Non Destructive Testing Ndt Equipment Market Report

Published Date: 31 January 2026 | Report Code: non-destructive-testing-ndt-equipment

Non Destructive Testing Ndt Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Non Destructive Testing (NDT) Equipment market, including insights on market size, growth projections, and trends from 2023 to 2033.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

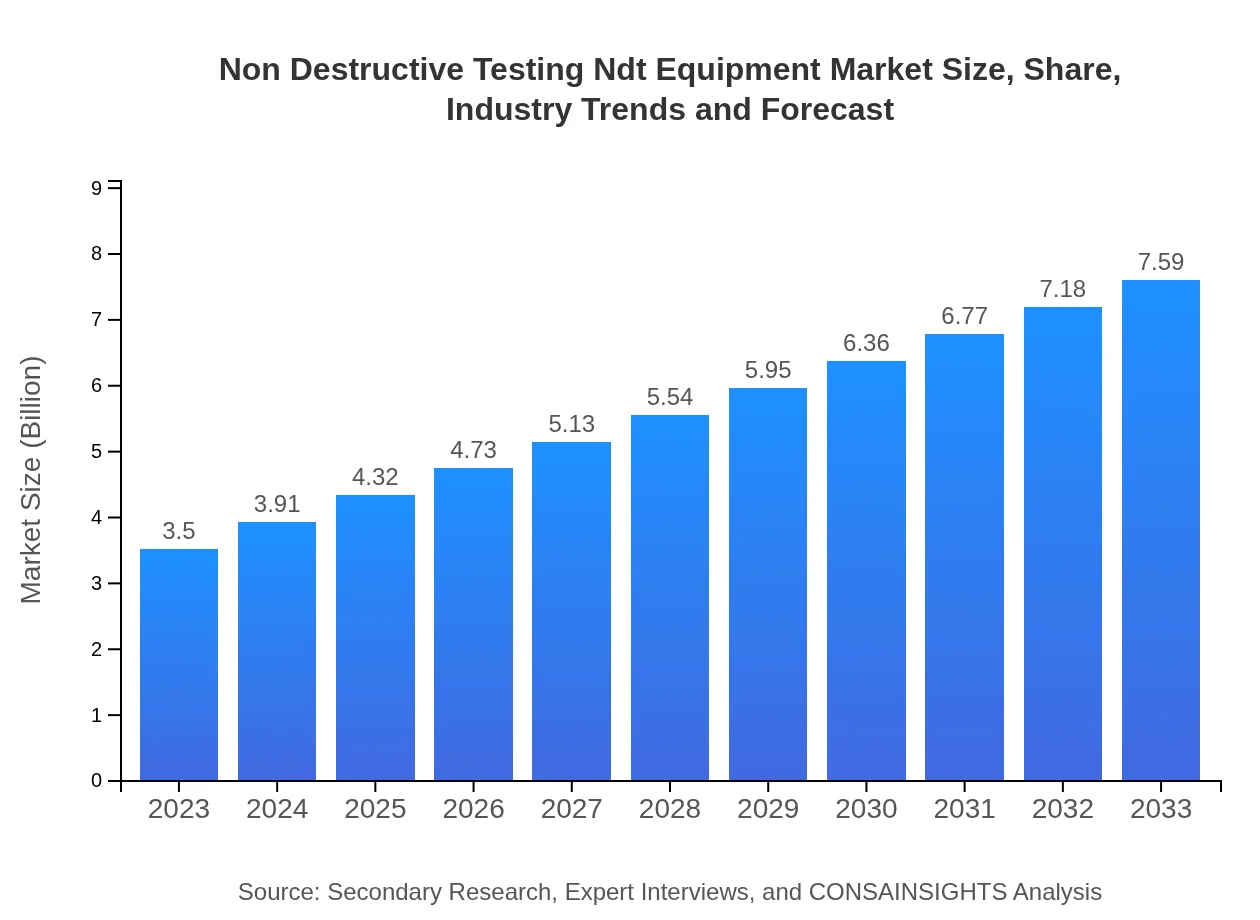

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 7.8% |

| 2033 Market Size | $7.59 Billion |

| Top Companies | General Electric (GE), Olympus Corporation, MTI Instruments, Filmetrics, Zetec |

| Last Modified Date | 31 January 2026 |

Non Destructive Testing Ndt Equipment Market Overview

Customize Non Destructive Testing Ndt Equipment Market Report market research report

- ✔ Get in-depth analysis of Non Destructive Testing Ndt Equipment market size, growth, and forecasts.

