Perfluoroalkoxy Pfa Coatings Market Report

Published Date: 02 February 2026 | Report Code: perfluoroalkoxy-pfa-coatings

Perfluoroalkoxy Pfa Coatings Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Perfluoroalkoxy PFA Coatings market trends and forecasts from 2023 to 2033. It includes market size, segmentation, regional insights, and a competitive landscape overview.

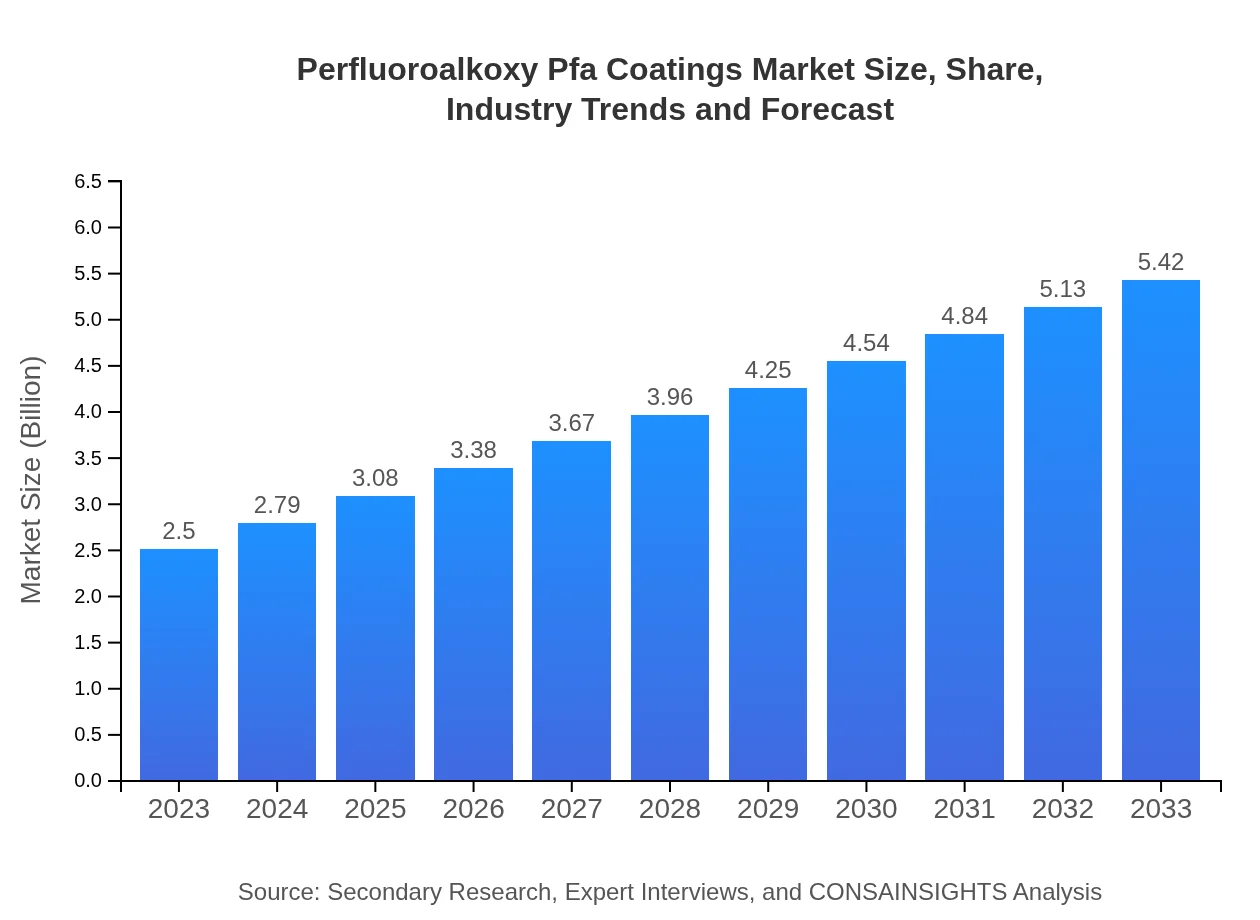

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 7.8% |

| 2033 Market Size | $5.42 Billion |

| Top Companies | Chemours Company, 3M Company, Daikin Industries, Ltd., Solvay SA |

| Last Modified Date | 02 February 2026 |

Perfluoroalkoxy PFA Coatings Market Overview

Customize Perfluoroalkoxy Pfa Coatings Market Report market research report

- ✔ Get in-depth analysis of Perfluoroalkoxy Pfa Coatings market size, growth, and forecasts.

