Package Boilers Market Report

Published Date: 22 January 2026 | Report Code: package-boilers

Package Boilers Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Package Boilers market from 2023 to 2033, including market size, CAGR, regional insights, technological advancements, and industry trends that influence growth.

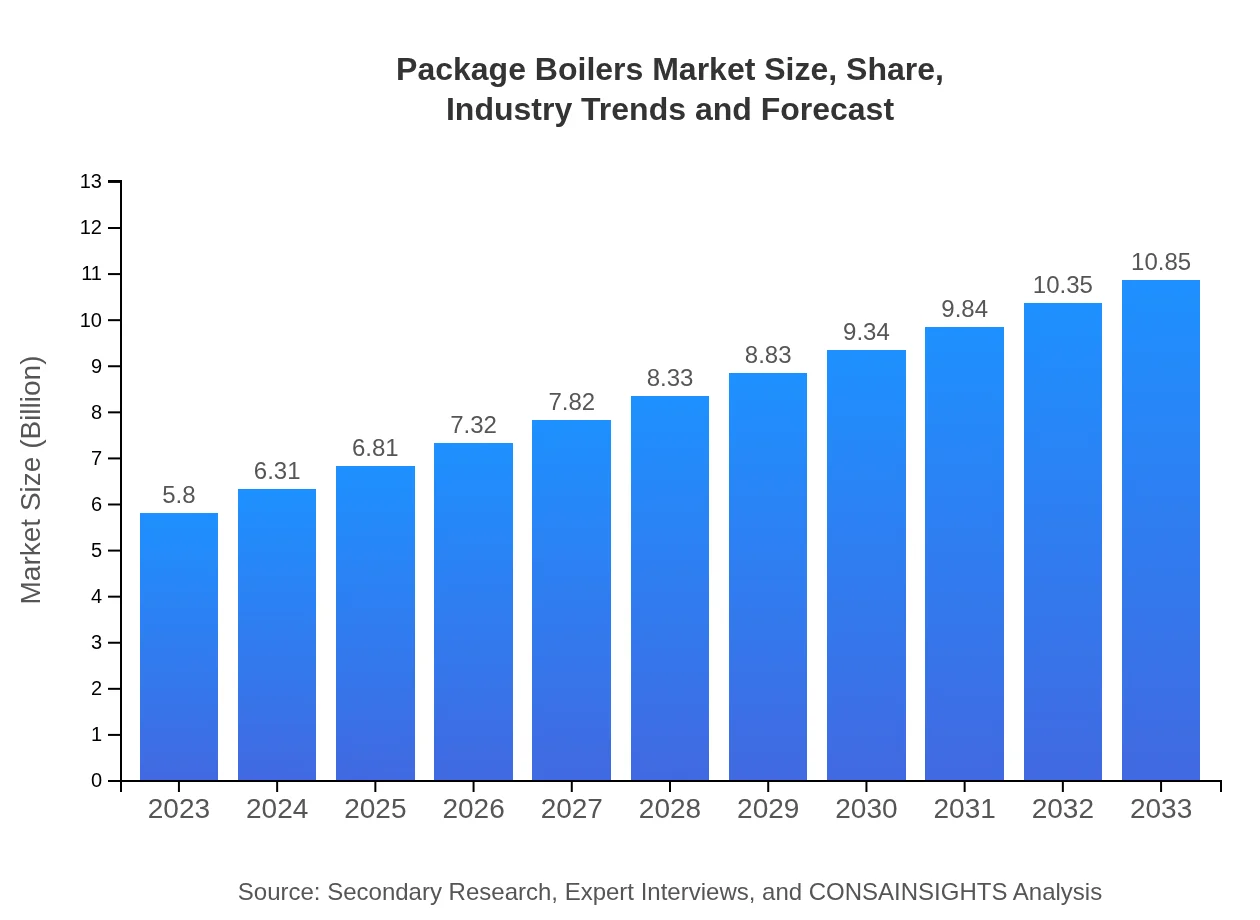

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.80 Billion |

| CAGR (2023-2033) | 6.3% |

| 2033 Market Size | $10.85 Billion |

| Top Companies | Bosch Industriekessel GmbH, Fulton, Thermal Solutions, Viessmann |

| Last Modified Date | 22 January 2026 |

Package Boilers Market Overview

Customize Package Boilers Market Report market research report

- ✔ Get in-depth analysis of Package Boilers market size, growth, and forecasts.

