Pneumatic Conveying Systems Market Report

Published Date: 22 January 2026 | Report Code: pneumatic-conveying-systems

Pneumatic Conveying Systems Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the pneumatic conveying systems market, outlining market size, trends, technology advancements, and regional insights from 2023 to 2033.

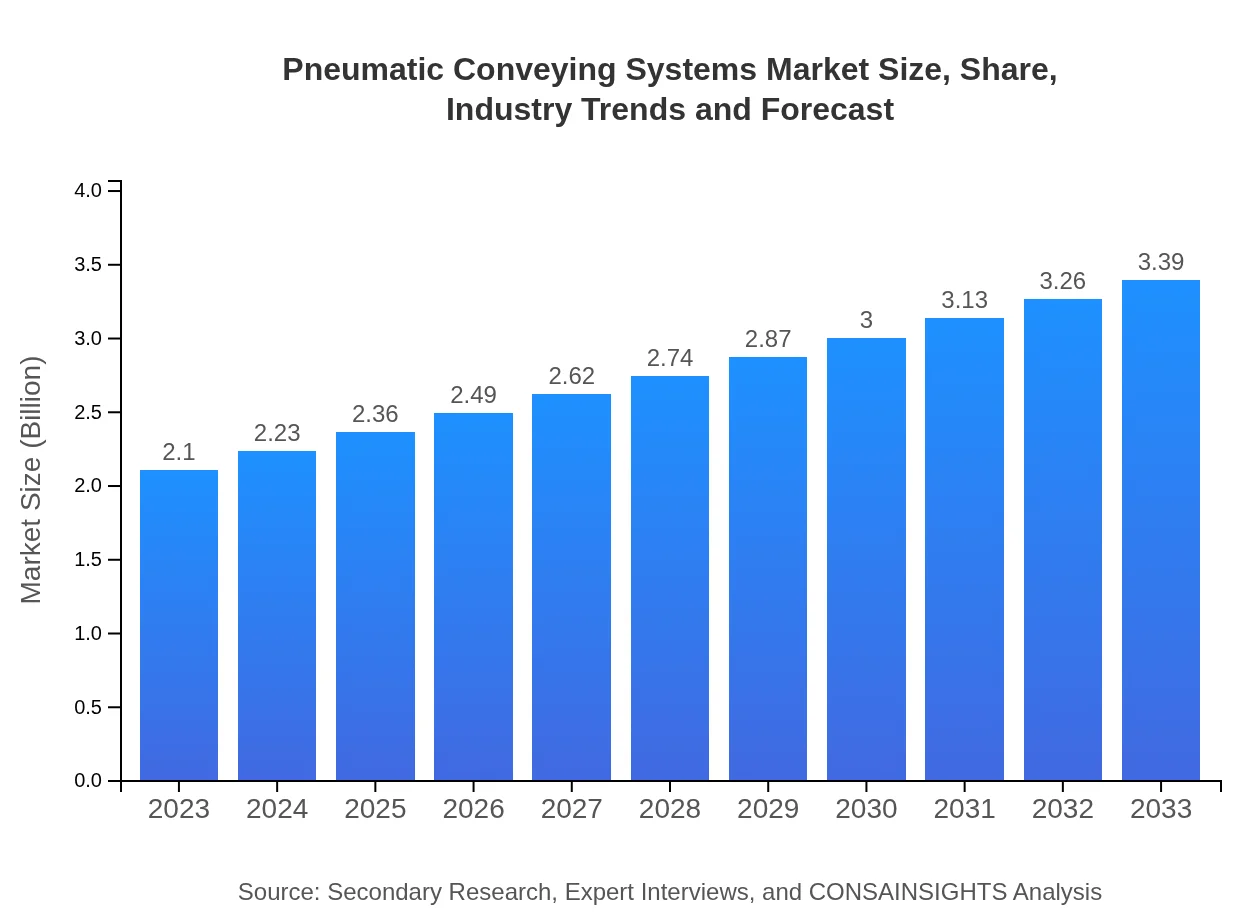

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.10 Billion |

| CAGR (2023-2033) | 4.8% |

| 2033 Market Size | $3.39 Billion |

| Top Companies | Schneider Electric, FLSmidth, Coperion GmbH, Nilfisk Group |

| Last Modified Date | 22 January 2026 |

Pneumatic Conveying Systems Market Overview

Customize Pneumatic Conveying Systems Market Report market research report

- ✔ Get in-depth analysis of Pneumatic Conveying Systems market size, growth, and forecasts.