- ✔ Understand Perfluoroalkoxy Pfa Coatings's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Perfluoroalkoxy Pfa Coatings

What is the Market Size & CAGR of Perfluoroalkoxy PFA Coatings market in 2023?

Perfluoroalkoxy PFA Coatings Industry Analysis

Perfluoroalkoxy PFA Coatings Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Perfluoroalkoxy PFA Coatings Market Analysis Report by Region

Europe Perfluoroalkoxy Pfa Coatings Market Report:

Europe's market size is expected to grow from USD 0.80 billion in 2023 to USD 1.73 billion by 2033. The presence of well-established manufacturing industries and a robust emphasis on research and development initiatives in coating technologies are responsible for this increase. An increasing demand for high-performance coatings in sectors like aerospace and automotive further contributes to market momentum.Asia Pacific Perfluoroalkoxy Pfa Coatings Market Report:

The Asia-Pacific region holds a significant share in the Perfluoroalkoxy PFA Coatings market, with a market size projected at USD 1.02 billion by 2033, up from USD 0.47 billion in 2023. This growth is driven by rapid industrialization and an increasing number of manufacturing units in countries like China and India, emphasizing the need for advanced coatings to enhance production efficiency.North America Perfluoroalkoxy Pfa Coatings Market Report:

North America anticipates substantial growth, with the market size increasing from USD 0.90 billion in 2023 to USD 1.96 billion by 2033. A strong focus on technological innovation, along with stringent regulations driving the need for environmentally safe materials, bolsters the demand for PFA coatings in this region.South America Perfluoroalkoxy Pfa Coatings Market Report:

In South America, the market remains relatively smaller, projected at USD -0.02 billion by 2033 from USD -0.01 billion in 2023. The industry faces challenges related to economic factors, limiting growth opportunities in this region. However, niche applications in specific sectors may offer potential for segmented growth.Middle East & Africa Perfluoroalkoxy Pfa Coatings Market Report:

In the Middle East and Africa, the market is projected to grow from USD 0.34 billion in 2023 to USD 0.74 billion by 2033. This region reflects a growing interest in advanced coating solutions, particularly in oil and gas industries, promoting the uptake of PFA coatings for enhanced operational efficiencies.Tell us your focus area and get a customized research report.

