Piece Picking Robots Market Report

Published Date: 22 January 2026 | Report Code: piece-picking-robots

Piece Picking Robots Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Piece Picking Robots market, exploring key trends, market size, and predictions for growth from 2023 to 2033. Insights into industry segmentation, regional performance, and leading companies are also included.

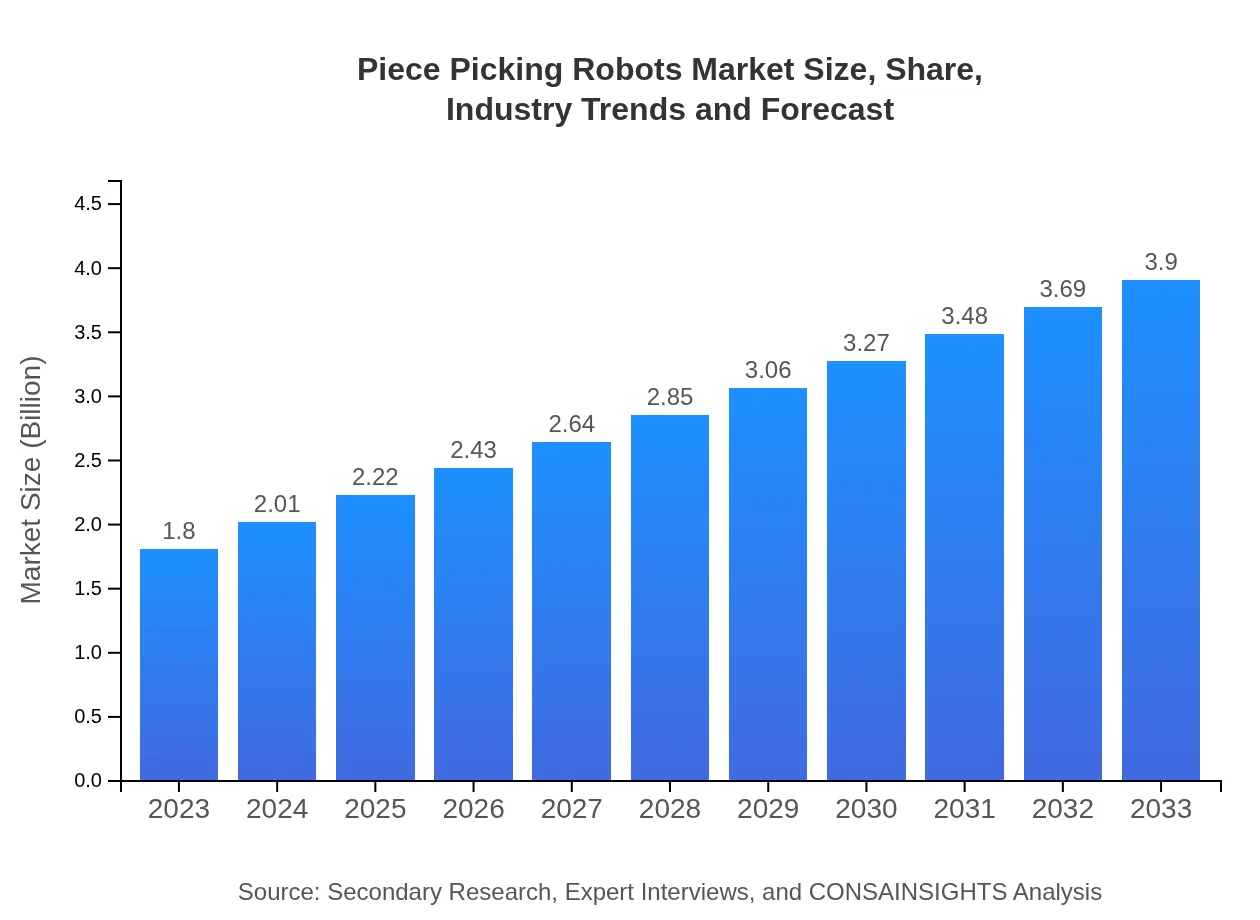

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.80 Billion |

| CAGR (2023-2033) | 7.8% |

| 2033 Market Size | $3.90 Billion |

| Top Companies | Kiva Systems, Amazon Robotics, Fanuc Corporation, Pickwise |

| Last Modified Date | 22 January 2026 |

Piece Picking Robots Market Overview

Customize Piece Picking Robots Market Report market research report

- ✔ Get in-depth analysis of Piece Picking Robots market size, growth, and forecasts.

