Optical Coordinate Measuring Machine Market Report

Published Date: 31 January 2026 | Report Code: optical-coordinate-measuring-machine

Optical Coordinate Measuring Machine Market Size, Share, Industry Trends and Forecast to 2033

This report delivers comprehensive insights into the Optical Coordinate Measuring Machine market, covering market size, growth forecasts, industry trends, and regional analysis for the period 2023 to 2033. It aims to provide key stakeholders with valuable data and projections for informed business decisions.

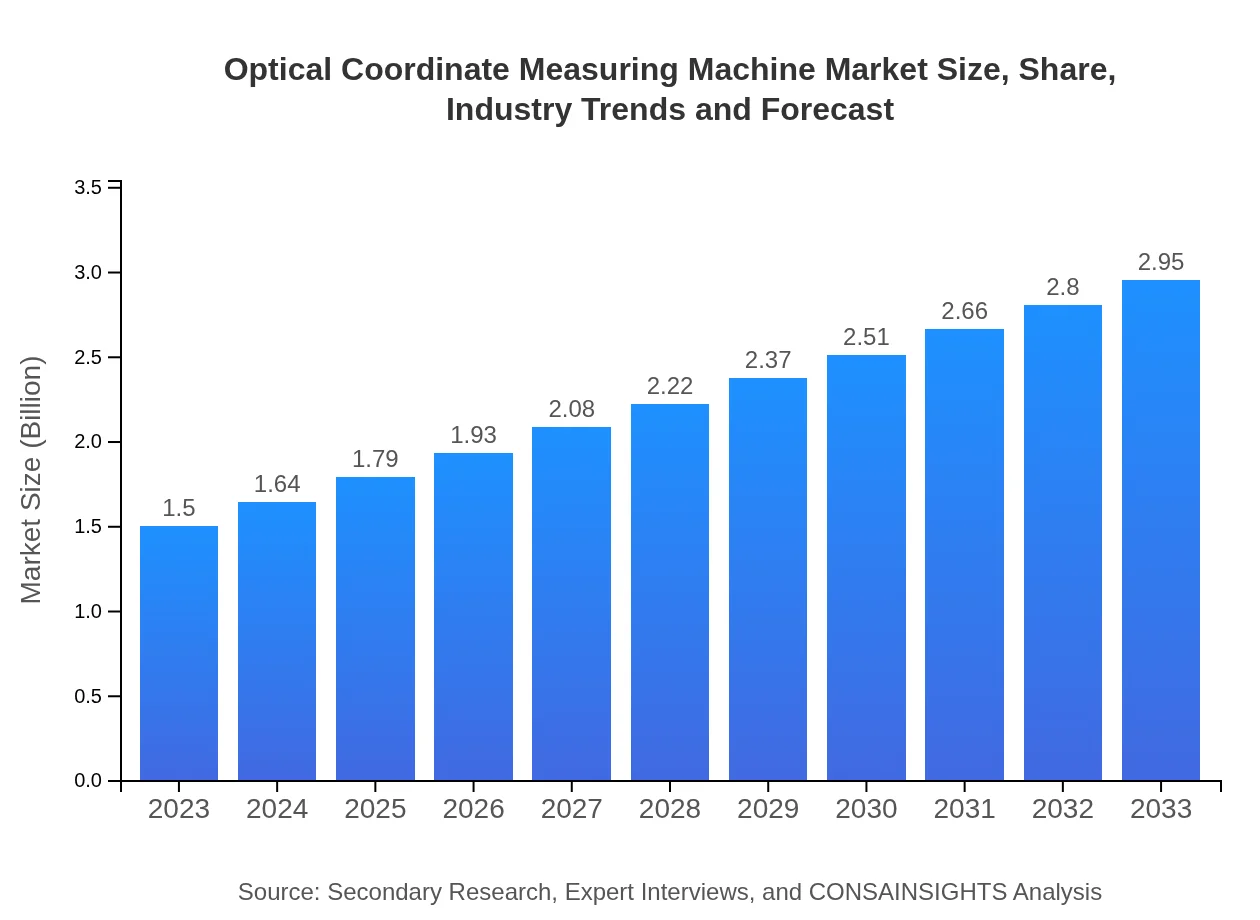

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $2.95 Billion |

| Top Companies | Renishaw PLC, Zeiss, Faro Technologies, Inc., Hexagon AB |

| Last Modified Date | 31 January 2026 |

Optical Coordinate Measuring Machine Market Overview

Customize Optical Coordinate Measuring Machine Market Report market research report

- ✔ Get in-depth analysis of Optical Coordinate Measuring Machine market size, growth, and forecasts.