- ✔ Understand Package Boilers's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Package Boilers

What is the Market Size & CAGR of Package Boilers market in 2023?

Package Boilers Industry Analysis

Package Boilers Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Package Boilers Market Analysis Report by Region

Europe Package Boilers Market Report:

Europe's market size is expected to nearly double from $1.44 billion in 2023 to $2.69 billion by 2033, spurred by regulations targeting emissions reduction and shifts toward renewable energy sources.Asia Pacific Package Boilers Market Report:

Asia Pacific holds a substantial market share with a projected market size of $2.09 billion by 2033, driven by rapid industrialization and urbanization. China, India, and Japan are primary contributors, implementing sustainable practices and new technologies.North America Package Boilers Market Report:

In North America, the market size will rise from $2.23 billion in 2023 to approximately $4.18 billion by 2033, thanks to technological advancements and increasing investments in energy efficiency.South America Package Boilers Market Report:

South America's market is expected to grow from $0.54 billion in 2023 to $1.01 billion in 2033, as economies focus on modernizing infrastructure and meeting energy demands sustainably.Middle East & Africa Package Boilers Market Report:

The Middle East and Africa are anticipated to grow from a market size of $0.47 billion in 2023 to $0.89 billion by 2033, driven by evolving energy demands and infrastructural developments.Tell us your focus area and get a customized research report.

