Plastic Compounding Machinery Market Report

Published Date: 22 January 2026 | Report Code: plastic-compounding-machinery

Plastic Compounding Machinery Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the plastic compounding machinery market from 2023 to 2033, highlighting current trends, insights, and forecasts in various regions, product types, and applications.

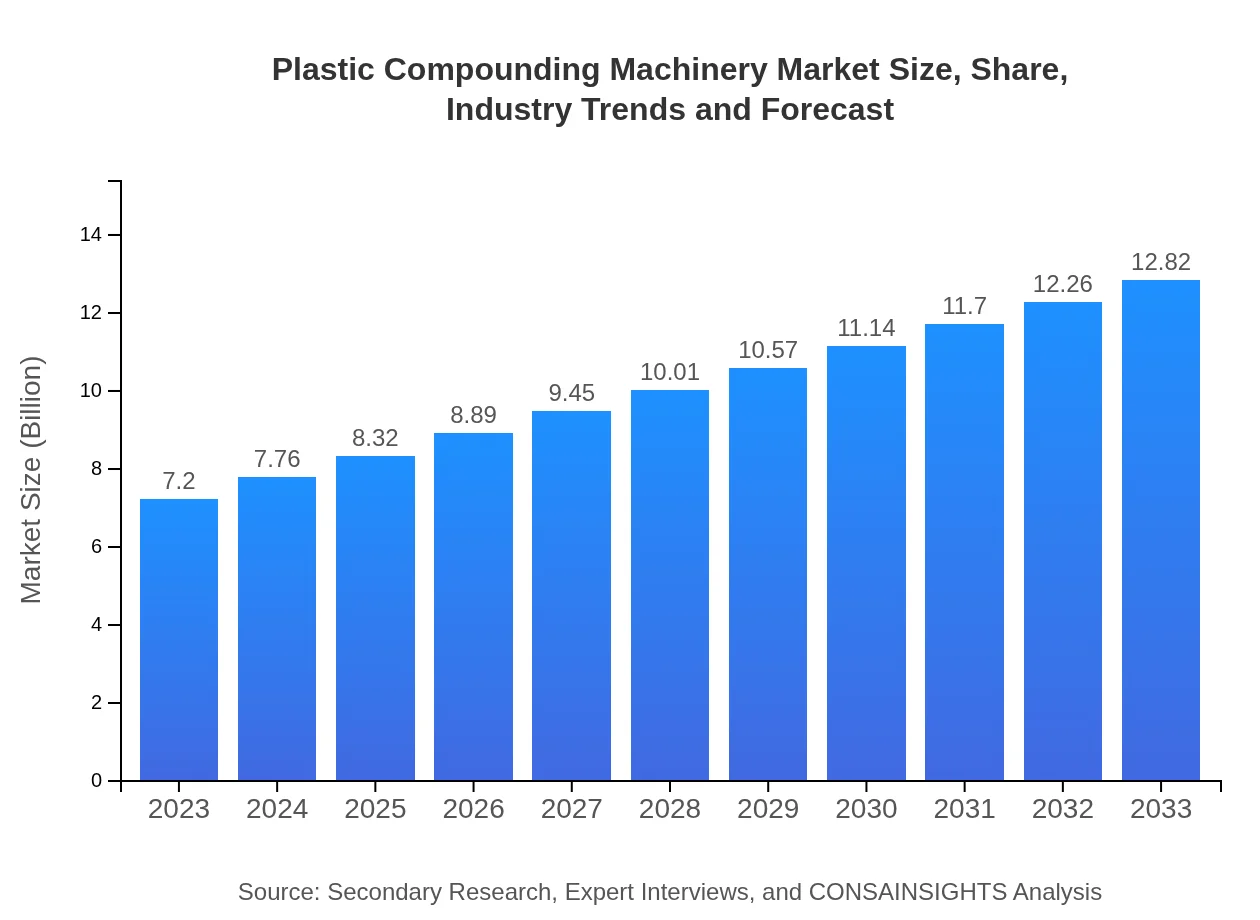

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $7.20 Billion |

| CAGR (2023-2033) | 5.8% |

| 2033 Market Size | $12.82 Billion |

| Top Companies | Battenfeld-Cincinnati, Coperion, Battenfeld Technologies, KraussMaffei |

| Last Modified Date | 22 January 2026 |

Plastic Compounding Machinery Market Overview

Customize Plastic Compounding Machinery Market Report market research report

- ✔ Get in-depth analysis of Plastic Compounding Machinery market size, growth, and forecasts.

