Non Woven Industrial Membrane Market Report

Published Date: 22 January 2026 | Report Code: non-woven-industrial-membrane

Non Woven Industrial Membrane Market Size, Share, Industry Trends and Forecast to 2033

This report delves into the Non Woven Industrial Membrane market, providing in-depth insights into market dynamics, size estimations, segmentation, key trends, and regional analysis from 2023 to 2033.

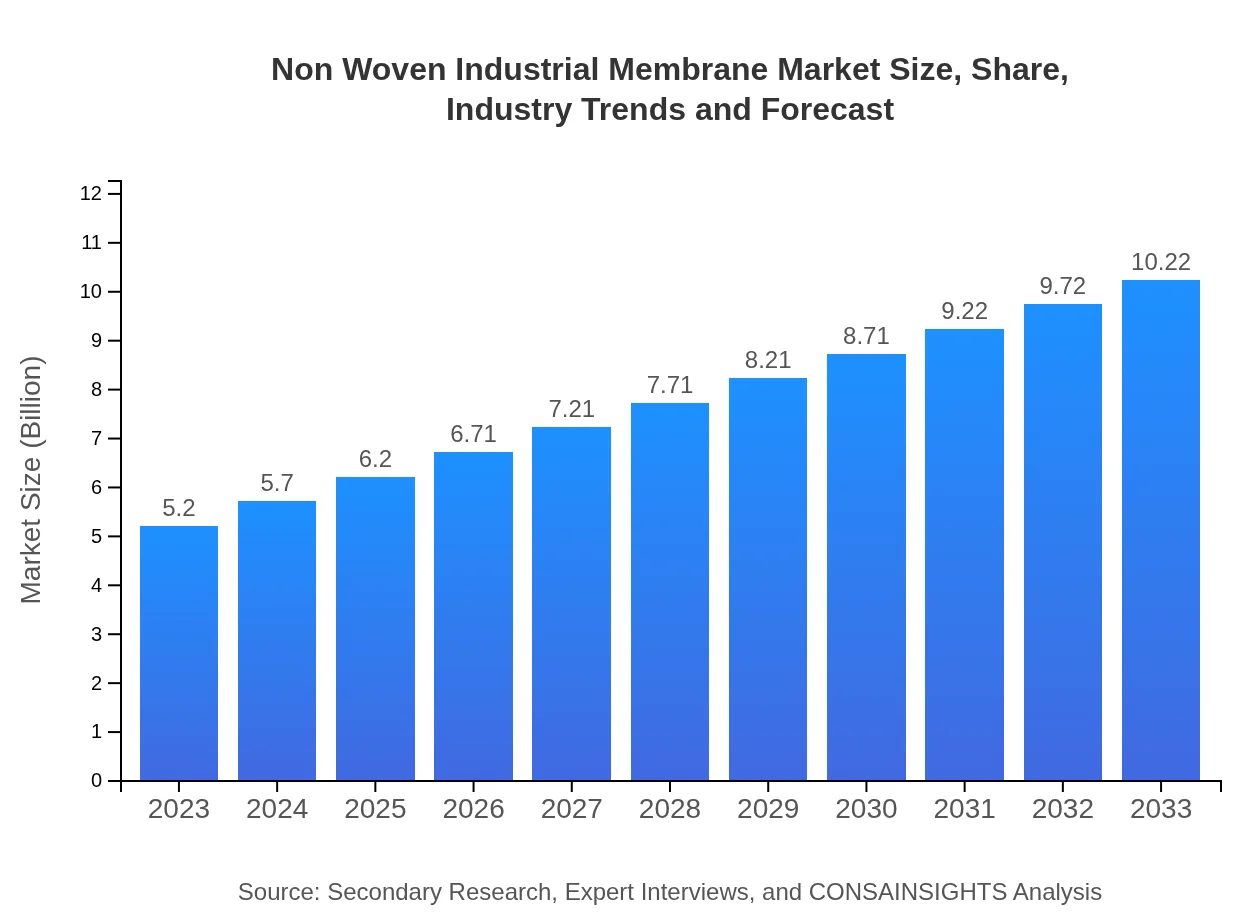

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.20 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $10.22 Billion |

| Top Companies | Freudenberg Group, Ahlstrom-Munksjö, Berry Global |

| Last Modified Date | 22 January 2026 |

Non Woven Industrial Membrane Market Overview

Customize Non Woven Industrial Membrane Market Report market research report

- ✔ Get in-depth analysis of Non Woven Industrial Membrane market size, growth, and forecasts.