- ✔ Understand Non Destructive Testing Ndt Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Non Destructive Testing Ndt Equipment

What is the Market Size & CAGR of Non Destructive Testing Ndt Equipment market in 2023?

Non Destructive Testing Ndt Equipment Industry Analysis

Non Destructive Testing Ndt Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Non Destructive Testing Ndt Equipment Market Analysis Report by Region

Europe Non Destructive Testing Ndt Equipment Market Report:

In Europe, the market is projected to expand from $0.99 billion in 2023 to $2.15 billion by 2033. The region's stringent safety and quality regulations in industries like aerospace and automotive promote the use of NDT technology. Furthermore, increased research initiatives focusing on developing advanced testing methods play a crucial role in market growth.Asia Pacific Non Destructive Testing Ndt Equipment Market Report:

In the Asia-Pacific region, the NDT equipment market is projected to grow from $0.70 billion in 2023 to $1.53 billion by 2033, driven by rapid industrialization, increased investment in infrastructure, and the growing aerospace sector. Countries like China and India are focusing on enhancing their manufacturing capabilities, which elevates the demand for efficient NDT solutions.North America Non Destructive Testing Ndt Equipment Market Report:

North America dominates the global NDT equipment market, estimated at $1.20 billion in 2023, with a forecast to reach $2.60 billion by 2033. The region is characterized by advanced technological adoption, rigorous safety regulations, and high demand from aerospace and automotive sectors, driving significant investments in innovative NDT solutions.South America Non Destructive Testing Ndt Equipment Market Report:

The South American market demonstrates growth potential, increasing from $0.30 billion in 2023 to $0.66 billion by 2033, owing to expanding oil and gas activities and the need for stringent inspection standards in construction projects. The emphasis on safety and compliance is expected to strengthen market growth in this region.Middle East & Africa Non Destructive Testing Ndt Equipment Market Report:

In the Middle East and Africa, the NDT equipment market is expected to grow from $0.30 billion in 2023 to $0.65 billion by 2033. This growth is supported by increasing investments in infrastructure development, oil exploration, and the need for compliance with international safety standards.Tell us your focus area and get a customized research report.

