Portable Bioprocessing Bioreactors Market Report

Published Date: 31 January 2026 | Report Code: portable-bioprocessing-bioreactors

Portable Bioprocessing Bioreactors Market Size, Share, Industry Trends and Forecast to 2033

This report provides an extensive analysis of the Portable Bioprocessing Bioreactors market from 2023 to 2033. It covers market dynamics, size, trends, technologies, and regional insights, offering crucial data for stakeholders.

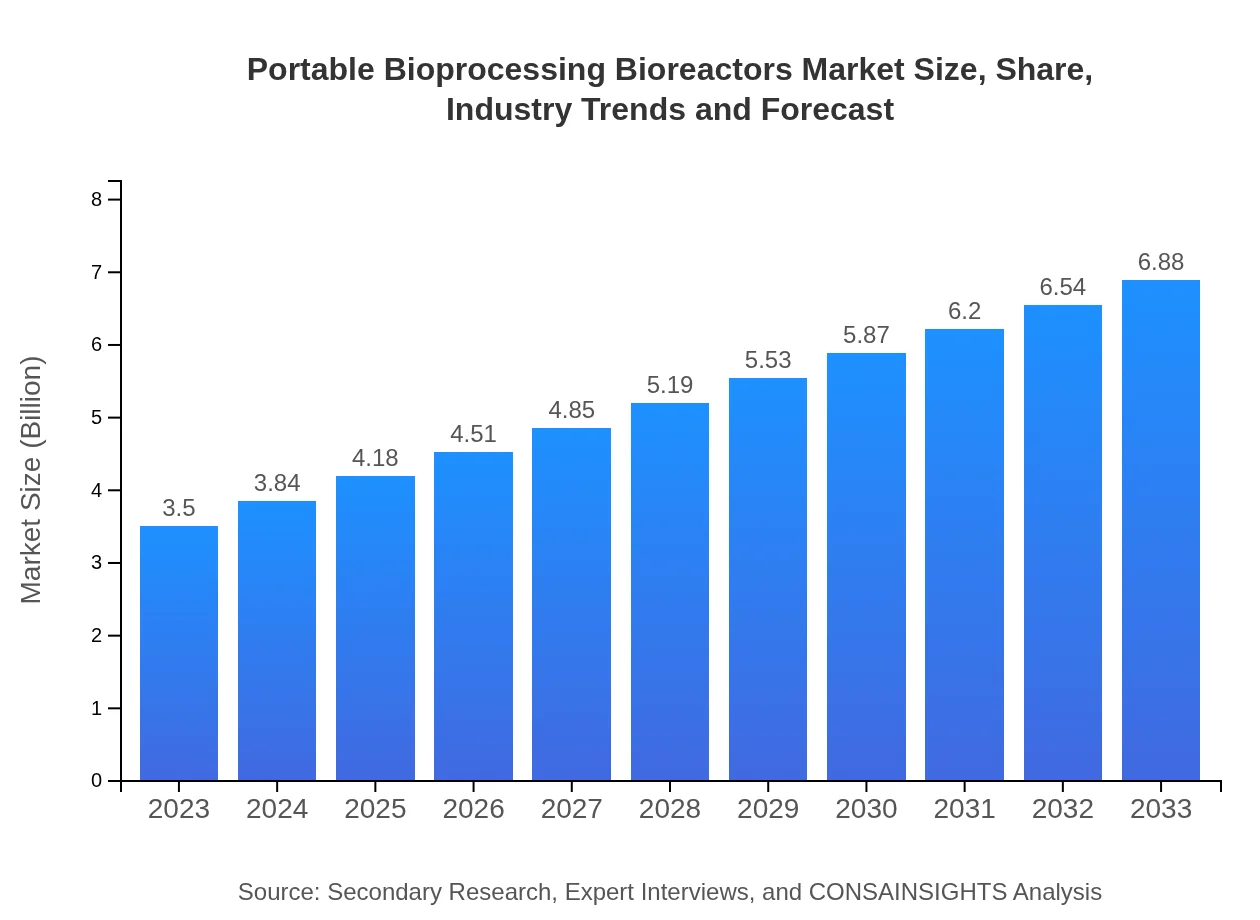

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $6.88 Billion |

| Top Companies | Sartorius AG, GE Healthcare, Eppendorf AG, Thermo Fisher Scientific |

| Last Modified Date | 31 January 2026 |

Portable Bioprocessing Bioreactors Market Overview

Customize Portable Bioprocessing Bioreactors Market Report market research report

- ✔ Get in-depth analysis of Portable Bioprocessing Bioreactors market size, growth, and forecasts.