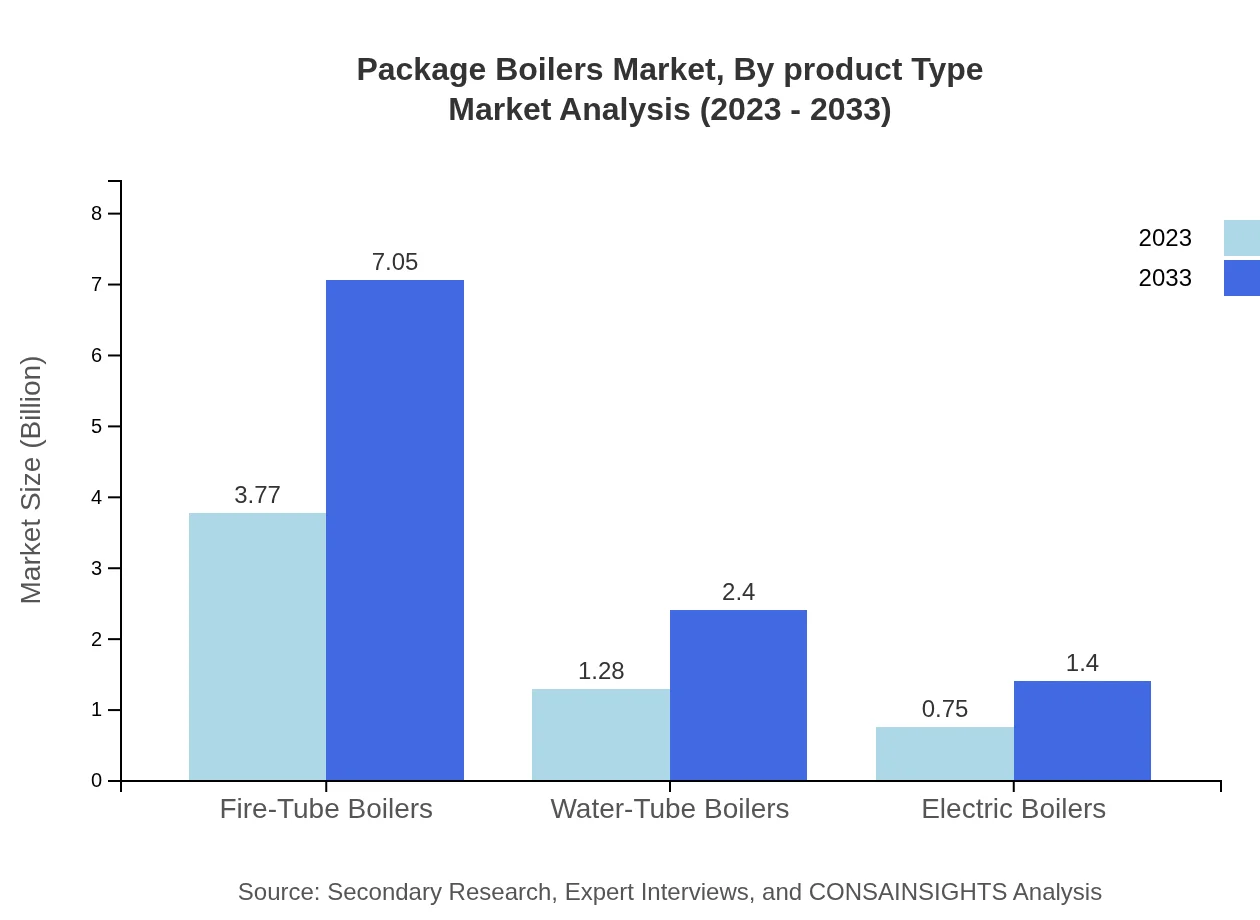

Package Boilers Market Analysis By Product Type

The Package Boilers market is primarily segmented by product type into Fire-Tube Boilers, Water-Tube Boilers, and Electric Boilers. Fire-Tube Boilers lead the market due to their efficiency and reliability in heavy-duty applications. Water-Tube Boilers are becoming popular in moderate temperature applications, delivering better heat transfer. Electric Boilers offer eco-friendly heating solutions, gaining traction with stricter emissions regulations.

