Pile Driving Equipment Market Report

Published Date: 22 January 2026 | Report Code: pile-driving-equipment

Pile Driving Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the global pile driving equipment market including market size forecasts, segment analysis, and regional insights, covering a forecast period from 2023 to 2033. This data guides stakeholders in making informed decisions.

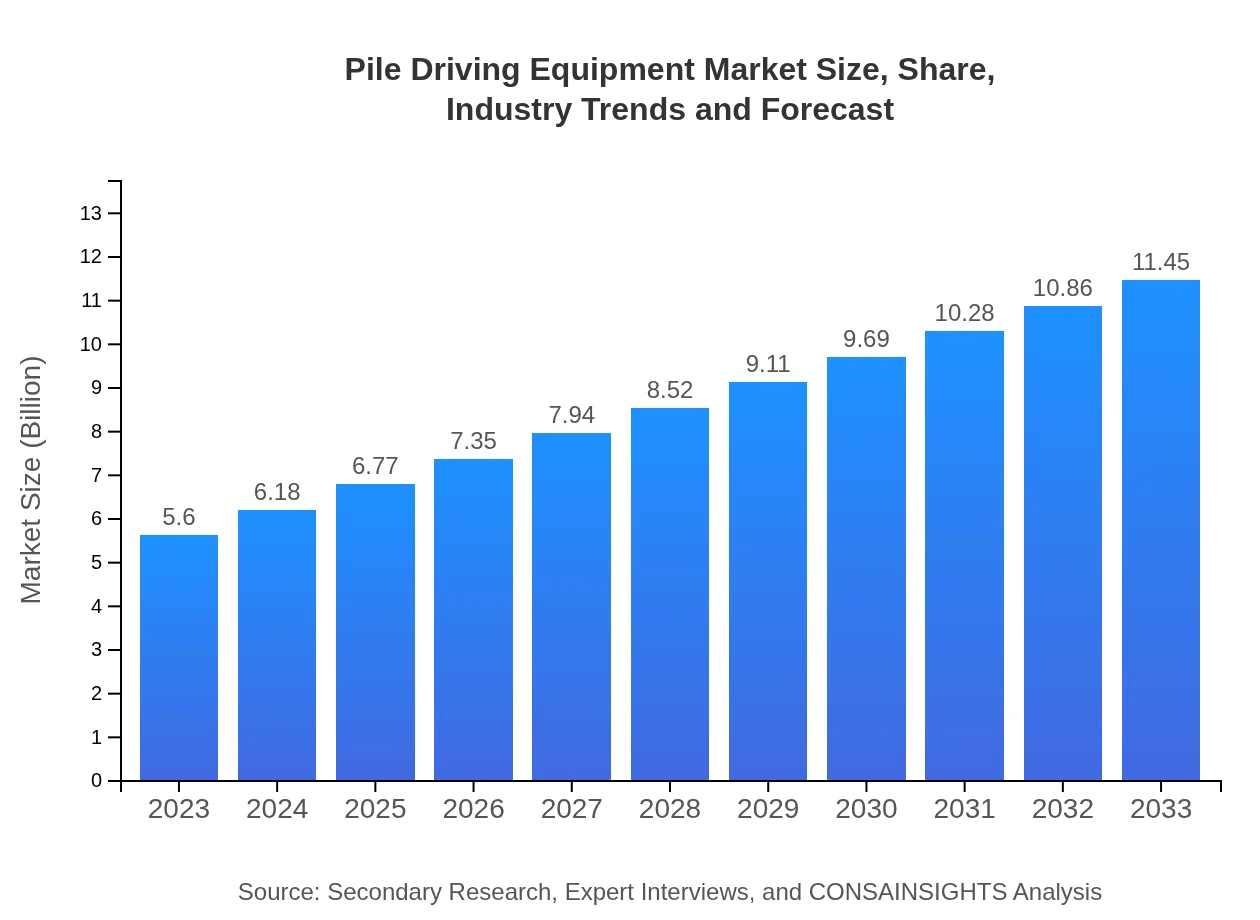

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.60 Billion |

| CAGR (2023-2033) | 7.2% |

| 2033 Market Size | $11.45 Billion |

| Top Companies | Terex Corporation, Soilmec S.p.A., Bauer Group, Layher, Atlas Copco |

| Last Modified Date | 22 January 2026 |

Pile Driving Equipment Market Overview

Customize Pile Driving Equipment Market Report market research report

- ✔ Get in-depth analysis of Pile Driving Equipment market size, growth, and forecasts.