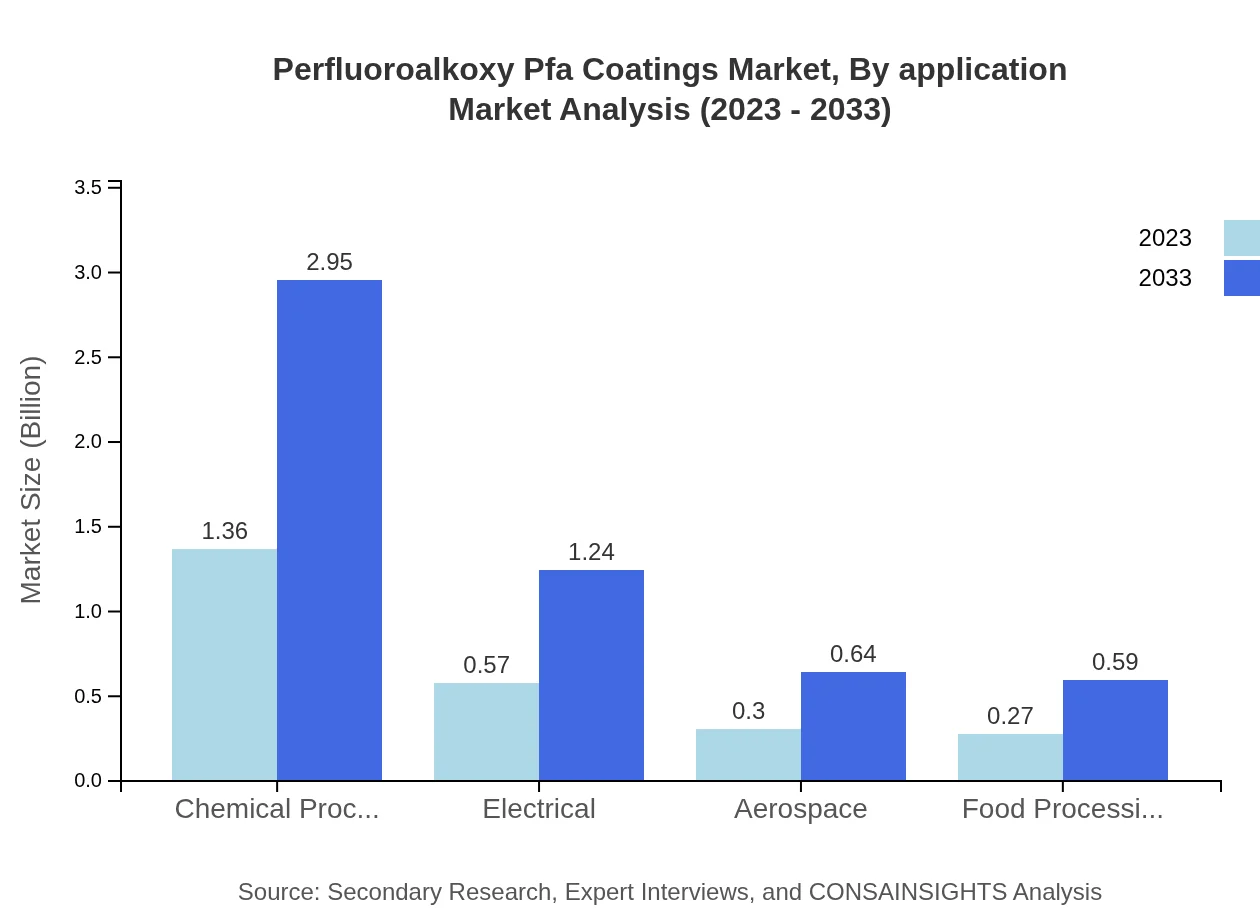

Perfluoroalkoxy Pfa Coatings Market Analysis By Application

The application segment of the Perfluoroalkoxy PFA Coatings market is diverse, showcasing significant demand from industries such as chemical processing, electrical, aerospace, and food processing. High-temperature resistance makes PFA coatings particularly valuable in these applications, ensuring operational efficiency and material longevity. The chemical processing industry, as the largest segment, accounts for approximately 54.44% of the market share in 2023, projected to increase in line with industrial growth.