- ✔ Understand Portable Bioprocessing Bioreactors's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Portable Bioprocessing Bioreactors

What is the Market Size & CAGR of Portable Bioprocessing Bioreactors market in 2023?

Portable Bioprocessing Bioreactors Industry Analysis

Portable Bioprocessing Bioreactors Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Portable Bioprocessing Bioreactors Market Analysis Report by Region

Europe Portable Bioprocessing Bioreactors Market Report:

The European market is anticipated to grow from $0.99 billion in 2023 to $1.94 billion by 2033. The stringent regulatory framework and emphasis on innovative bioprocessing solutions in countries like Germany and Switzerland are key growth enablers.Asia Pacific Portable Bioprocessing Bioreactors Market Report:

In the Asia Pacific region, the market is projected to grow significantly, with a value of $1.44 billion by 2033, up from $0.73 billion in 2023. This growth is attributed to rising investments in biotechnology and increasing demand for bioprocessing technologies in countries like China and India.North America Portable Bioprocessing Bioreactors Market Report:

North America currently leads the market with an estimated size of $1.15 billion in 2023, forecast to reach $2.25 billion by 2033. The growth is supported by a strong biopharmaceutical sector and ongoing research and development activities.South America Portable Bioprocessing Bioreactors Market Report:

The South American market is expected to expand from $0.18 billion in 2023 to $0.36 billion by 2033. Factors driving this growth include the rising bioeconomy and government initiatives supporting biotechnology research.Middle East & Africa Portable Bioprocessing Bioreactors Market Report:

The Middle East and Africa market is expected to reach $0.88 billion by 2033, growing from $0.45 billion in 2023. The increasing adoption of biotechnology in healthcare and environmental applications drives market expansion in this region.Tell us your focus area and get a customized research report.

