Plastic Fasteners Market Report

Published Date: 22 January 2026 | Report Code: plastic-fasteners

Plastic Fasteners Market Size, Share, Industry Trends and Forecast to 2033

This market report delves into the Plastic Fasteners industry, providing insights into market size, trends, segmentation, and future forecasts through to 2033. It aims to equip stakeholders with critical data for informed decision-making.

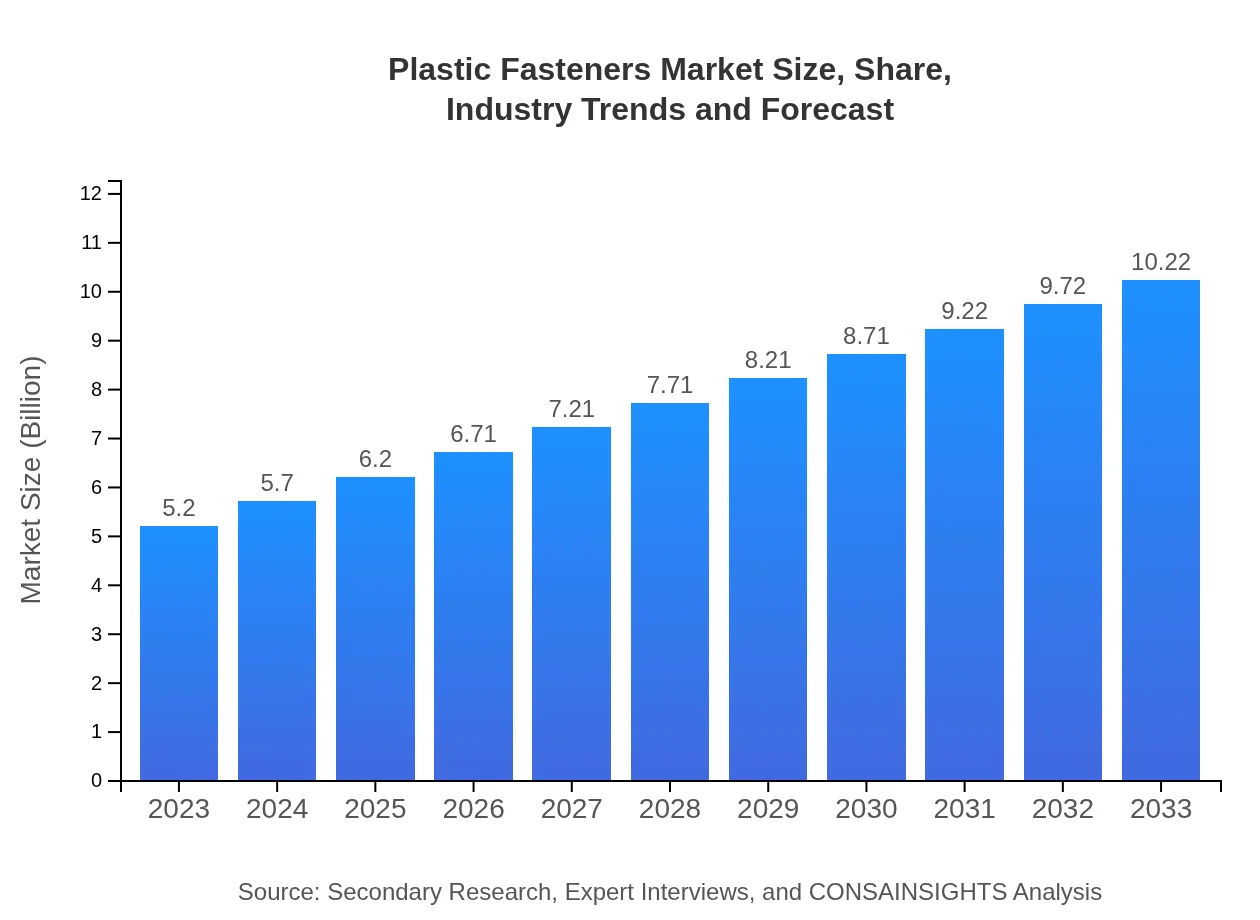

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.20 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $10.22 Billion |

| Top Companies | Bollhoff, ITW (Illinois Tool Works), 3M, Fastenal, Hilti |

| Last Modified Date | 22 January 2026 |

Plastic Fasteners Market Overview

Customize Plastic Fasteners Market Report market research report

- ✔ Get in-depth analysis of Plastic Fasteners market size, growth, and forecasts.