- ✔ Understand Pneumatic Conveying Systems's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Pneumatic Conveying Systems

What is the Market Size & CAGR of Pneumatic Conveying Systems market in 2023?

Pneumatic Conveying Systems Industry Analysis

Pneumatic Conveying Systems Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Pneumatic Conveying Systems Market Analysis Report by Region

Europe Pneumatic Conveying Systems Market Report:

The European market, valued at USD 0.51 billion in 2023, is set to increase to USD 0.82 billion by 2033. Regulations favoring cleaner technologies and investments in food and beverage processing are key factors driving this growth.Asia Pacific Pneumatic Conveying Systems Market Report:

The Asia-Pacific region is projected to grow significantly due to rapid industrialization and urbanization, with a market size of USD 0.46 billion in 2023 expected to reach USD 0.74 billion by 2033. Countries such as China and India are leading this growth, driven by increasing manufacturing activity.North America Pneumatic Conveying Systems Market Report:

North America is expected to hold a significant share of the market, starting at USD 0.79 billion in 2023 and projected to grow to USD 1.27 billion by 2033. The U.S. leads this growth due to technological advancements and automation in food and beverage industries.South America Pneumatic Conveying Systems Market Report:

In South America, the market for pneumatic conveying systems is expected to rise from USD 0.16 billion in 2023 to USD 0.26 billion by 2033. This growth is fueled by expansion in sectors such as food processing and pharmaceuticals across nations like Brazil and Argentina.Middle East & Africa Pneumatic Conveying Systems Market Report:

The Middle East and Africa region's market is anticipated to grow from USD 0.18 billion in 2023 to USD 0.30 billion by 2033. Economic diversification strategies and the drive toward automation in industries will contribute to this increase.Tell us your focus area and get a customized research report.

