $906.98 million between 2023 and 2033. Non-contact mode techniques, although smaller, are also valued for certain applications, reflecting the importance of innovation in material characterization methodologies.

Nanomechanical Testing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Nanomechanical Testing Industry

Agilent Technologies:

Agilent Technologies is a leading company in the field of measurement and nanotechnology, offering advanced solutions in nanoindentation and dynamic mechanical analysis.Hysitron (part of Bruker):

Hysitron is well-known for its pioneering advancements in nanomechanical testing technologies, pushing the boundaries of material characterization through innovative testing equipment.Anton Paar:

Anton Paar provides high-tech measuring and analysis instruments, blending precision engineering with research excellence in nanomechanical properties testing.Micro Materials Ltd.:

Micro Materials specializes in sub-micron and nanomechanical testing solutions, offering a variety of systems for dynamic and static measurements.We're grateful to work with incredible clients.

FAQs

What is the market size of nanomechanical testing?

The global nanomechanical testing market is valued at approximately $500 million in 2023 and is anticipated to grow at a CAGR of 7.5%, reaching an estimated size of $1.05 billion by 2033.

What are the key market players or companies in the nanomechanical testing industry?

Key players in the nanomechanical testing industry include KLA Corporation, Bruker Corporation, and Keysight Technologies. These firms are pivotal in advancing technologies and methodologies within the nanomechanical testing domain, contributing to market growth.

What are the primary factors driving the growth in the nanomechanical testing industry?

The growth of the nanomechanical testing industry is propelled by the increasing demand for advanced materials, advancements in nanotechnology, and the expansion of research and development activities in academia and industry, boosting investment in testing methodologies.

Which region is the fastest Growing in the nanomechanical testing market?

The Asia Pacific region is the fastest-growing area in the nanomechanical testing market, projected to expand from $87.80 million in 2023 to $184.83 million by 2033, driven by rising industrial applications and research initiatives.

Does ConsaInsights provide customized market report data for the nanomechanical testing industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the nanomechanical testing industry, enabling stakeholders to gain insights suited to their strategic goals and market environments.

What deliverables can I expect from this nanomechanical testing market research project?

Deliverables from the nanomechanical testing market research project will include comprehensive market analysis reports, growth forecasts, segmentation studies, competitive landscape assessments, and actionable insights tailored to stakeholders' requirements.

What are the market trends of nanomechanical testing?

Key trends in the nanomechanical testing market include the integration of automation in testing processes, increasing focus on nanoscale materials, and the adoption of eco-friendly testing methods, contributing to the dynamic evolution of this field.