- ✔ Understand Plastic Fasteners's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Plastic Fasteners

What is the Market Size & CAGR of Plastic Fasteners market in 2023?

Plastic Fasteners Industry Analysis

Plastic Fasteners Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Plastic Fasteners Market Analysis Report by Region

Europe Plastic Fasteners Market Report:

The European market is anticipated to expand from $1.72 billion in 2023 to $3.39 billion by 2033. Factors contributing to this growth include stringent regulations mandating the use of lightweight materials and increased production activities in the automotive and general manufacturing sectors. Europe also emphasizes sustainable practices, further pushing the demand for high-quality plastic fasteners.Asia Pacific Plastic Fasteners Market Report:

In the Asia-Pacific region, the Plastic Fasteners market is projected to grow from $1.00 billion in 2023 to approximately $1.96 billion by 2033. This growth is fueled by the industrial expansion in countries like China and India, where manufacturing activities are on the rise. The increasing automotive production in Asia has significantly contributed to the demand for fasteners, reflecting a robust market outlook.North America Plastic Fasteners Market Report:

In North America, the market is forecasted to grow from $1.67 billion in 2023 to $3.27 billion by 2033. The U.S. remains the largest market due to its advanced manufacturing sector and growing demand in industries such as aerospace and automotive. Innovations in production technologies and rising environmental concerns are likely to drive market growth.South America Plastic Fasteners Market Report:

Latin America is characterized by moderate growth, with the market growing from $0.31 billion in 2023 to $0.61 billion by 2033. The growth is attributed to infrastructural developments and increasing investments in the automotive sector. Challenges include economic fluctuations impacting manufacturing costs and investments in sustainable materials.Middle East & Africa Plastic Fasteners Market Report:

The Middle East and Africa are expected to see the plastic fasteners market grow from $0.50 billion in 2023 to $0.99 billion by 2033. Construction activities across various countries are key growth drivers. However, the market faces challenges from political instability and economic uncertainty in parts of the region.Tell us your focus area and get a customized research report.

