Polystyrene Market Report

Published Date: 22 January 2026 | Report Code: polystyrene

Polystyrene Market Size, Share, Industry Trends and Forecast to 2033

This report delves into the Polystyrene market, providing comprehensive insights and data on market size, growth forecasts, trends, and regional dynamics from 2023 to 2033.

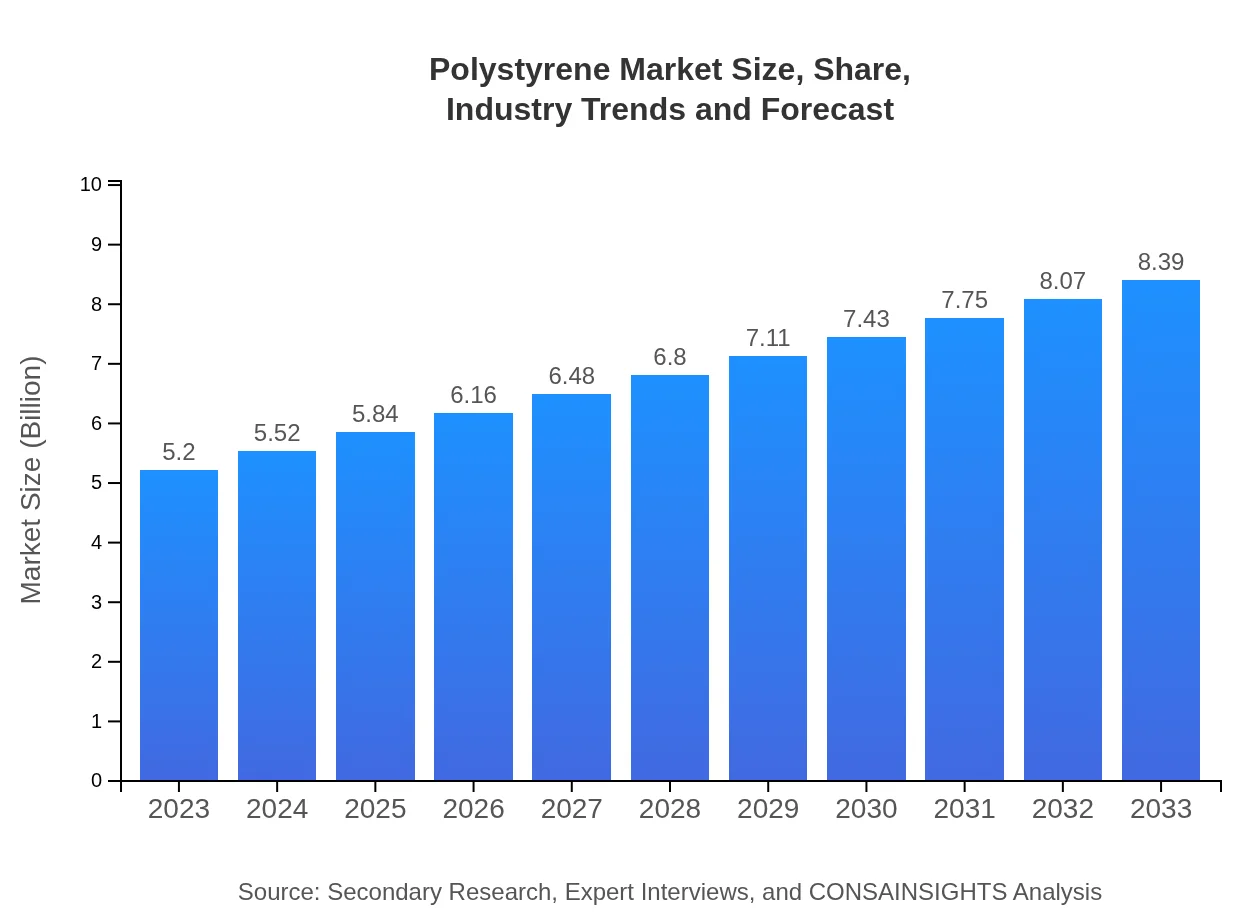

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.20 Billion |

| CAGR (2023-2033) | 4.8% |

| 2033 Market Size | $8.39 Billion |

| Top Companies | BASF SE, Total S.A., INEOS Styrolution, SABIC |

| Last Modified Date | 22 January 2026 |

Polystyrene Market Overview

Customize Polystyrene Market Report market research report

- ✔ Get in-depth analysis of Polystyrene market size, growth, and forecasts.