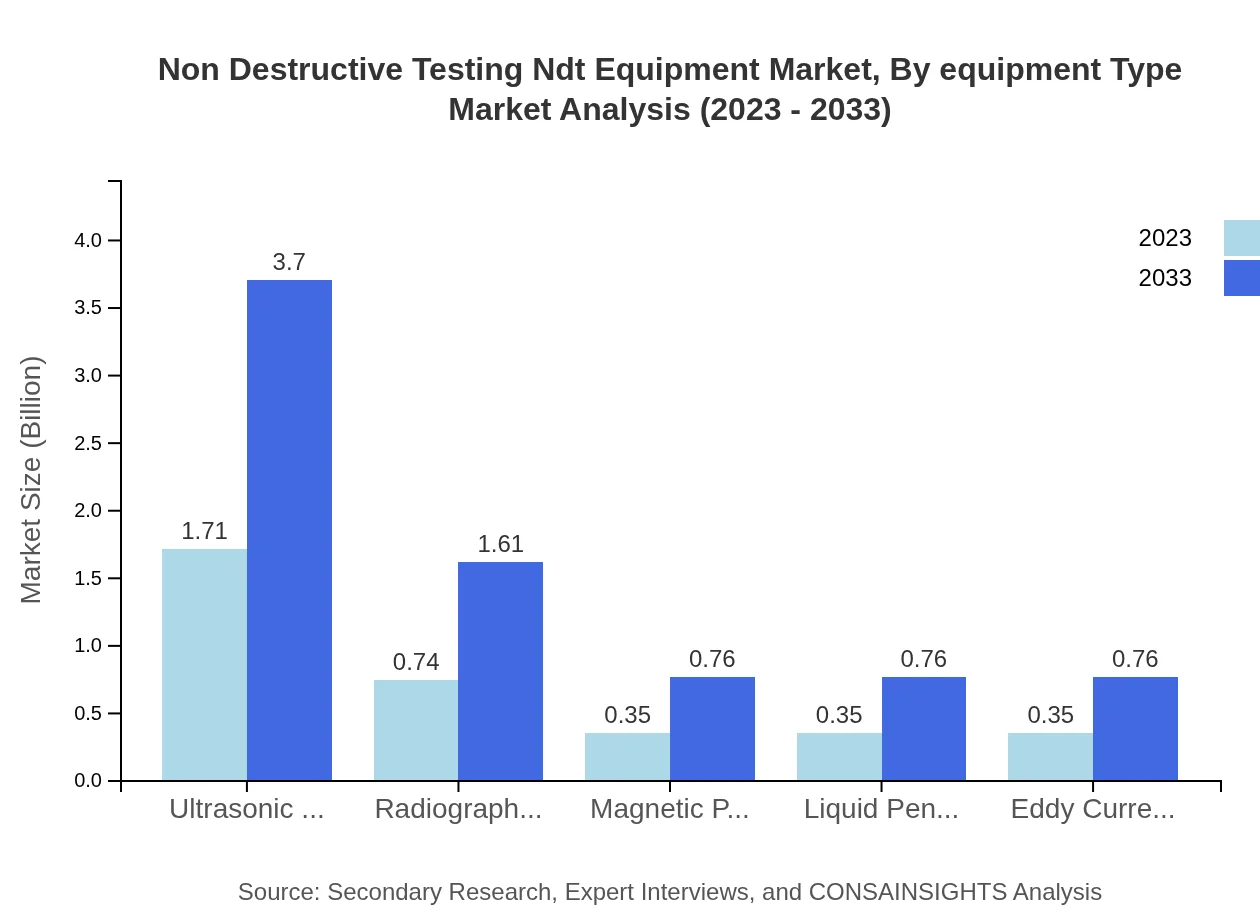

Non Destructive Testing Ndt Equipment Market Analysis By Equipment Type

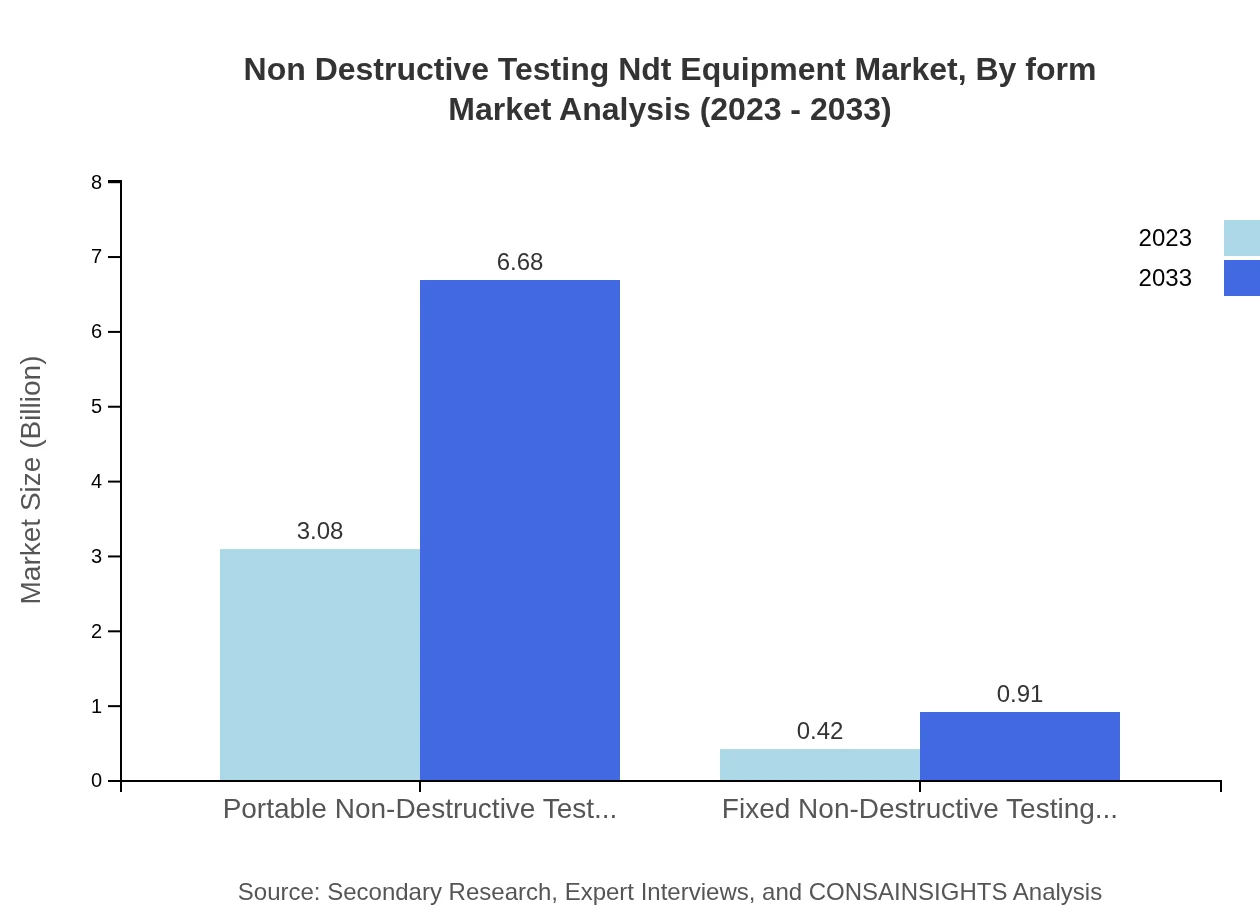

The Non-Destructive Testing Equipment market is primarily segmented by equipment type, with portable NDT equipment dominating the market, growing from $3.08 billion in 2023 to $6.68 billion by 2033. Fixed NDT equipment, while smaller in size, also shows growth, from $0.42 billion to $0.91 billion during the same period.