- ✔ Understand Non Woven Industrial Membrane's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Non Woven Industrial Membrane

What is the Market Size & CAGR of Non Woven Industrial Membrane market in 2023?

Non Woven Industrial Membrane Industry Analysis

Non Woven Industrial Membrane Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Non Woven Industrial Membrane Market Analysis Report by Region

Europe Non Woven Industrial Membrane Market Report:

The European market for Non Woven Industrial Membrane is valued at $1.39 billion in 2023, set to double approximately to $2.74 billion by 2033. Adoption of stringent regulations and increasing awareness of environmental sustainability fuels the market's growth.Asia Pacific Non Woven Industrial Membrane Market Report:

In 2023, the Asia Pacific Non Woven Industrial Membrane market is valued at $1.09 billion, projected to grow to $2.13 billion by 2033. Rapid industrialization, coupled with increased construction activities across countries like China and India, drives market expansion.North America Non Woven Industrial Membrane Market Report:

North America holds a significant position in the Non Woven Industrial Membrane market with an estimated value of $1.86 billion in 2023 and expected growth to $3.65 billion by 2033, driven by increasing regulations promoting the use of non-woven products.South America Non Woven Industrial Membrane Market Report:

The South American market, valued at $0.21 billion in 2023, is estimated to reach $0.41 billion by 2033. Growing investments in infrastructure and the rise of environmentally friendly products contribute to market growth in this region.Middle East & Africa Non Woven Industrial Membrane Market Report:

Valued at $0.66 billion in 2023, the Middle East and Africa market is projected to grow to $1.29 billion by 2033. The rising demand for filtration products and improved construction techniques enhances market potential in this region.Tell us your focus area and get a customized research report.