- ✔ Understand Pile Driving Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Pile Driving Equipment

What is the Market Size & CAGR of Pile Driving Equipment Market in 2023?

Pile Driving Equipment Industry Analysis

Pile Driving Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Pile Driving Equipment Market Analysis Report by Region

Europe Pile Driving Equipment Market Report:

Europe's pile driving equipment market is anticipated to grow from $1.39 billion in 2023 to $2.84 billion by 2033, representing a CAGR of 7.6%. The region is seeing significant legislative support for infrastructure projects, driving demand.Asia Pacific Pile Driving Equipment Market Report:

In 2023, the Asia Pacific region's pile driving equipment market is valued at $1.20 billion and is expected to reach $2.45 billion by 2033, growing at a CAGR of 8.4%. Rapid urbanization, particularly in countries like India and China, along with substantial government investments in infrastructure, contributes to this growth.North America Pile Driving Equipment Market Report:

North America's market is expected to grow from $2.01 billion in 2023 to $4.11 billion by 2033, with a CAGR of 7.5%. The focus on sustainable construction practices and renewable energy projects in the U.S. and Canada is augmenting the demand for advanced pile driving technologies.South America Pile Driving Equipment Market Report:

The South American market for pile driving equipment was valued at $0.49 billion in 2023, projected to reach $1.01 billion by 2033, reflecting a CAGR of 7.8%. Growth is primarily driven by the increasing need for infrastructure improvement in response to urban development.Middle East & Africa Pile Driving Equipment Market Report:

In the Middle East and Africa, the pile driving equipment market is projected to grow from $0.51 billion in 2023 to $1.05 billion by 2033, with an expected CAGR of 7.8%. The ongoing infrastructure development in the GCC countries plays a crucial role in this expansion.Tell us your focus area and get a customized research report.