- ✔ Understand Plastic Compounding Machinery's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Plastic Compounding Machinery

What is the Market Size & CAGR of Plastic Compounding Machinery market in 2023?

Plastic Compounding Machinery Industry Analysis

Plastic Compounding Machinery Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Plastic Compounding Machinery Market Analysis Report by Region

Europe Plastic Compounding Machinery Market Report:

Europe's market, starting at $2.41 billion in 2023 and expected to grow to $4.30 billion by 2033, benefits from robust manufacturing industries and significant investments in R&D for compounding machinery and processes.Asia Pacific Plastic Compounding Machinery Market Report:

In the Asia Pacific region, the market value is anticipated to grow from $1.25 billion in 2023 to $2.23 billion by 2033. The region's growth is driven by expanding manufacturing sectors and increased adoption of advanced compounding technologies, primarily in countries like China and India.North America Plastic Compounding Machinery Market Report:

North America will see its market grow from $2.59 billion in 2023 to $4.61 billion in 2033. The demand is largely driven by stringent regulations pushing for sustainable practices, along with innovation in compounding technologies that facilitate recycling.South America Plastic Compounding Machinery Market Report:

The South American market, valued at $0.38 billion in 2023, is projected to reach $0.68 billion by 2033. The growth in this region is influenced by rising plastic consumption and developments in local manufacturing capabilities, albeit at a slower pace compared to other regions.Middle East & Africa Plastic Compounding Machinery Market Report:

The Middle East and Africa saw a market value of $0.57 billion in 2023, anticipated to grow to $1.01 billion by 2033. Growth in this region can be attributed to increasing industrialization and plastic demand, coupled with foreign investment in manufacturing.Tell us your focus area and get a customized research report.

