Powder Induction And Dispersion Systems Market Report

Published Date: 22 January 2026 | Report Code: powder-induction-and-dispersion-systems

Powder Induction And Dispersion Systems Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Powder Induction And Dispersion Systems market, covering key insights, market size forecasts, trends, and sectoral performance from 2023 to 2033.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

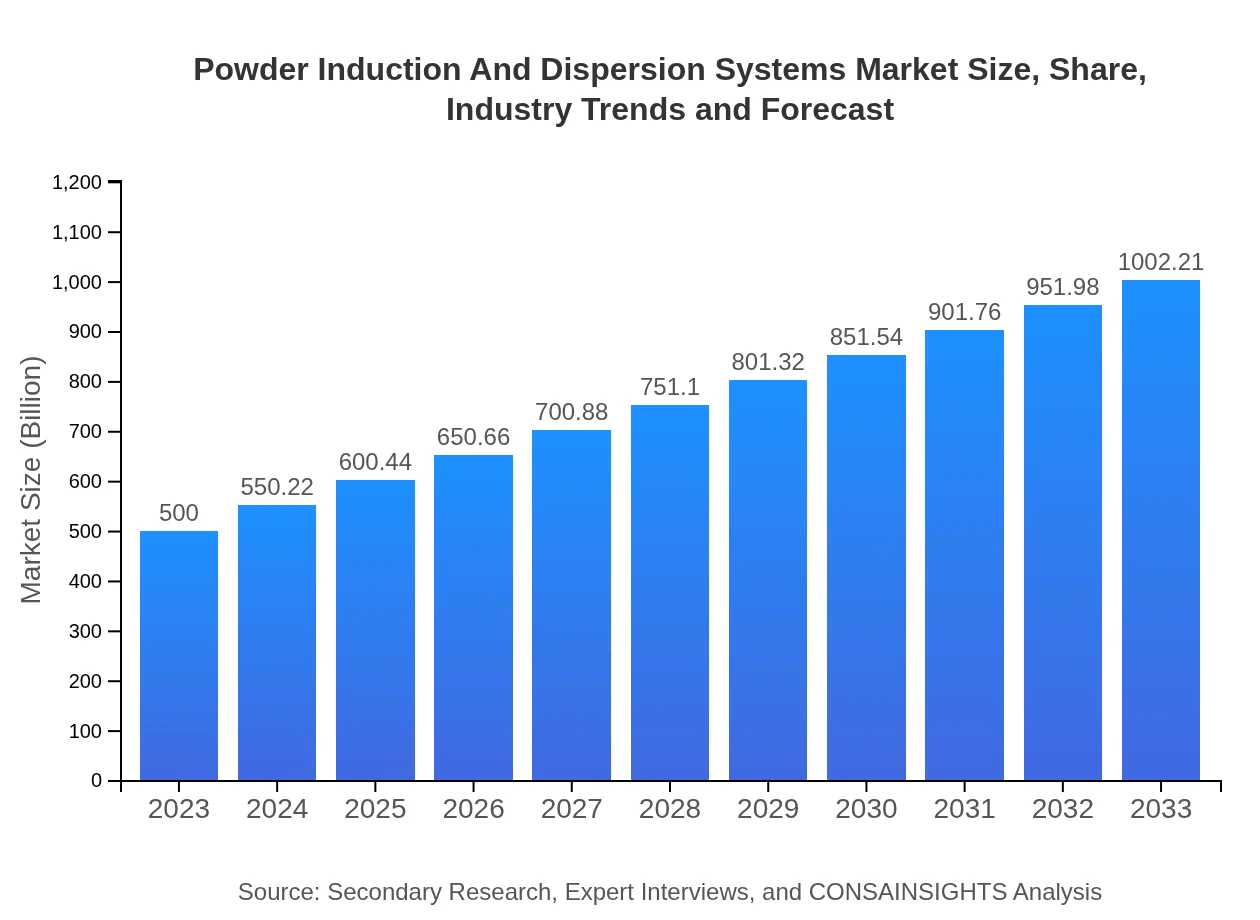

| 2023 Market Size | $500.00 Million |

| CAGR (2023-2033) | 7% |

| 2033 Market Size | $1002.21 Million |

| Top Companies | Charles Ross & Son Company, Silverson Machines, GAlibrand Technologies, |

| Last Modified Date | 22 January 2026 |

Powder Induction And Dispersion Systems Market Overview

Customize Powder Induction And Dispersion Systems Market Report market research report

- ✔ Get in-depth analysis of Powder Induction And Dispersion Systems market size, growth, and forecasts.

- ✔ Understand Powder Induction And Dispersion Systems's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Powder Induction And Dispersion Systems

What is the Market Size & CAGR of Powder Induction And Dispersion Systems market in 2023?

