Polymer Concrete Market Report

Published Date: 22 January 2026 | Report Code: polymer-concrete

Polymer Concrete Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Polymer Concrete market, including current trends, market size, regional insights, and emerging technologies. It covers projections and insights for the forecast period from 2023 to 2033.

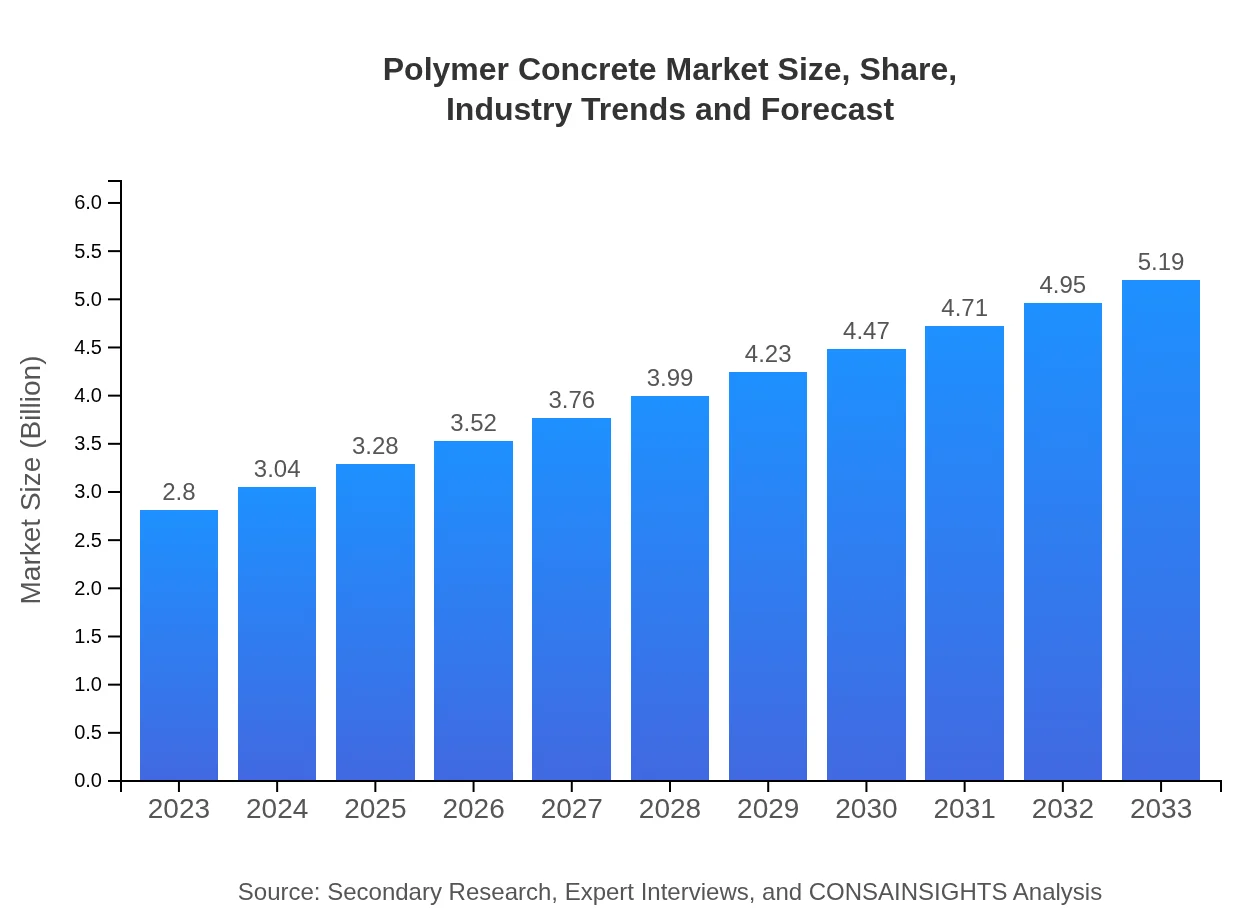

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.80 Billion |

| CAGR (2023-2033) | 6.2% |

| 2033 Market Size | $5.19 Billion |

| Top Companies | Sika AG, BASF SE, Fischer Building Materials Company, Amcor Limited |

| Last Modified Date | 22 January 2026 |

Polymer Concrete Market Overview

Customize Polymer Concrete Market Report market research report

- ✔ Get in-depth analysis of Polymer Concrete market size, growth, and forecasts.