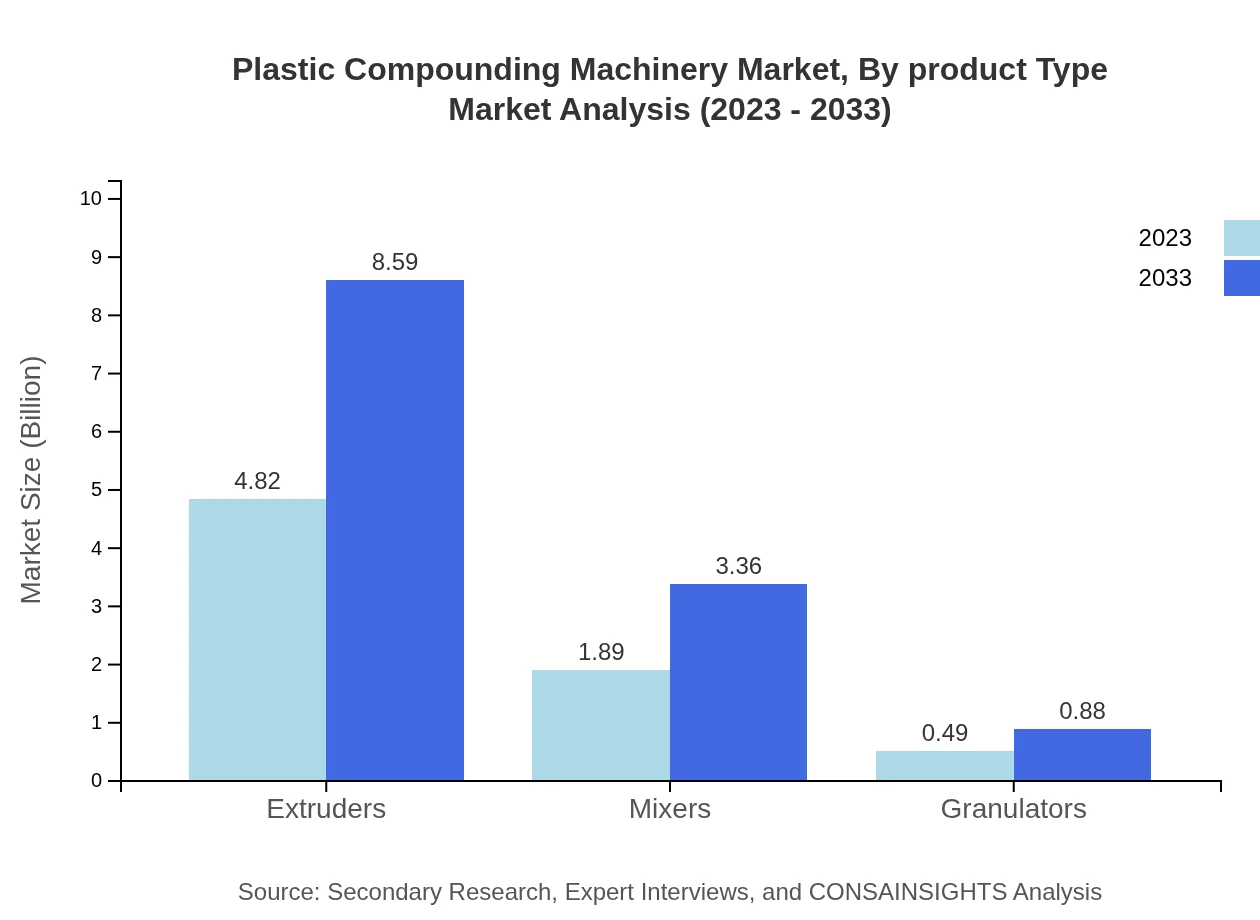

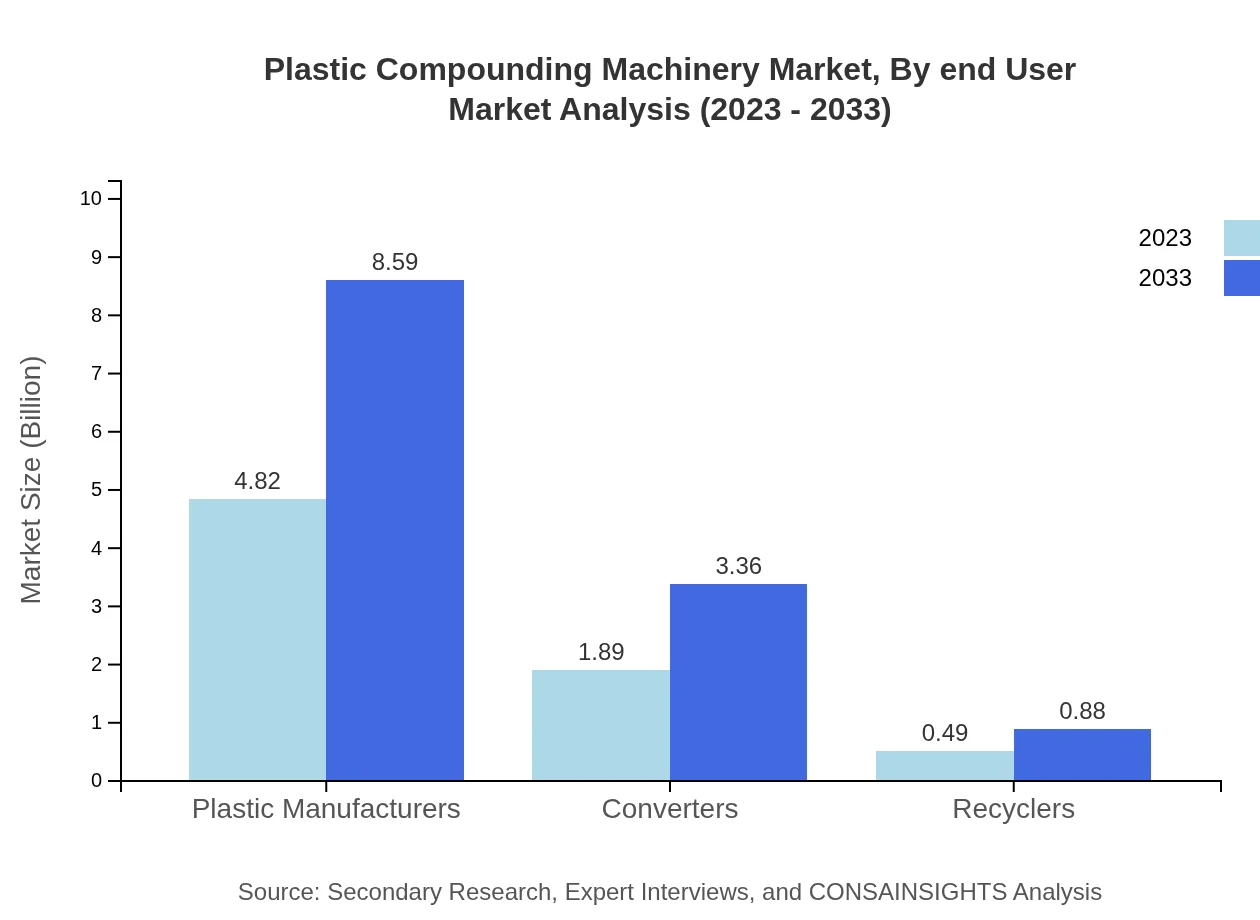

Plastic Compounding Machinery Market Analysis By Product Type

The key product types in the plastic compounding machinery market include extruders, mixers, and granulators. In 2023, the market for extruders is valued at $4.82 billion, projected to increase to $8.59 billion by 2033. This segment holds a 66.97% market share. Mixers follow with $1.89 billion in 2023, growing to $3.36 billion by 2033, holding a 26.2% share. Granulators are also significant, valued at $0.49 billion in 2023, with forecasts up to $0.88 billion in 2033, accounting for 6.83%.