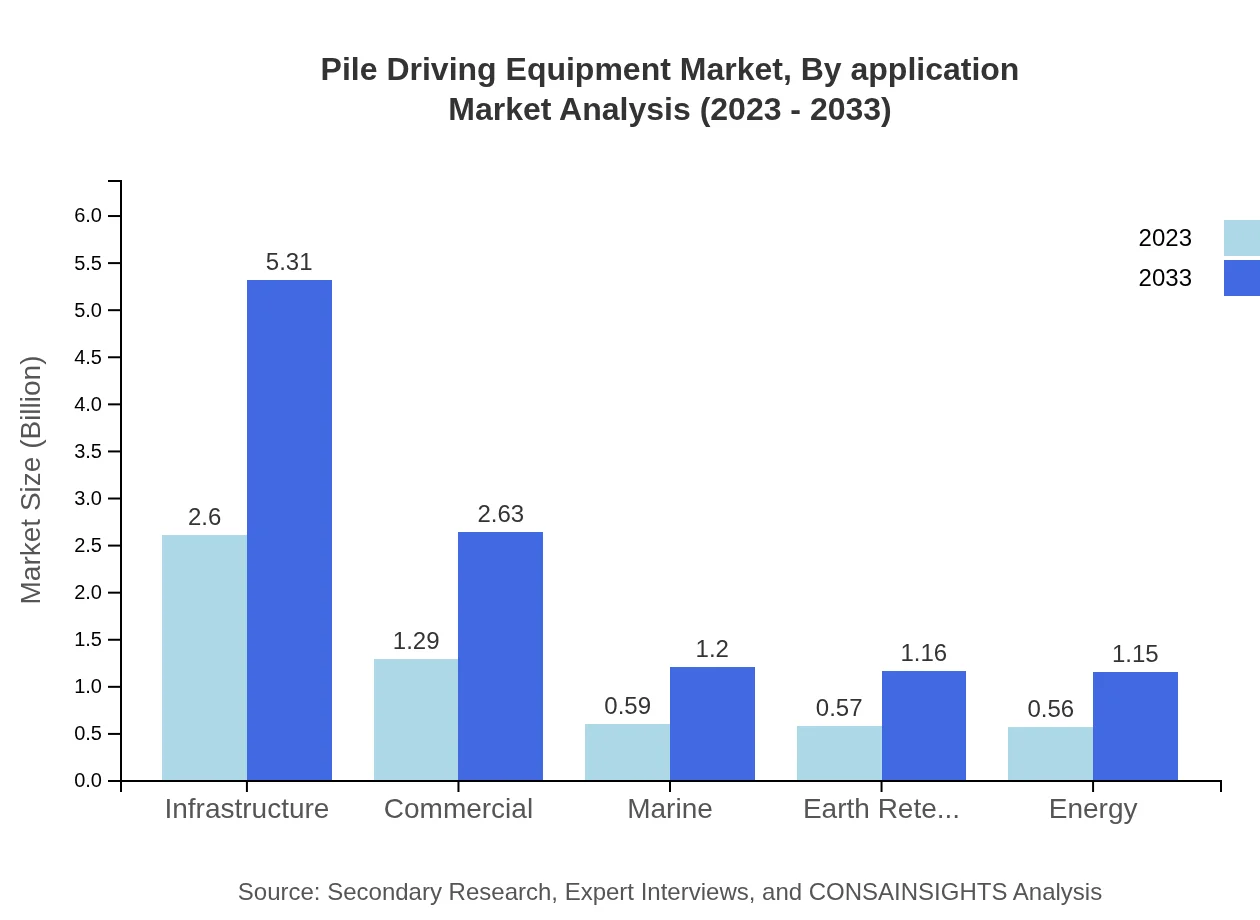

Pile Driving Equipment Market Analysis By Application

The application of pile driving equipment is heavily dominated by the construction industry, which holds a market value of $2.60 billion in 2023 and is expected to rise to $5.31 billion by 2033, maintaining a 46.39% market share throughout the forecast period. Other significant segments include government projects and the energy sector, each showing moderate growth as infrastructure and renewable energy projects proliferate.