- ✔ Understand Polymer Concrete's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Polymer Concrete

What is the Market Size & CAGR of Polymer Concrete market in 2023?

Polymer Concrete Industry Analysis

Polymer Concrete Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Polymer Concrete Market Analysis Report by Region

Europe Polymer Concrete Market Report:

The European market, valued at $0.70 billion in 2023, is expected to increase to $1.30 billion by 2033. The stringent sustainability regulations and a shift towards eco-friendly construction practices support the growth of polymer concrete in this region.Asia Pacific Polymer Concrete Market Report:

The Asia Pacific region, valued at $0.54 billion in 2023, is projected to grow to $1.01 billion by 2033. The region is witnessing rapid urban growth and significant investments in infrastructure, driving demand for polymer concrete. Additionally, countries like India and China are expanding their construction sectors.North America Polymer Concrete Market Report:

North America, with a market size of $1.04 billion in 2023 and projected to reach $1.93 billion by 2033, is experiencing high demand for polymer concrete due to increasing regulatory standards and innovations in construction technology.South America Polymer Concrete Market Report:

In South America, the Polymer Concrete market is expected to rise from $0.24 billion in 2023 to $0.44 billion in 2033. Growing construction activities and government investments in infrastructure projects are key factors contributing to this growth.Middle East & Africa Polymer Concrete Market Report:

The Middle East and Africa region is projected to grow from $0.27 billion in 2023 to $0.50 billion in 2033. The growth is driven by increased governmental spending on infrastructure development and urbanization.Tell us your focus area and get a customized research report.