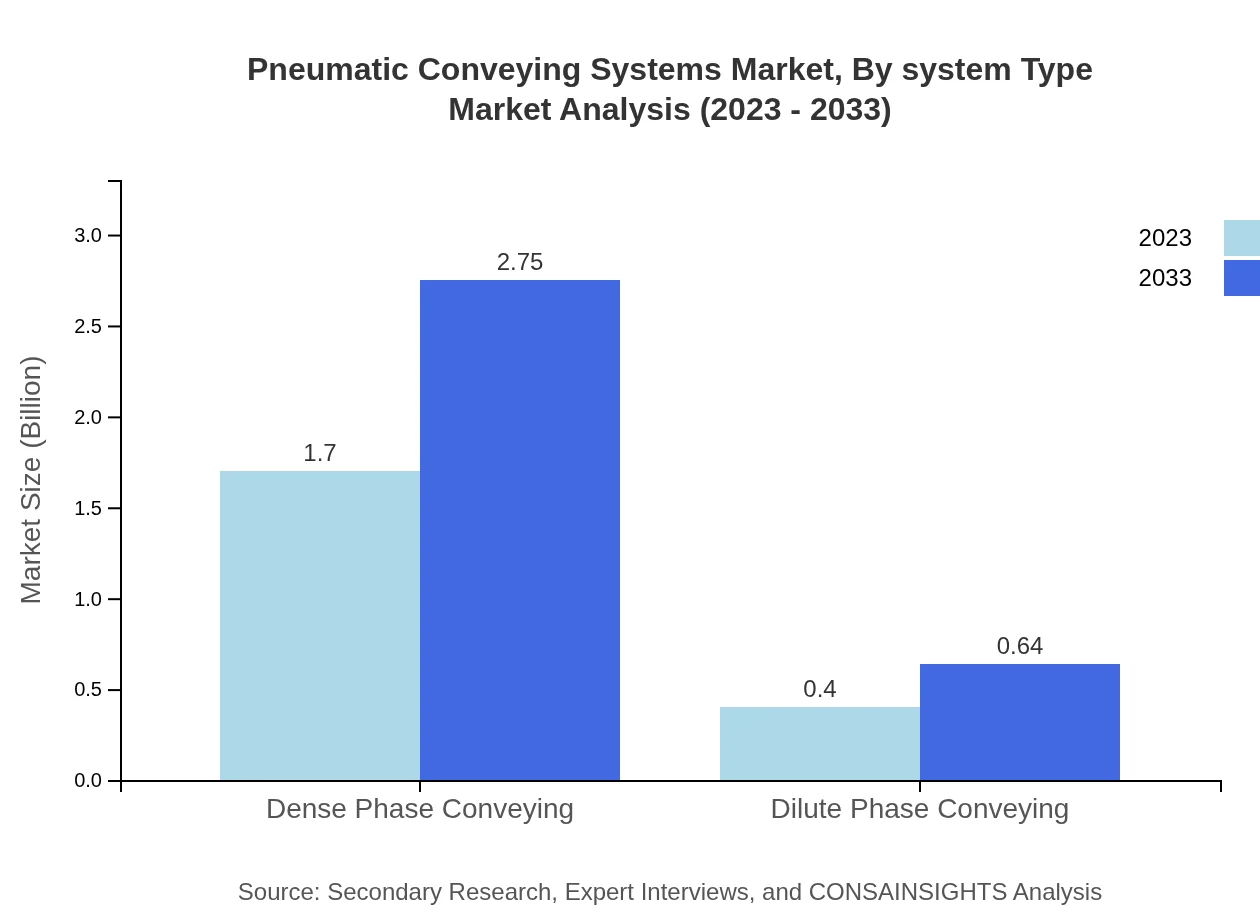

Pneumatic Conveying Systems Market Analysis By System Type

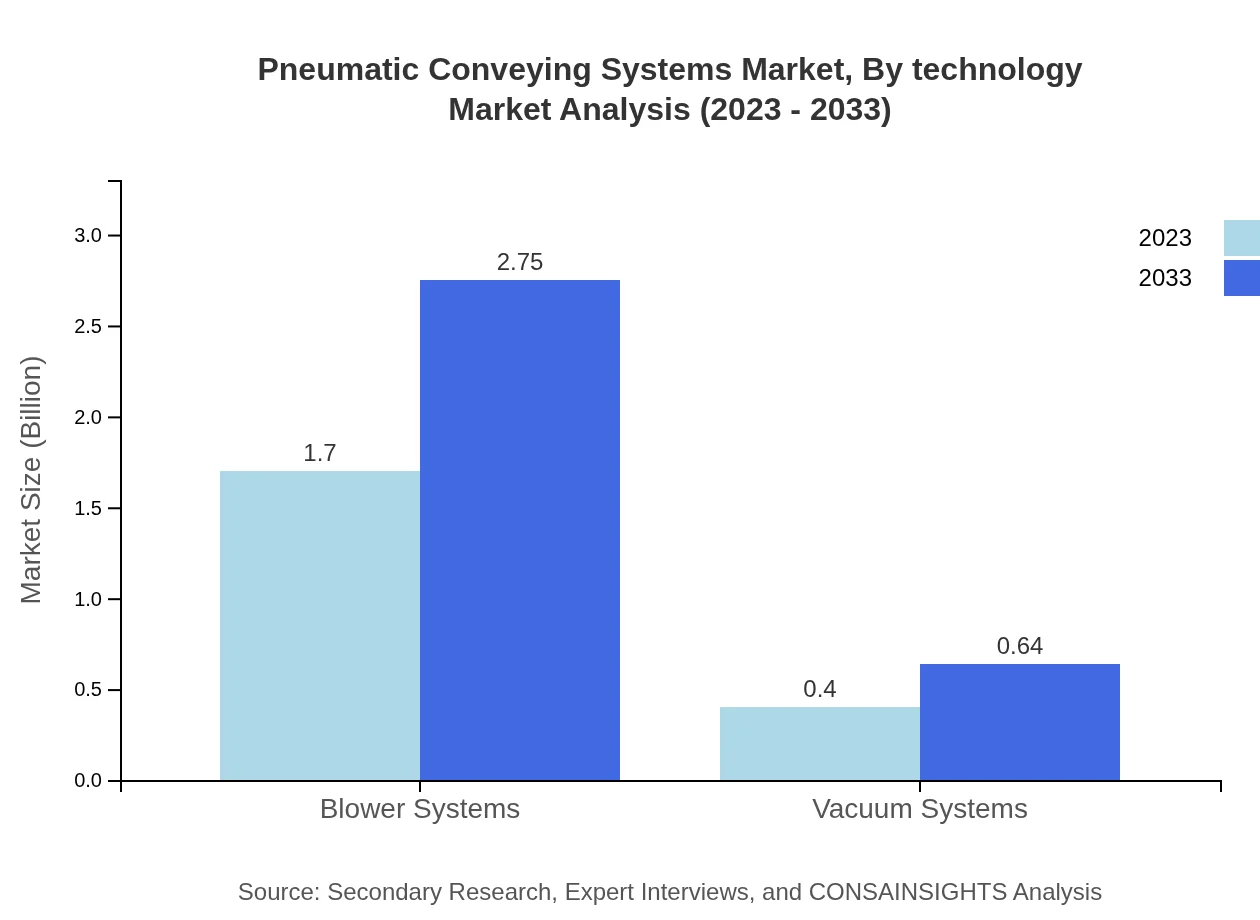

The system type segmentation highlights two main categories: blower systems and vacuum systems. Blower systems dominate the market with a size of USD 1.70 billion in 2023, projected to increase to USD 2.75 billion by 2033, holding 81.13% market share. Conversely, vacuum systems are valued at USD 0.40 billion in 2023 and expected to grow to USD 0.64 billion with an 18.87% share.