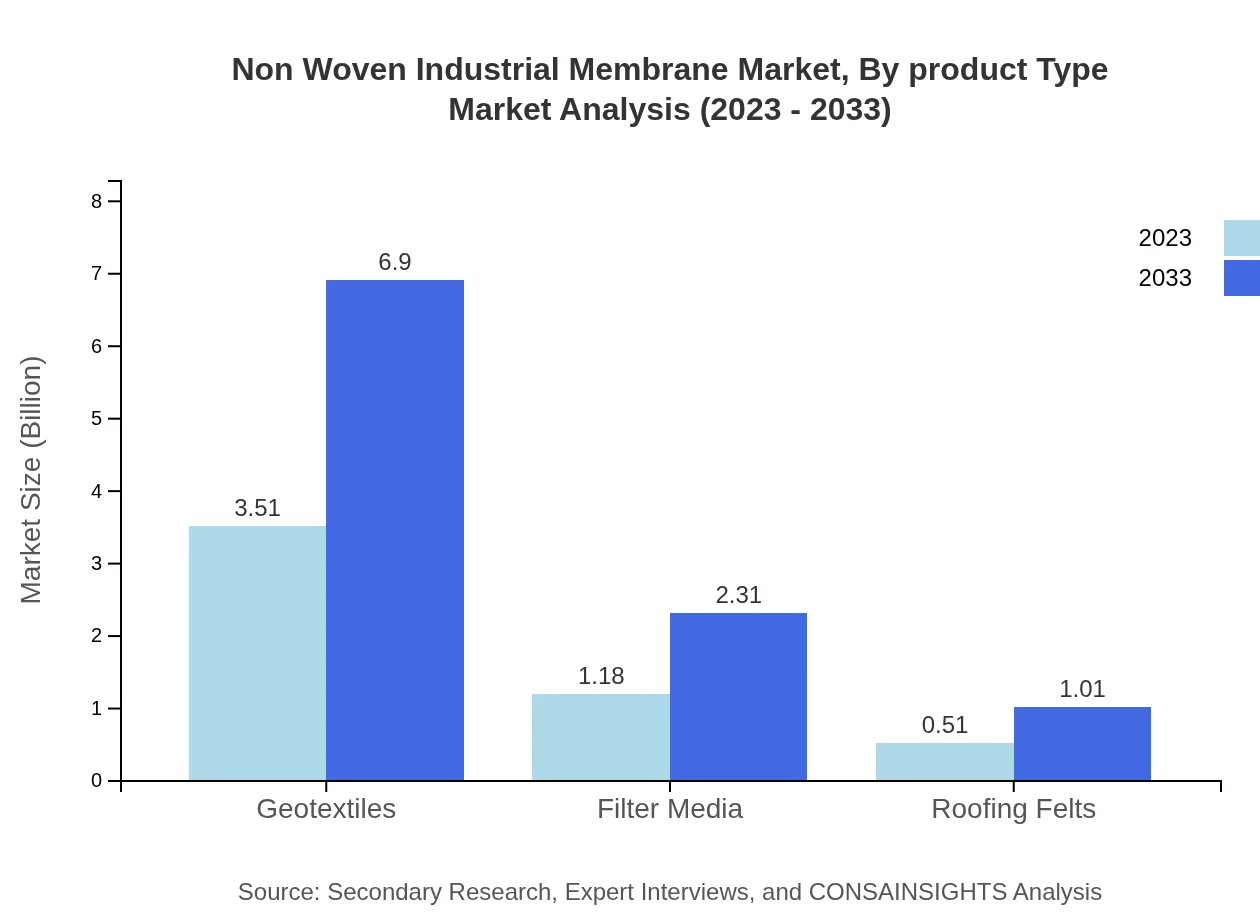

Non Woven Industrial Membrane Market Analysis By Product Type

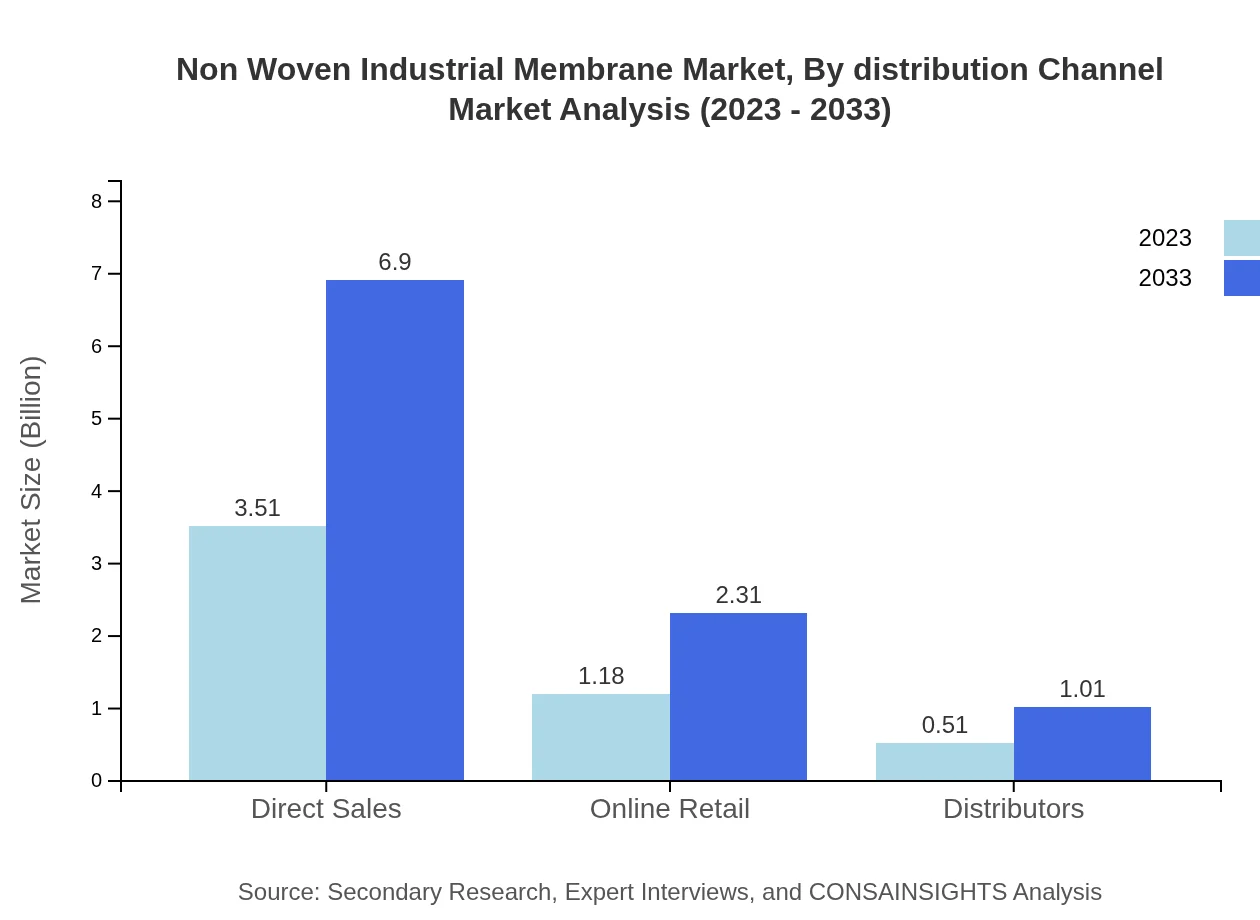

The Non-Woven Industrial Membrane market by product type, including spunbond, meltblown, and composite, reflects significant performance. Spunbond accounts for a market size of $3.51 billion in 2023, expected to rise to $6.90 billion by 2033, due to its extensive use across various applications.

