Polyarylsulfone Market Report

Published Date: 22 January 2026 | Report Code: polyarylsulfone

Polyarylsulfone Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Polyarylsulfone (PARS) market, covering market size, growth rates, regional insights, and industry trends for the forecast period from 2023 to 2033.

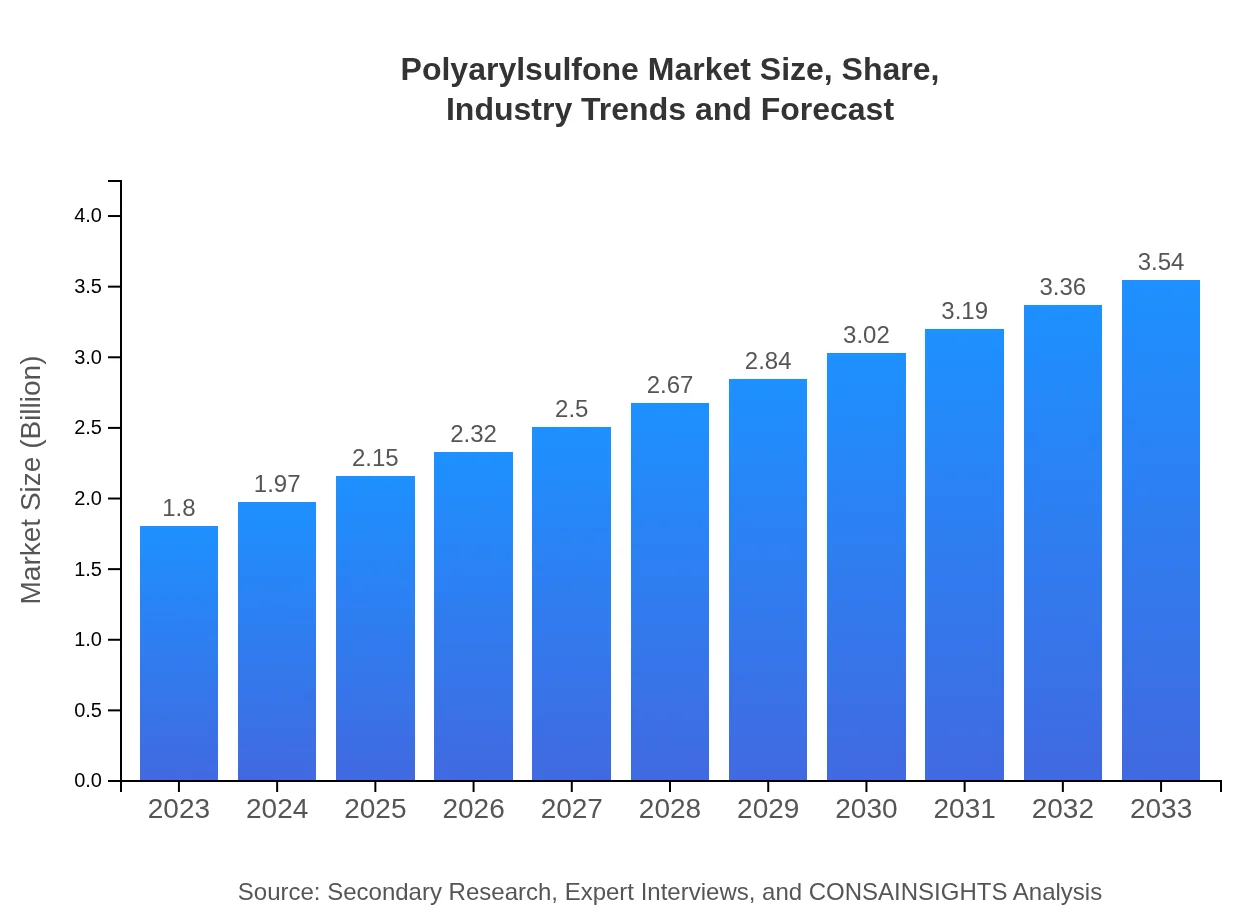

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.80 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $3.54 Billion |

| Top Companies | BASF, Solvay, Victrex |

| Last Modified Date | 22 January 2026 |

Polyarylsulfone Market Overview

Customize Polyarylsulfone Market Report market research report

- ✔ Get in-depth analysis of Polyarylsulfone market size, growth, and forecasts.