- ✔ Understand Optical Coordinate Measuring Machine's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Optical Coordinate Measuring Machine

What is the Market Size & CAGR of Optical Coordinate Measuring Machine market in 2023?

Optical Coordinate Measuring Machine Industry Analysis

Optical Coordinate Measuring Machine Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Optical Coordinate Measuring Machine Market Analysis Report by Region

Europe Optical Coordinate Measuring Machine Market Report:

Europe is a significant market for Optical CMMs, projected to grow from $0.40 billion in 2023 to $0.78 billion by 2033. The region's focus on precision manufacturing especially in Germany and the UK, and stringent quality regulations are key factors driving this growth.Asia Pacific Optical Coordinate Measuring Machine Market Report:

The Asia Pacific region had a market size of $0.29 billion in 2023 and is projected to grow to $0.57 billion by 2033, driven by booming manufacturing sectors in countries like China, Japan, and India. The demand for precision measuring technology is increasing in electronics and automotive sectors, facilitating significant investments in optical CMMs.North America Optical Coordinate Measuring Machine Market Report:

The North American market, valued at $0.56 billion in 2023, is set to expand to $1.10 billion by 2033. The presence of major manufacturers and a strong emphasis on technological advancements in industries such as aerospace, defense, and automotive contribute to robust market growth.South America Optical Coordinate Measuring Machine Market Report:

In South America, the Optical Coordinate Measuring Machine market is valued at $0.12 billion in 2023 with expectations to reach $0.23 billion by 2033. The gradual industrialization in Brazil and Argentina is paving the way for growth, particularly in automotive and consumer goods manufacturing segments.Middle East & Africa Optical Coordinate Measuring Machine Market Report:

In the Middle East and Africa, the market size is expected to increase from $0.13 billion in 2023 to $0.26 billion by 2033. The ongoing infrastructural developments and increasing investments in manufacturing capabilities in the UAE and South Africa are influencing market growth.Tell us your focus area and get a customized research report.