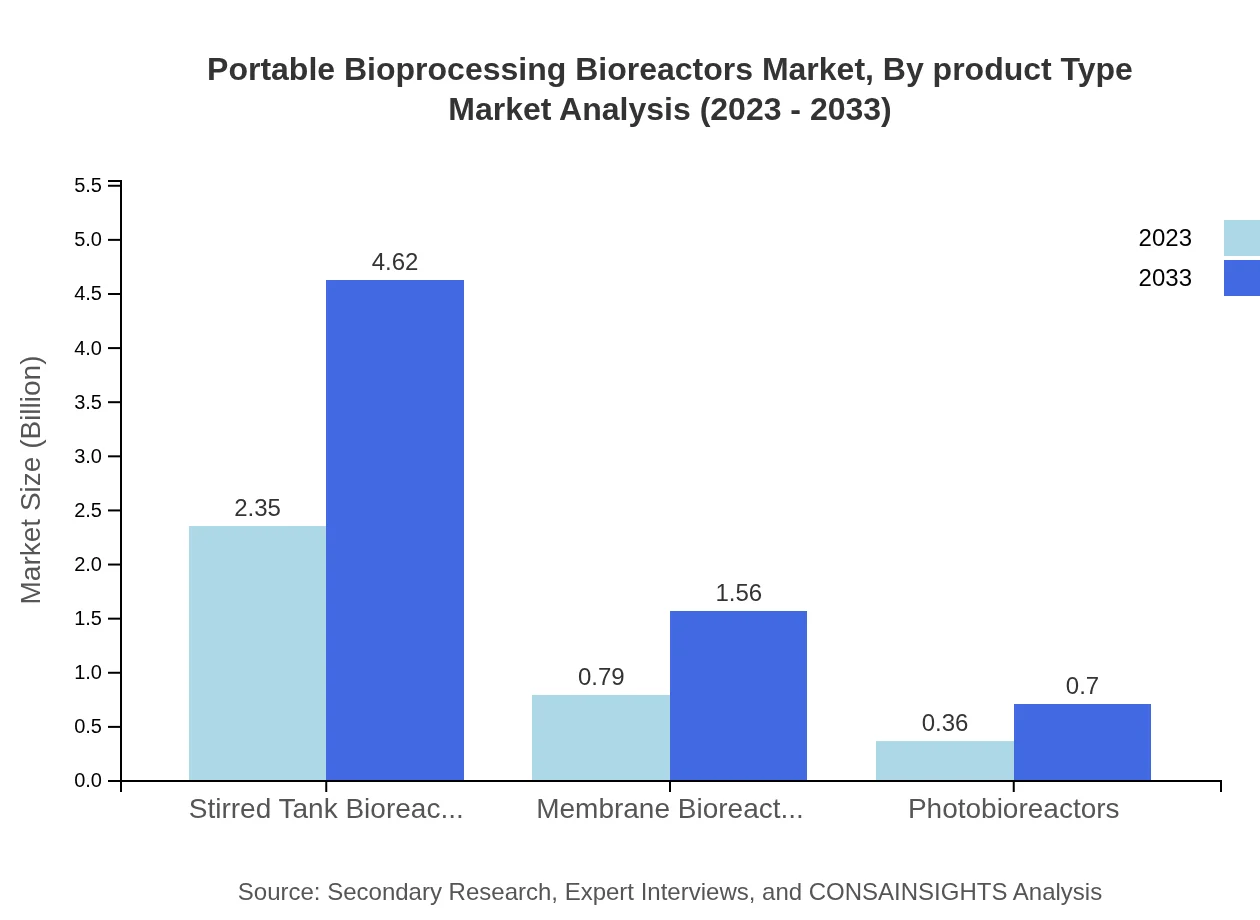

Portable Bioprocessing Bioreactors Market Analysis By Product Type

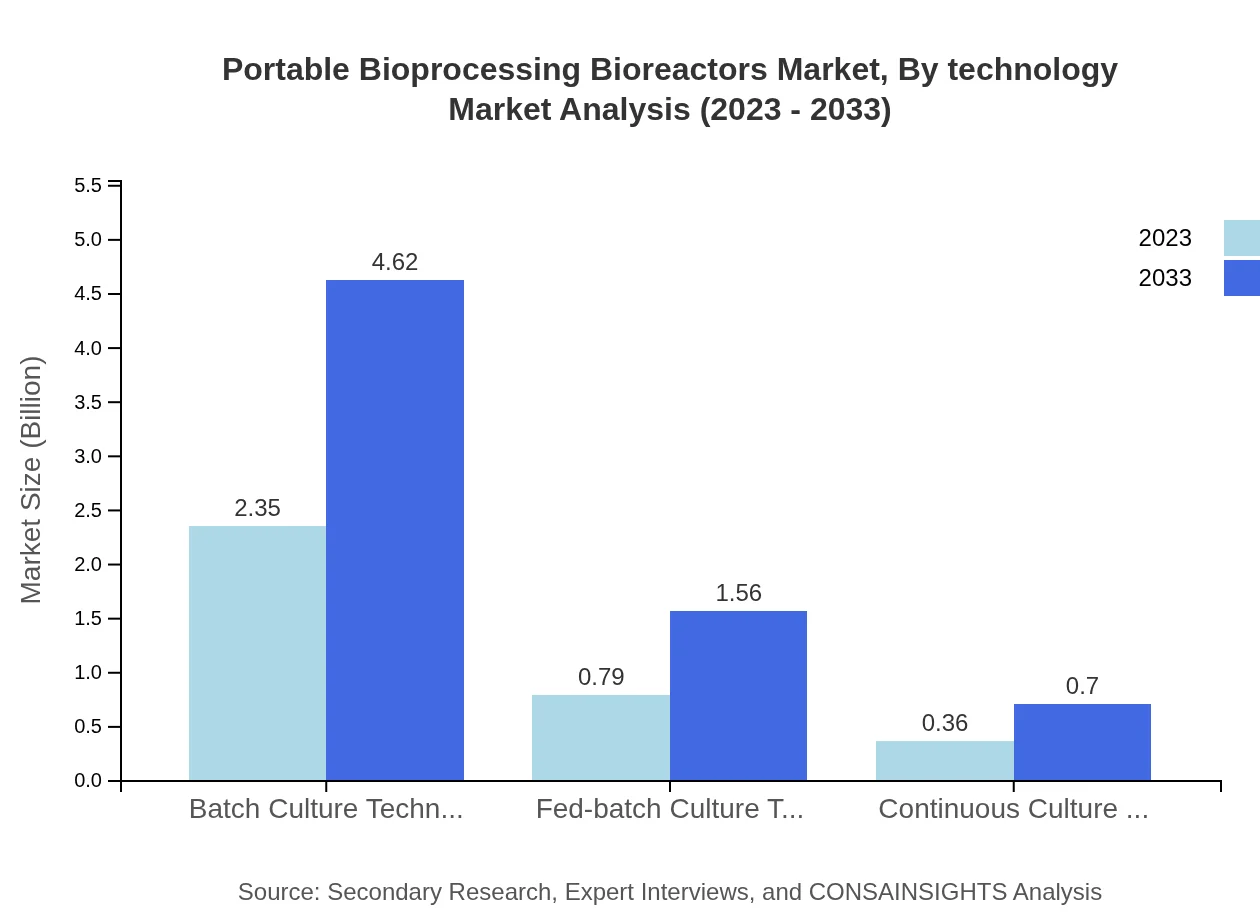

The product types in Portable Bioprocessing Bioreactors consist of batch culture systems, which dominate the market with a size of $2.35 billion in 2023, projected to reach $4.62 billion by 2033. Fed-batch culture technology, with a size of $0.79 billion in 2023, is also poised for significant growth. Continuous culture technology is smaller but is steadily increasing in market share.