- ✔ Understand Polyarylsulfone's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Polyarylsulfone

What is the Market Size & CAGR of Polyarylsulfone market in 2023?

Polyarylsulfone Industry Analysis

Polyarylsulfone Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Polyarylsulfone Market Analysis Report by Region

Europe Polyarylsulfone Market Report:

In Europe, the market size is anticipated to increase significantly from $0.56 billion in 2023 to $1.09 billion by 2033. The region's established aerospace and healthcare industries are pivotal in maintaining this momentum.Asia Pacific Polyarylsulfone Market Report:

In the Asia Pacific region, the Polyarylsulfone market is projected to grow from $0.36 billion in 2023 to $0.71 billion by 2033, reflecting a robust CAGR. This growth is attributed to rapid industrialization, increasing manufacturing capabilities, and heightened demand in aerospace and electronics.North America Polyarylsulfone Market Report:

North America leads the market, growing from $0.60 billion in 2023 to an expected $1.18 billion by 2033. High demand in aerospace and defense applications, coupled with technological advancements, fuels this prominent growth.South America Polyarylsulfone Market Report:

The South American market is smaller but shows promising growth potential, with estimates rising from $0.08 billion in 2023 to $0.15 billion by 2033. The automotive sector's expansion is a significant driver in this region.Middle East & Africa Polyarylsulfone Market Report:

The Middle East and Africa market is expected to double from $0.20 billion in 2023 to $0.40 billion by 2033, driven by growth in industrial applications and rising investments in technology and infrastructure.Tell us your focus area and get a customized research report.