- ✔ Understand Polystyrene's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Polystyrene

What is the Market Size & CAGR of Polystyrene market in {Year}?

Polystyrene Industry Analysis

Polystyrene Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Polystyrene Market Analysis Report by Region

Europe Polystyrene Market Report:

The European market for Polystyrene is estimated at $1.68 billion in 2023 and is expected to reach $2.71 billion by 2033. The region is experiencing stringent regulations on plastic use which is pushing manufacturers towards adopting innovative, sustainable solutions and recycling processes to comply with EU regulations.Asia Pacific Polystyrene Market Report:

The Asia Pacific region is one of the largest markets for Polystyrene, valued at approximately $0.99 billion in 2023, expected to expand to $1.60 billion by 2033. Significant growth drivers include rapid urbanization, growing construction activities, and a booming consumer market. The region’s increasing focus on packaging for food and consumer goods, alongside sustainable practices in production, is contributing to the expected growth.North America Polystyrene Market Report:

North America demonstrates a healthy market for Polystyrene; the valuation in 2023 stands at $1.75 billion, forecasted to grow to $2.82 billion by 2033. The demand is primarily driven by advancements in technology, particularly in the construction and packaging sectors, with a significant push towards sustainability and eco-friendly materials.South America Polystyrene Market Report:

In South America, the Polystyrene market valuation was $0.52 billion in 2023, projected to reach $0.84 billion by 2033. The growth in this region is accelerated by infrastructure development and increasing disposable incomes, which lead to greater product demand in the packaging and electronics sectors.Middle East & Africa Polystyrene Market Report:

In the Middle East and Africa, the Polystyrene market is valued at approximately $0.26 billion in 2023, anticipated to grow to $0.43 billion by 2033. The growth trajectory is facilitated through rising demand in construction and packaging sectors, supported by various infrastructural developments and urbanization projects.Tell us your focus area and get a customized research report.