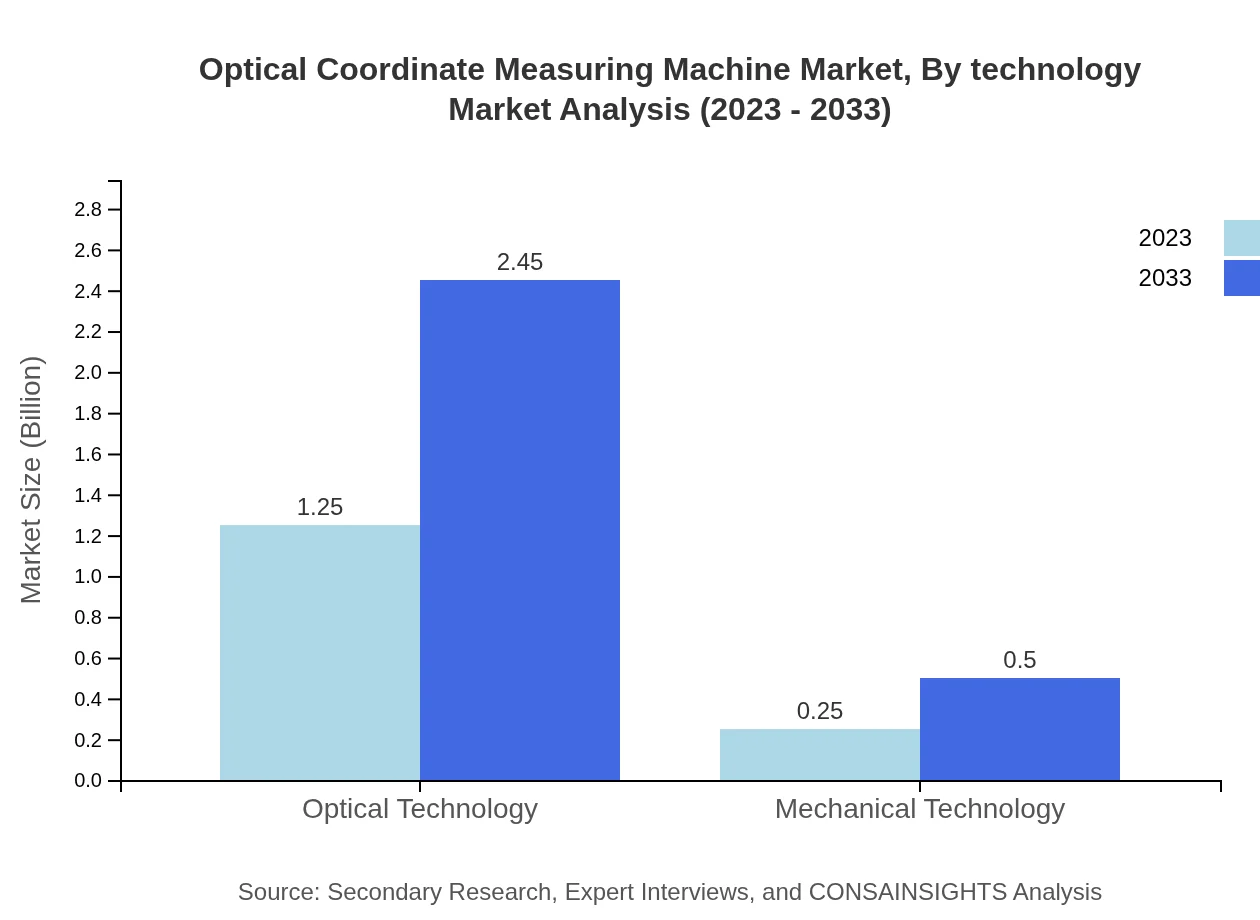

Optical Coordinate Measuring Machine Market Analysis By Technology

The Optical Coordinate Measuring Machine market by technology primarily consists of optical and mechanical technologies. As of 2023, optical technology dominates with a market share of 83.1%, valued at $1.25 billion, and is anticipated to grow to $2.45 billion by 2033. This growth can be attributed to the enhanced precision and accuracy optical CMMs provide, aligning with the industry demands for advanced measurement capabilities.