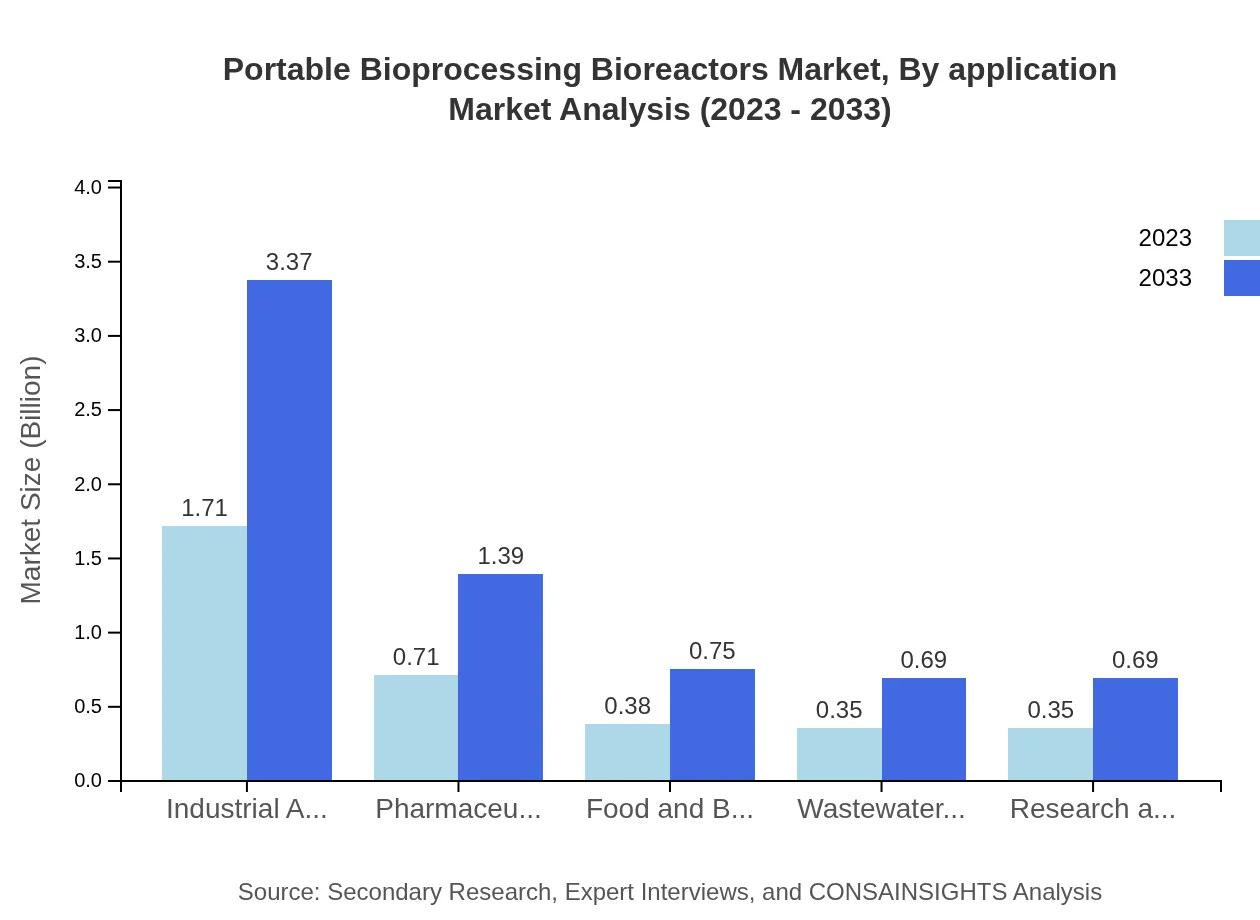

Portable Bioprocessing Bioreactors Market Analysis By Application

Market applications for Portable Bioprocessing Bioreactors include pharmaceuticals ($0.71 billion in 2023), food and beverages ($0.38 billion), and industrial applications ($1.71 billion). Each application grows at differing rates, with pharmaceuticals showing strong future prospects due to the rise in biopharmaceuticals and personalized medicine approaches.

Portable Bioprocessing Bioreactors Market Analysis By Technology

Technologies such as stirred tank bioreactors, membrane bioreactors, and photobioreactors capture different shares of the market. Stirred tank bioreactors lead with a significant share and are valued at $2.35 billion in 2023, reflecting their dominant presence in the industry.