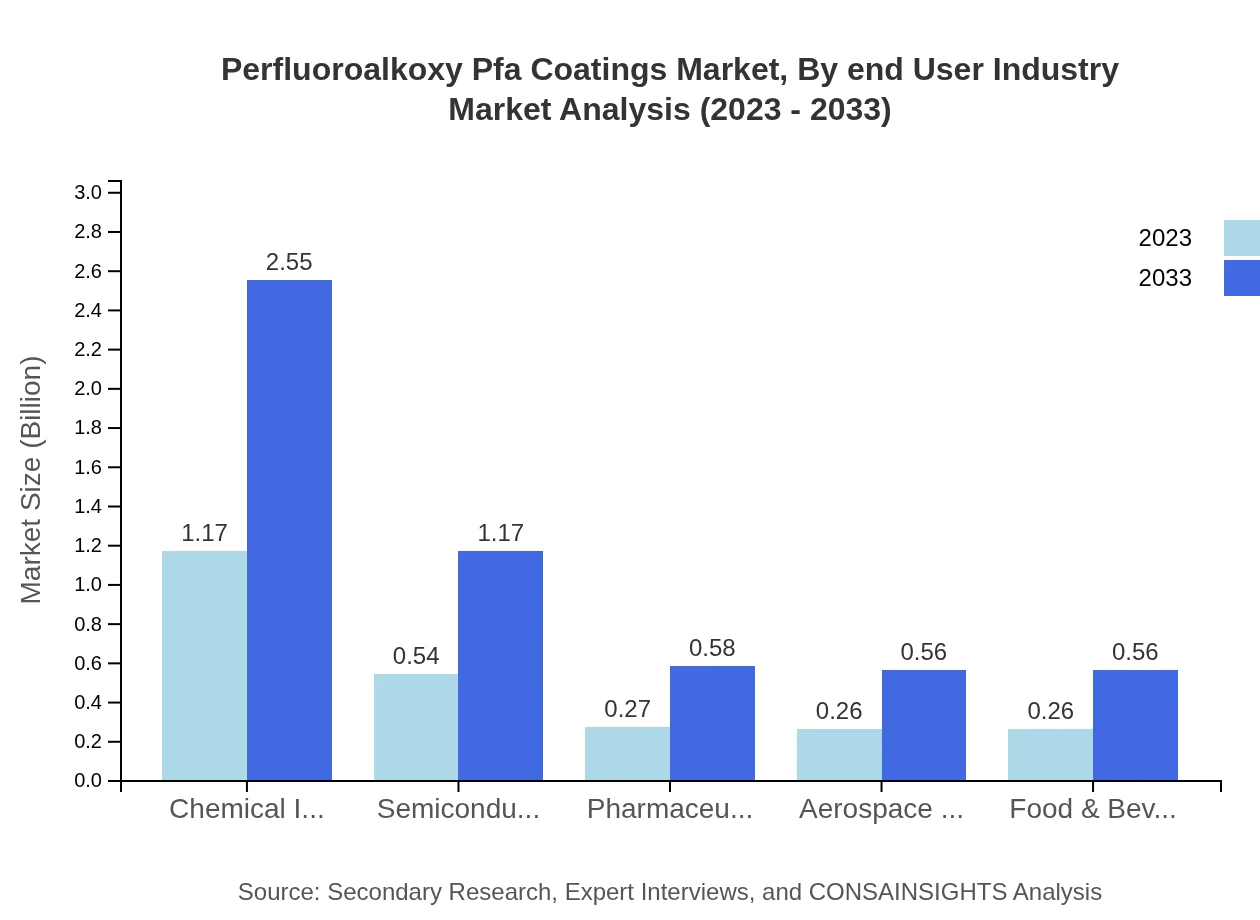

Perfluoroalkoxy Pfa Coatings Market Analysis By End User Industry

Key end-user industries for PFA coatings include semiconductors, pharmaceuticals, and food & beverage, each with unique performance demands. The semiconductor industry is expected to account for around 21.58% of the market share, driven by the need for high-purity coatings that can withstand stringent manufacturing environments. The food processing segment is also notable, showing steady growth due to increasing health regulations and quality standards.