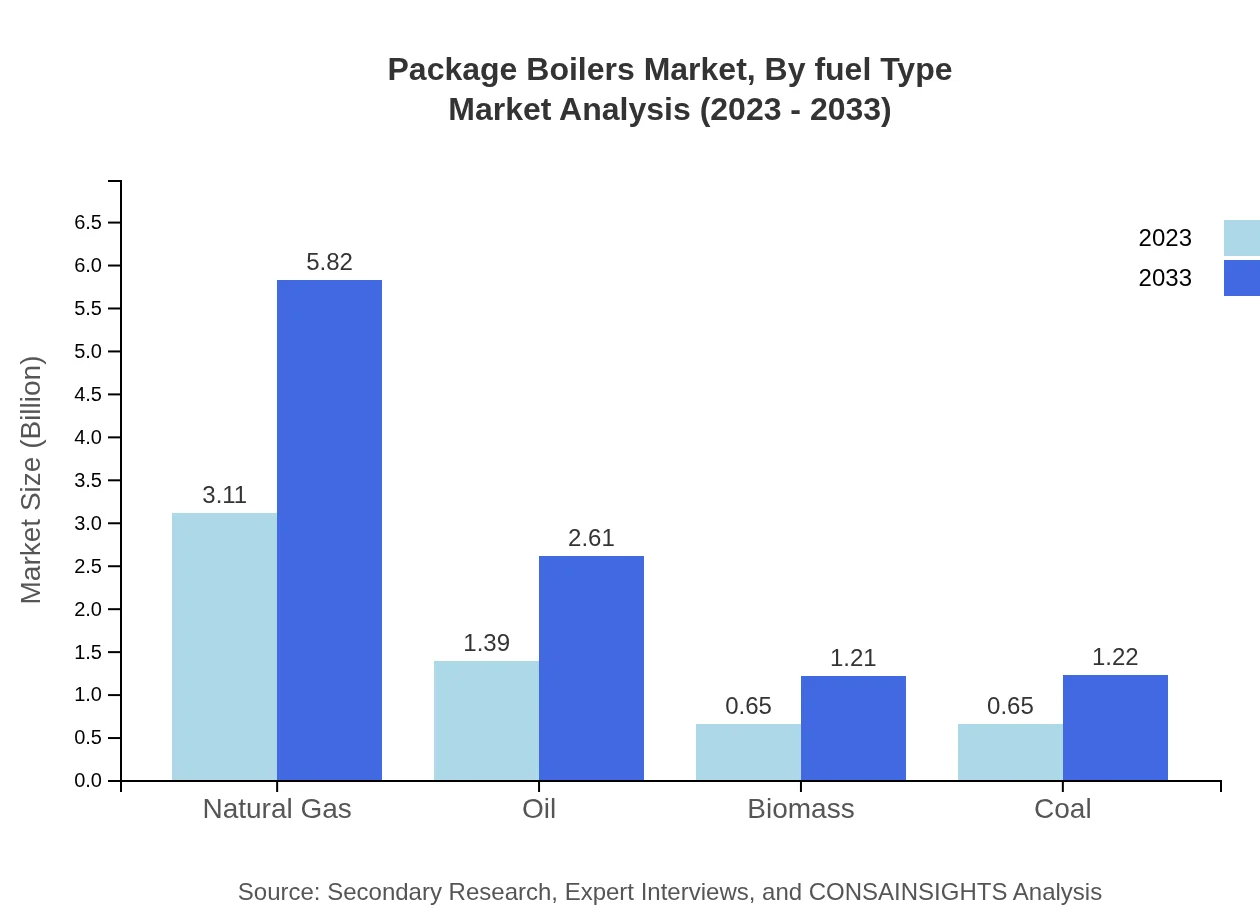

Package Boilers Market Analysis By Fuel Type

Natural Gas remains the dominant fuel type, commanding a market size of $3.11 billion in 2023 and expected to rise to $5.82 billion by 2033, driven by its cost-effectiveness and environmental advantages. Oil and Biomass follow, valued at $1.39 billion and $0.65 billion respectively in 2023. Studies highlight a steady shift towards Biomass as a renewable alternative.