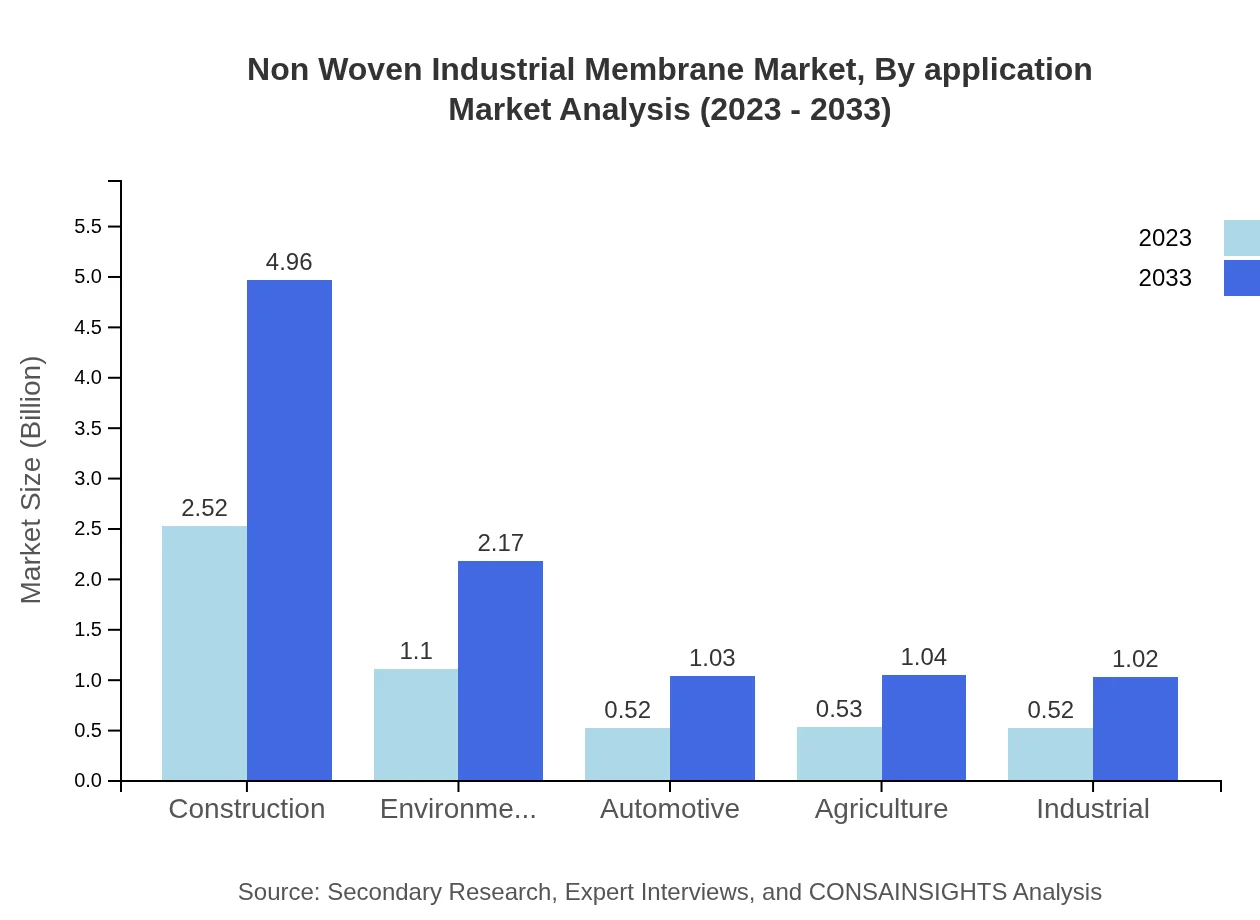

Non Woven Industrial Membrane Market Analysis By Application

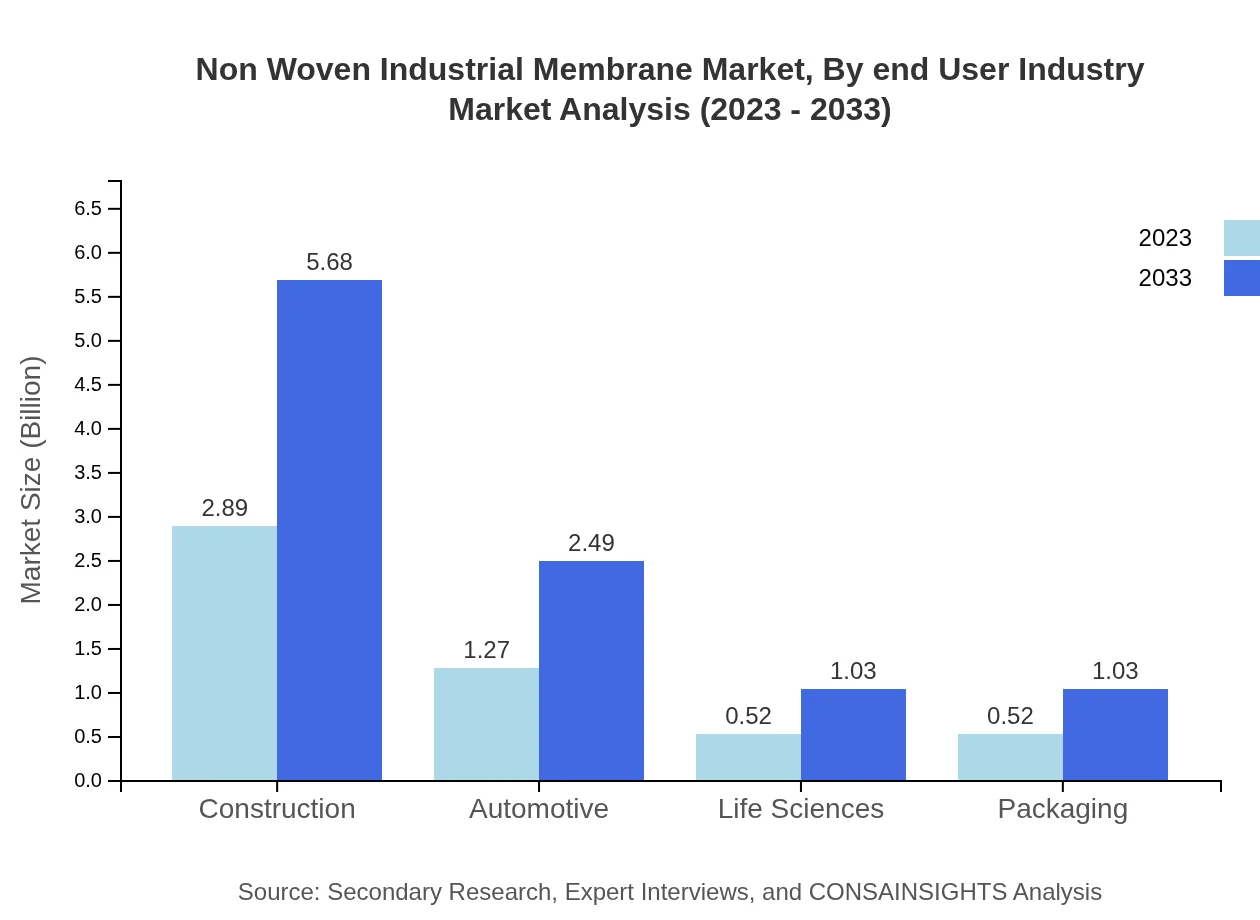

Applications such as construction, automotive, and agriculture represent key segments in this market. The construction segment leads with a size of $2.89 billion in 2023, predicted to grow to $5.68 billion by 2033, highlighting its vital role in enhancing building efficiency.