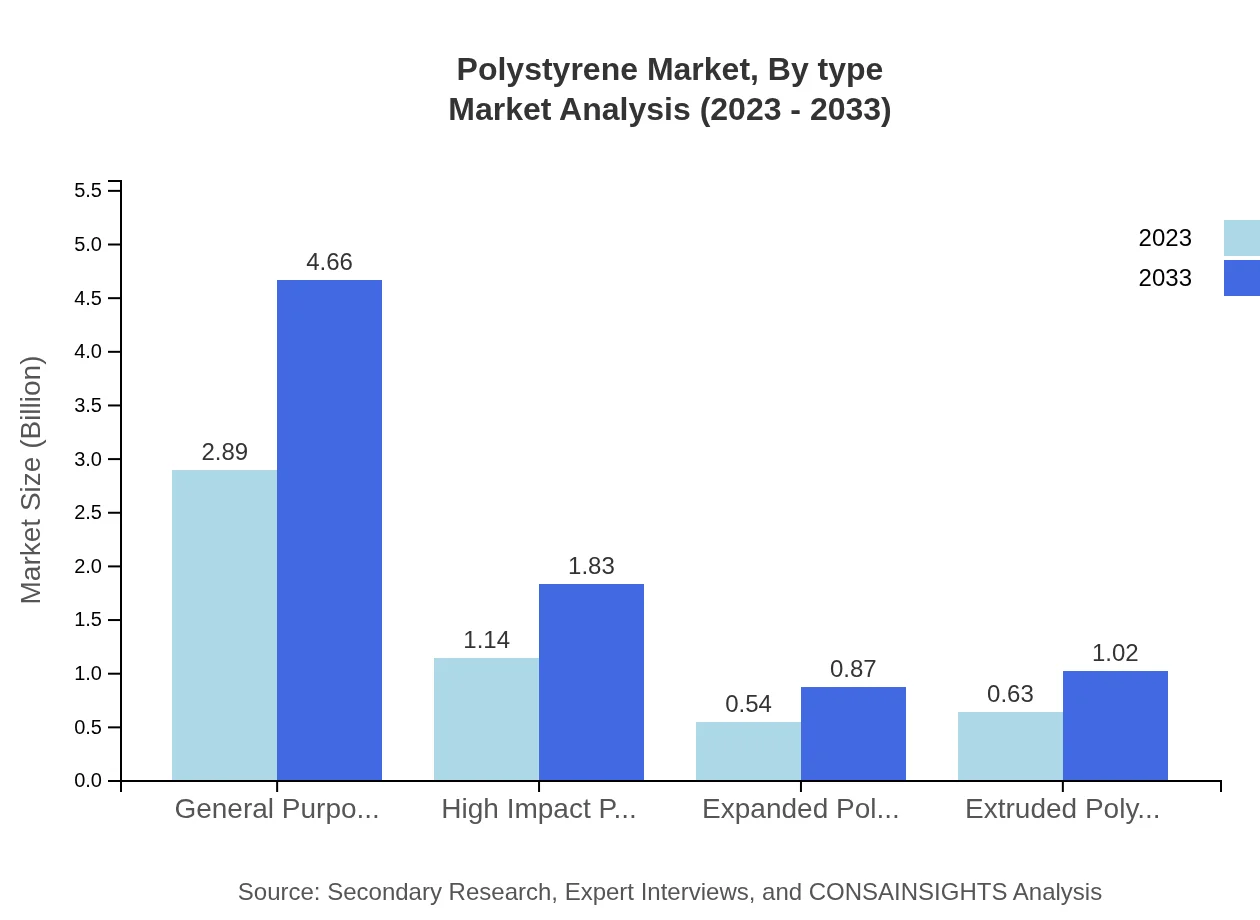

Polystyrene Market Analysis By Type

The Polystyrene market segments include: General Purpose Polystyrene (GPPS), valued at $2.89 billion in 2023, forecasted to increase to $4.66 billion by 2033, holding a 55.58% market share throughout the period. High Impact Polystyrene (HIPS) follows with a size of $1.14 billion expected to reach $1.83 billion by 2033, covering 21.84% of the market share. Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS) are also crucial segments, with expected growth from $0.54 billion and $0.63 billion in 2023 to $0.87 billion and $1.02 billion by 2033 respectively.