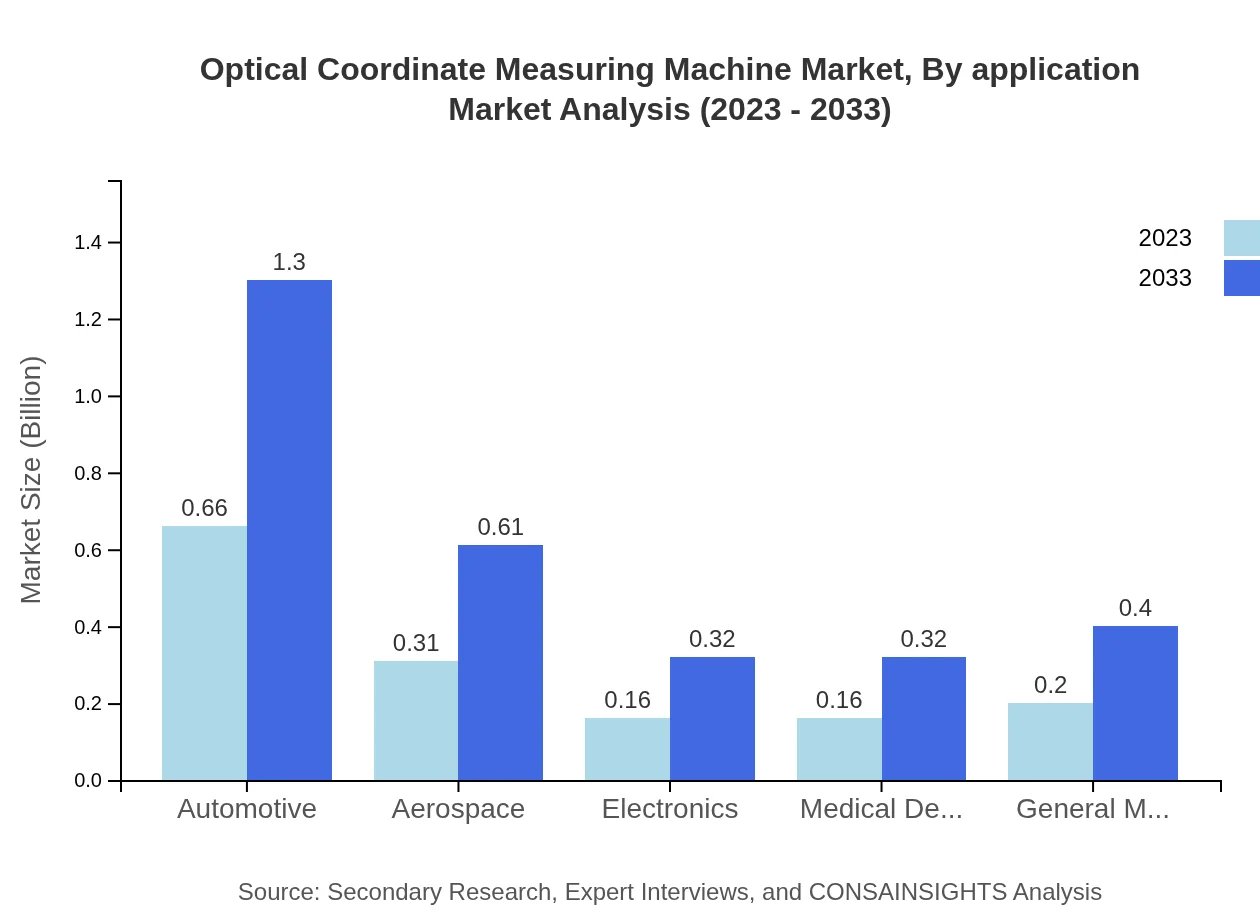

Optical Coordinate Measuring Machine Market Analysis By Application

Applications of Optical Coordinate Measuring Machines include automotive, aerospace, electronics, and medical device industries. The automotive segment leads with a market share of 44.09%, growing from $0.66 billion in 2023 to $1.30 billion by 2033, driven by increased mandates for quality assurance in automotive manufacturing.