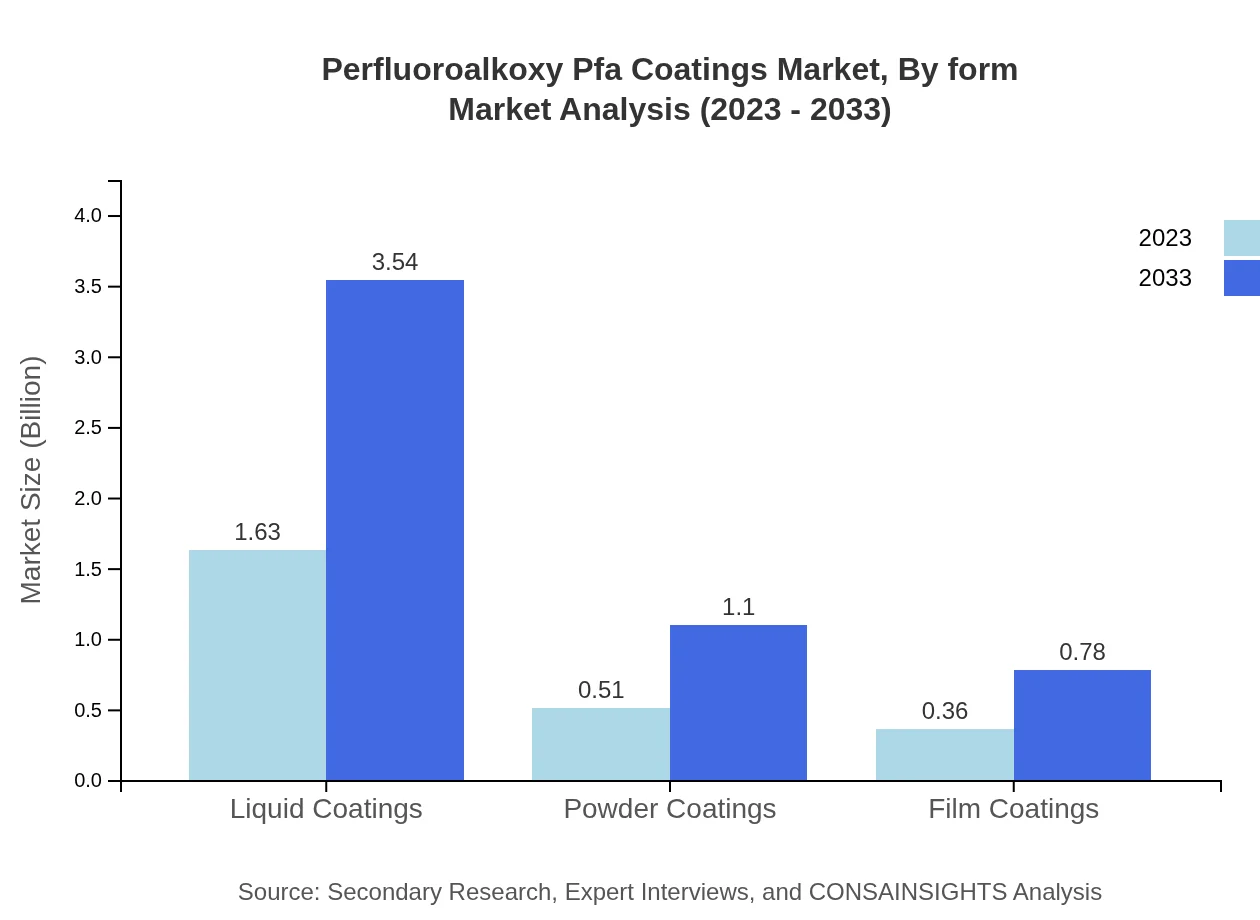

Perfluoroalkoxy Pfa Coatings Market Analysis By Form

PFA coatings are available in numerous forms, predominantly as liquid and powder coatings. Liquid coatings dominate the market, accounting for 65.28% of market share in 2023, providing excellent versatility and ease of application. Conversely, powder coatings are gaining traction, reflecting industry shifts towards eco-friendly options that reduce waste and improve durability.

