Pipe Insulation Market Report

Published Date: 22 January 2026 | Report Code: pipe-insulation

Pipe Insulation Market Size, Share, Industry Trends and Forecast to 2033

This report covers the Pipe Insulation market, providing insights on market conditions, segments, regional analysis, and future forecasts for 2023-2033. It offers a detailed overview and expert forecasts aimed at stakeholders in the industry.

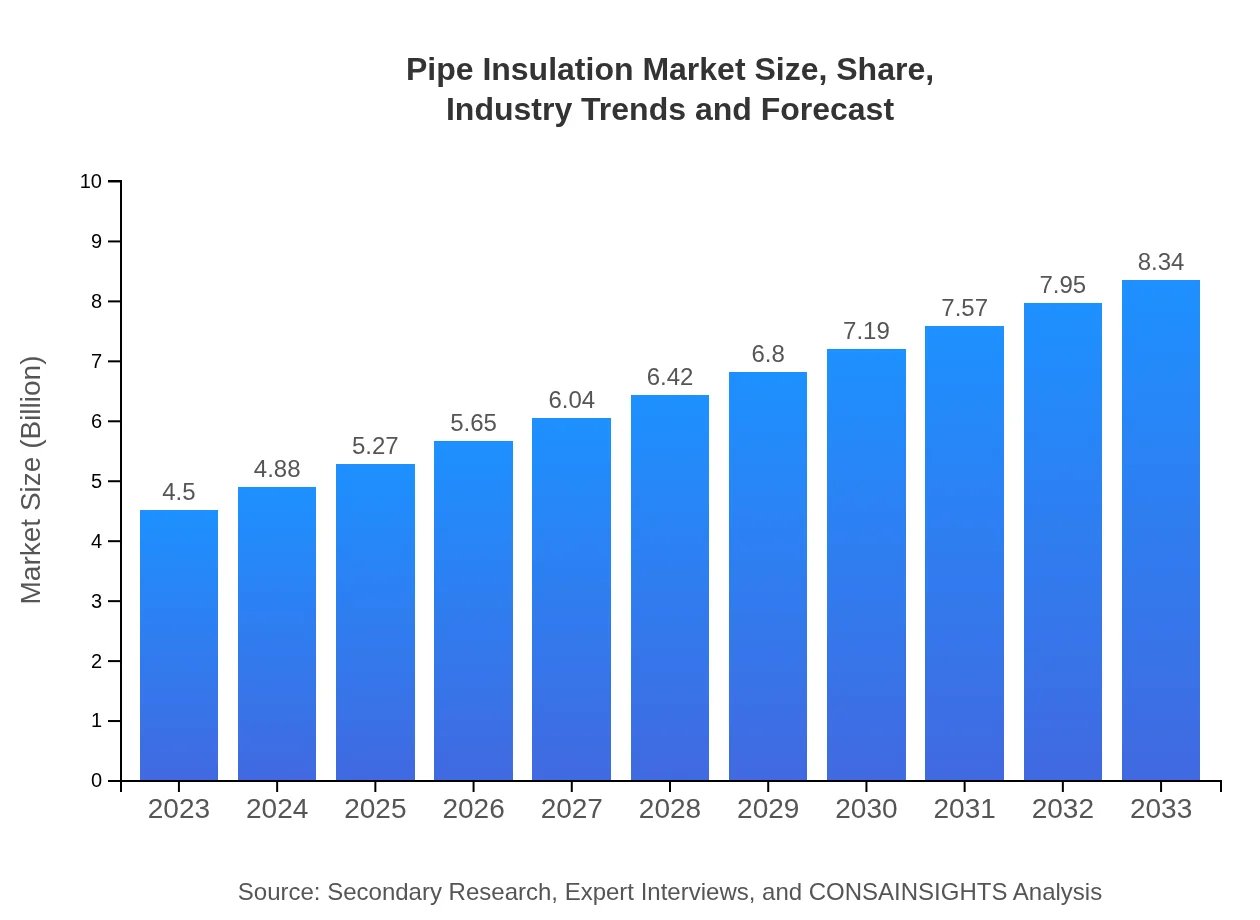

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $4.50 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $8.34 Billion |

| Top Companies | Owens Corning, Johns Manville, Kingspan Group, Rockwool International, Thermafiber |

| Last Modified Date | 22 January 2026 |

Pipe Insulation Market Overview

Customize Pipe Insulation Market Report market research report

- ✔ Get in-depth analysis of Pipe Insulation market size, growth, and forecasts.