- ✔ Understand Piece Picking Robots's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Piece Picking Robots

What is the Market Size & CAGR of Piece Picking Robots market in 2023?

Piece Picking Robots Industry Analysis

Piece Picking Robots Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Piece Picking Robots Market Analysis Report by Region

Europe Piece Picking Robots Market Report:

In Europe, the market for Piece Picking Robots is set to increase from $0.54 billion in 2023 to $1.18 billion by 2033. The region’s regulatory push for efficiency and sustainability in logistics makes it a hotspot for robotic automation.Asia Pacific Piece Picking Robots Market Report:

In the Asia Pacific region, the Piece Picking Robots market is expected to grow from $0.35 billion in 2023 to $0.75 billion by 2033. This growth is driven by the rapid industrialization and the push toward automation in countries like China and Japan, where manufacturing and logistics are becoming increasingly sophisticated.North America Piece Picking Robots Market Report:

North America leads the market growth, with a size of $0.63 billion in 2023 projected to reach $1.36 billion by 2033. The region's inclination towards automation in warehouses and fulfillment centers, particularly in the U.S., significantly propels this growth.South America Piece Picking Robots Market Report:

The South American market is anticipated to expand from $0.06 billion in 2023 to $0.14 billion by 2033. E-commerce growth and rising investments in technology from logistics companies are key drivers for this region.Middle East & Africa Piece Picking Robots Market Report:

The Middle East and Africa market is projected to grow from $0.22 billion in 2023 to $0.48 billion by 2033. With investments in technology and infrastructure improvements, countries in this region are slowly adopting robotic solutions.Tell us your focus area and get a customized research report.