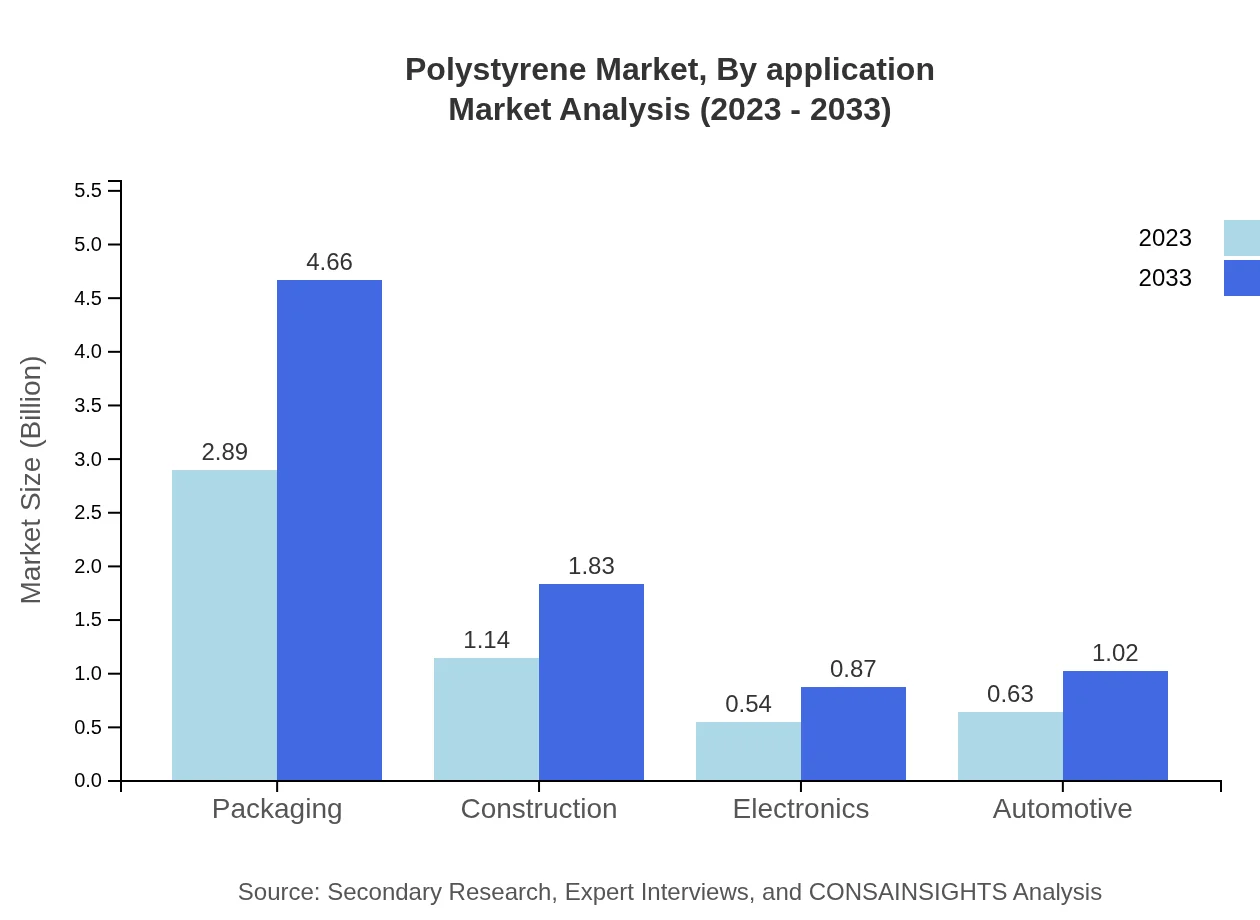

Polystyrene Market Analysis By Application

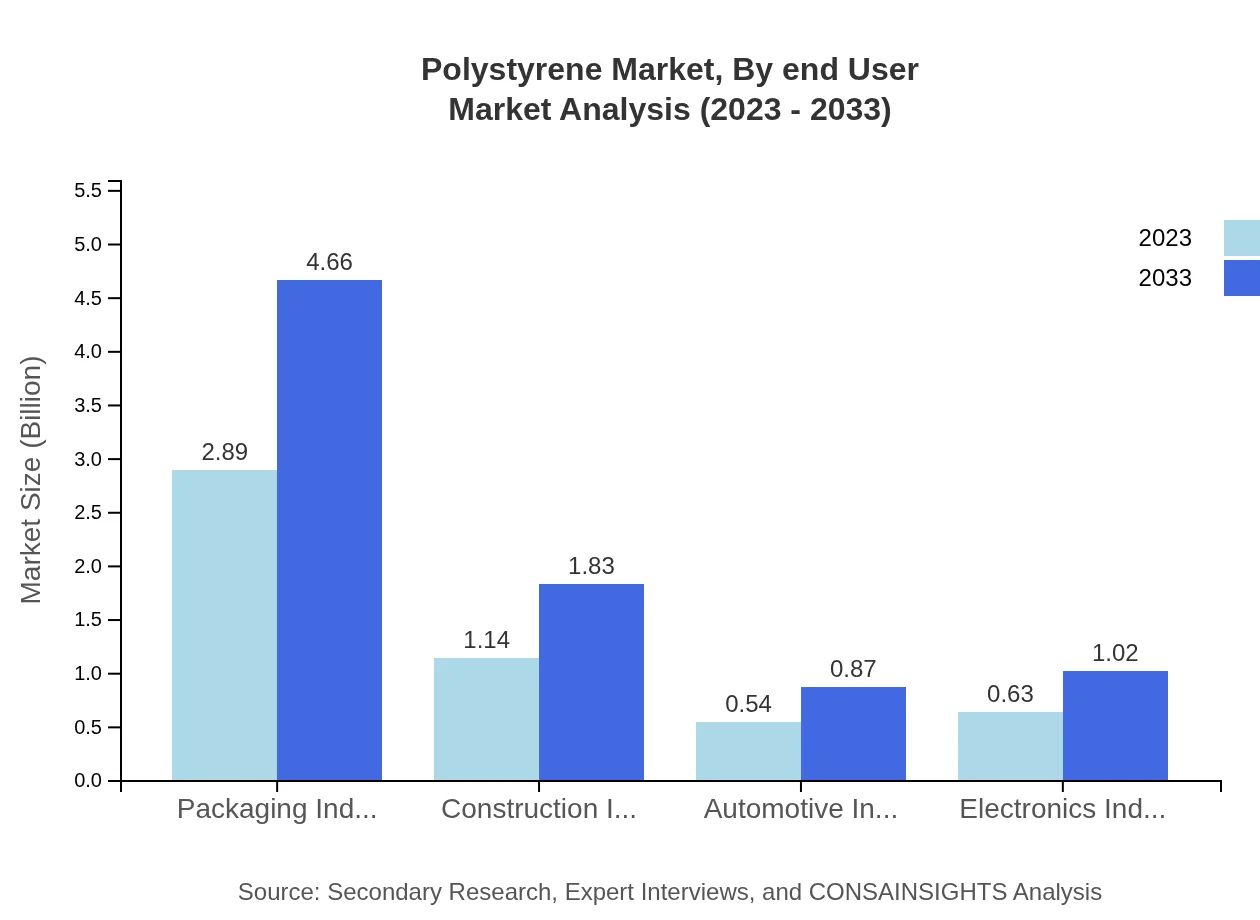

The applications of Polystyrene are prominently seen in packaging, construction, automotive, and electronics. The packaging industry leads with $2.89 billion in 2023 and predicted to reach $4.66 billion by 2033, representing a robust share. Construction usage is projected to grow from $1.14 billion to $1.83 billion. Additionally, automotive and electronics sectors require Polystyrene for lightweight components, with expectations of growth from $0.54 billion and $0.63 billion to $0.87 billion and $1.02 billion by 2033.