- ✔ Understand Pipe Insulation's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Pipe Insulation

What is the Market Size & CAGR of Pipe Insulation market in 2023?

Pipe Insulation Industry Analysis

Pipe Insulation Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Pipe Insulation Market Analysis Report by Region

Europe Pipe Insulation Market Report:

The European market is anticipated to increase from $1.30 billion in 2023 to $2.40 billion by 2033 as a result of rigorous environmental standards and initiatives aimed at reducing carbon footprints. The construction and manufacturing sectors in countries like Germany, France, and the UK are major consumers of pipe insulation.Asia Pacific Pipe Insulation Market Report:

In the Asia-Pacific region, the Pipe Insulation market is expected to grow from $0.92 billion in 2023 to $1.70 billion in 2033, driven primarily by rapid urbanization and increasing industrial activities in countries like China and India. The adoption of stringent energy efficiency regulations is also promoting the usage of advanced insulation materials.North America Pipe Insulation Market Report:

North America's Pipe Insulation market is forecasted to expand significantly from $1.51 billion in 2023 to $2.80 billion by 2033, supported by a strong regulatory environment and a growing emphasis on sustainable building practices. The U.S. and Canada are leading the charge in promoting energy-efficient technologies.South America Pipe Insulation Market Report:

The South American market for Pipe Insulation is projected to grow from $0.35 billion in 2023 to $0.65 billion in 2033. This growth is influenced by emerging economies focusing on infrastructure development and energy efficiency improvements within the construction sector.Middle East & Africa Pipe Insulation Market Report:

In the Middle East and Africa, the Pipe Insulation market is expected to grow from $0.42 billion in 2023 to $0.79 billion in 2033, driven by the oil and gas sector's demand for efficient insulation materials. Additionally, growing construction projects due to economic diversification in the Gulf Cooperation Council (GCC) countries are boosting market demand.Tell us your focus area and get a customized research report.