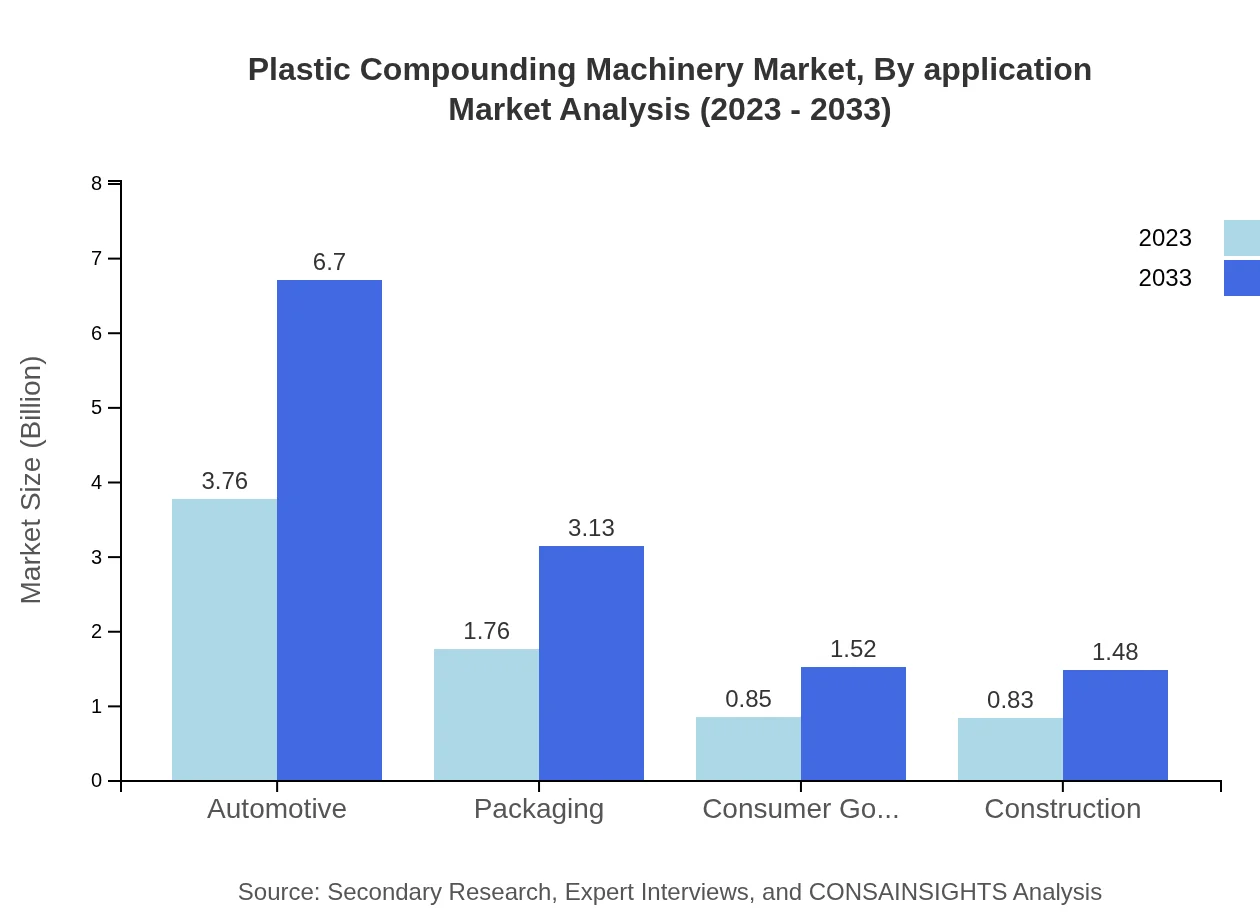

Plastic Compounding Machinery Market Analysis By Application

Application-wise, the automotive sector is the largest consumer, valued at $3.76 billion in 2023 and expected to reach $6.70 billion by 2033, holding a 52.23% market share. The packaging industry follows with a market size of $1.76 billion in 2023, increasing to $3.13 billion by 2033, representing 24.4%. The consumer goods and construction applications hold shares of 11.83% and 11.54%, respectively, highlighting their importance in the market.