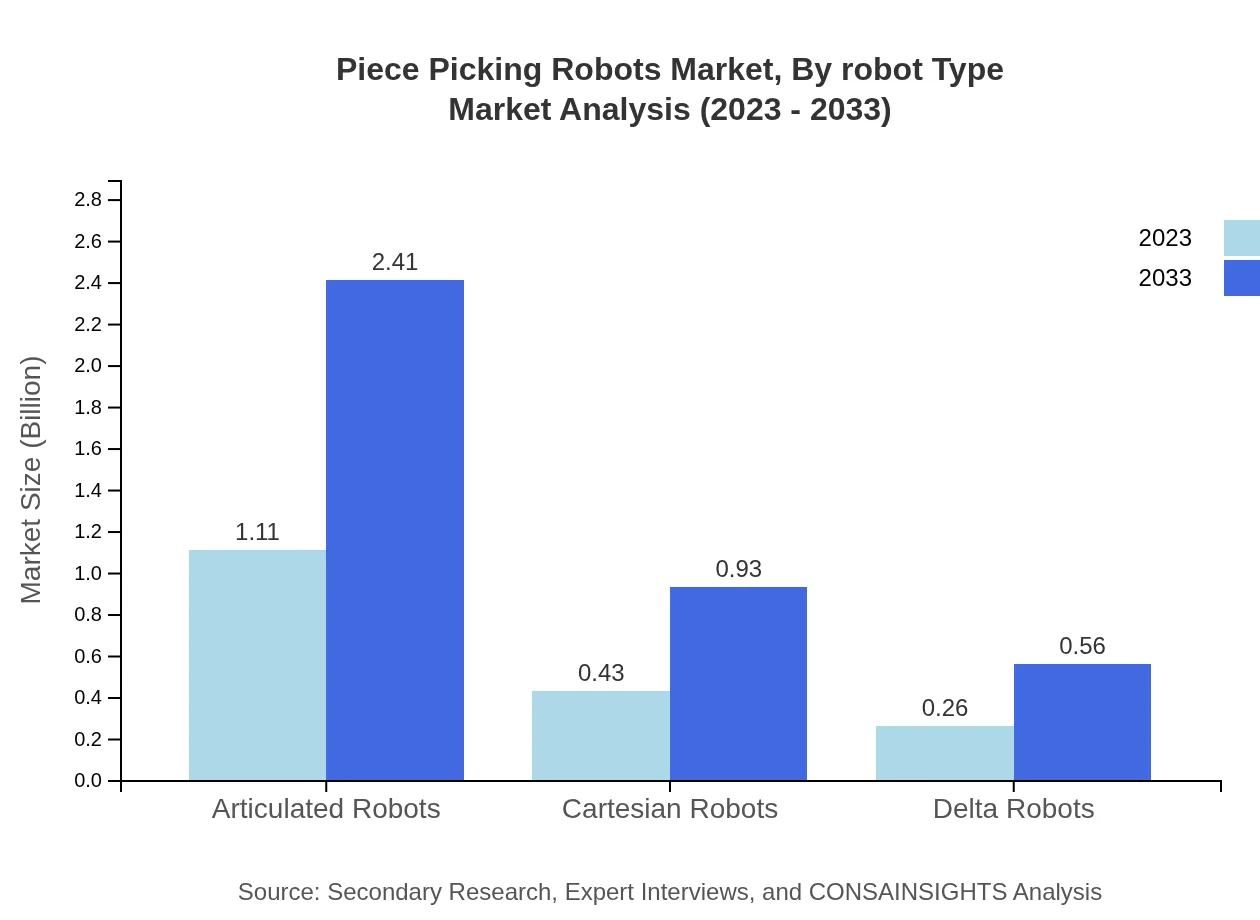

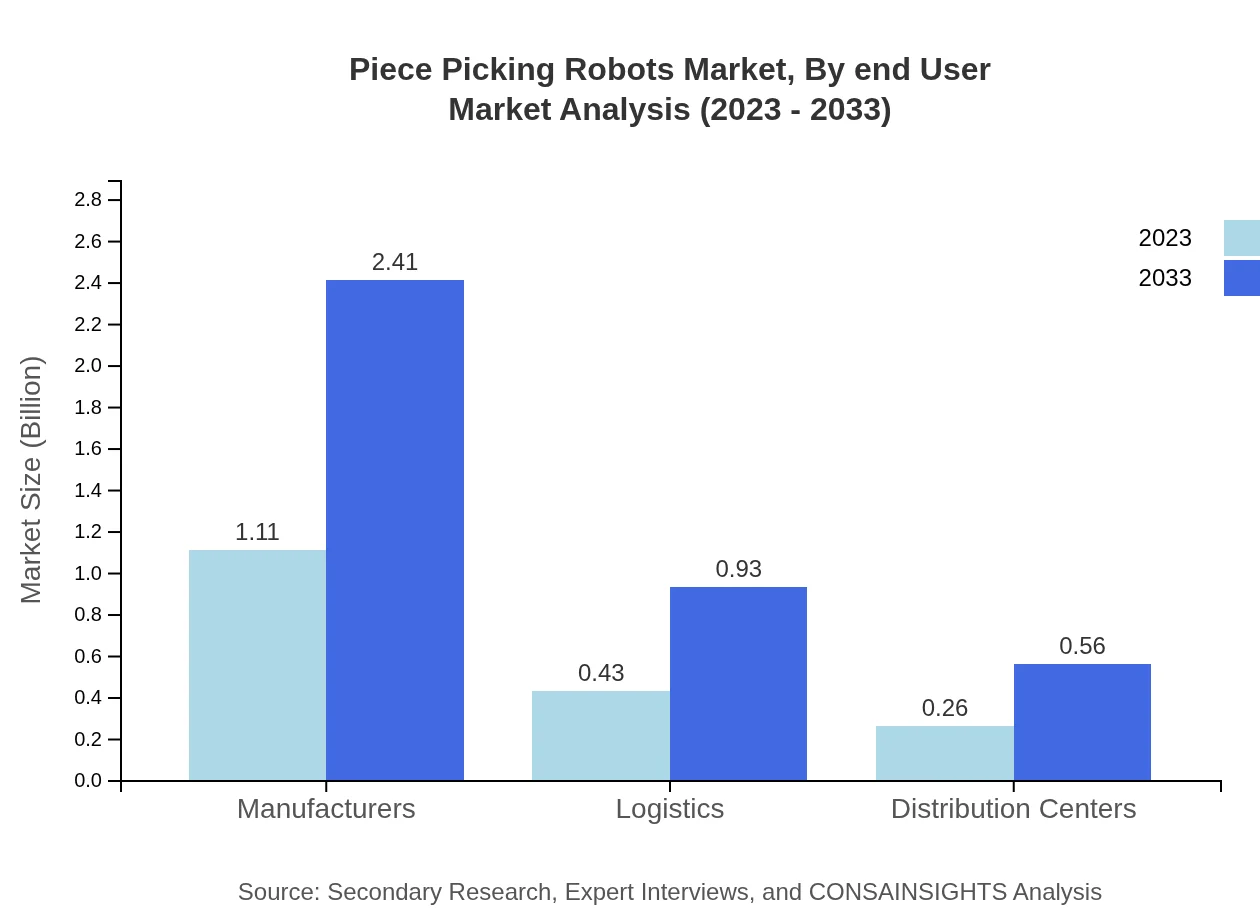

Piece Picking Robots Market Analysis By Robot Type

The market, segmented by robot type, emphasizes articulated robots, which dominate the market with a size of $1.11 billion in 2023, expected to rise to $2.41 billion by 2033, holding a 61.89% market share. Following them, Cartesian and delta robots also represent significant but smaller segments, with Cartesian robots at $0.43 billion (23.77%) and delta robots at $0.26 billion (14.34%) in 2023.