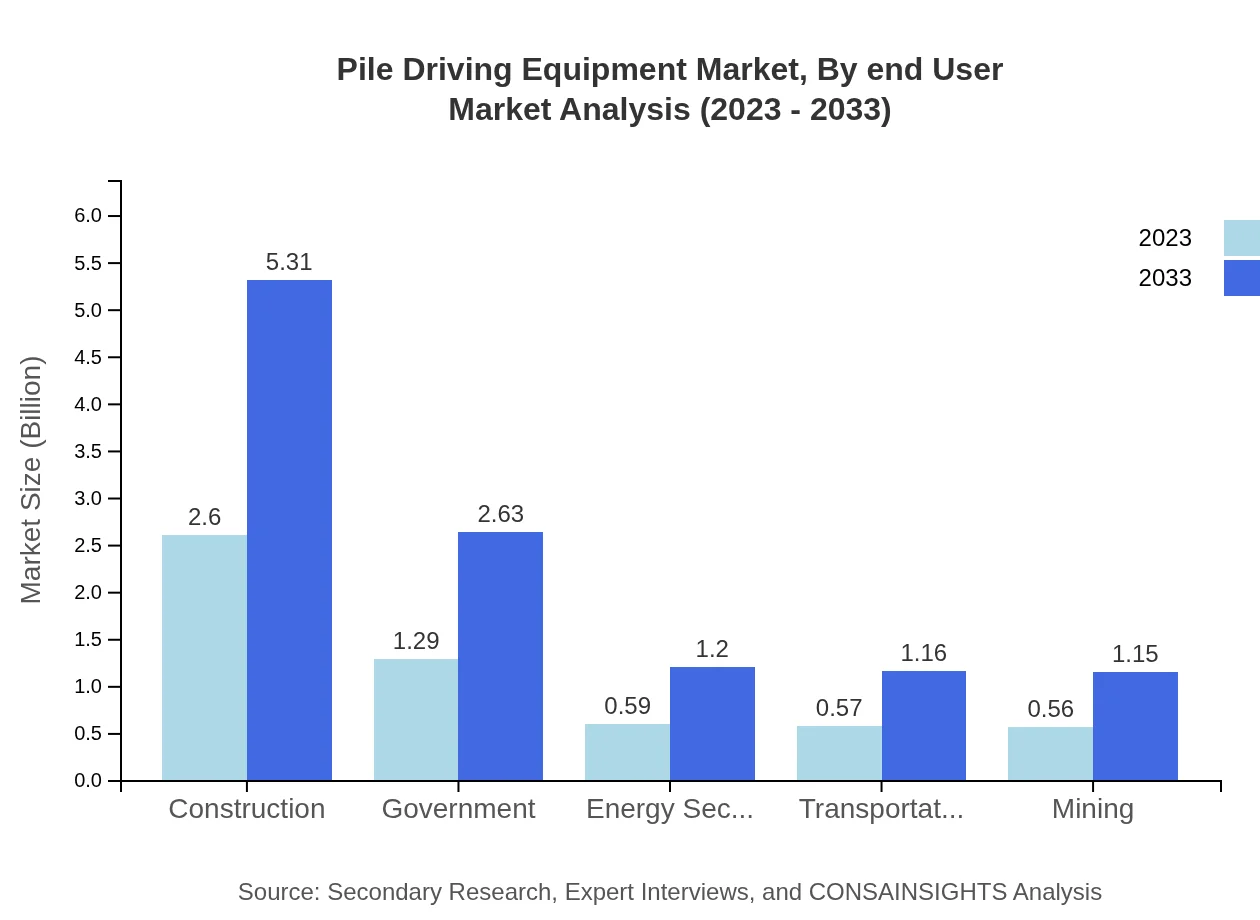

Pile Driving Equipment Market Analysis By End User

The end-user analysis reveals construction and infrastructure as the leading user of pile driving equipment, accounting for 46.39% of market share. The government sector also plays a pivotal role, with a current market share of 22.99% projected to grow in response to increased public infrastructure initiatives.