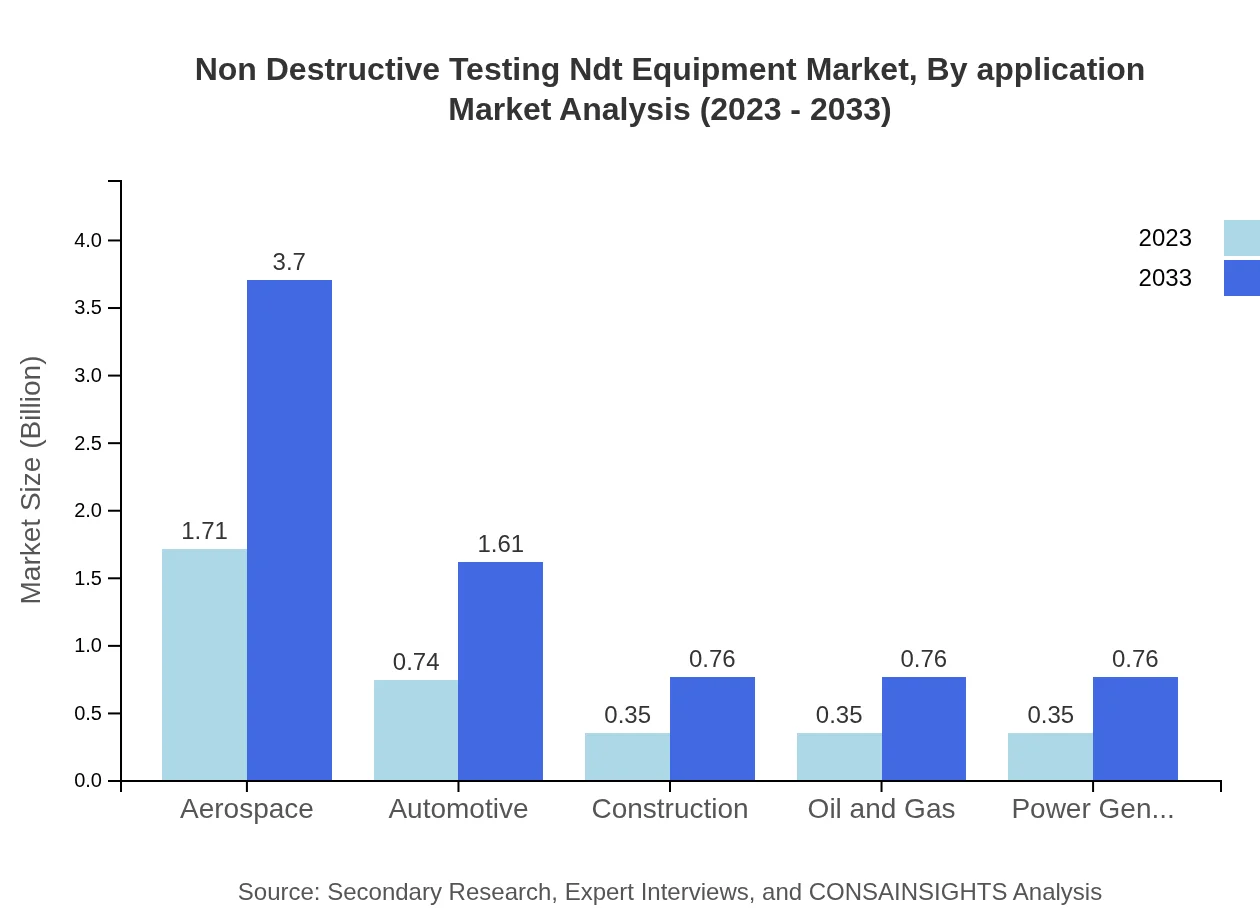

Non Destructive Testing Ndt Equipment Market Analysis By Application

Applications for NDT include manufacturing, energy and utilities, healthcare, defense, and aerospace. Manufacturing leads, holding substantial market share, while the healthcare sector's use of NDT techniques is on the rise due to stringent quality control measures required in medical device production.