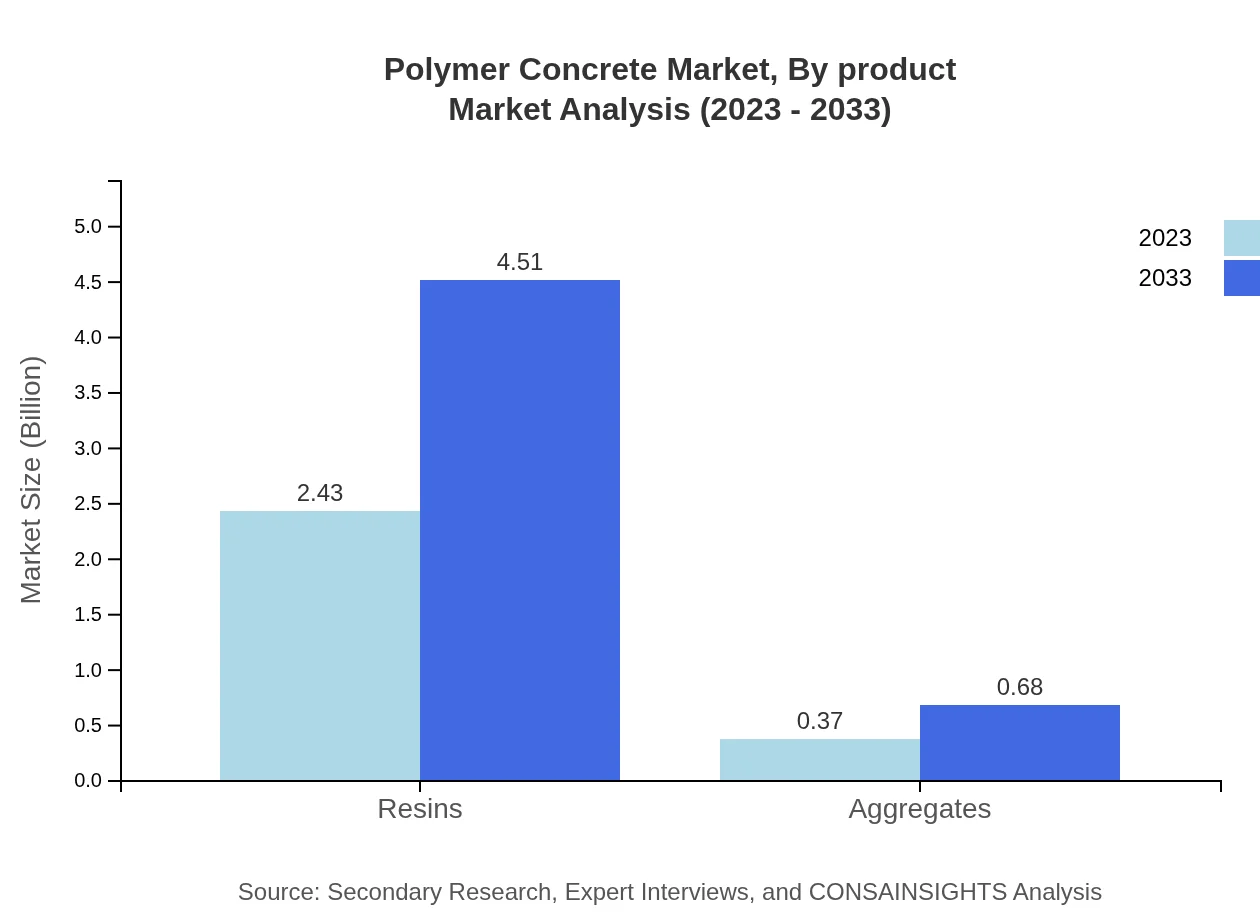

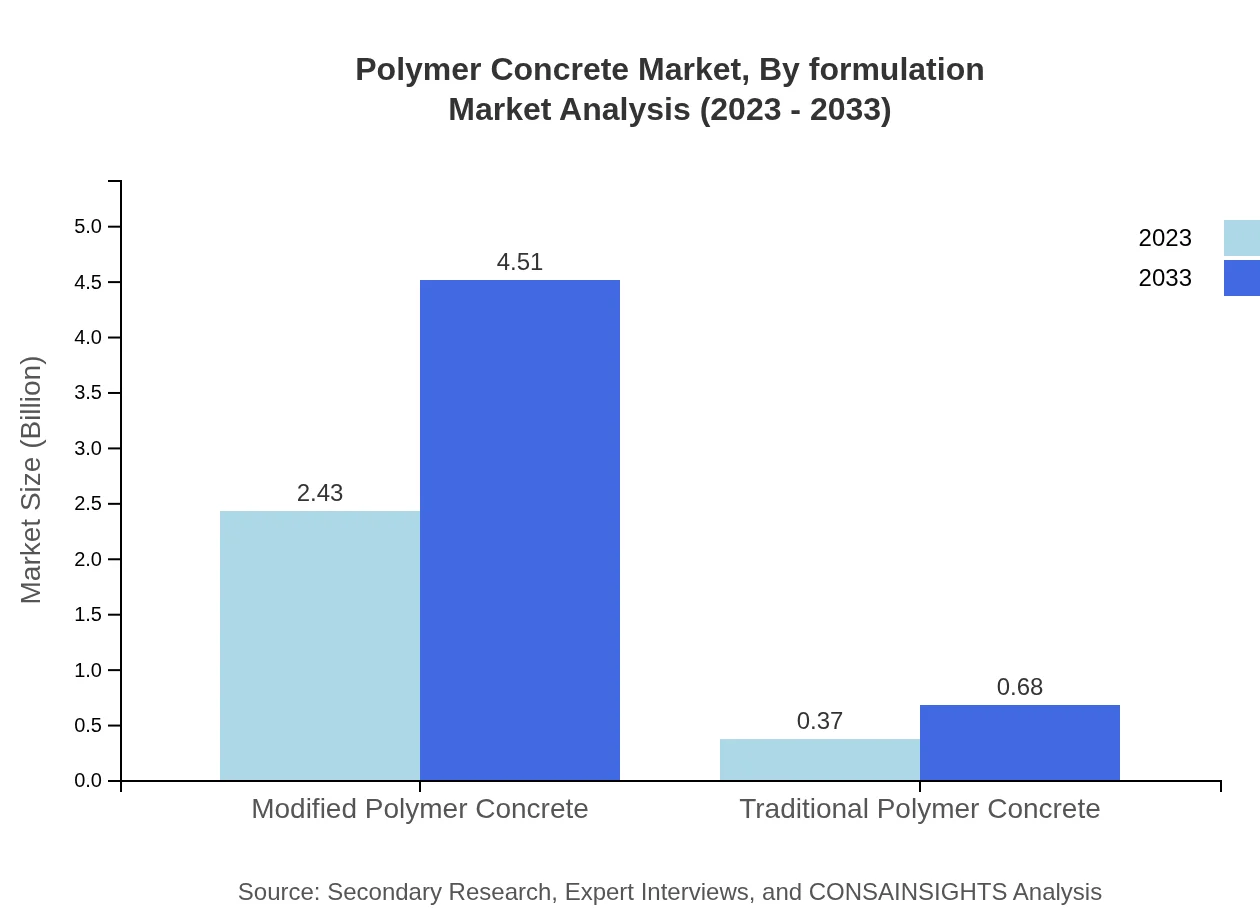

Polymer Concrete Market Analysis By Product

The Polymer Concrete market is significantly segmented by product type, where modified polymer concrete holds the largest market share due to its superior properties. In 2023, modified polymer concrete represents an impressive $2.43 billion, projected to reach approximately $4.51 billion by 2033, capturing about 86.85% of the market share.