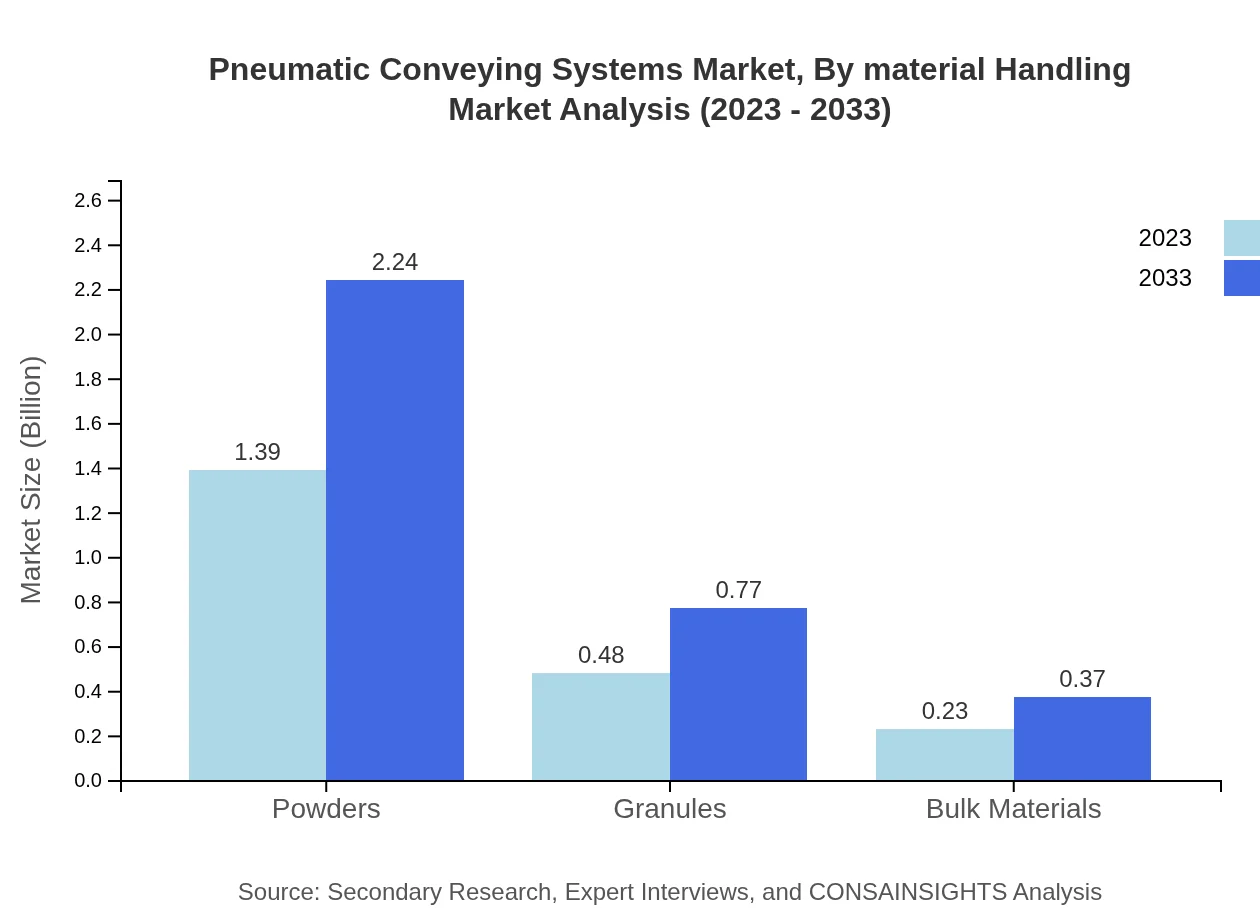

Pneumatic Conveying Systems Market Analysis By Material Handling

Material handling analysis showcases powders, granules, and bulk materials as key segments. Powders dominate the market with a size of USD 1.39 billion in 2023 and expected growth to USD 2.24 billion by 2033, maintaining 66.24% of the market share. Granules represent USD 0.48 billion, projecting upward to USD 0.77 billion, and bulk materials from USD 0.23 billion to USD 0.37 billion, with respective shares of 22.7% and 11.06%.