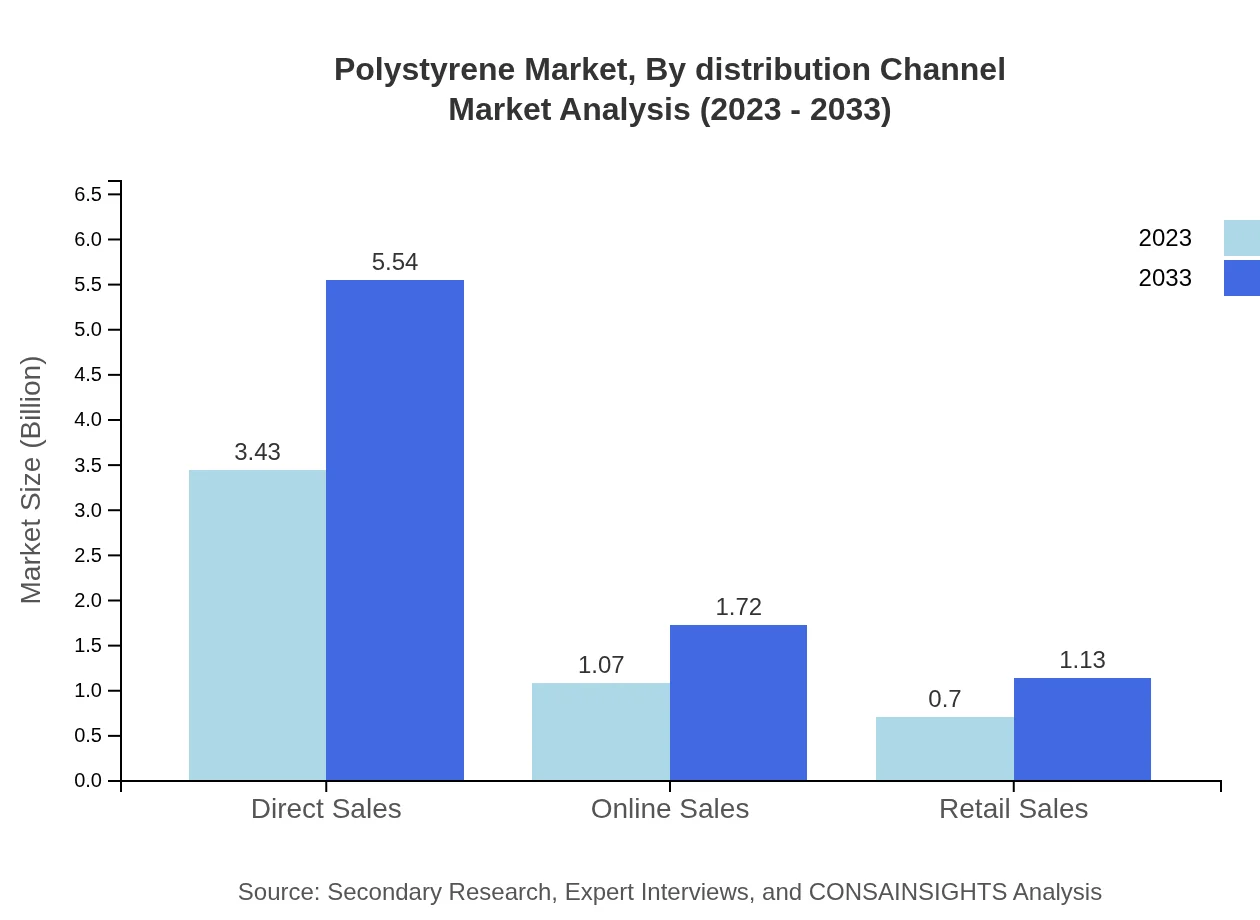

Polystyrene Market Analysis By Distribution Channel

Distribution channels in the Polystyrene market comprise direct sales, online sales, and retail sales. Direct sales account for a predominant market size of $3.43 billion in 2023, expected to grow to $5.54 billion by 2033. Online sales, while smaller, are growing rapidly, starting from $1.07 billion to $1.72 billion, driven by e-commerce. Retail sales also contribute significantly, increasing from $0.70 billion to $1.13 billion over the same period.

Polystyrene Market Analysis By End User

End-user industries for Polystyrene are diverse, including packaging, construction, automotive, and electronics. The packaging sector remains the longest-standing consumer of Polystyrene, accounting for a significant market share that is stable and expected to maintain its growth trajectory. Construction and automotive industries are increasingly adopting Polystyrene products due to their cost-effectiveness and efficiency, indicating a growing trend in usage across these sectors.

Polystyrene Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Polystyrene Industry

BASF SE:

A global leader in the chemical industry, BASF has made significant advancements in Polystyrene production technologies, focusing on sustainability and environmental impact.Total S.A.:

Total is a major petroleum and petrochemical corporation known for producing a wide range of Polystyrene products, with a strong emphasis on innovation in sustainable materials.INEOS Styrolution:

INEOS Styrolution is a leading producer of styrenics, providing innovative Polystyrene products to various industries, focusing on recycling and sustainable solutions.SABIC:

Saudi Basic Industries Corporation (SABIC) is a key player in the Polystyrene market, known for its large-scale production capabilities and sustainable solutions.We're grateful to work with incredible clients.

FAQs

What is the market size of polystyrene?

The polystyrene market is valued at approximately $5.2 billion in 2023, with a projected CAGR of 4.8% leading to significant growth by 2033.

What are the key market players or companies in this polystyrene industry?

Key players in the polystyrene market include industry leaders in chemical manufacturing, plastic production, and packaging solutions, driving innovation and competitive dynamics.

What are the primary factors driving the growth in the polystyrene industry?

Growth in the polystyrene industry is primarily due to increasing applications in packaging, construction, and electronics, alongside rising demand for lightweight materials.

Which region is the fastest Growing in the polystyrene market?

The fastest-growing region for polystyrene is North America, where the market is anticipated to expand from $1.75 billion in 2023 to $2.82 billion by 2033.

Does ConsaInsights provide customized market report data for the polystyrene industry?

Yes, ConsaInsights offers tailored market research reports for the polystyrene industry, allowing clients to obtain specific insights and data tailored to their needs.

What deliverables can I expect from this polystyrene market research project?

Deliverables include detailed market analysis, forecasts, competitive landscape insights, and region-wise market segmentation data for informed decision-making.

What are the market trends of polystyrene?

Market trends indicate a shift towards sustainable alternatives, enhanced recycling processes, and innovation in polystyrene applications, particularly in packaging and insulation.