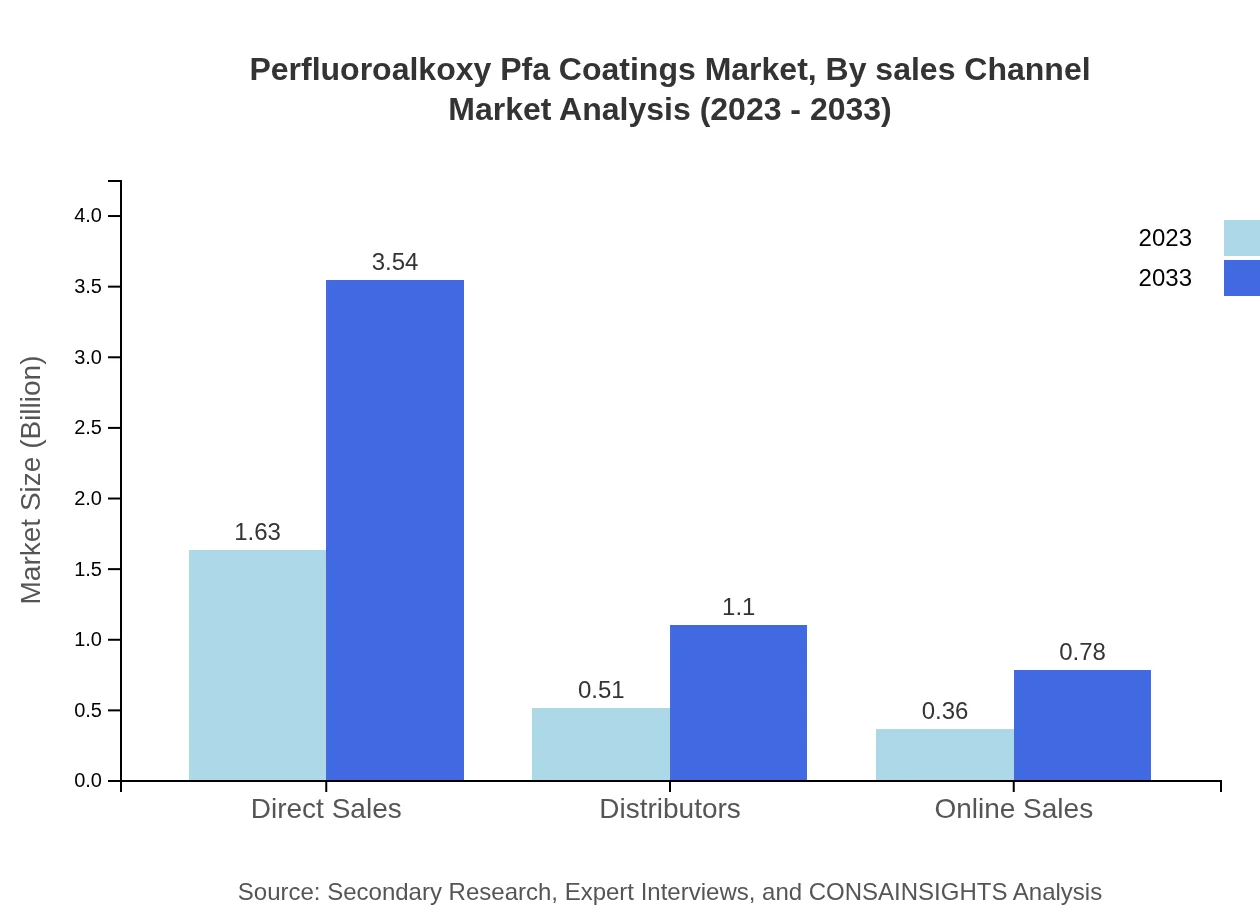

Perfluoroalkoxy Pfa Coatings Market Analysis By Sales Channel

Sales channels for PFA coatings are diversifying, with direct sales and distributors playing critical roles. Direct sales are forecast to encompass 65.28% of the market share in 2023 due to established relationships and better service delivery in the supply chain, while online sales are gaining ground, signifying a shift towards digital commerce in response to changing customer preferences.