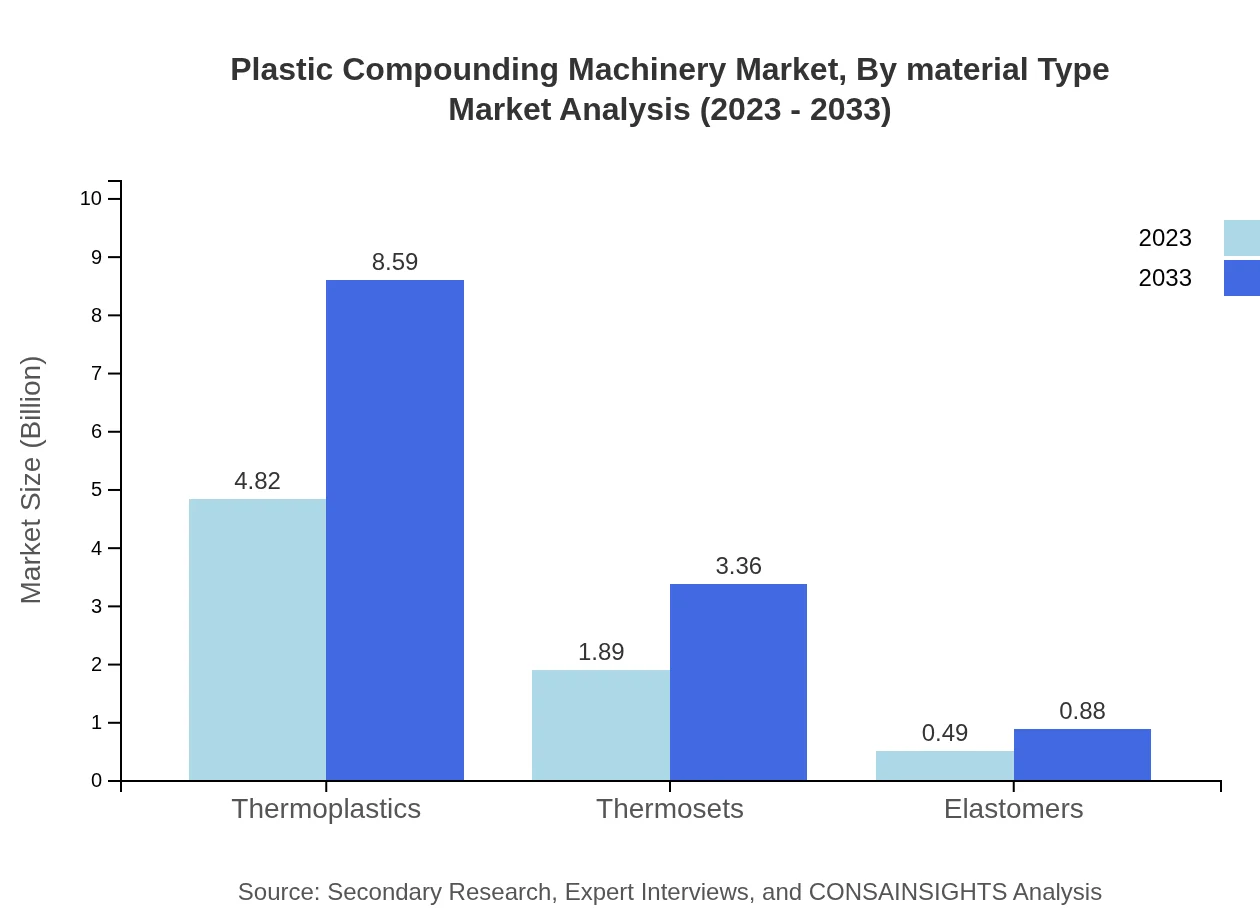

Plastic Compounding Machinery Market Analysis By Material Type

Material usage in production is segmented into thermoplastics, thermosets, and elastomers. Thermoplastics dominate the market with a size of $4.82 billion in 2023 and an increase to $8.59 billion by 2033, maintaining a 66.97% market share. Thermosets exhibit growth from $1.89 billion to $3.36 billion within the same period (26.2% market share), while elastomers account for 6.83%, from $0.49 billion to $0.88 billion.

Plastic Compounding Machinery Market Analysis By End User

End-user analysis reveals that the automotive sector remains the leading consumer of compounding machinery. However, other industries like packaging, consumer goods, and construction are steadily increasing their demand for efficient plastic compounding solutions to support production lines.