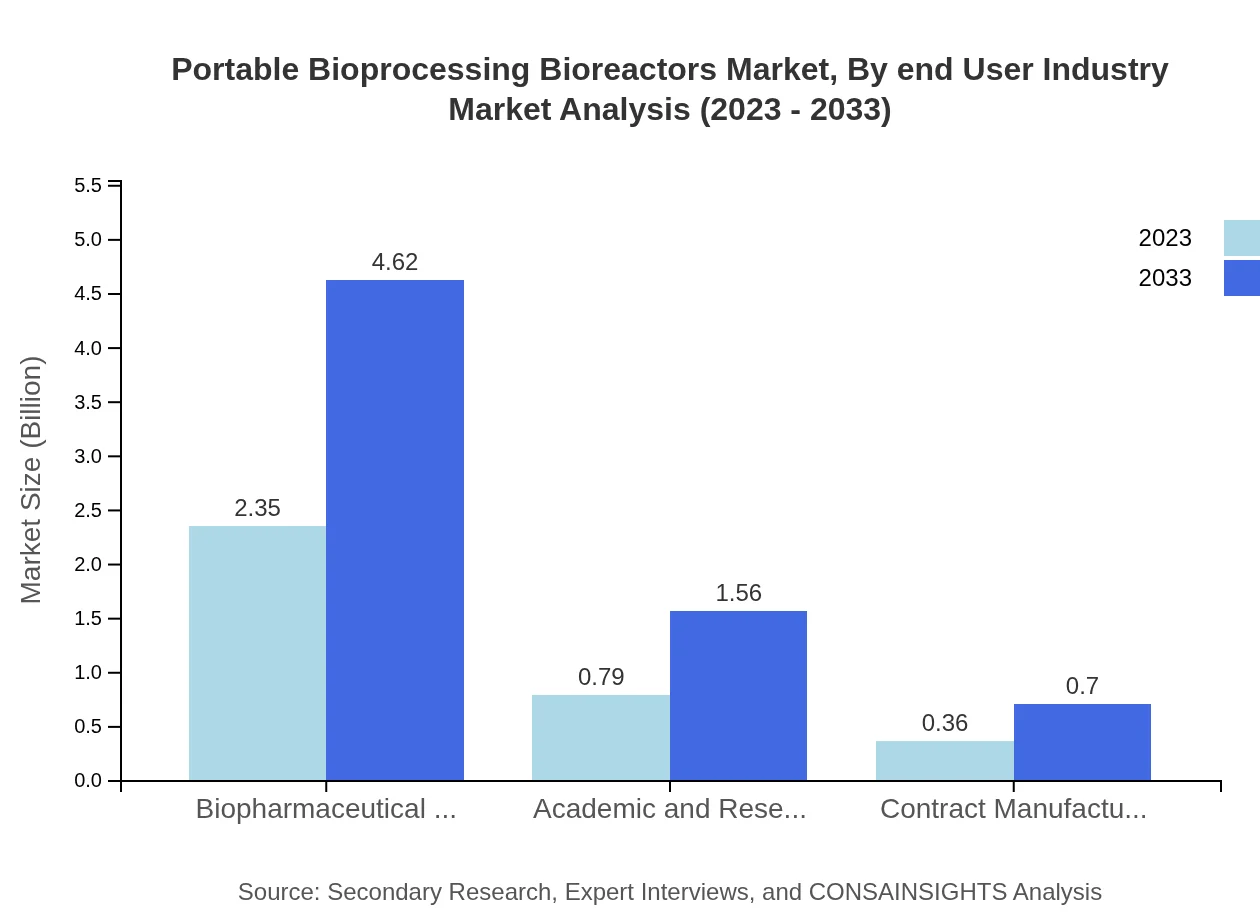

Portable Bioprocessing Bioreactors Market Analysis By End User Industry

Key end-user industries include biopharmaceutical companies, academic and research institutes, and contract manufacturing organizations. Biopharmaceutical companies account for the largest share, reflecting the high demand for innovative production processes.