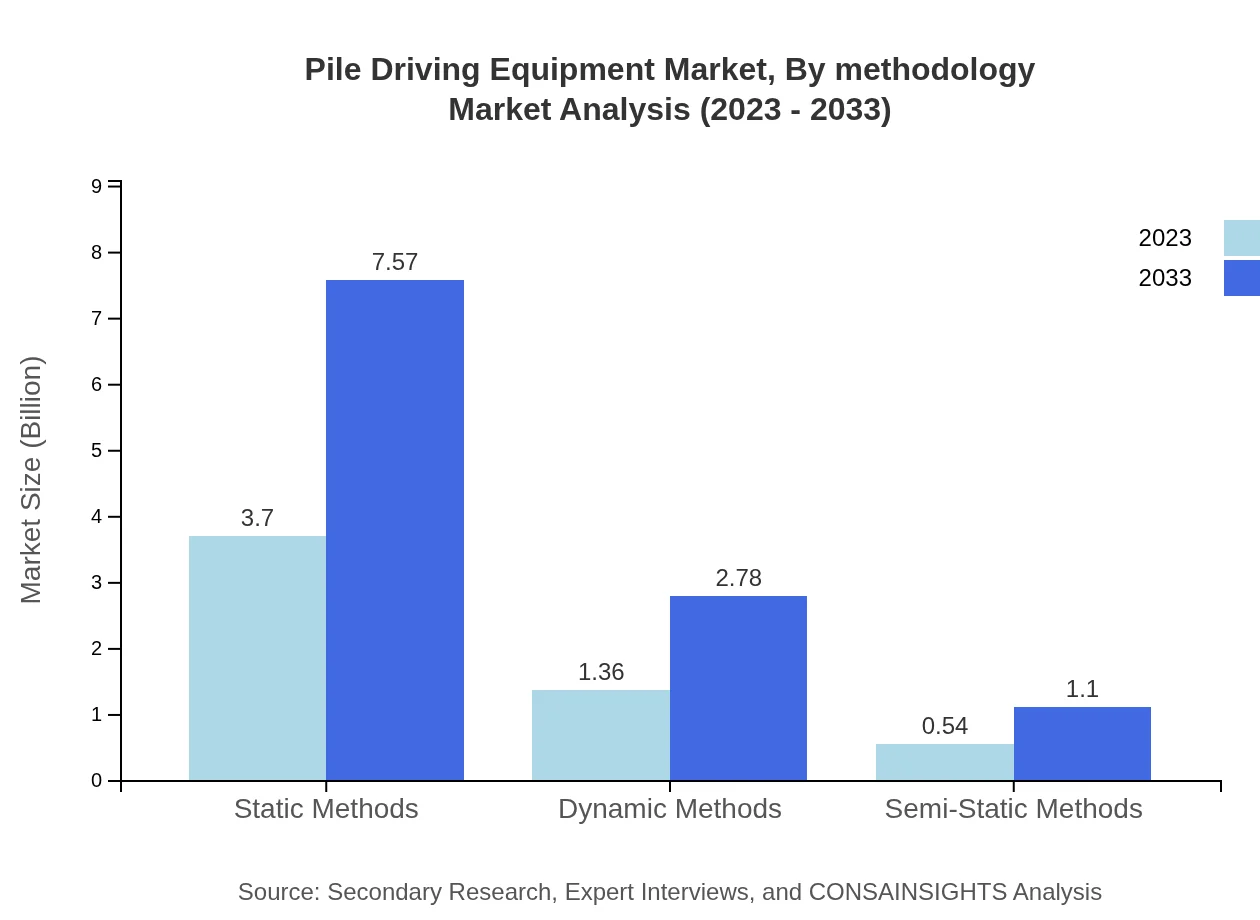

Pile Driving Equipment Market Analysis By Methodology

In terms of methodology, static methods dominate the market with a size of $3.70 billion in 2023 and are expected to reach $7.57 billion by 2033, retaining a strong 66.15% share. Dynamic methods follow with a solid performance in specific applications requiring high efficiency.