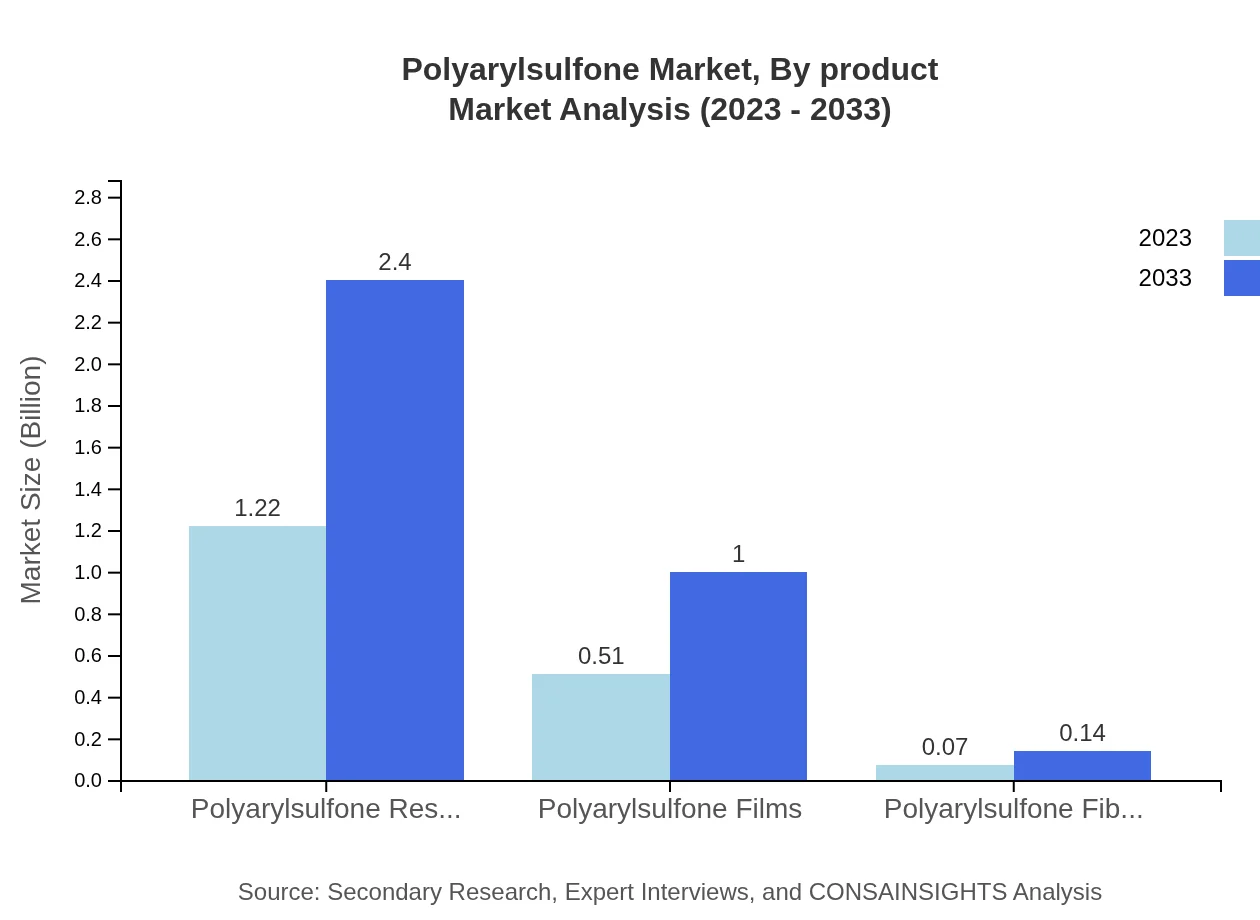

Polyarylsulfone Market Analysis By Product

Polyarylsulfone is classified into various product types, including Resins, Films, and Fibers. Resins dominate the market due to their extensive applications in manufacturing robust components for aerospace and industrial chemicals. Films and Fibers cater to specialized applications in healthcare and textiles, reflecting significant growth tailored to industry needs.