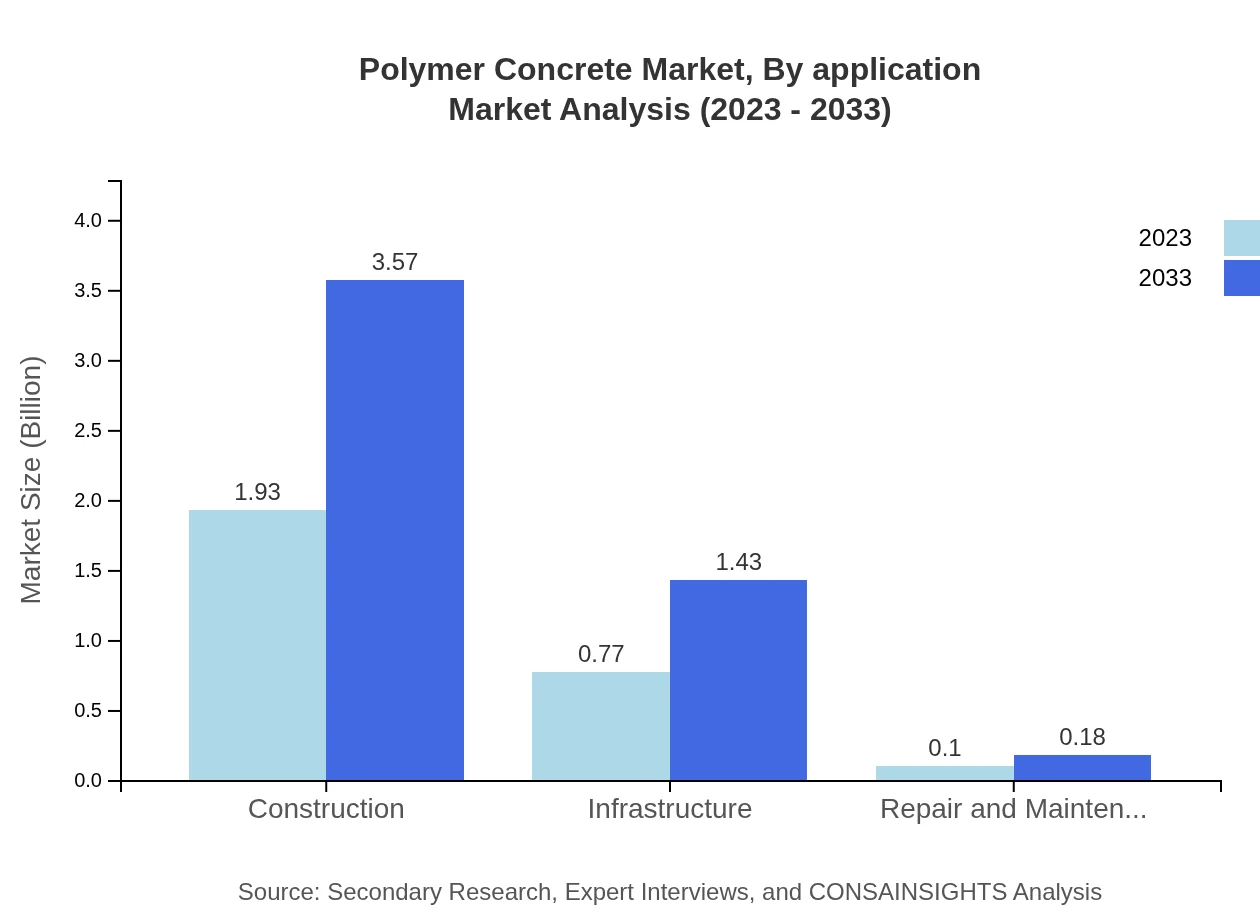

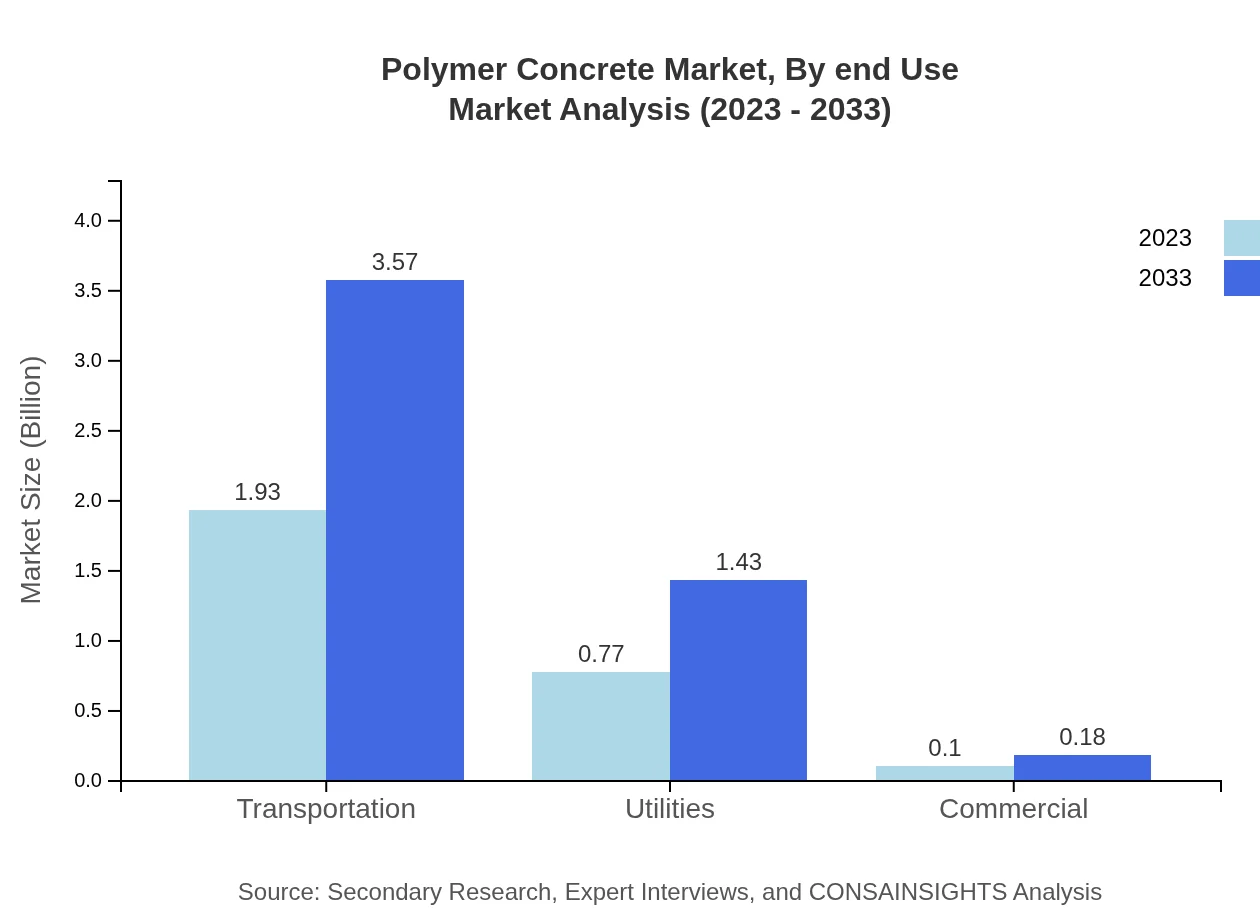

Polymer Concrete Market Analysis By Application

Transportation is the largest application segment for polymer concrete, valued at $1.93 billion in 2023 and expected to grow to $3.57 billion by 2033, maintaining a steady share of 68.83%. Meanwhile, the utilities segment, valued at $0.77 billion in 2023, is also experiencing growth, forecasted to reach $1.43 billion by 2033.