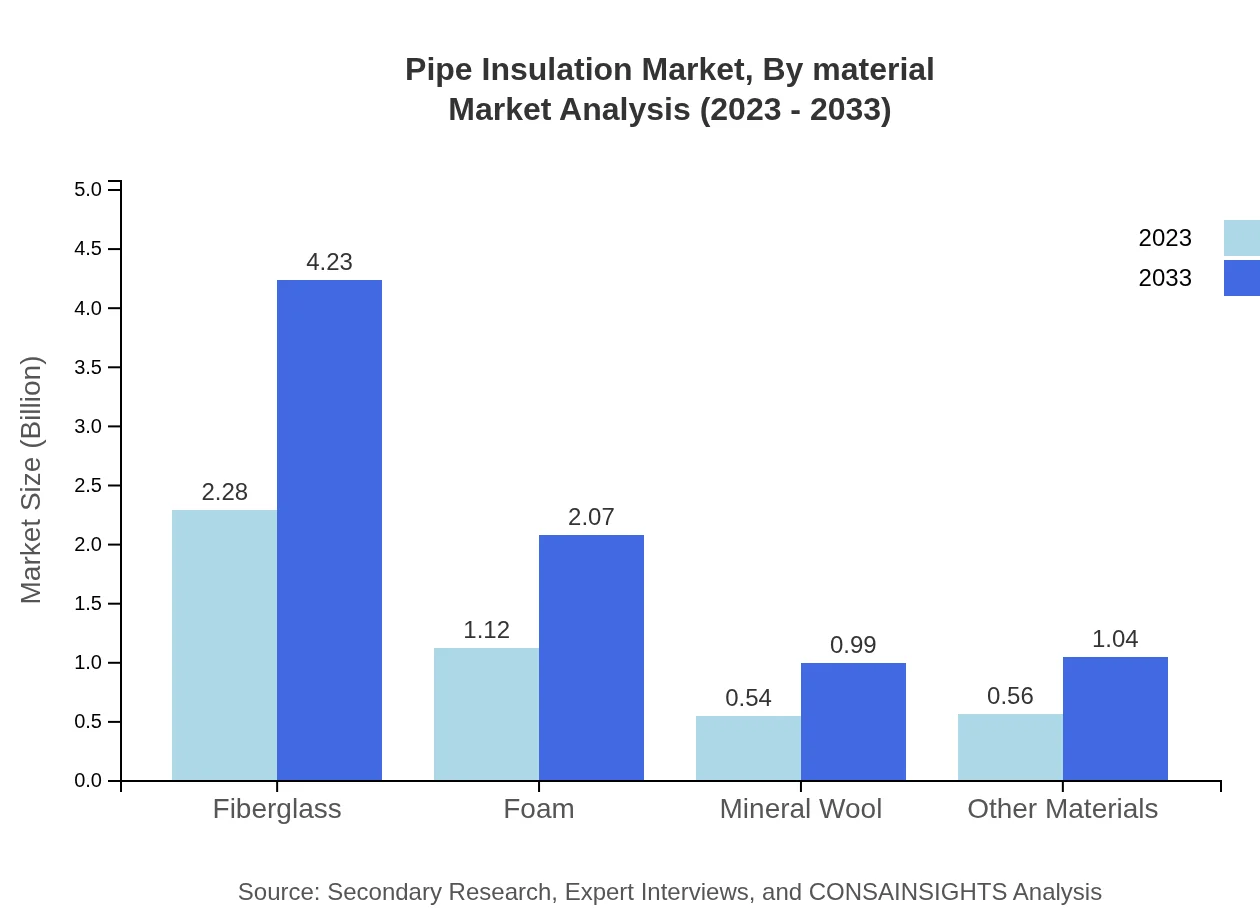

Pipe Insulation Market Analysis By Material

The material segment of the Pipe Insulation market includes diverse types such as fiberglass, foam, mineral wool, and others. As of 2023, fiberglass dominates the market with a volume of $2.28 billion, accounting for 50.77% of the total market share. Foam insulation, valued at $1.12 billion and capturing 24.82% share, is favored for its lightweight and excellent thermal performance. Mineral wool, while smaller at $0.54 billion, is notable for its fire-resistant properties.