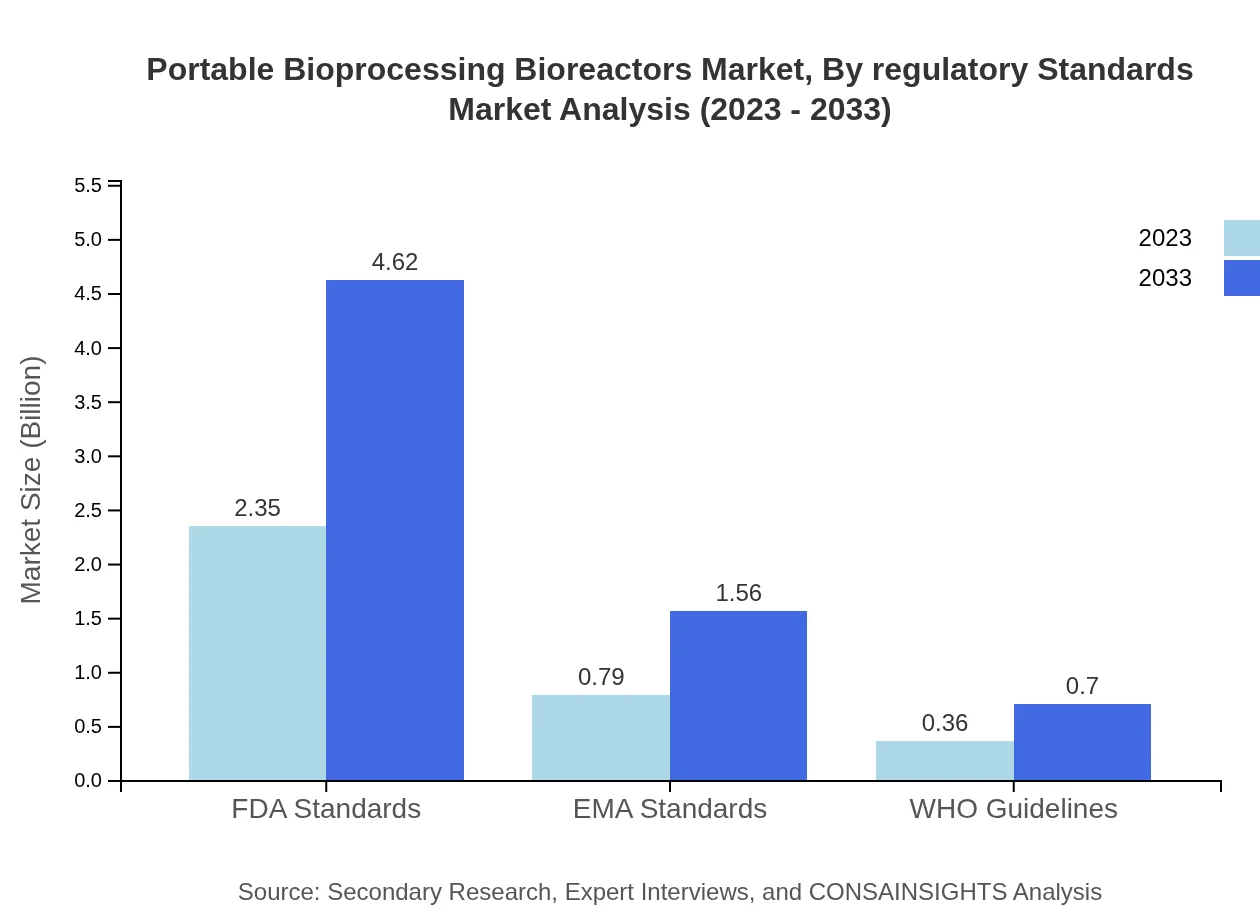

Portable Bioprocessing Bioreactors Market Analysis By Regulatory Standards

Regulatory standards such as FDA, EMA, and WHO guidelines set the framework for market operations. Compliance with these standards is crucial for market players to ensure product efficacy and safety, thereby influencing market growth.

Portable Bioprocessing Bioreactors Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Portable Bioprocessing Bioreactors Industry

Sartorius AG:

A leading player in bioprocessing technology, Sartorius AG offers innovative solutions and equipment for biopharmaceutical production, aiding in efficient and compliant processes.GE Healthcare:

GE Healthcare provides advanced bioprocessing equipment and systems, supporting the development and production of biopharmaceuticals, with a focus on automation and scalability.Eppendorf AG:

Famous for its bioreactors and fermentation systems, Eppendorf AG supports the lifecycle of bioprocess development, from research to commercial scale.Thermo Fisher Scientific:

Thermo Fisher Scientific offers a wide range of products, including portable bioreactors that enhance bioprocessing capabilities across various sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of portable bioprocessing bioreactors?

The global market size for portable bioprocessing bioreactors is estimated at $3.5 billion in 2023, with a projected CAGR of 6.8% over the next 10 years, reaching significant growth as demand rises across multiple applications.

What are the key market players or companies in this portable bioprocessing bioreactors industry?

Key players in the portable bioprocessing bioreactors industry include leading biopharmaceutical companies, biotechnology firms, and equipment manufacturers who are innovating to enhance production efficiency and compliance with regulatory standards.

What are the primary factors driving the growth in the portable bioprocessing bioreactors industry?

Key growth drivers include rising demand for biopharmaceuticals, advancements in bioprocessing technologies, increasing applications in research and development, and the need for cost-effective manufacturing solutions to optimize production.

Which region is the fastest Growing in the portable bioprocessing bioreactors market?

The Asia Pacific region is the fastest-growing market for portable bioprocessing bioreactors, projected to grow from $0.73 billion in 2023 to $1.44 billion by 2033, driven by expanding biotechnology sectors and increased research facilities.

Does ConsaInsights provide customized market report data for the portable bioprocessing bioreactors industry?

Yes, ConsaInsights offers customized market report data tailored to the specific needs of clients in the portable bioprocessing bioreactors industry, allowing for detailed insights into market trends, regional analysis, and sector growth.

What deliverables can I expect from this portable bioprocessing bioreactors market research project?

Deliverables include comprehensive reports detailing market size, segmentation analysis, competitive landscapes, regional trends, and forecasts along with graphical representations of data for easier interpretation and business strategy development.

What are the market trends of portable bioprocessing bioreactors?

Current trends include an increasing shift towards automation, a focus on environmentally sustainable practices in bioprocessing, and rising integration of AI and data analytics to enhance operational efficiency in bioreactor processes.