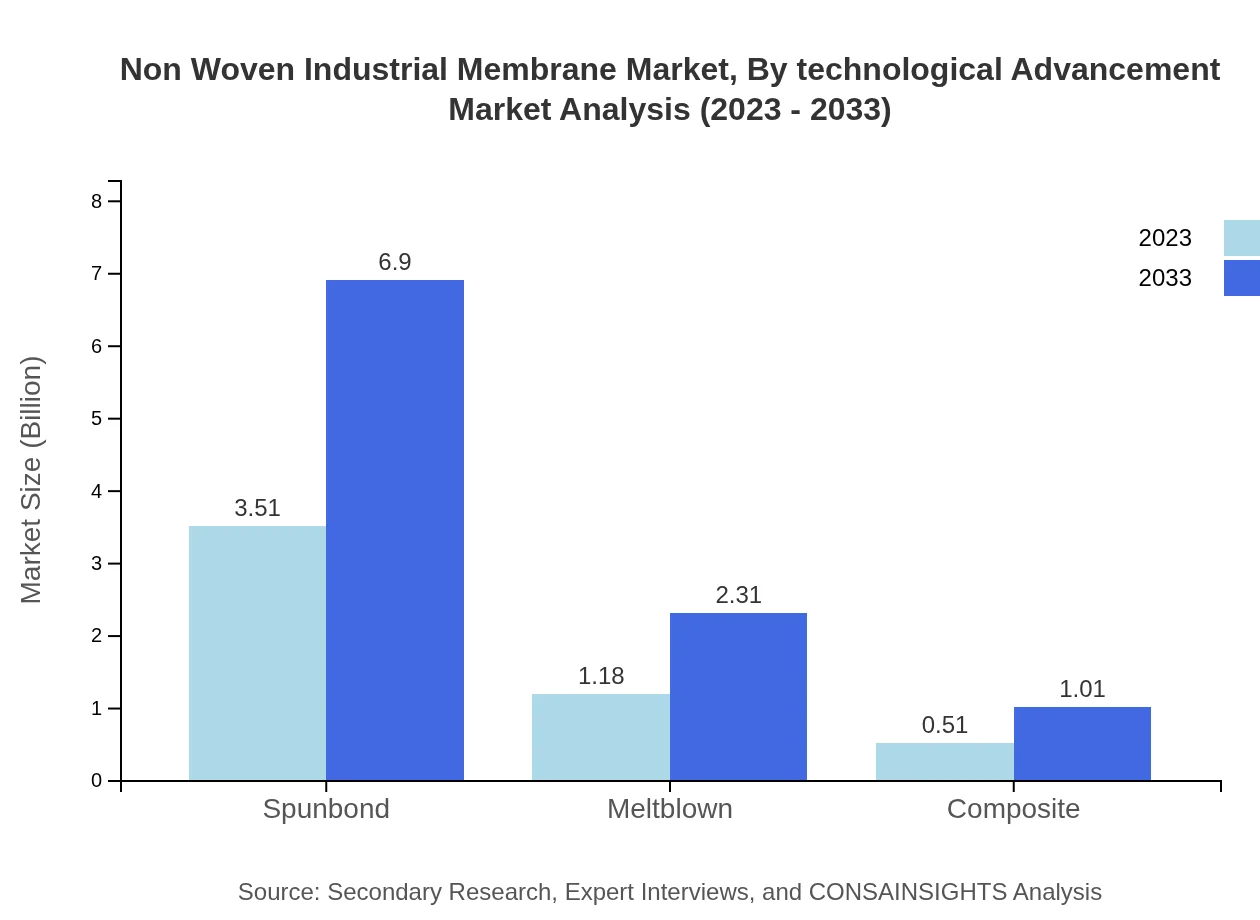

Non Woven Industrial Membrane Market Analysis By Technological Advancement

Technological advancements play a crucial role in product innovation and efficiency. Emerging technologies such as automation in manufacturing and advanced polymer processing are likely to enhance product performance and sustainability, thereby expanding the market.

Non Woven Industrial Membrane Market Analysis By End User Industry

Key end-user industries such as construction, automotive, and agriculture are pivotal in market dynamics. The construction sector alone holds a major share with a projection of $4.96 billion by 2033, showcasing the indispensable nature of non-woven membranes in modern construction.

Non Woven Industrial Membrane Market Analysis By Distribution Channel

Distribution channels, including direct sales, online retail, and distributors, drive market access. Direct sales dominate the landscape, accounting for 67.49% in 2023, with expectations to remain steady through 2033, supporting the wider distribution of non-woven products.

Non Woven Industrial Membrane Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Non Woven Industrial Membrane Industry

Freudenberg Group:

A leading global supplier of non-woven fabrics, Freudenberg Group specializes in developing innovative and high-quality industrial membranes for multiple applications.Ahlstrom-Munksjö:

Known for producing technically advanced non-woven materials, Ahlstrom-Munksjö leads the market with a strong focus on sustainability and resource efficiency.Berry Global:

Berry Global is a major player in the non-woven market, recognized for its comprehensive product portfolio and significant contributions to the automotive and healthcare sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of non Woven industrial membrane?

The global non-woven industrial membrane market is valued at approximately $5.2 billion in 2023 and is projected to reach substantial growth with a CAGR of about 6.8% up to 2033, indicating heightened demand and sector expansion.

What are the key market players or companies in the non Woven industrial membrane industry?

Key players in the non-woven industrial membrane market include well-established companies such as Berry Global, Freudenberg Group, and Ahlstrom-Munksjö. These organizations play significant roles in advancing technology and product development in the sector.

What are the primary factors driving the growth in the non Woven industrial membrane industry?

Growth in the non-woven industrial membrane industry is driven by increasing applications in construction, environmental management, and automotive sectors. Moreover, technological advancements and rising awareness regarding sustainable materials contribute significantly to market expansion.

Which region is the fastest Growing in the non Woven industrial membrane?

The fastest-growing region for non-woven industrial membranes is North America, with a market size projected to grow from $1.86 billion in 2023 to $3.65 billion by 2033. This is followed closely by Europe, where the market size is expected to increase from $1.39 billion to $2.74 billion during the same period.

Does ConsaInsights provide customized market report data for the non Woven industrial membrane industry?

Yes, ConsaInsights offers customized market reports tailored to specific client requirements in the non-woven industrial membrane industry. This enables clients to gain precise insights and strategic recommendations based on their needs.

What deliverables can I expect from this non Woven industrial membrane market research project?

From the non-woven industrial membrane market research project, you can expect comprehensive reports including market size analysis, growth forecasts, competitive landscape assessments, and segmented market insights that illuminate key trends and dynamics.

What are the market trends of non Woven industrial membrane?

Current market trends in the non-woven industrial membrane industry include a shift towards eco-friendly materials, increasing investment in high-tech manufacturing processes, and a growing emphasis on product innovation across diverse applications like geotextiles and automotive components.