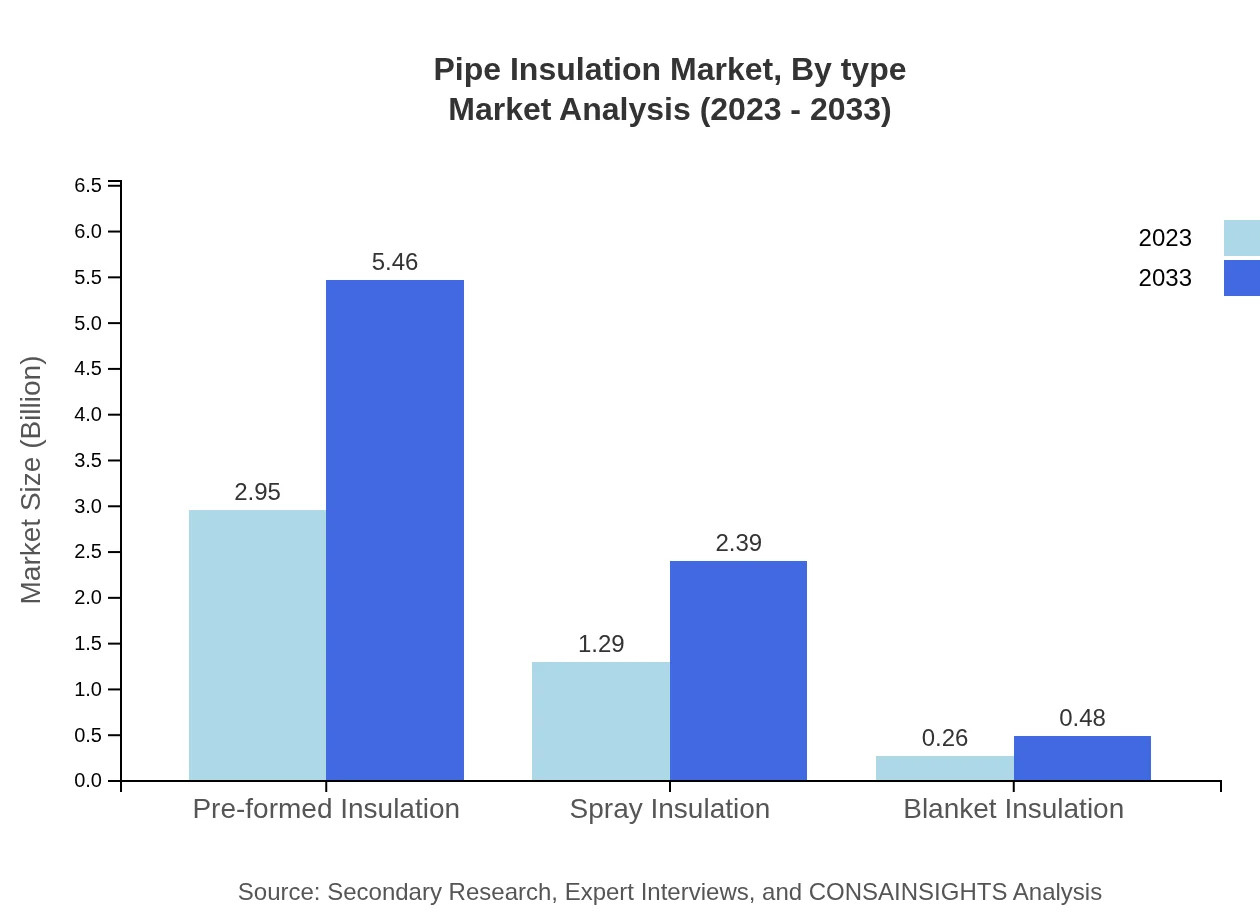

Pipe Insulation Market Analysis By Type

The Pipe Insulation market segments by type into pre-formed insulation, spray insulation, and blanket insulation. Pre-formed insulation leads the market at $2.95 billion in 2023, with its robustness in various applications. Spray insulation accounts for $1.29 billion and is known for its seamless application, while blanket insulation, though smaller at $0.26 billion, serves specific niche requirements.