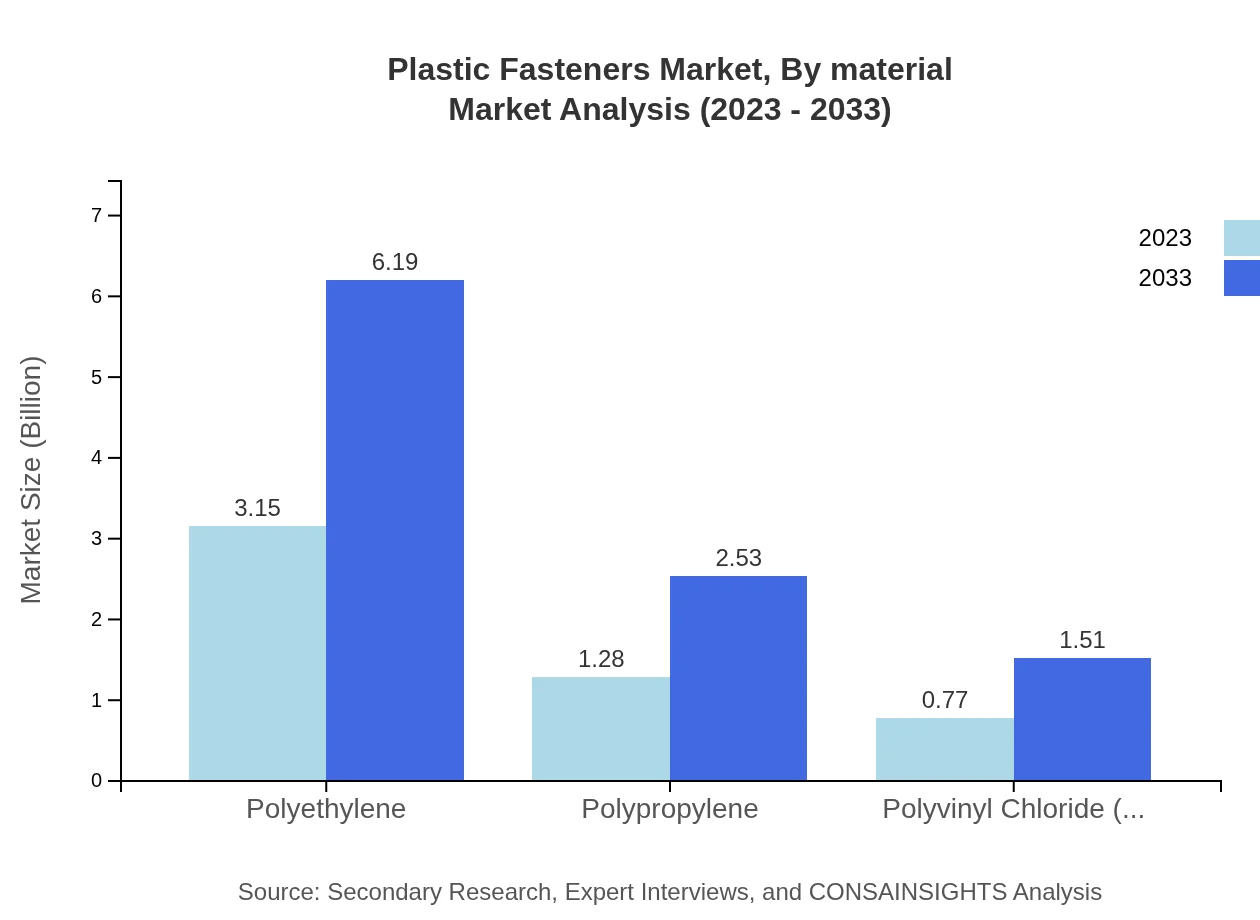

Plastic Fasteners Market Analysis By Material

The material segment comprises various polymers such as polyethylene, polypropylene, and polyvinyl chloride. Polyethylene leads the market with a 60.53% share in 2023 and is projected to maintain this position through to 2033, growing from $3.15 billion to $6.19 billion. Polypropylene constitutes 24.71% of the segment share, indicating significant growth from $1.28 billion to $2.53 billion. PVC is also significant, with expected growth from $0.77 billion to $1.51 billion, holding a steady 14.76% market share.