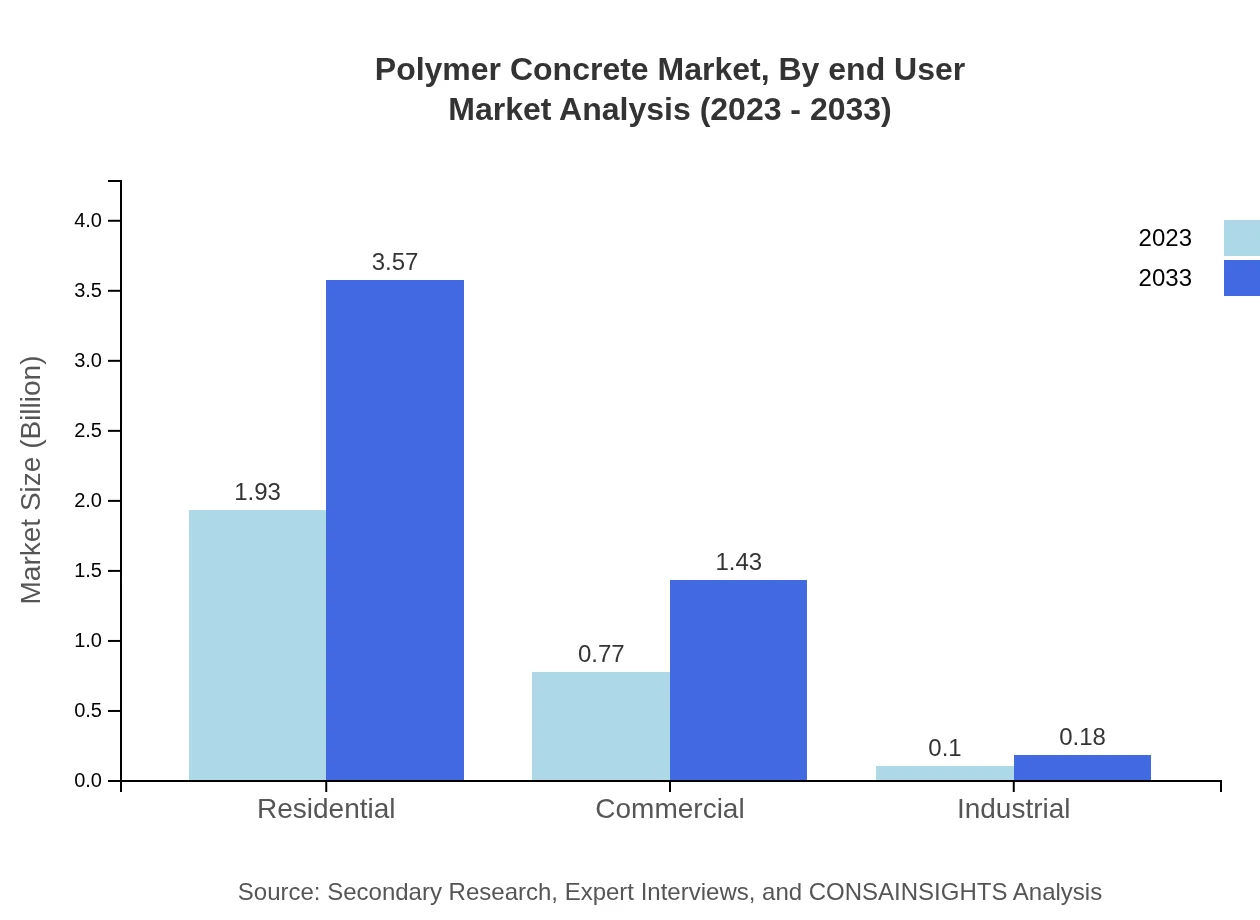

Polymer Concrete Market Analysis By End User

End-user segmentation reveals that the construction industry dominates the market, accounting for approximately 68.83% share valued at $1.93 billion in 2023. The commercial and residential segments also contribute, with projected growth reflecting industry trends toward durable materials.

Polymer Concrete Market Analysis By Formulation

The market segmentation by formulation indicates that modified polymer concrete, accounting for an overwhelming 86.85% share, is critical for applications requiring heightened durability. This is expected to see substantial growth over the forecast period, reinforcing its position as the preferred material.

Polymer Concrete Market Analysis By End Use

In terms of end-use industries, the demand across infrastructure and commercial sectors is driving market expansion. Polymer concrete's superior performance in high-stress environments makes it ideal for use in infrastructure applications, which hold a significant stake in the market share.

Polymer Concrete Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Polymer Concrete Industry

Sika AG:

Sika AG is a global leader specializing in chemical products for construction. Its innovative polymer concrete solutions are renowned for enhancing durability and sustainability in infrastructure projects.BASF SE:

BASF SE, one of the largest chemical producers, provides a wide range of polymer concrete solutions, contributing to enhanced material performance and extended life cycles.Fischer Building Materials Company:

Fischer is known for its advanced polymer-based materials for construction applications, fostering efficiency and sustainability in the polymer concrete segment.Amcor Limited:

As a global packaging and materials company, Amcor has a strong focus on sustainability and innovation within polymer concrete products, driving eco-friendly practices in the industry.We're grateful to work with incredible clients.

FAQs

What is the market size of polymer Concrete?

The polymer-concrete market is currently valued at approximately $2.8 billion, with an anticipated CAGR of 6.2%. This growth reflects increasing applications across various sectors including construction, transportation, and infrastructure.

What are the key market players or companies in this polymer Concrete industry?

Key players in the polymer-concrete industry include established manufacturers and suppliers who specialize in construction materials and polymers. This segment is characterized by both multinational corporations and regional firms that drive innovation.

What are the primary factors driving the growth in the polymer concrete industry?

The growth in the polymer concrete industry is driven by the rising demand for durable and resilient construction materials, environmental sustainability trends, and increased investment in infrastructure projects, particularly in emerging economies.

Which region is the fastest Growing in the polymer Concrete?

The fastest-growing region for polymer concrete is projected to be North America, with the market increasing from $1.04 billion in 2023 to $1.93 billion by 2033. This reflects a robust demand for innovative materials in construction.

Does ConsaInsights provide customized market report data for the polymer Concrete industry?

Yes, ConsaInsights offers customized market report data tailored to the polymer-concrete industry, allowing businesses to obtain targeted insights that align with their specific strategic goals and market needs.

What deliverables can I expect from this polymer Concrete market research project?

From the polymer-concrete market research project, clients can expect comprehensive reports detailing market trends, segment analysis, competitive landscapes, and forecasts that encapsulate current and projected market data.

What are the market trends of polymer Concrete?

Current trends in the polymer concrete market include increased adaptation of modified polymer concrete, a focus on sustainable materials, and growing applications in infrastructure, which significantly influence growth prospects.