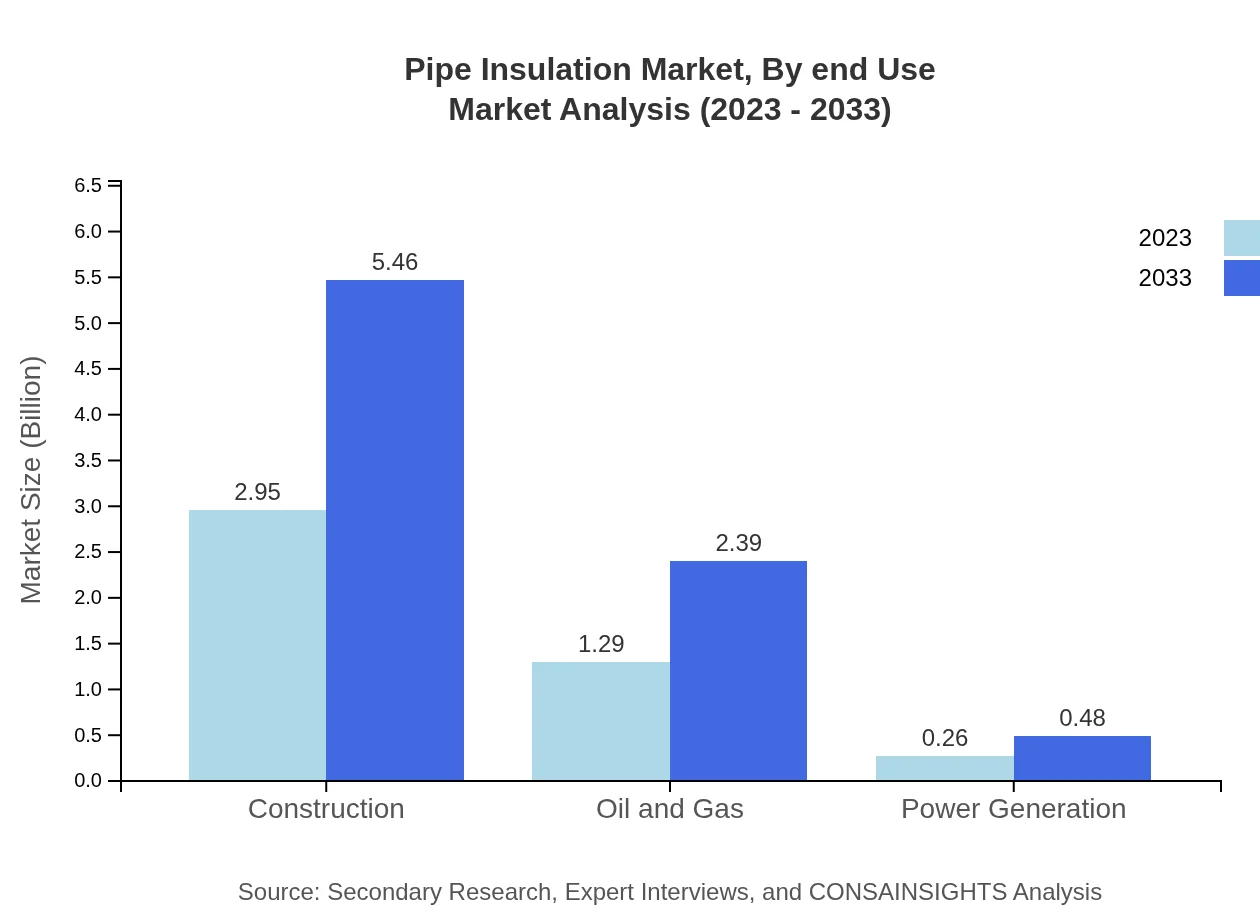

Pipe Insulation Market Analysis By Application

The applications of Pipe Insulation extend across construction, oil and gas, and power generation. Construction holds the largest share, valued at $2.95 billion in 2023 due to its significant role in energy conservation strategies. The oil and gas sector follows closely, valued at $1.29 billion, reflecting its critical need for thermal management. Power generation applications account for $0.26 billion.