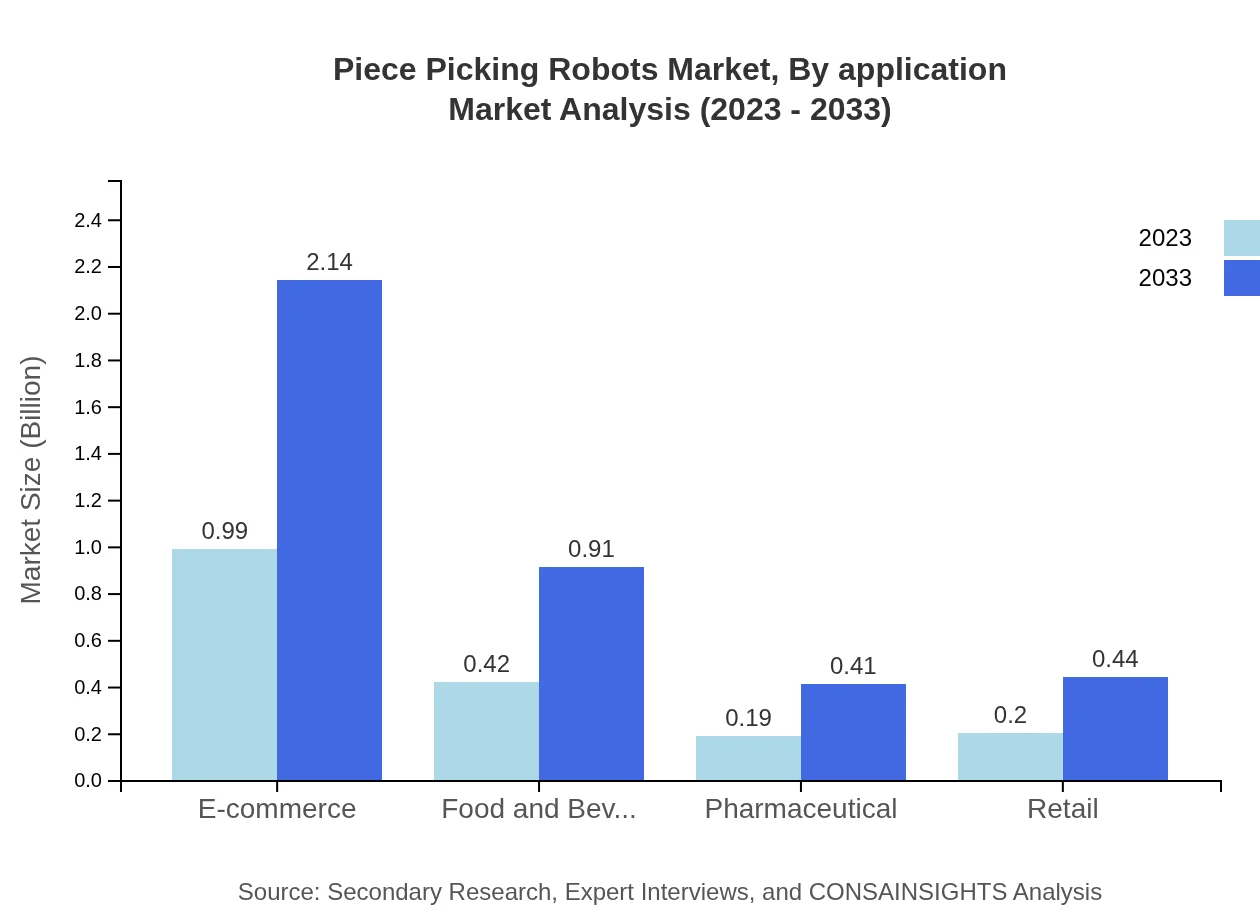

Piece Picking Robots Market Analysis By Application

By application, the e-commerce segment leads with a market size of $0.99 billion in 2023, projected to grow to $2.14 billion by 2033, maintaining a 54.96% market share. Other crucial segments include logistics, food and beverage, and pharmaceuticals, which are increasingly utilizing robotic solutions to enhance efficiency.