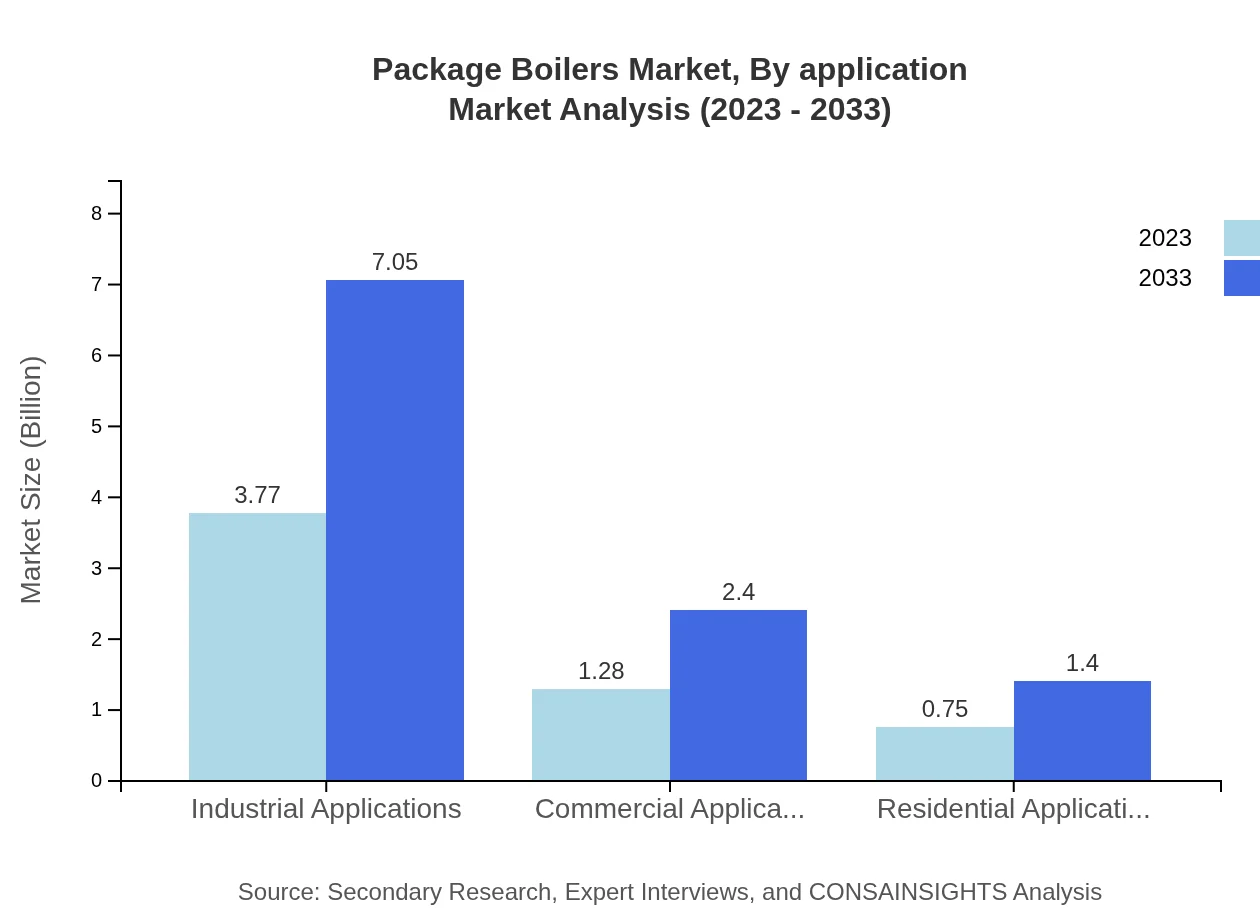

Package Boilers Market Analysis By Application

The Industrial application segment constitutes the largest share, valued at $3.77 billion in 2023 and projected to expand to $7.05 billion by 2033. Commercial and Residential applications also hold significant positions, with respective market sizes of $1.28 billion and $0.75 billion initially, highlighting the versatility of package boilers across sectors.