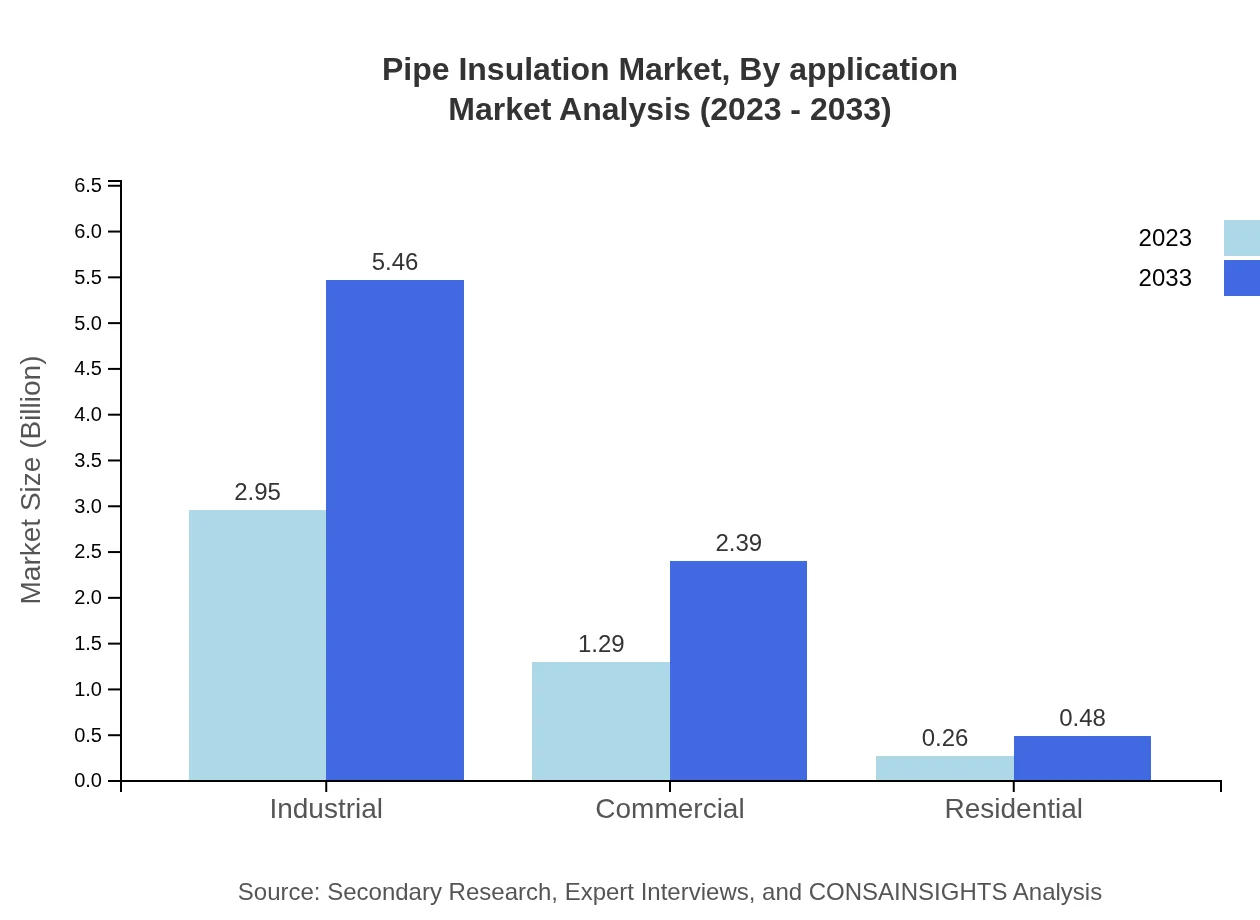

Pipe Insulation Market Analysis By End Use

The end-use segment is divided into industrial, commercial, and residential. Industrial applications lead with $2.95 billion in 2023, ensuring optimal thermal regulation. Commercial applications follow with $1.29 billion, addressing the need for energy efficiency in business settings. Residential applications, at $0.26 billion, represent a growing segment as homeowners focus on sustainability.