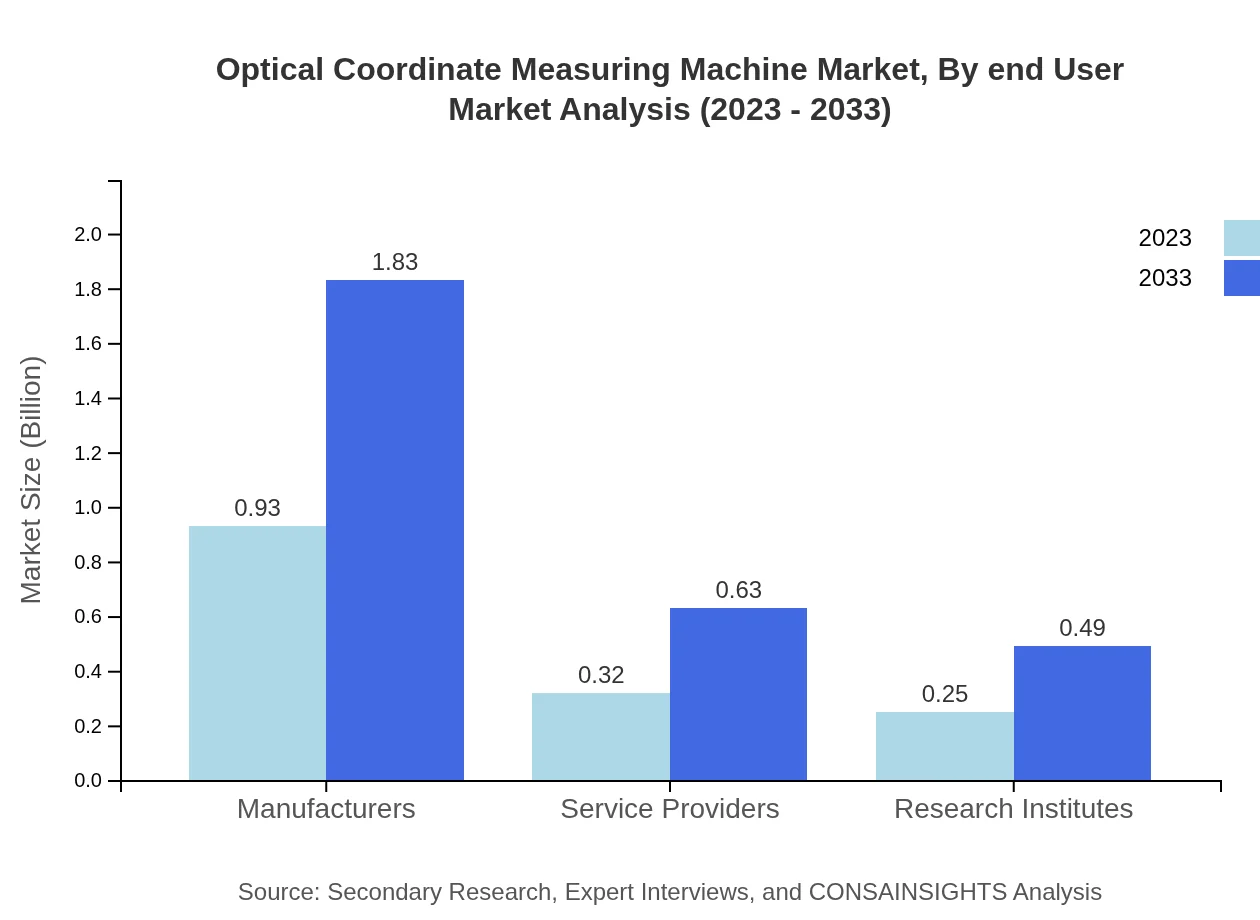

Optical Coordinate Measuring Machine Market Analysis By End User

The end-user market for Optical CMMs includes manufacturers, service providers, and research institutions. Manufacturers hold the largest share with a market size of $0.93 billion in 2023, growing to $1.83 billion by 2033, owing to their necessity in production lines where accuracy is paramount.