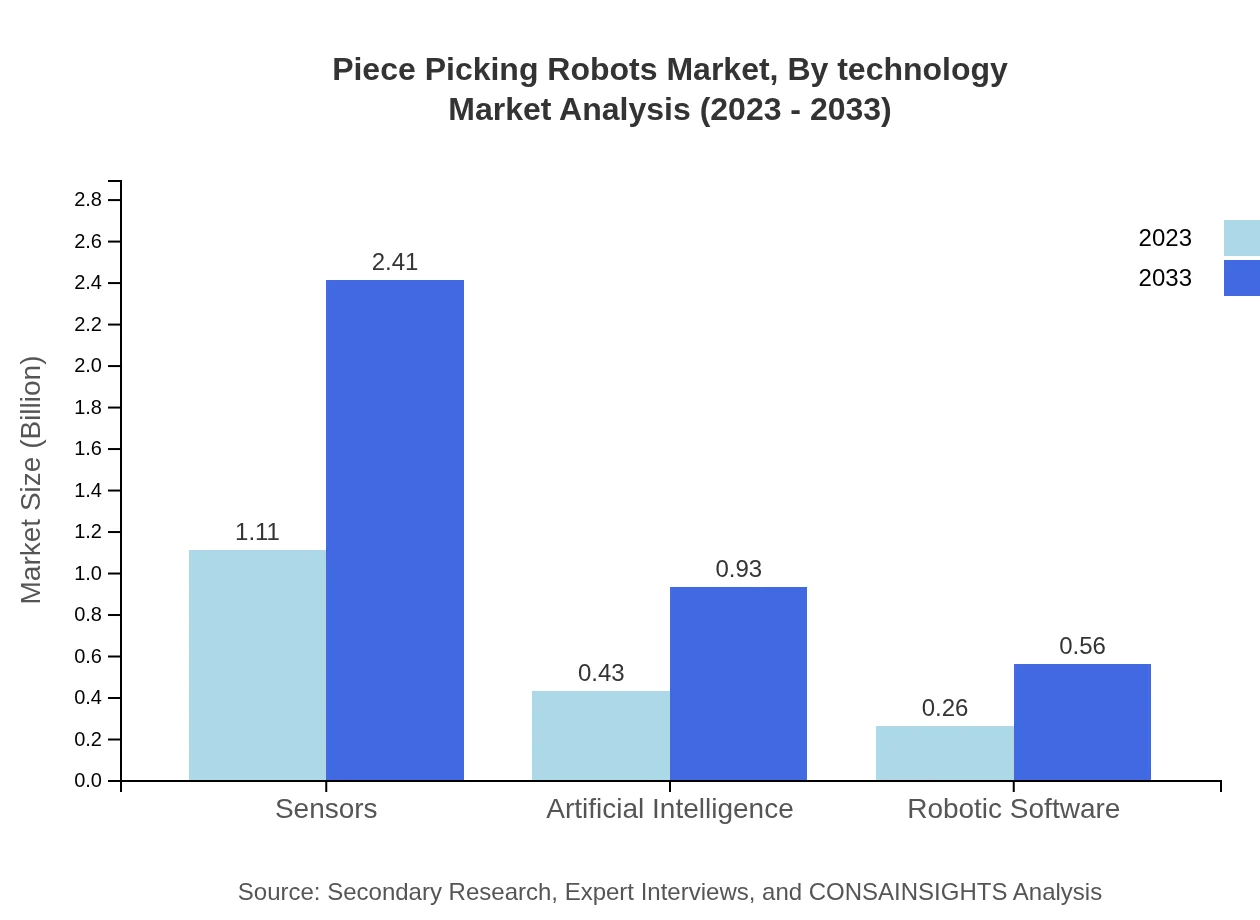

Piece Picking Robots Market Analysis By Technology

Technological advances prominently shape the market landscape, with a significant focus on AI and robotics software. The segment for AI-enabled solutions will grow from $0.43 billion in 2023 to $0.93 billion by 2033, maintaining a market share of 23.77%. The demand for sensors integrates seamlessly into operational efficiency, fostering rapid development in robotic capabilities.

Piece Picking Robots Market Analysis By End User

Industries such as retail, pharmaceuticals, and food and beverage are continuing to adopt piece picking robots to enhance workflow. The retail sector, holding an 11.26% market share with a $0.20 billion size in 2023, anticipates growth in tandem with e-commerce expansion, demanding faster and more reliable fulfillment.