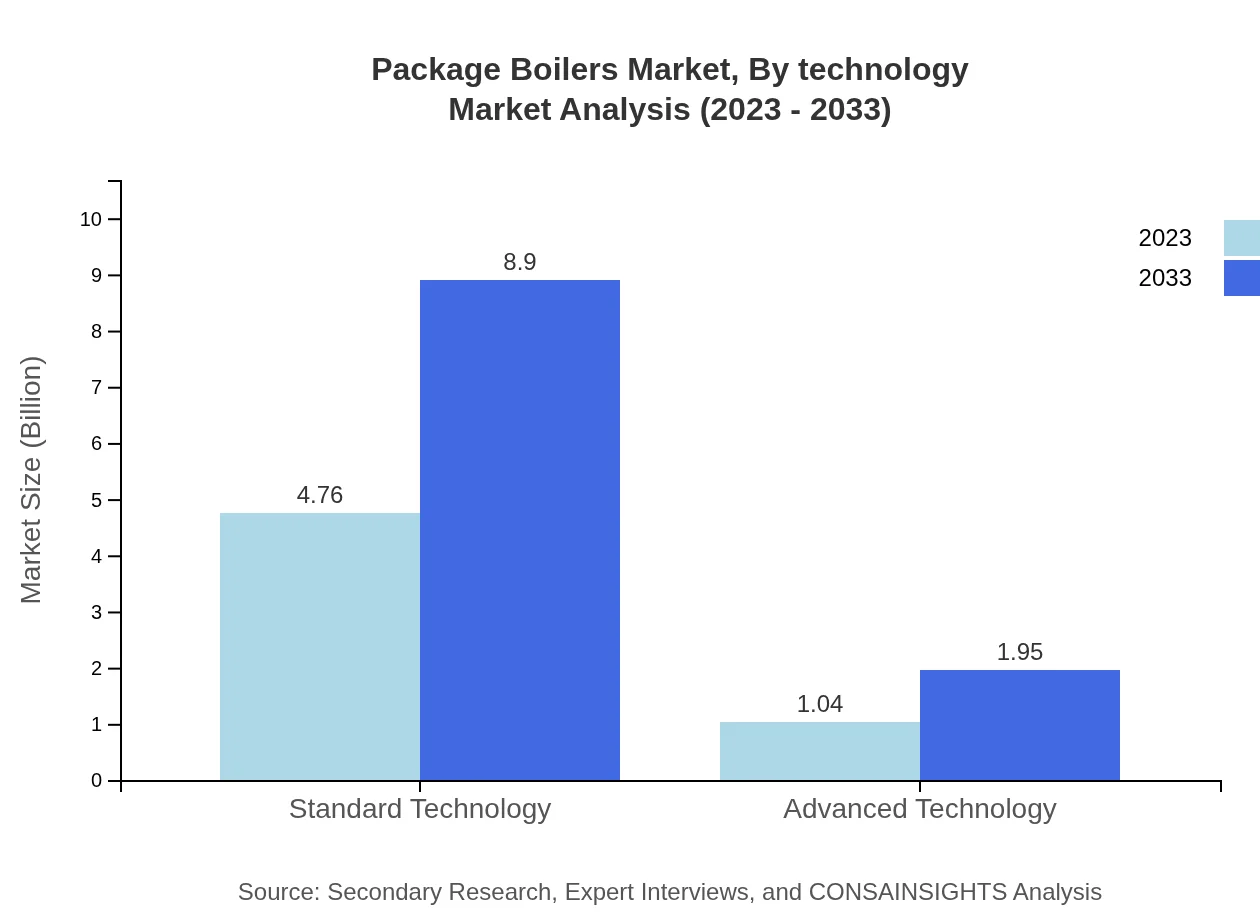

Package Boilers Market Analysis By Technology

Standard Technology dominates with a market share of 82.04% in 2023, focused on conventional heating solutions. However, Advanced Technology is gaining ground with increasing market size from $1.04 billion in 2023 to $1.95 billion by 2033, characterized by smart controls and automation features.