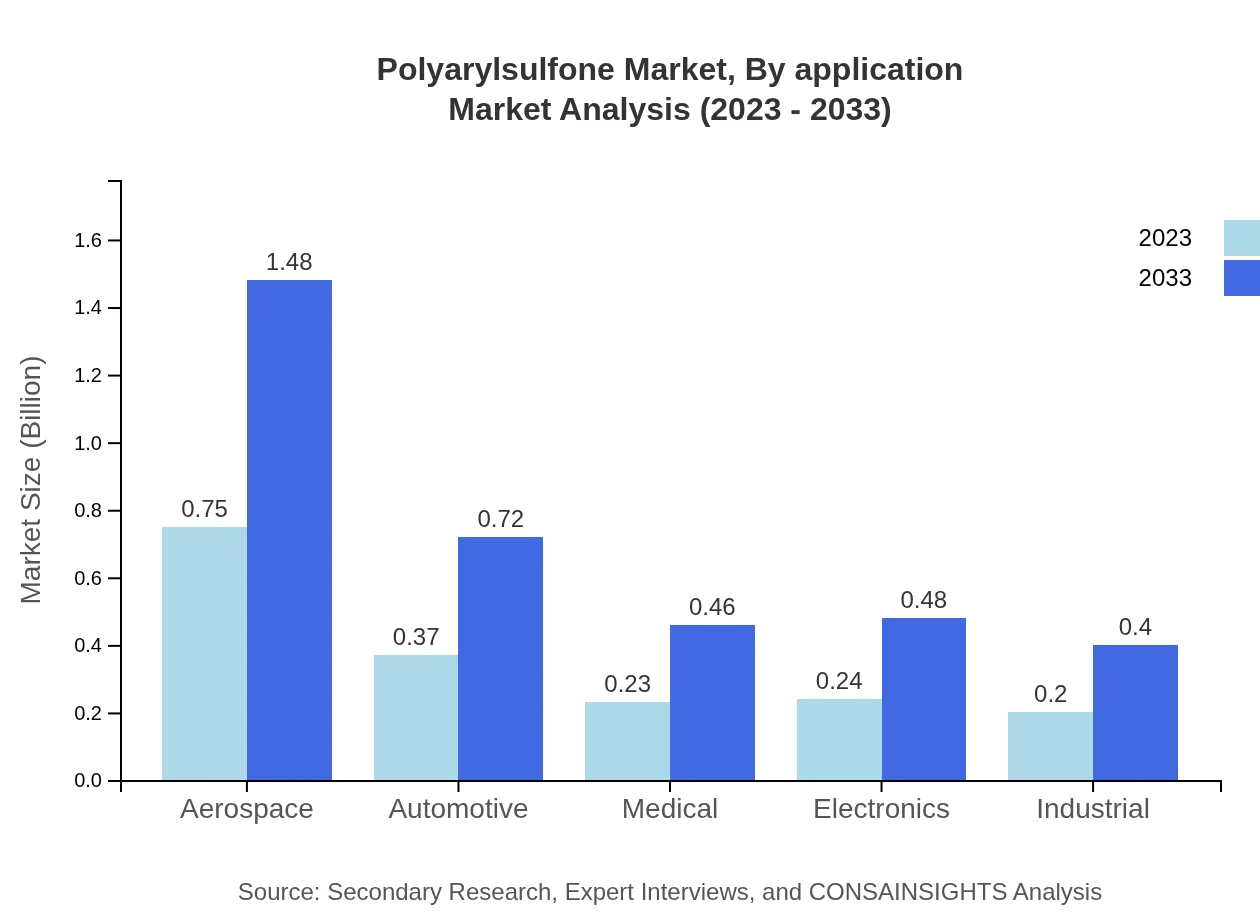

Polyarylsulfone Market Analysis By Application

Applications of Polyarylsulfone span aerospace, healthcare, automotive, and electronics industries. Aerospace and Defense represent the largest share, utilizing PARS for components that require high heat resistance and durability. The healthcare sector follows closely behind, employing PARS in medical devices due to its sterilization capabilities.