Optical Coordinate Measuring Machine Market Analysis By Product Type

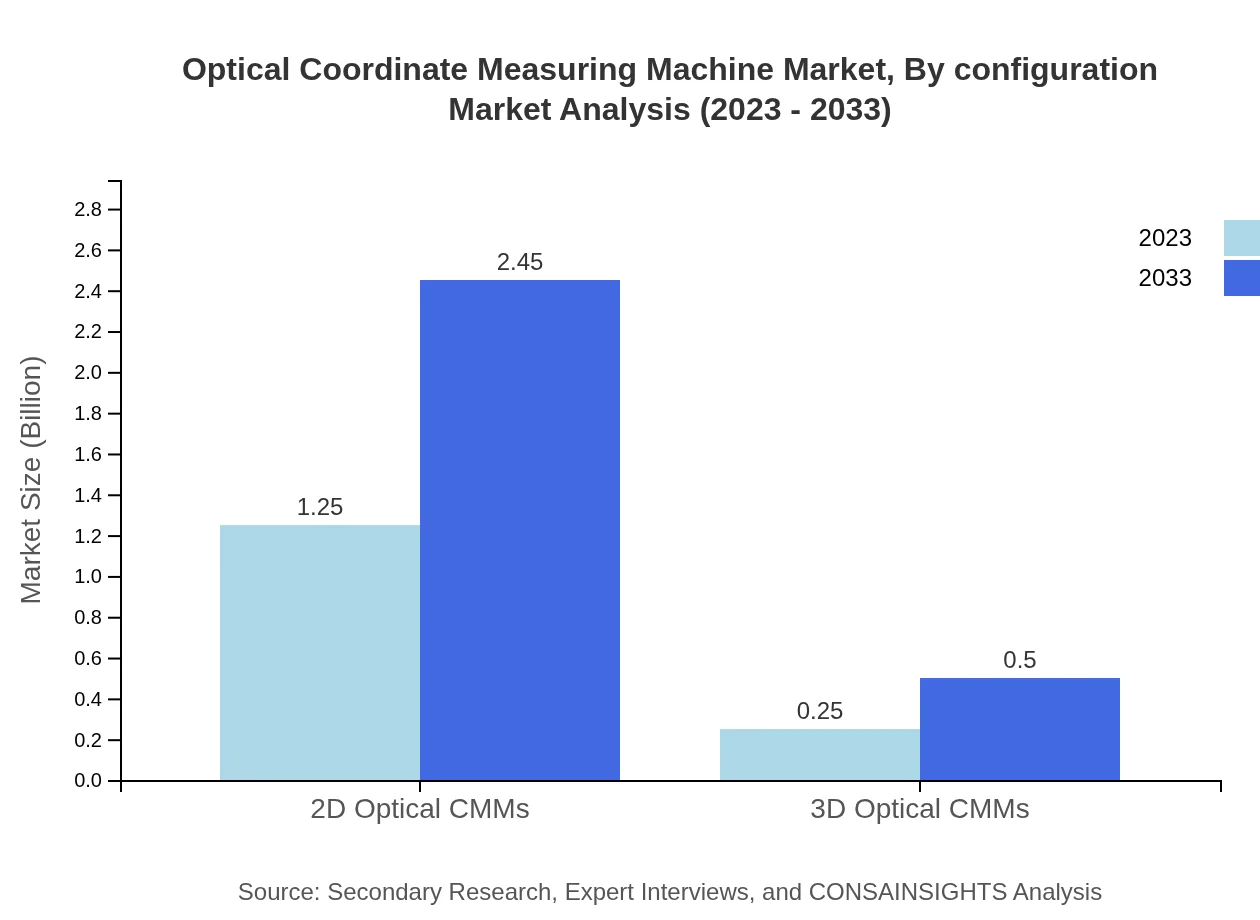

Product types within the Optical CMM market include 2D and 3D systems. 2D Optical CMMs capture the majority of the market share at 83.1% and are projected to see considerable growth, while 3D Optical CMMs, though smaller, are growing rapidly due to their evolving applications across industries.