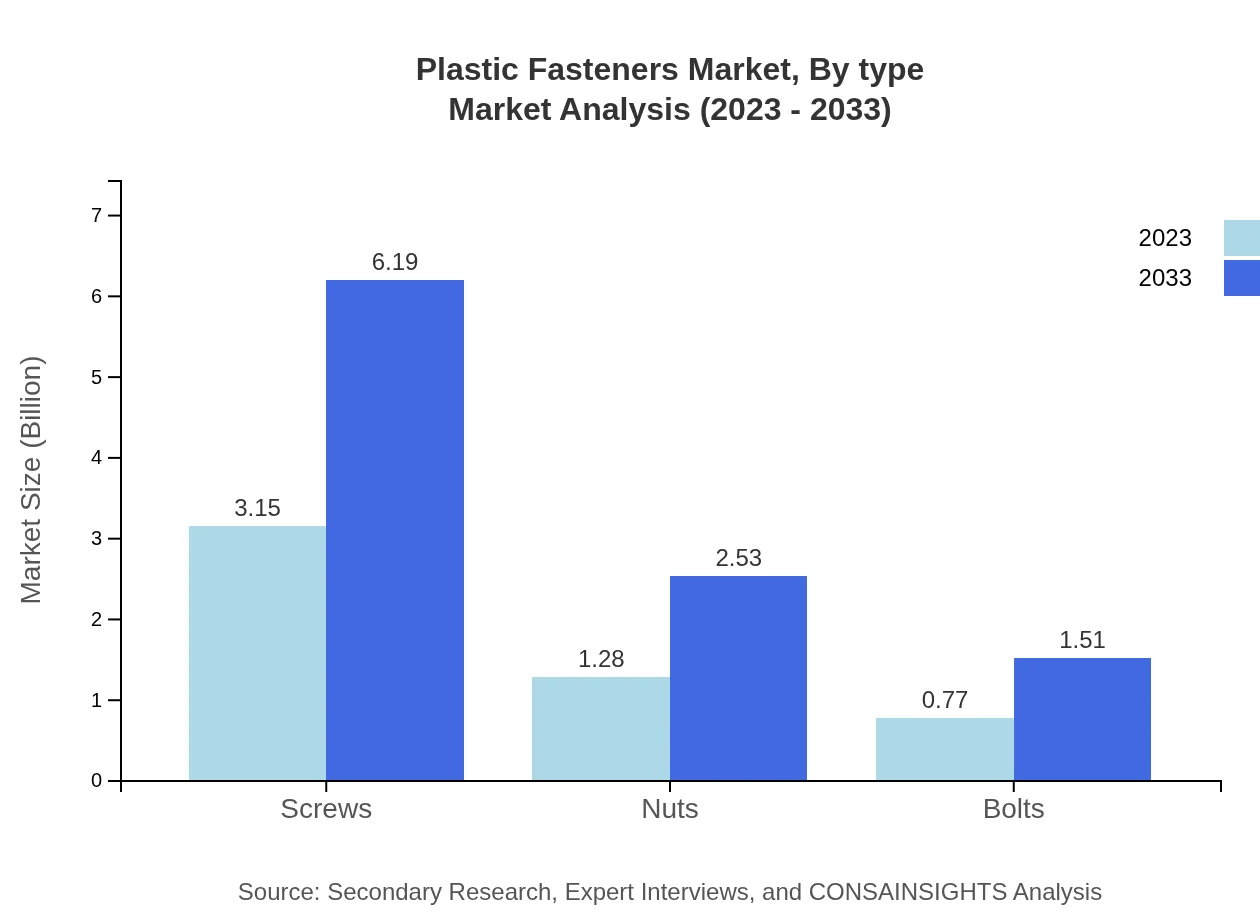

Plastic Fasteners Market Analysis By Type

The market is predominantly segmented by screws, nuts, and bolts. Screws are the most significant segment, capturing a 60.53% market share in 2023, with projections to grow from $3.15 billion to $6.19 billion by 2033. Nuts, constituting 24.71% of the market, are expected to grow from $1.28 billion to $2.53 billion. Bolts hold a smaller share at 14.76%, forecasting growth from $0.77 billion to $1.51 billion.