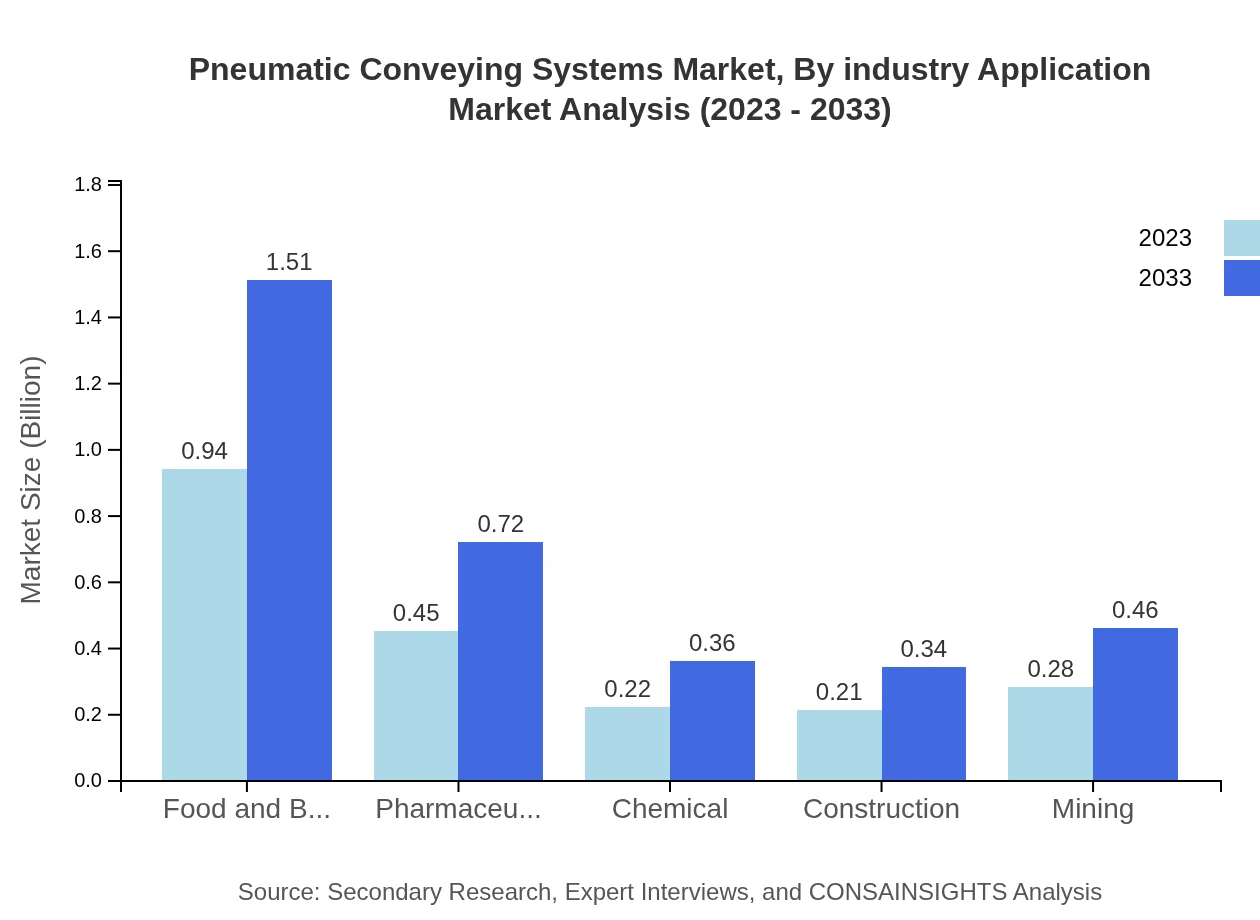

Pneumatic Conveying Systems Market Analysis By Industry Application

In the industry application segment, the food and beverage sector leads with a market size of USD 0.94 billion in 2023, poised to expand to USD 1.51 billion by 2033, reflecting a 44.7% share. The pharmaceuticals and chemicals sectors follow closely, with respective sizes of USD 0.45 billion rising to USD 0.72 billion and USD 0.22 billion to USD 0.36 billion, sharing 21.21% and 10.55%.

Pneumatic Conveying Systems Market Analysis By Technology

Technological advancements in pneumatic conveying systems are essential to meeting industry demands. Innovations in automation, process control, and environmental sustainability drive market efficiency and effectiveness, influencing system types and material handling capabilities.

Pneumatic Conveying Systems Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Pneumatic Conveying Systems Industry

Schneider Electric:

A leading provider in automation and energy management, Schneider Electric enhances the efficiency of pneumatic conveying systems with innovative solutions and comprehensive services.FLSmidth:

FLSmidth specializes in sustainable productivity, offering efficient pneumatic conveying systems tailored for diverse industries focusing on bulk materials handling.Coperion GmbH:

Coperion is a global leader in the field of bulk material handling, offering technologically advanced pneumatic systems that optimize production processes across various sectors.Nilfisk Group:

Nilfisk is dedicated to building and sustaining cleaner environments, providing high-performance pneumatic systems designed for handling various materials effectively.We're grateful to work with incredible clients.

FAQs

What is the market size of pneumatic conveying systems?

The global pneumatic conveying systems market was valued at $2.1 billion in 2023 and is projected to grow at a CAGR of 4.8%, reaching significant market size by 2033.

What are the key market players or companies in this pneumatic conveying systems industry?

Key players in the pneumatic conveying systems industry include leading manufacturers like Schenck Process, Nordson Corporation, and Atlas Copco, which significantly influence the market through their innovative technologies and product offerings.

What are the primary factors driving the growth in the pneumatic conveying systems industry?

Growth drivers include increased demand for automation in manufacturing, rising material handling efficiency needs, and advancements in conveying technology, contributing to enhanced operational productivity across various sectors.

Which region is the fastest Growing in the pneumatic conveying systems?

The fastest-growing region is North America, projected to rise from $0.79 billion in 2023 to $1.27 billion by 2033, driven by technological innovations and increased investments in manufacturing infrastructure.

Does ConsaInsights provide customized market report data for the pneumatic conveying systems industry?

Yes, ConsaInsights offers customized market reports tailored to specific client needs in the pneumatic conveying systems industry, providing in-depth insights and analytics.

What deliverables can I expect from this pneumatic conveying systems market research project?

Deliverables include detailed market analyses, competitive landscape evaluations, market forecasts, segmentation breakdowns, and tailored insights to support strategic decision-making.

What are the market trends of pneumatic conveying systems?

Current trends include increased adoption of smart technologies, a shift towards sustainable practices in materials handling, and growing demand for bulk material transportation solutions, shaping the future of the industry.