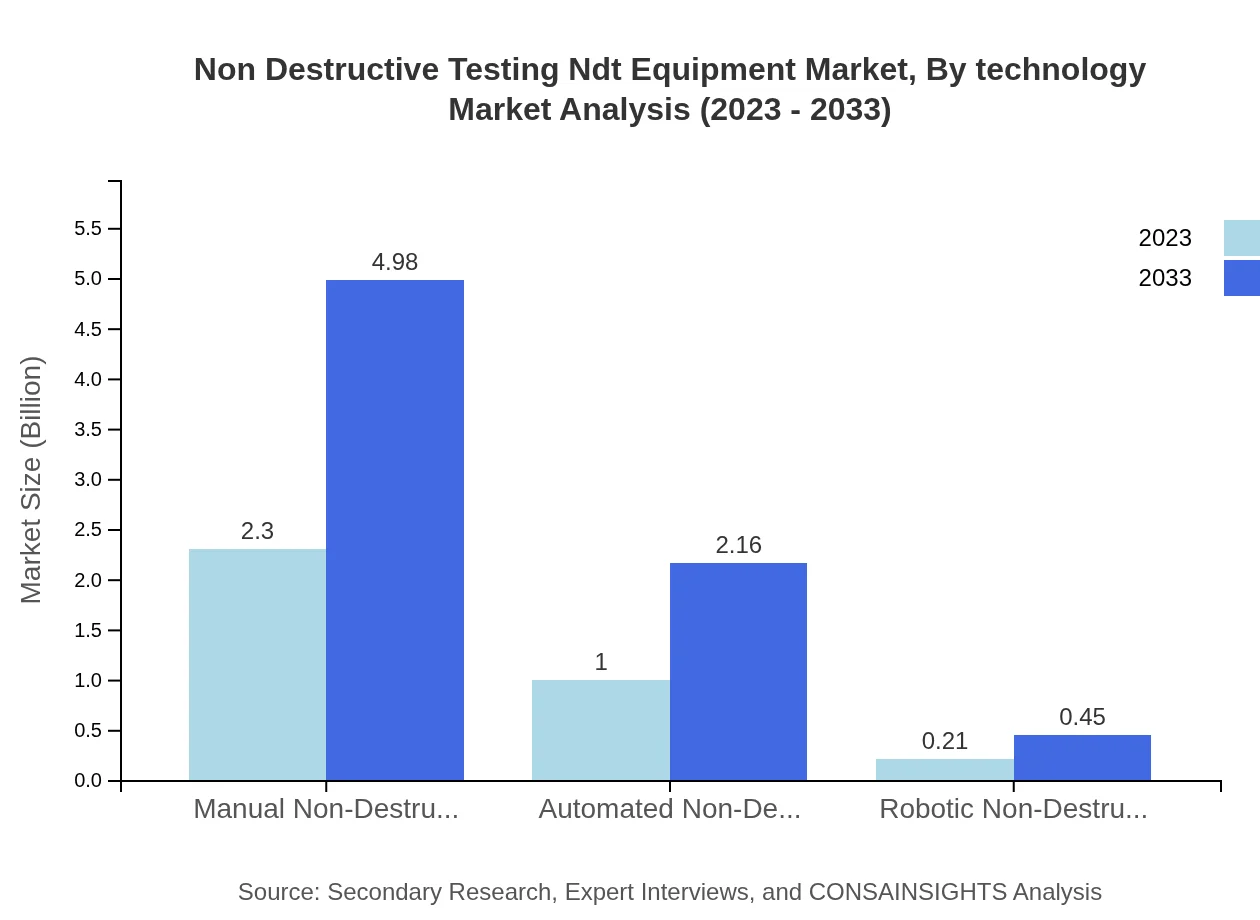

Non Destructive Testing Ndt Equipment Market Analysis By Technology

The market is segmented by technology into manual, automated, and robotic NDT systems. Manual techniques maintain a dominant share (65.59% in 2023), but automated and robotic solutions are rapidly gaining traction due to their efficiency and ability to perform complex inspections.