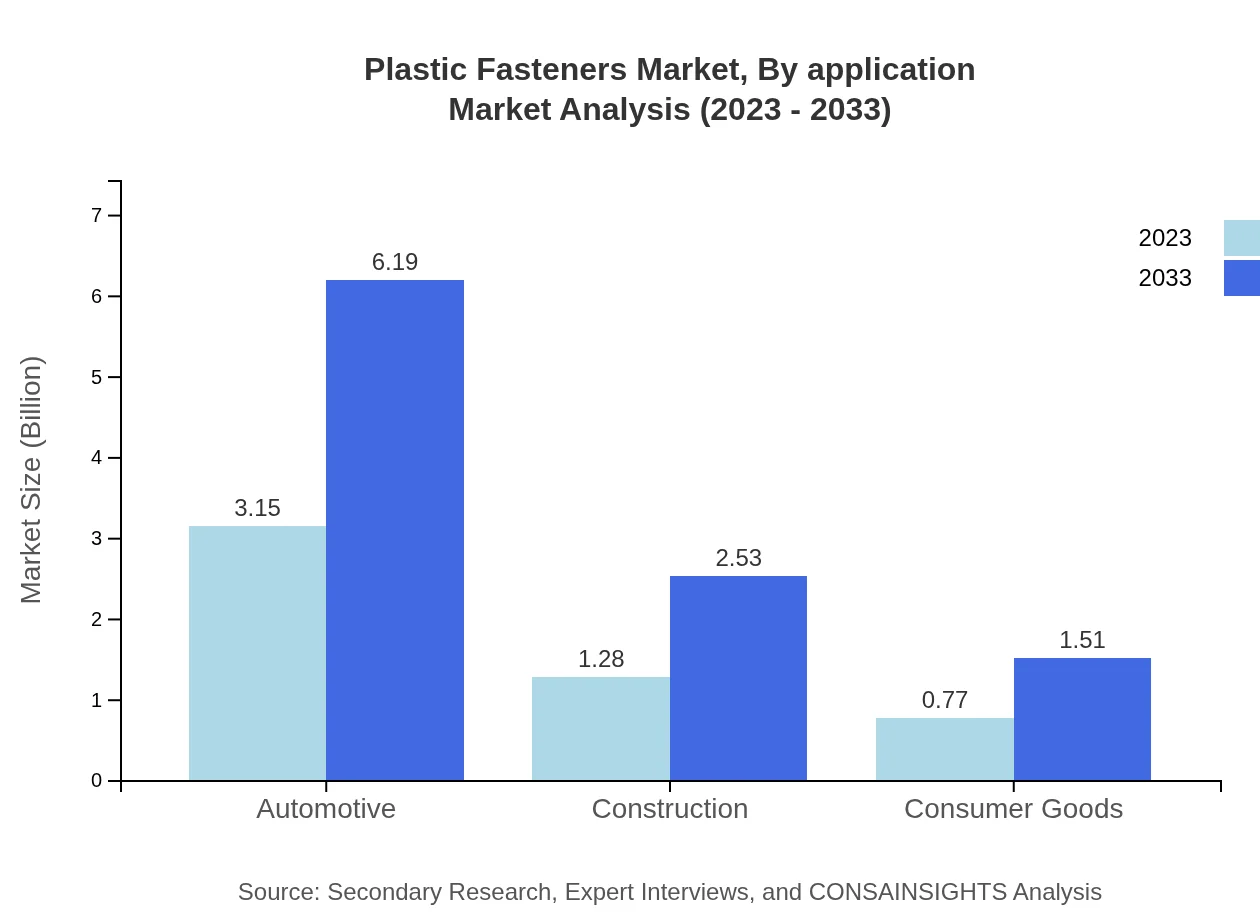

Plastic Fasteners Market Analysis By Application

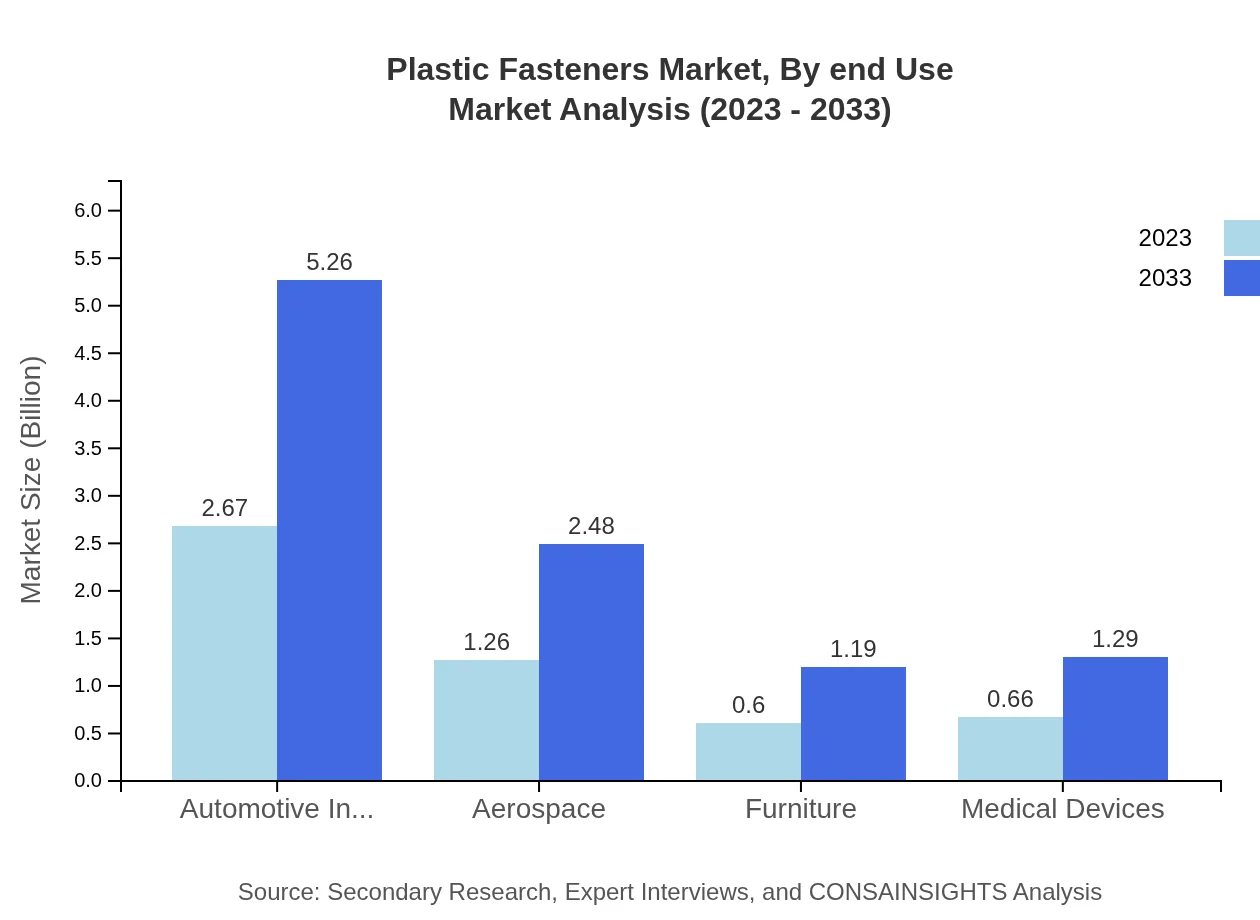

The application segmentation shows strong demand from the automotive industry, which represents 51.43% of the market share in 2023. This sector is expected to grow from $2.67 billion to $5.26 billion by 2033. Aerospace and medical devices also hold significant shares, with the aerospace segment anticipated to grow from $1.26 billion to $2.48 billion, while the medical devices segment is forecasted to increase from $0.66 billion to $1.29 billion.

Plastic Fasteners Market Analysis By End Use

The Plastic Fasteners market exhibits robust performance across various end-use industries. Notable end-users include automotive, construction, and consumer goods, with automotive contributing significantly to the market. The construction industry, holding 24.71% market share, is projected to grow steadily. Consumer goods see a market growth from $0.77 billion to $1.51 billion, emphasizing the versatility of plastic fasteners across sectors.