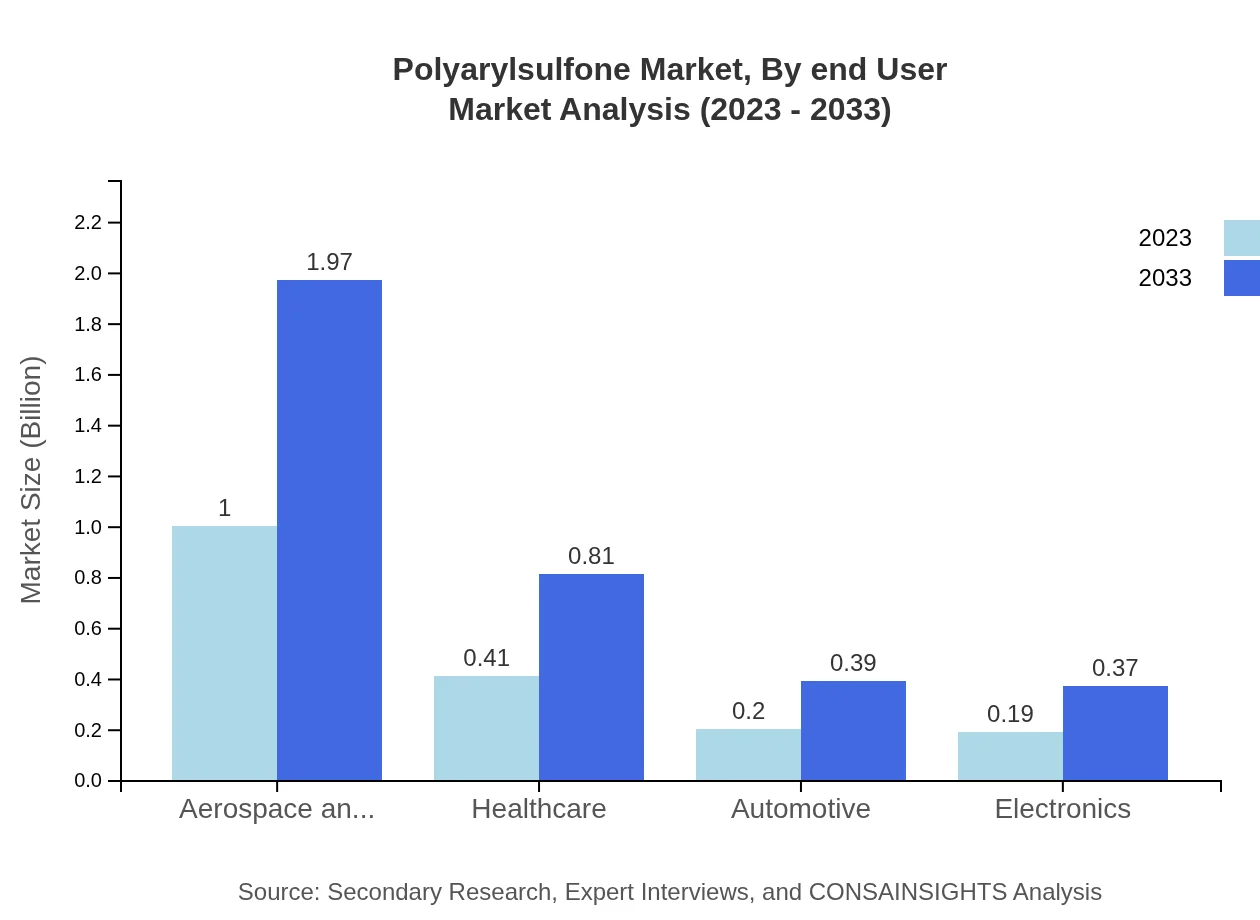

Polyarylsulfone Market Analysis By End User

The end-use industries of Polyarylsulfone include Aerospace, Healthcare, Automotive, and Electronics. Aerospace leads with a significant contribution of about 55.58%, showcasing the importance of high-performance materials in this field. Healthcare follows with a 22.79% share, driven by the demand for reliable medical devices.