Optical Coordinate Measuring Machine Market Analysis By Configuration

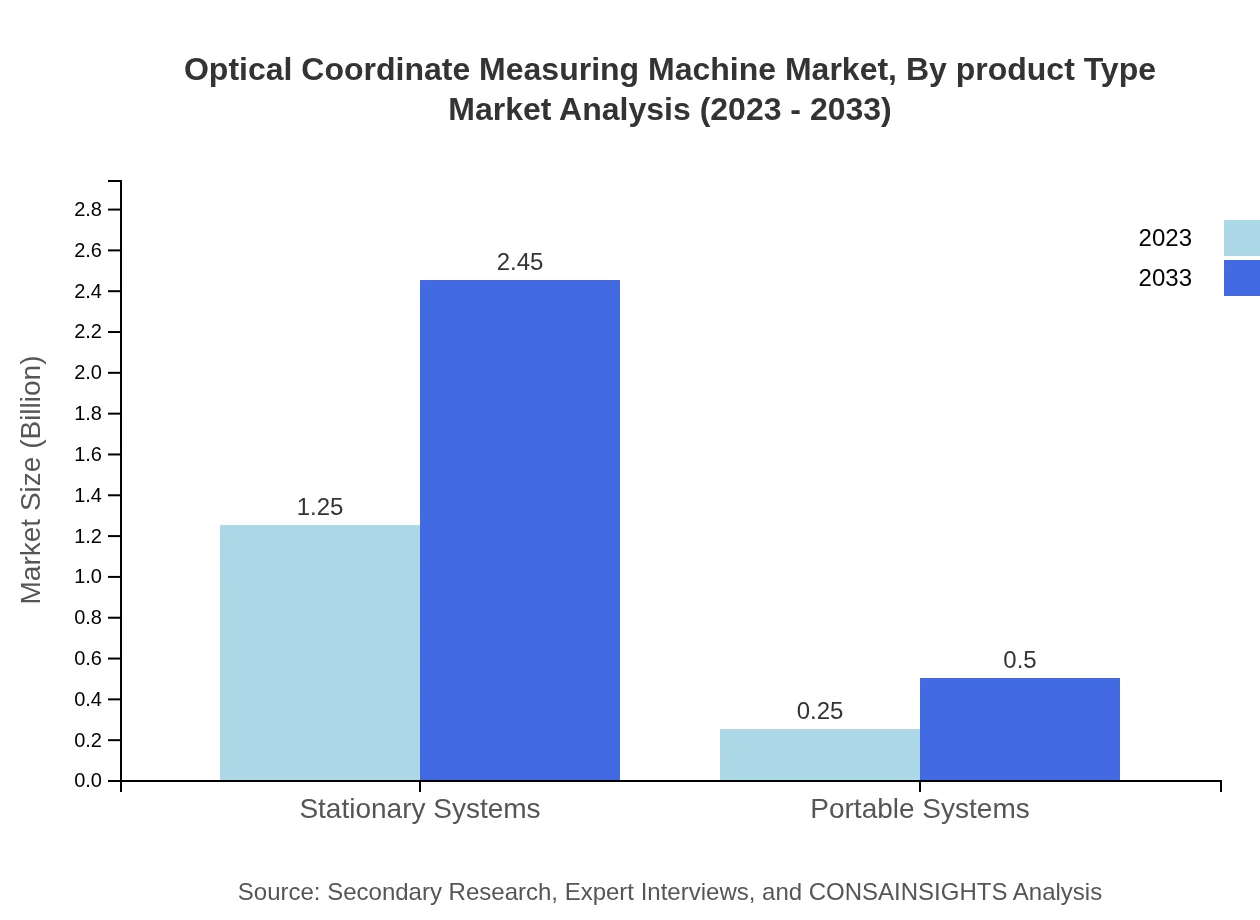

The market segmentation by configuration includes stationary and portable systems. Stationary systems currently dominate the market, catering to the need for high-volume and precision measurements in factories, while portable systems are gaining traction due to flexibility and on-site measurement capabilities.

Optical Coordinate Measuring Machine Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Optical Coordinate Measuring Machine Industry

Renishaw PLC:

Renishaw is a UK-based company that specializes in measurement and calibration systems, providing innovative solutions within the optical CMM market.Zeiss:

Carl Zeiss AG is a German manufacturer known for its advanced optical measurement technology, making substantial contributions to the precision measurement industry.Faro Technologies, Inc.:

FARO is a global leader in 3D measurement, imaging, and realization solutions, focusing on providing cutting-edge optical CMMs for various applications.Hexagon AB:

Hexagon offers a range of measurement technologies, including advanced optical CMMs, serving various industries with high precision and quality.We're grateful to work with incredible clients.

FAQs

What is the market size of optical Coordinate Measuring Machine?

The optical coordinate measuring machine market is projected to grow from approximately $1.5 billion in 2023 to significant values by 2033, with a CAGR of 6.8%. This growth reflects increasing demand in various manufacturing sectors.

What are the key market players or companies in this optical Coordinate Measuring Machine industry?

Key players in the optical coordinate measuring machine market include renowned manufacturers and innovative startups specializing in precision measurement technology. Companies are focusing on R&D to enhance measurement capabilities and expand their market presence.

What are the primary factors driving the growth in the optical Coordinate Measuring Machine industry?

Growth in the optical coordinate measuring machine industry is driven by advancements in manufacturing technologies, increasing demand for precision measurement in sectors such as automotive and aerospace, and the integration of automation in manufacturing processes.

Which region is the fastest Growing in the optical Coordinate Measuring Machine?

North America is the fastest-growing region in the optical coordinate measuring machine market, expected to grow from $0.56 billion in 2023 to $1.10 billion by 2033. This growth is fueled by high demand in automotive and aerospace sectors.

Does ConsaInsights provide customized market report data for the optical Coordinate Measuring Machine industry?

Yes, ConsaInsights offers customized market reports tailored to the specific needs of clients in the optical coordinate measuring machine industry, providing in-depth analysis and data to support strategic decision-making.

What deliverables can I expect from this optical Coordinate Measuring Machine market research project?

From the optical coordinate measuring machine market research project, you can expect comprehensive reports featuring market data, trends, competitive landscapes, and forecasts that enable strategic insights and enhance decision-making processes.

What are the market trends of optical Coordinate Measuring Machine?

Current trends in the optical coordinate measuring machine market include increasing automation, the rise of hybrid technology solutions integrating optical and traditional measuring methods, and growing demand for CMM systems in diverse applications spanning different industries.