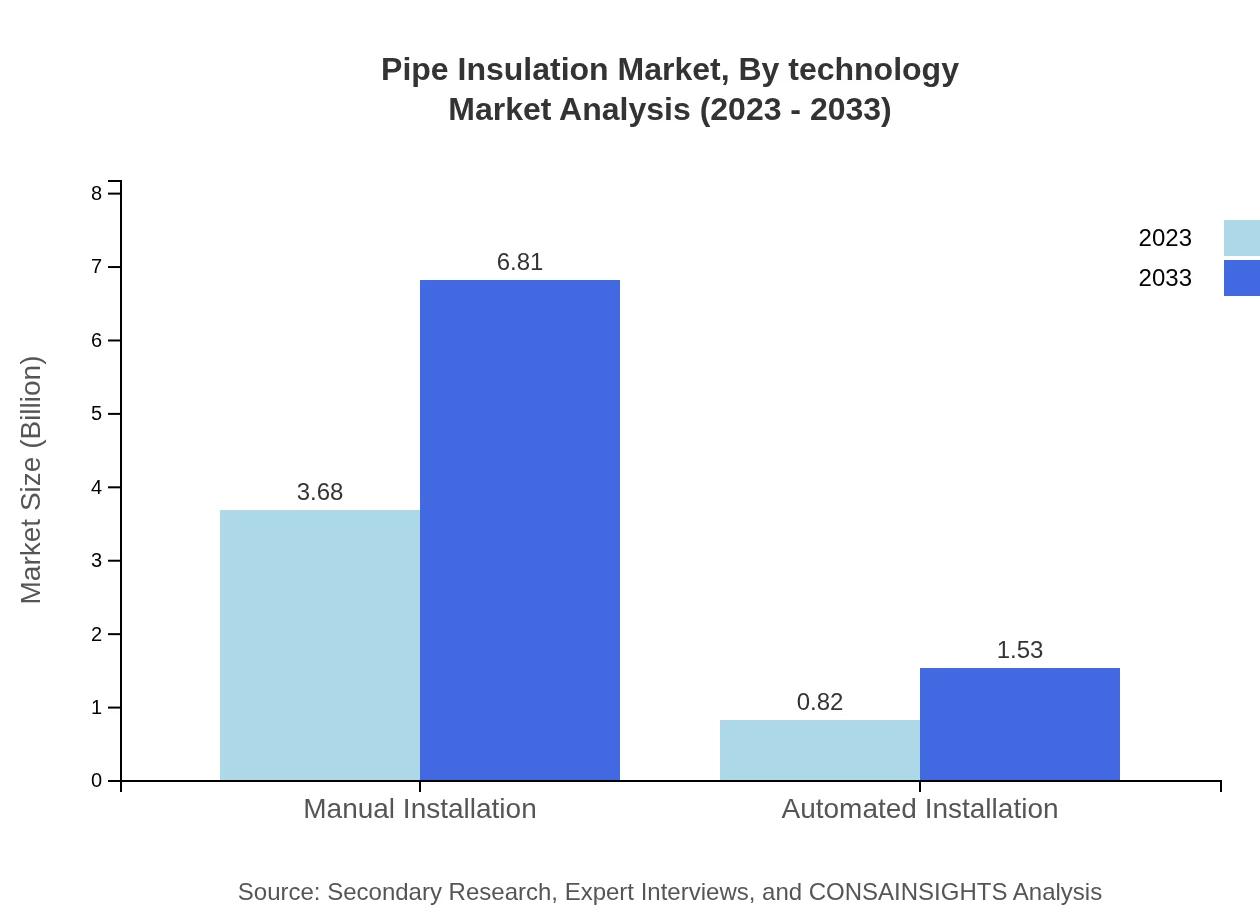

Pipe Insulation Market Analysis By Technology

Technological advancements in the Pipe Insulation market focus on manual and automated installation techniques. Manual installation currently dominates, representing $3.68 billion in 2023. However, automated installation is gradually gaining traction with potential growth from $0.82 billion as efficiency in on-site applications is optimized.

Pipe Insulation Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Pipe Insulation Industry

Owens Corning:

A leading global producer that specializes in fiberglass insulation solutions, Owens Corning is recognized for its energy-efficient products tailored for both residential and commercial applications.Johns Manville:

Part of Berkshire Hathaway, Johns Manville manufactures a variety of insulation products including fiberglass and mineral wool solutions, known for their high performance and sustainability.Kingspan Group:

Kingspan is a prominent innovator providing energy-efficient insulation boards and systems, widely used in construction and industrial sectors to boost energy performance.Rockwool International:

Rockwool focuses on stone wool insulation products that offer fire resistance and thermal efficiency, catering mainly to the construction and industrial segments.Thermafiber:

A leading manufacturer of mineral wool insulation products, Thermafiber is recognized for its environmentally sustainable insulation solutions used in various building projects.We're grateful to work with incredible clients.

FAQs

What is the market size of pipe insulation?

The global pipe insulation market is valued at approximately $4.5 billion in 2023, with an expected CAGR of 6.2% from 2023 to 2033, projecting significant growth in the coming decade.

What are the key market players or companies in the pipe insulation industry?

Key players in the pipe insulation industry include renowned companies such as Owens Corning, Armacell, and Rockwool International, which lead the market with advanced insulation products and innovations.

What are the primary factors driving the growth in the pipe insulation industry?

The growth of the pipe insulation market is driven by increasing energy efficiency regulations, rising construction activities, and a growing focus on reducing thermal losses in industrial applications.

Which region is the fastest Growing in the pipe insulation market?

The Asia Pacific region is projected to be the fastest-growing market for pipe insulation, expected to grow from $0.92 billion in 2023 to $1.70 billion by 2033, driven by urbanization and industrial expansion.

Does ConsaInsights provide customized market report data for the pipe insulation industry?

Yes, ConsaInsights offers customized market reports and data tailored to specific needs within the pipe insulation industry, accommodating unique client requirements for in-depth analysis.

What deliverables can I expect from this pipe insulation market research project?

Deliverables include a comprehensive market report, segment analysis, competitive landscape insights, trends, forecasts, and customized data visualizations to aid decision-making.

What are the market trends of pipe insulation?

Current trends in the pipe insulation market include increased adoption of eco-friendly materials, innovations in installation techniques, and a growing preference for pre-formed insulation products.