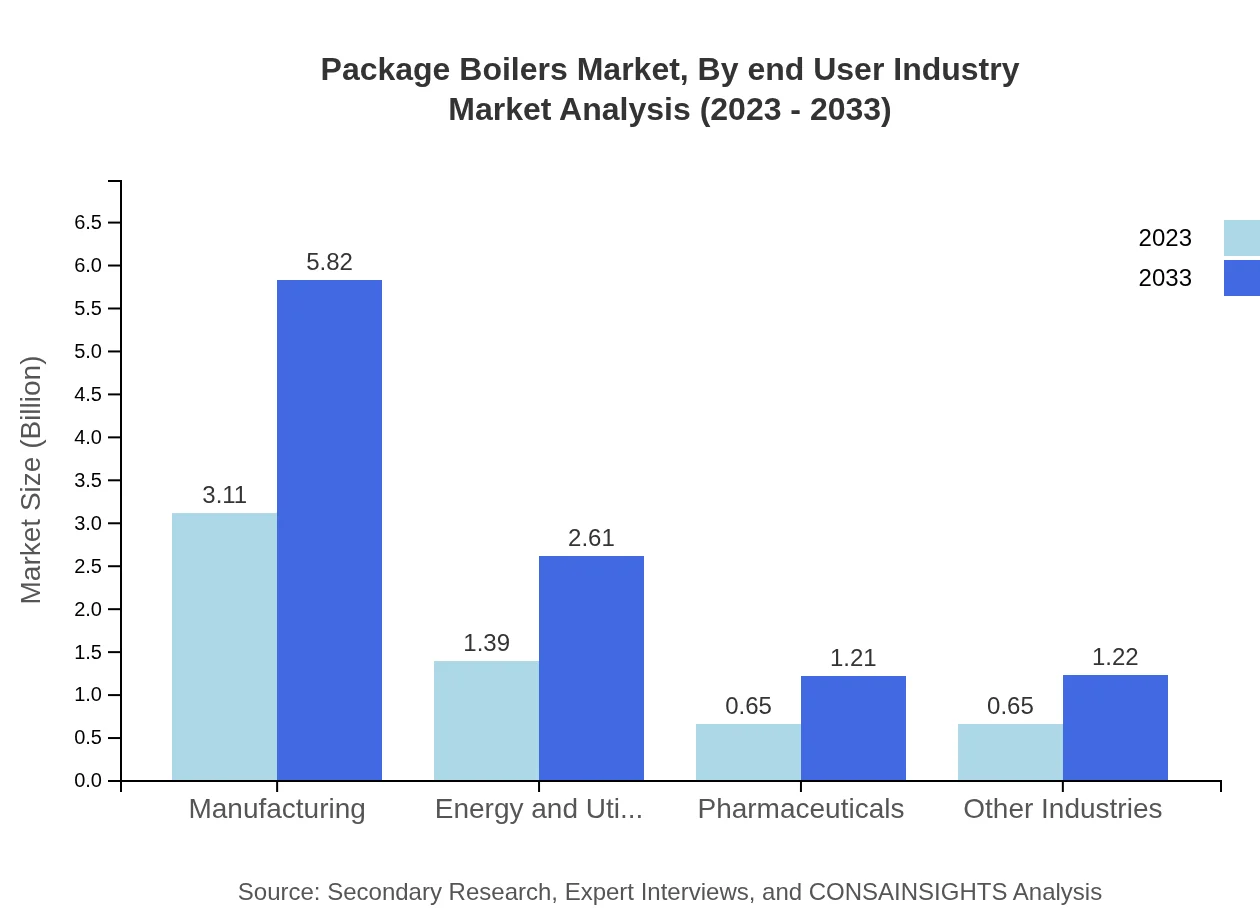

Package Boilers Market Analysis By End User Industry

The Manufacturing sector leads the end-user industry segment, accounting for a size of $3.11 billion in 2023. Energy and Utilities is another crucial sector with great demand for package boilers, valued at $1.39 billion initially, amidst escalating energy needs across the globe. Pharmaceutical industries are also significant contributors, utilizing package boilers for processes requiring specific temperature control.

Package Boilers Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Package Boilers Industry

Bosch Industriekessel GmbH:

A leader in developing efficient boiler systems, Bosch offers a wide range of solutions tailored for industrial applications, focusing on sustainability and reliability.Fulton:

Fulton is renowned for its innovative steam boiler manufacture, providing high-quality products for industrial sectors with shifting regulatory landscapes.Thermal Solutions:

Specializes in providing exceptional heating solutions, including condensing and non-condensing boilers, making strides toward energy-efficient products.Viessmann:

Known for its edge in advanced technology, Viessmann focuses on smart heating solutions and robust performance, serving residential and commercial applications.We're grateful to work with incredible clients.

FAQs

What is the market size of package Boilers?

The package boilers market is projected to grow from $5.8 billion in 2023 to an estimated $10.4 billion by 2033, with a CAGR of 6.3% over the decade.

What are the key market players or companies in this package Boilers industry?

Key players in the package-boilers market include major manufacturers known for innovation and quality, contributing to growth through advanced product offerings. Leading companies focus on expanding their market presence through strategic partnerships and acquisitions.

What are the primary factors driving the growth in the package Boilers industry?

The package-boilers industry is driven by increasing energy demand, stringent environmental regulations, and a shift towards energy-efficient technologies. Additionally, growth in industries such as pharmaceuticals and food processing fuels demand.

Which region is the fastest Growing in the package Boilers market?

The Asia Pacific region is the fastest-growing market for package boilers, expected to increase from $1.11 billion in 2023 to $2.09 billion by 2033, reflecting significant industrial expansion and energy needs.

Does ConsaInsights provide customized market report data for the package Boilers industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the package-boilers industry, allowing clients to obtain in-depth insights that cater to their unique market requirements.

What deliverables can I expect from this package Boilers market research project?

In this package-boilers market research project, expect comprehensive reports, detailed segment analysis, competitive landscape assessments, and regional market insights, tailored to support strategic decision-making.

What are the market trends of package Boilers?

Current market trends in package-boilers include increased adoption of natural gas boilers, advancements in technology, and a growing focus on sustainability, particularly with biomass and electric options gaining prominence.