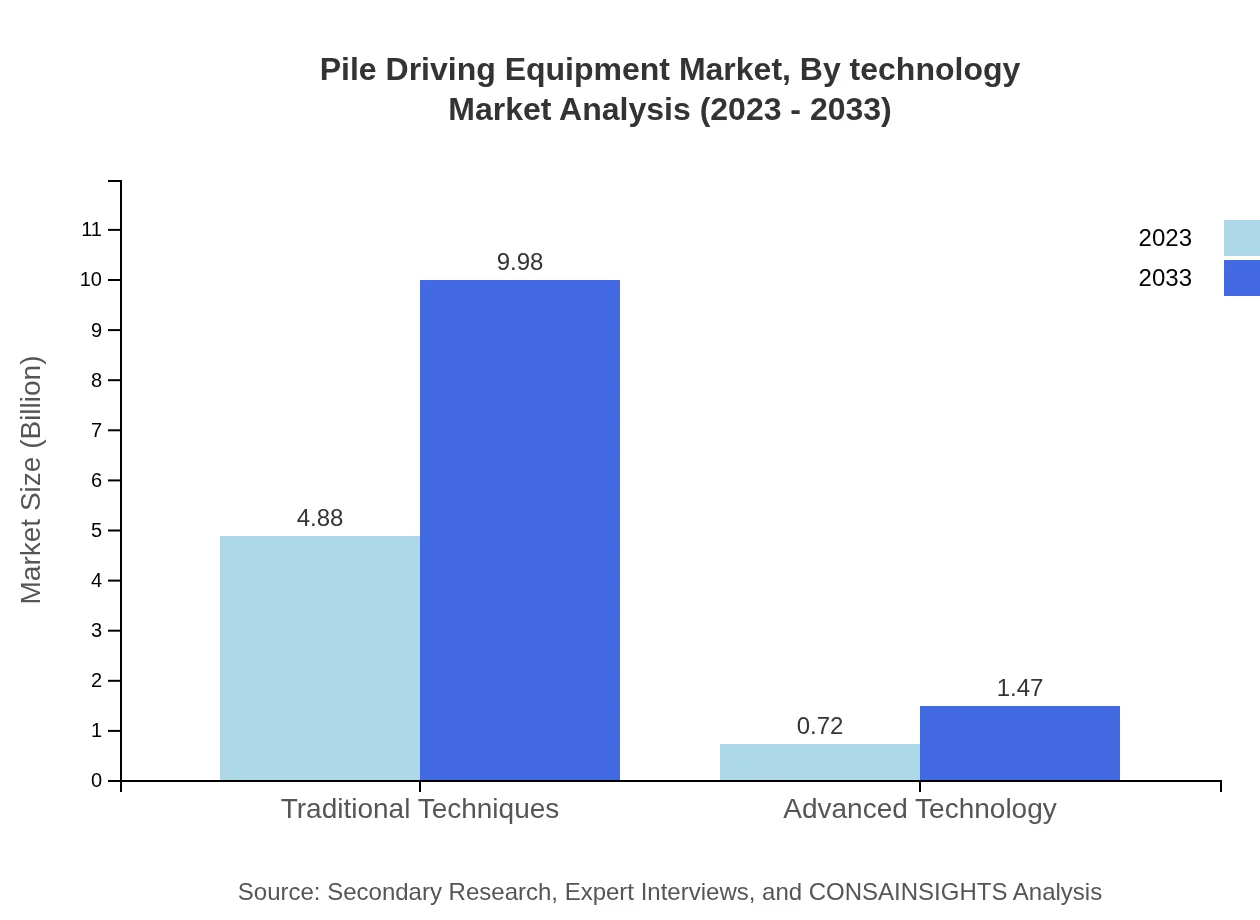

Pile Driving Equipment Market Analysis By Technology

Traditional techniques still make up the majority of market share at 87.16%, but advanced technology solutions are rapidly gaining ground, indicated by an increase to a market size of $0.72 billion by 2023, ramping up to $1.47 billion by 2033, showcasing a shift in preferences toward efficiency and lower environmental impact.

Pile Driving Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Pile Driving Equipment Industry

Terex Corporation:

A prominent player in the construction and mining markets, Terex has robust offerings in pile driving equipment and a global footprint.Soilmec S.p.A.:

An Italian-based company that specializes in foundation engineering and offers a range of advanced pile driving equipment.Bauer Group:

A major player in the construction field, Bauer offers solutions for building foundations and has significant expertise in pile driving technologies.Layher:

Layher provides innovative equipment, including high-performance pile driving solutions known for their efficiency and reliability.Atlas Copco:

A leading provider of sustainable productivity solutions including efficient pile driving equipment across global markets.We're grateful to work with incredible clients.

FAQs

What is the market size of pile Driving Equipment?

The global pile-driving equipment market has a current size of approximately $5.6 billion and is projected to grow at a CAGR of 7.2%. By 2033, this market is expected to significantly expand, reflecting the growing infrastructure needs worldwide.

What are the key market players or companies in the pile Driving Equipment industry?

Key players in the pile-driving equipment market include several established manufacturers and suppliers specializing in construction and heavy machinery. Their contributions and competitive strategies play a crucial role in shaping market dynamics and advancing technology innovations.

What are the primary factors driving the growth in the pile Driving equipment industry?

Growth in the pile-driving equipment industry is driven by increased construction activities, infrastructural development, and urbanization. Additionally, advancements in technology and methods of execution enhance efficiency, thereby boosting market demand as well.

Which region is the fastest Growing in the pile Driving equipment?

The Asia Pacific region emerges as the fastest-growing market for pile-driving equipment, expected to grow from $1.20 billion in 2023 to $2.45 billion by 2033. Factors include rapid industrialization and urban development efforts in the region.

Does ConsaInsights provide customized market report data for the pile Driving equipment industry?

Yes, ConsaInsights offers customized market report data tailored to the specific needs of clients within the pile-driving equipment industry, facilitating more precise insights and strategic planning for stakeholders.

What deliverables can I expect from this pile Driving equipment market research project?

Clients can expect comprehensive deliverables, including detailed market analysis, growth projections, competitive landscape assessments, and actionable insights on trends, weaknesses, and opportunities within the pile-driving equipment sector.

What are the market trends of pile Driving equipment?

Current market trends in pile-driving equipment include a shift towards advanced technology utilization, greater efficiency in techniques, and an increasing emphasis on sustainable practices. This aligns with demands for infrastructure investment and modernization across various sectors.