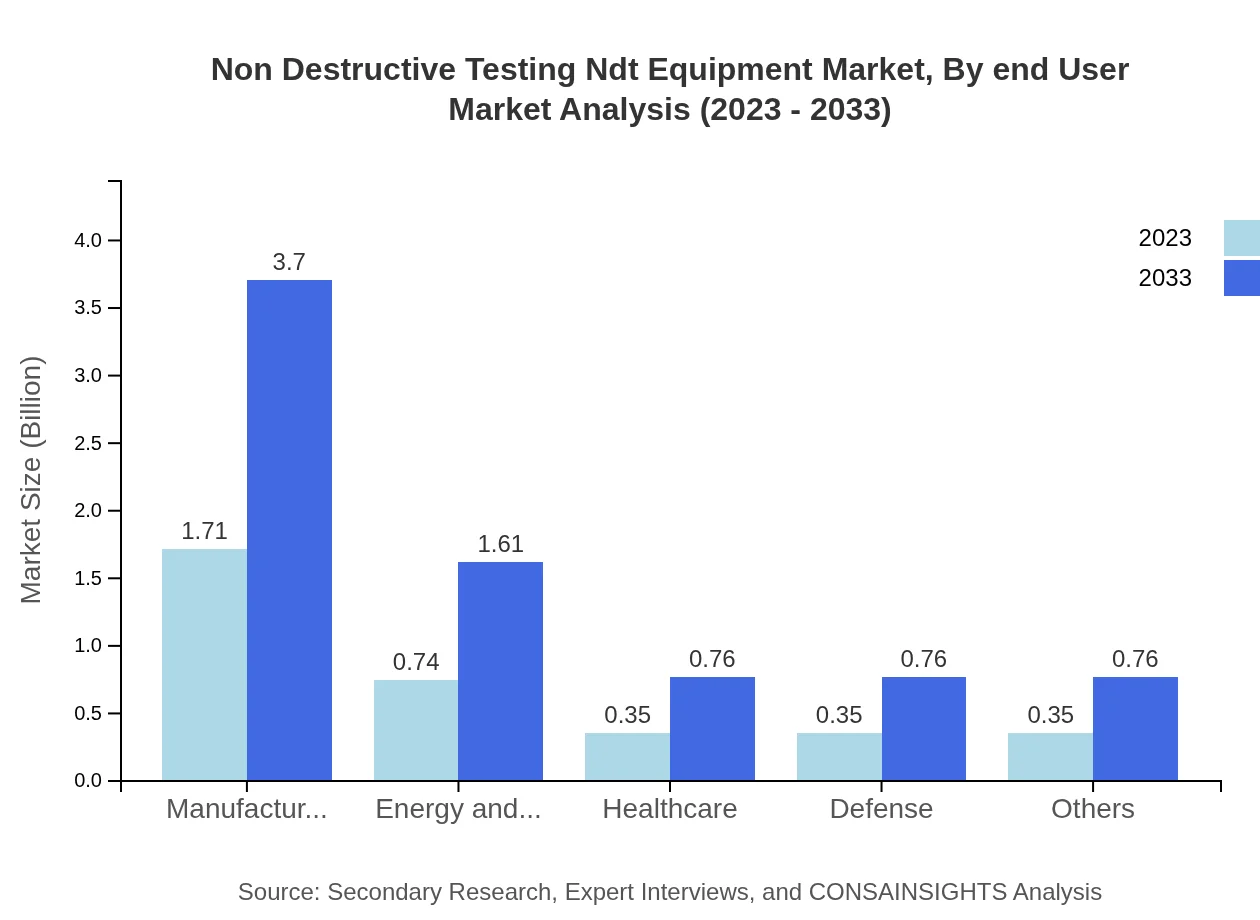

Non Destructive Testing Ndt Equipment Market Analysis By End User

End-user industries for NDT equipment include aerospace, automotive, construction, and oil & gas. The aerospace sector commands a large share of the market, necessitated by strict safety certifications, while oil & gas increasingly invests in NDT to enhance safety and operational efficiency.

Non Destructive Testing Ndt Equipment Market Analysis By Form

NDT equipment forms range from portable handheld devices to sophisticated fixed systems. Portable equipment enjoys the highest market share due to its versatility and ease of use in various inspection environments.

Non Destructive Testing Ndt Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Non Destructive Testing Ndt Equipment Industry

General Electric (GE):

GE is a leading player in the NDT equipment market, offering advanced ultrasonic and electromagnetic testing solutions tailored for various industries including aerospace, automotive, and healthcare.Olympus Corporation:

Olympus specializes in innovative NDT technologies, known for their high-performance ultrasonic testing and endoscopic inspection equipment, catering primarily to the manufacturing sector.MTI Instruments:

MTI Instruments provides precision measurement and NDT solutions, focusing on offering reliable and efficient equipment designed for rigorous industrial applications.Filmetrics:

Filmetrics focuses on optical measurement and NDT applications, providing technologies that support the measurement of thin films in various industries, including semiconductor and flat-panel display manufacturing.Zetec:

Zetec is a key provider of advanced NDT solutions, delivering high-performance systems for critical applications in energy and aerospace sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of non Destructive Testing Ndt Equipment?

The non-destructive testing (NDT) equipment market is valued at approximately $3.5 billion in 2023, with a projected Compound Annual Growth Rate (CAGR) of 7.8% through 2033. This growth reflects increasing demand across various industries.

What are the key market players or companies in the non Destructive Testing Ndt Equipment industry?

Key players in the non-destructive testing equipment industry include established companies such as Olympus Corporation, GE Measurement & Control Solutions, Karl Deutsch GmbH, and SGS S.A. Their innovation and market presence significantly shape industry trends.

What are the primary factors driving the growth in the non Destructive Testing Ndt Equipment industry?

Primary growth factors include increased safety regulations in industries such as aerospace and automotive, the rising importance of preventive maintenance in operations, and technological advancements in NDT techniques ensuring accuracy and reliability.

Which region is the fastest Growing in the non Destructive Testing Ndt Equipment?

Asia Pacific represents the fastest-growing region in the NDT equipment market, with expected growth from $0.70 billion in 2023 to $1.53 billion in 2033, driven by rapid industrialization and investments in infrastructure.

Does ConsaInsights provide customized market report data for the non Destructive Testing Ndt Equipment industry?

Yes, ConsaInsights offers tailored market reports for the non-destructive testing equipment industry. Clients can request customized analyses to meet specific business needs and strategic objectives tailored to their operational contexts.

What deliverables can I expect from this non Destructive Testing Ndt Equipment market research project?

Deliverables include comprehensive market analysis, detailed segmentation data, trends and forecasts, competitive landscapes, and insights into regional markets, which will provide actionable strategies to enhance market positioning.

What are the market trends of non Destructive Testing Ndt Equipment?

Current market trends include increasing automation in testing processes, growing adoption of digital technologies, rising demand for portable NDT equipment, and an emphasis on environmentally friendly testing solutions that drive operational efficiencies.