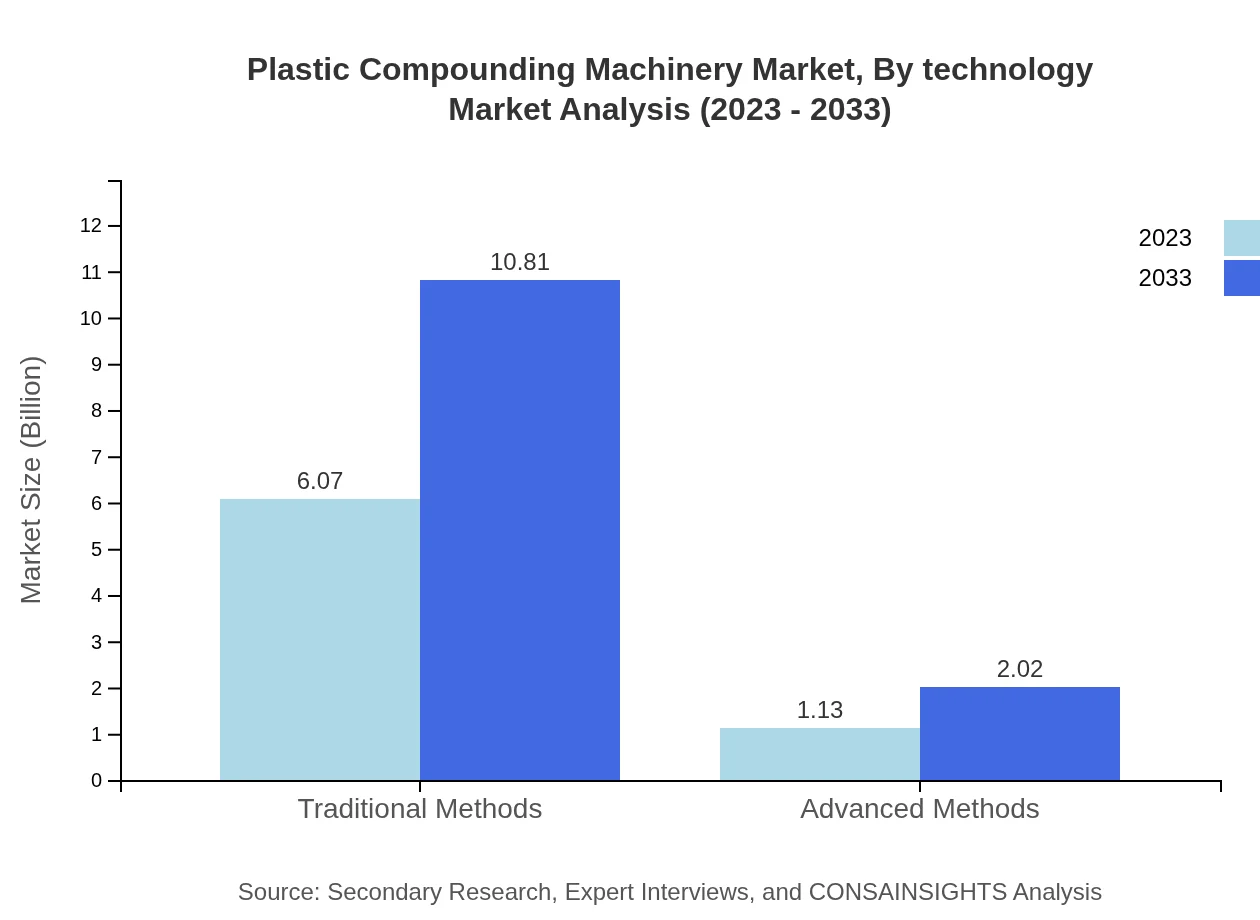

Plastic Compounding Machinery Market Analysis By Technology

There are emerging technologies influencing the market such as traditional methods and advanced methods. Traditional methods still command a large market share with $6.07 billion in 2023, growing to $10.81 billion by 2033 (84.28%). In comparison, advanced methods, although smaller in size, are growing from $1.13 billion to $2.02 billion, constituting 15.72% of market share, indicating a shift towards modernization in the industry.

Plastic Compounding Machinery Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Plastic Compounding Machinery Industry

Battenfeld-Cincinnati:

Known for advanced extruder technology, Battenfeld-Cincinnati has established itself as a leader in the compounding process, offering innovative solutions that enhance productivity.Coperion:

Coperion specializes in compounding and extrusion technologies, providing high-quality machinery that supports the needs of diverse industrial applications.Battenfeld Technologies:

A prominent player in the market, Battenfeld Technologies delivers cutting-edge machinery aimed at enhancing production efficiency and ensuring environmental sustainability.KraussMaffei:

KraussMaffei is famous for its highly advanced mixing and compounding processes which bolster manufacturing capabilities across various sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of plastic Compounding Machinery?

The plastic compounding machinery market is valued at approximately $7.2 billion in 2023, with a projected growth at a CAGR of 5.8%, indicating robust development and increasing demand through 2033.

What are the key market players or companies in this plastic Compounding Machinery industry?

Prominent players in the plastic compounding machinery sector include leading manufacturers focused on innovation and technological advancements, capturing a substantial market share through strategic partnerships and product diversification.

What are the primary factors driving the growth in the plastic Compounding Machinery industry?

Key drivers of growth in the plastic compounding machinery market include increasing demand for sustainable materials, advancements in production technology, and the expanding automotive and packaging sectors which significantly rely on innovative plastic solutions.

Which region is the fastest Growing in the plastic Compounding Machinery?

The Asia Pacific region is exhibiting the fastest growth in the plastic compounding machinery market, projected to escalate from $1.25 billion in 2023 to $2.23 billion by 2033, reflecting a strong industrial base and rising consumer demand.

Does ConsaInsights provide customized market report data for the plastic Compounding Machinery industry?

Yes, ConsaInsights specializes in offering customized market reports tailored to specific client requirements in the plastic compounding machinery sector, enabling unique insights and strategic decision-making.

What deliverables can I expect from this plastic Compounding Machinery market research project?

Deliverables from the plastic compounding machinery market research will include comprehensive reports, detailed market analyses, growth forecasts, competitive landscape assessments, and actionable insights tailored to stakeholder needs.

What are the market trends of plastic Compounding Machinery?

Key market trends include a strong shift towards automation, an increasing emphasis on recyclable materials, and growing diversification in production processes across various applications, enhancing overall efficiency and sustainability.