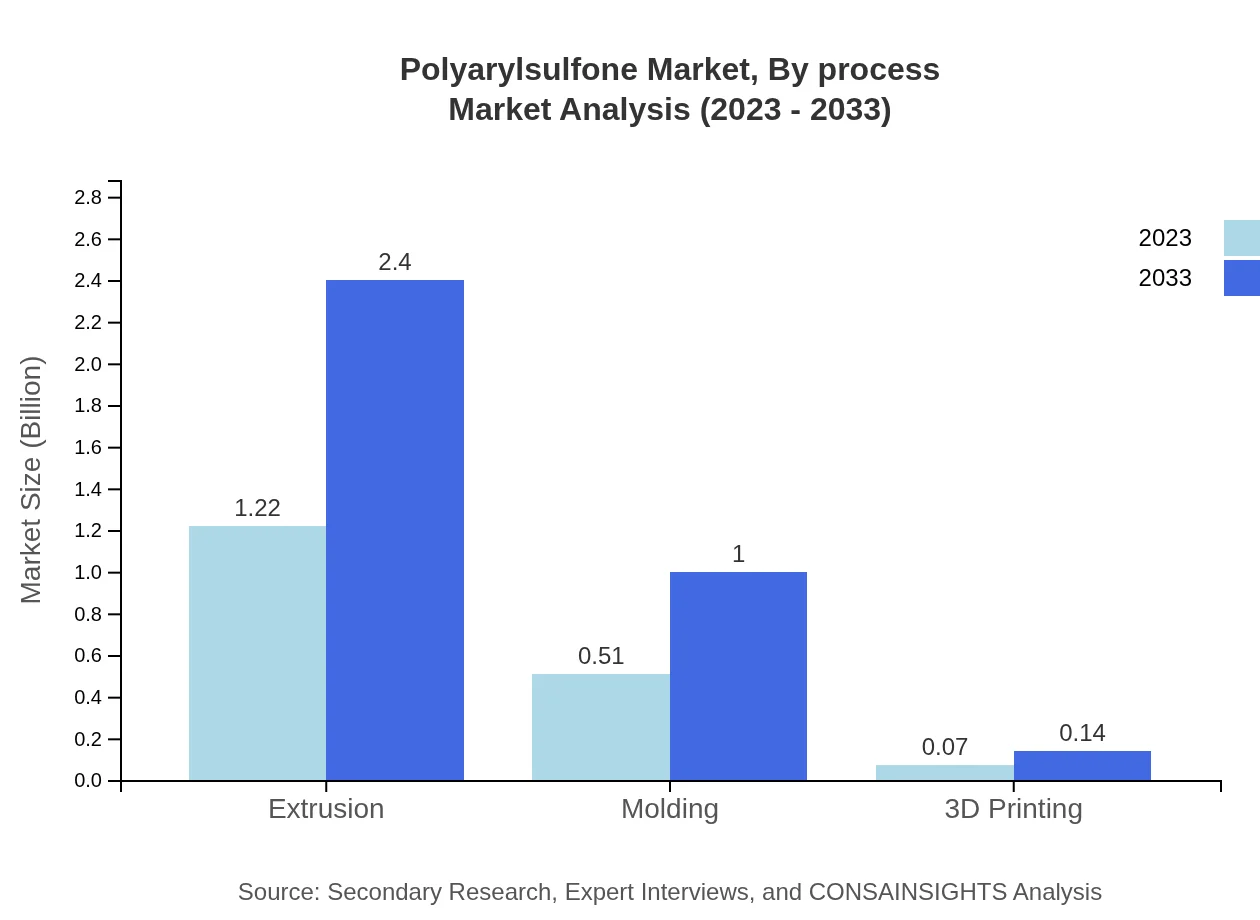

Polyarylsulfone Market Analysis By Process

The processes for Polyarylsulfone production include extrusion, molding, and 3D printing. Extrusion asserts dominance with a market share of 67.83%, owing to its efficiency in producing consistent and high-quality products for various applications.

Polyarylsulfone Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Polyarylsulfone Industry

BASF:

BASF is a leading global chemical company offering a wide range of Polyarylsulfone products designed for various applications, particularly in the aerospace sector. Their focus on research and development helps drive industry innovations.Solvay:

Solvay specializes in high-performance polymers, including Polyarylsulfone. Their advanced materials are extensively used in aerospace, healthcare, and industrial sectors, demonstrating a commitment to sustainability and innovation.Victrex:

Victrex is a recognized leader in polymer solutions, producing high-performance Polyarylsulfone products. The company's innovation-driven approach supports their strong market position in various high-tech sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of polyarylsulfone?

The global market size for polyarylsulfone is projected to reach $1.8 billion by 2033, registering a CAGR of 6.8% from 2023 to 2033. This growth is indicative of increasing applications across various industries.

What are the key market players or companies in the polyarylsulfone industry?

Key players in the polyarylsulfone market include leading manufacturers such as BASF, Solvay, and SABIC. These companies are known for their innovations and extensive product portfolios, catering to automotive, aerospace, and healthcare sectors.

What are the primary factors driving the growth in the polyarylsulfone industry?

Growth in the polyarylsulfone market is driven by increased demand for lightweight, high-performance materials in aerospace, automotive, and healthcare sectors. Technological advancements and rising investment in R&D further stimulate market expansion.

Which region is the fastest Growing in the polyarylsulfone market?

The Asia Pacific region is the fastest-growing market for polyarylsulfone, projected to expand from $0.36 billion in 2023 to $0.71 billion by 2033, driven by industrial growth and increased manufacturing activities.

Does ConsaInsights provide customized market report data for the polyarylsulfone industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs within the polyarylsulfone industry. This includes detailed analysis and insights on regional markets, competitive landscapes, and segment performance.

What deliverables can I expect from this polyarylsulfone market research project?

Deliverables from the polyarylsulfone market research project include comprehensive reports, market forecasts, competitive analysis, and insights on key segments and regional trends, aiding strategic decision-making.

What are the market trends of polyarylsulfone?

Current trends in the polyarylsulfone market include a shift towards sustainable manufacturing practices, increased adoption of 3D printing technologies, and heightened demand in the aerospace and healthcare sectors, enhancing product innovation.