Plastic Fasteners Market Analysis By Distribution Channel

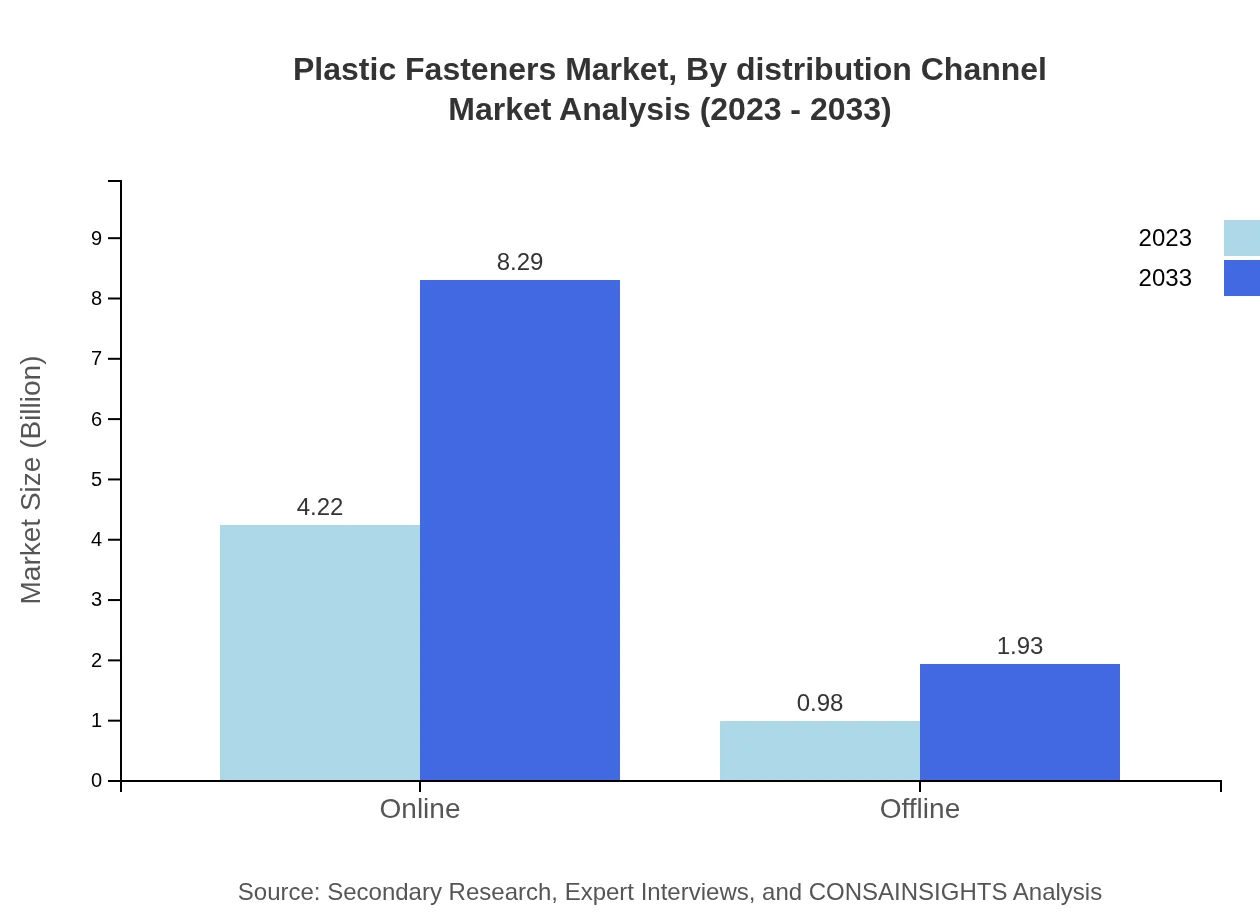

The distribution channels are segmented into online and offline markets. The online segment dominates with an 81.15% market share in 2023, showing strong growth potential from $4.22 billion to $8.29 billion by 2033. Offline channels, while smaller at 18.85%, are also projected to grow from $0.98 billion to $1.93 billion, showing the importance of both direct sales and e-commerce in the distribution of plastic fasteners.

Plastic Fasteners Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Plastic Fasteners Industry

Bollhoff:

Bollhoff is a leading manufacturer of fastening and assembly technology, known for its innovative solutions and applications in various sectors, including automotive and aerospace.ITW (Illinois Tool Works):

ITW specializes in engineered fasteners and is recognized for its strong presence in the construction and electronics markets. Their commitment to quality and sustainability is paramount.3M:

3M is a global leader in industrial adhesives and fasteners, providing a wide array of products that ensure strong, reliable performance for various applications.Fastenal:

Fastenal offers a comprehensive range of fasteners and industrial supplies, emphasizing customer service and expansive distribution channels.Hilti:

Known for its commitment to innovation and high-performance products, Hilti is a dominant player in the fastening market, especially within the construction sector.We're grateful to work with incredible clients.

FAQs

What is the market size of plastic fasteners?

The plastic fasteners market is projected to reach USD 5.2 billion by 2033, growing at a CAGR of 6.8%. This growth reflects increased demand across various industries including automotive, aerospace, and furniture.

What are the key market players or companies in the plastic fasteners industry?

Key players in the plastic fasteners market include major companies offering diverse fastening solutions. They focus on innovation and expanding product portfolios to maintain competitive advantages in this growing industry.

What are the primary factors driving the growth in the plastic fasteners industry?

Driving factors include increasing demand from the automotive sector, advancements in manufacturing technology, and a shift towards lightweight and cost-effective materials. These factors collectively contribute to market growth.

Which region is the fastest Growing in the plastic fasteners market?

The fastest-growing region is Europe, with an increase from USD 1.72 billion in 2023 to USD 3.39 billion by 2033. This growth is fueled by strong manufacturing and automotive sectors.

Does ConsaInsights provide customized market report data for the plastic fasteners industry?

Yes, ConsaInsights offers customized market reports tailored to specific needs within the plastic fasteners industry. Clients can request specific segments or insights for a comprehensive analysis.

What deliverables can I expect from this plastic fasteners market research project?

Deliverables typically include a detailed report with market size, growth forecasts, segmentation analysis, competitor profiles, and regional insights, providing a comprehensive view of the plastic fasteners market.

What are the market trends of plastic fasteners?

Current trends include a shift towards sustainable materials, increased adoption of automation in production, and growing popularity in the renewable energy sector, indicating a progressive growth trajectory.