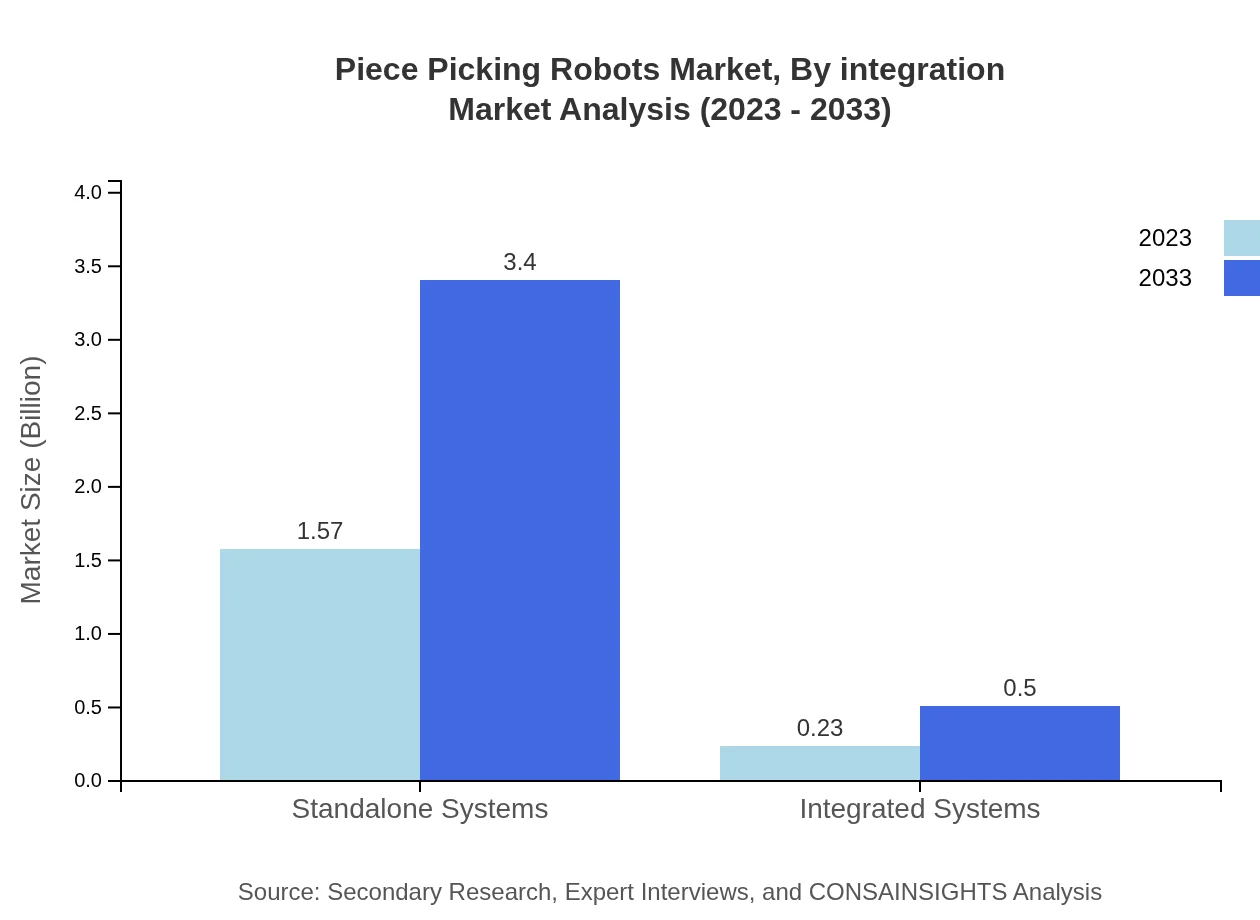

Piece Picking Robots Market Analysis By Integration

The standalone systems segment is highly prevalent, projected to escalate from $1.57 billion in 2023 to $3.40 billion by 2033, commanding 87.07% of the market share. Integrated systems are gradually gaining interest, but their adoption reflects the complexity and varied needs of operational environments.

Piece Picking Robots Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Piece Picking Robots Industry

Kiva Systems:

Specializing in robotic fulfillment solutions, Kiva Systems has revolutionized warehouse automation with innovative robotics that boost efficiency.Amazon Robotics:

A subsidiary of Amazon, providing end-to-end robotic solutions for warehousing, significantly lowering operational costs and improving order retrieval speeds.Fanuc Corporation:

A leader in robotic automation and manufacturing, offering versatile robotic arms for various industrial applications, including piece picking.Pickwise:

Focused on integrating AI into robot systems, enhancing the flexibility and efficiency of piece picking operations in logistics.We're grateful to work with incredible clients.

FAQs

What is the market size of piece Picking robots?

As of 2023, the global market size for piece-picking robots is approximately $1.8 billion, with an expected CAGR of 7.8% through to 2033, indicating robust growth opportunities in the industry.

What are the key market players or companies in the piece Picking robots industry?

The piece-picking robots market features several leading companies, including ABB, Fanuc, Kuka, Yaskawa, and Omron. These players specialize in robotics solutions, automated systems, and innovative technologies to enhance operational efficiency.

What are the primary factors driving the growth in the piece Picking robots industry?

Key factors driving growth include advancements in automation technology, increasing demand for efficiency and precision, the rise of e-commerce, and the shift towards integrated robotic systems in logistics and manufacturing sectors.

Which region is the fastest Growing in the piece Picking robots market?

North America is currently the fastest-growing region, projected to increase from $0.63 billion in 2023 to $1.36 billion by 2033. Europe and Asia-Pacific also show significant growth potential in response to automation adoption.

Does ConsaInsights provide customized market report data for the piece Picking robots industry?

Yes, Consainsights offers customized market report data catering to specific requirements in the piece-picking robots industry, allowing clients to access tailored insights based on individual needs and market dynamics.

What deliverables can I expect from this piece Picking robots market research project?

From the market research project, you can expect comprehensive reports including market size data, growth forecasts, competitive landscape analysis, regional insights, and key trends within the piece-picking robots market.

What are the market trends of piece Picking robots?

Current trends include the integration of Artificial Intelligence in robotics, increasing adoption in e-commerce, enhancements in sensor technology, and a shift towards automated solutions in supply chain management.