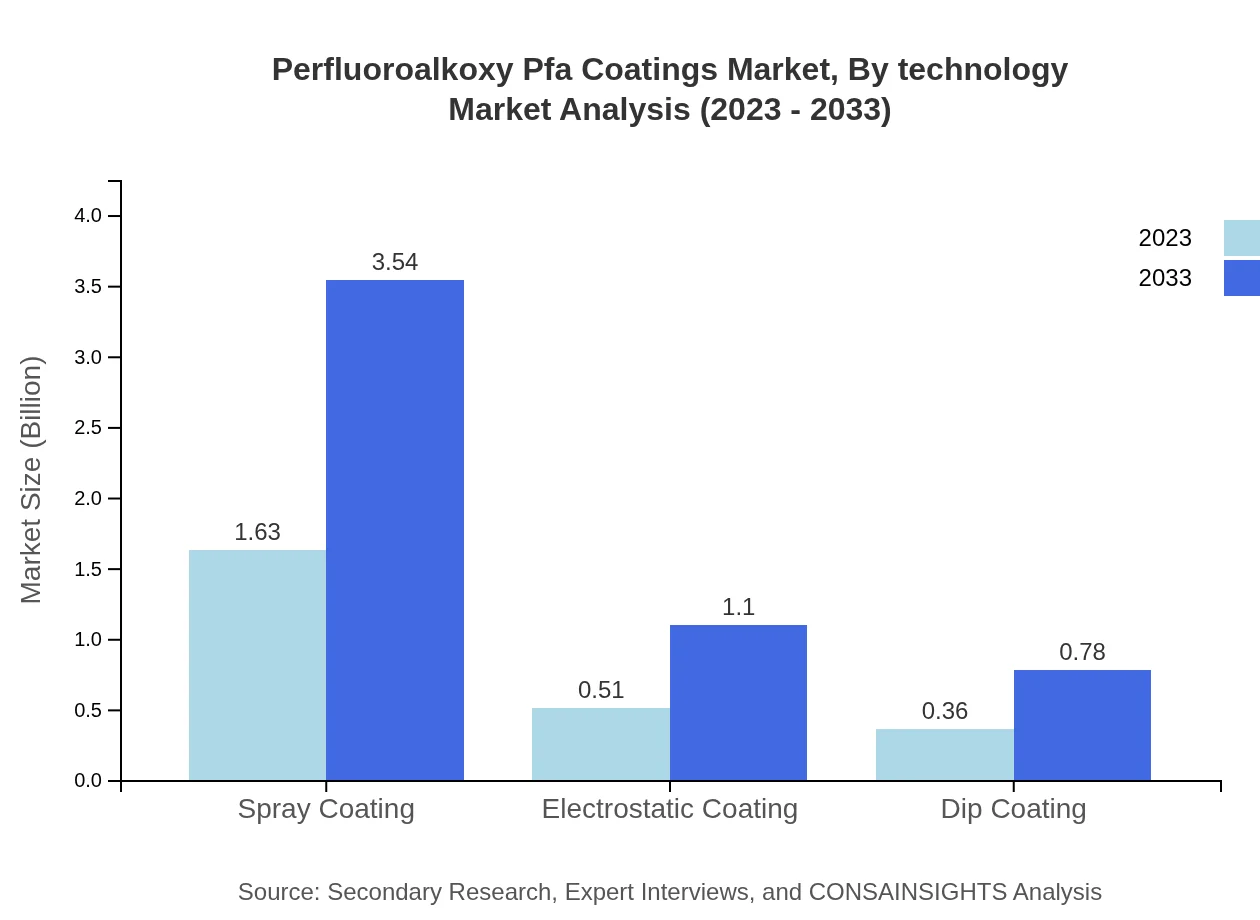

Perfluoroalkoxy Pfa Coatings Market Analysis By Technology

The technological advancements in application methods for PFA coatings, such as electrostatic coating and spray coating, are enhancing efficiency and quality. Innovations in formulation composition also play a vital role in improving performance characteristics, thus driving market growth across various sectors. The increasing emphasis on automation and high-throughput systems in manufacturing processes is expected to bolster the demand for technologically advanced coating solutions.

Perfluoroalkoxy PFA Coatings Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Perfluoroalkoxy PFA Coatings Industry

Chemours Company:

Chemours is a leading global provider of innovative chemical solutions, including PFA coatings. Their focus on sustainability and advanced material science positions them at the forefront of industry advancements.3M Company:

Known for its diverse portfolio, 3M offers high-performance PFA coatings that cater to various industrial needs. Their commitment to R&D drives continuous product improvements and customer satisfaction.Daikin Industries, Ltd.:

Daikin is recognized for its expertise in fluoropolymer materials. They develop advanced PFA coatings used in critical applications across several industries, reinforcing their position as a market leader.Solvay SA:

With strong capabilities in specialty polymers, Solvay is a key player in the PFA coatings market, focusing on innovation and sustainable practices to meet evolving industry demands.We're grateful to work with incredible clients.

FAQs

What is the market size of Perfluoroalkoxy-PFA Coatings?

The global market size for Perfluoroalkoxy-PFA Coatings is expected to reach approximately $2.5 billion by 2033, growing at a CAGR of 7.8% from 2023. This significant growth is indicative of the increasing demand for high-performance coatings.

What are the key market players or companies in the Perfluoroalkoxy-PFA Coatings industry?

Key players in the Perfluoroalkoxy-PFA Coatings market include established chemical manufacturers and specialized coating companies that focus on innovative coating solutions to meet industry needs. These companies are crucial in driving technological advancements and market growth.

What are the primary factors driving the growth in the Perfluoroalkoxy-PFA Coatings industry?

The growth of the Perfluoroalkoxy-PFA Coatings industry is primarily driven by increasing demand in automotive and chemical processing industries, enhanced properties of PFA coatings, and rising adoption in high-temperature applications which require excellent chemical resistance.

Which region is the fastest Growing in the Perfluoroalkoxy-PFA Coatings?

The fastest-growing region for Perfluoroalkoxy-PFA Coatings from 2023 to 2033 is Europe, with its market projected to expand from $0.80 billion to $1.73 billion. This growth is driven by increasing industrial activities and stringent regulatory requirements.

Does ConsaInsights provide customized market report data for the Perfluoroalkoxy-PFA Coatings industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the Perfluoroalkoxy-PFA Coatings industry. This ensures businesses receive relevant insights tailored to their strategic objectives and market conditions.

What deliverables can I expect from this Perfluoroalkoxy-PFA Coatings market research project?

Deliverables from this market research project include comprehensive market analysis, segmentation data, trends, forecasts, competitive landscape insights, and strategic recommendations, all designed to support informed decision-making in the Perfluoroalkoxy-PFA Coatings market.

What are the market trends of Perfluoroalkoxy-PFA Coatings?

Current market trends for Perfluoroalkoxy-PFA Coatings include a shift towards eco-friendly coating solutions, increased application in electronics and aerospace, and rising investments in R&D to improve coating performance and develop new formulations.