Powder Induction And Dispersion Systems Industry Analysis

Powder Induction And Dispersion Systems Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Powder Induction And Dispersion Systems Market Analysis Report by Region

Europe Powder Induction And Dispersion Systems Market Report:

Europe showcases a robust market with an estimated size of $129.20 million in 2023, increasing to approximately $258.97 million by 2033. The demand for clean-label products and compliance with strict regulations in food safety drive the adoption of advanced systems in this region.Asia Pacific Powder Induction And Dispersion Systems Market Report:

The Asia Pacific region is witnessing remarkable growth in the Powder Induction and Dispersion Systems market due to rapid industrialization and increased demand in the food and beverage sectors. As of 2023, the market size stands at approximately $95.25 million and is projected to reach $190.92 million by 2033, fueled by expanding manufacturing capabilities and rising consumer demand.North America Powder Induction And Dispersion Systems Market Report:

North America holds a prominent position in the Powder Induction and Dispersion Systems market, with a valuation of $187.10 million in 2023, expected to rise to $375.03 million by 2033. Growing technological advancements and a strong focus on quality control in food production are significant contributors.South America Powder Induction And Dispersion Systems Market Report:

In South America, the market for Powder Induction and Dispersion Systems is expected to grow steadily, with the current market size of $47.35 million projected to almost double to $94.91 million by 2033. This growth is primarily driven by increasing investments in the food and pharmaceutical industries.Middle East & Africa Powder Induction And Dispersion Systems Market Report:

The Middle East and Africa market is gradually expanding, calculated at $41.10 million in 2023, and is expected to grow to $82.38 million by 2033. This growth can be attributed to increasing urbanization and the expanding food processing and chemical industries.Tell us your focus area and get a customized research report.

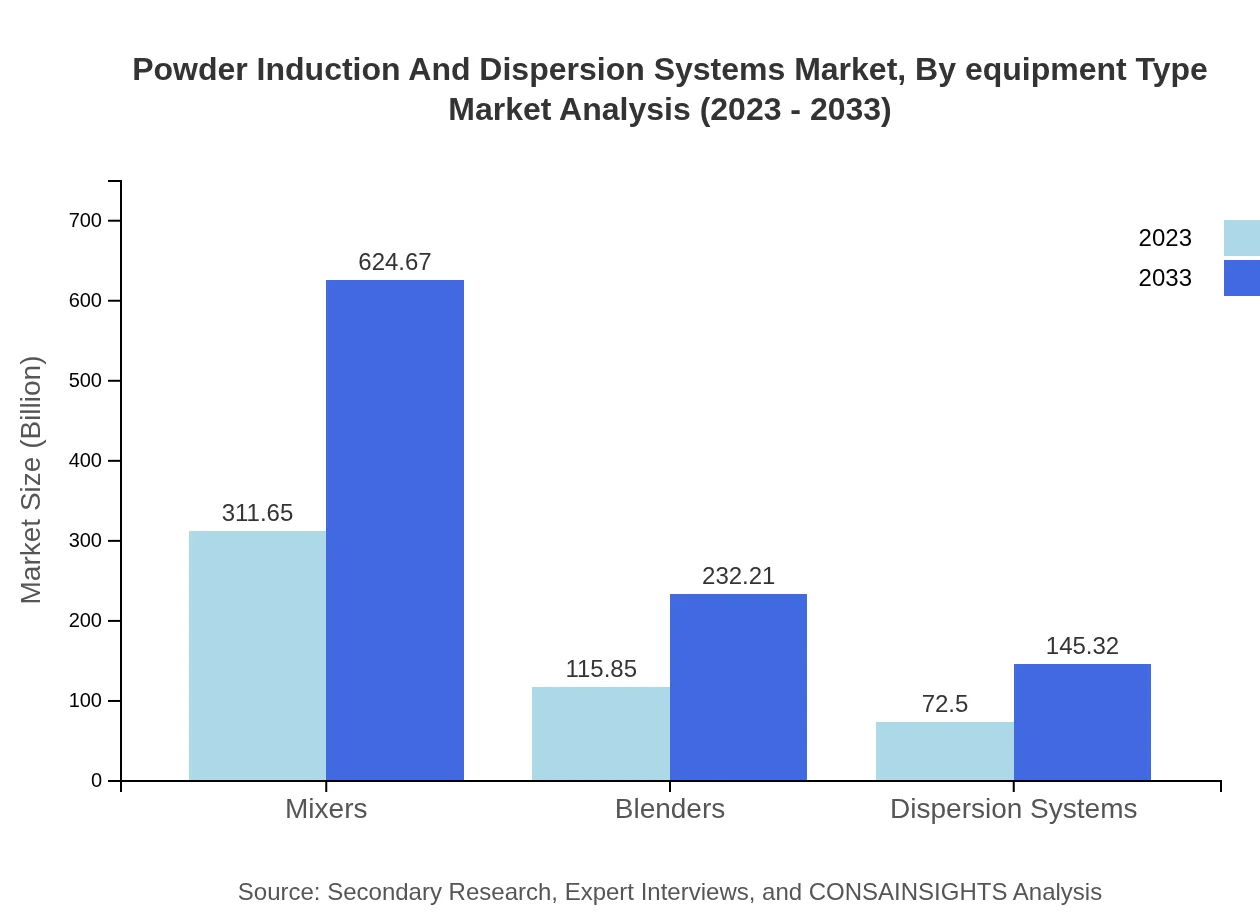

Powder Induction And Dispersion Systems Market Analysis By Equipment Type

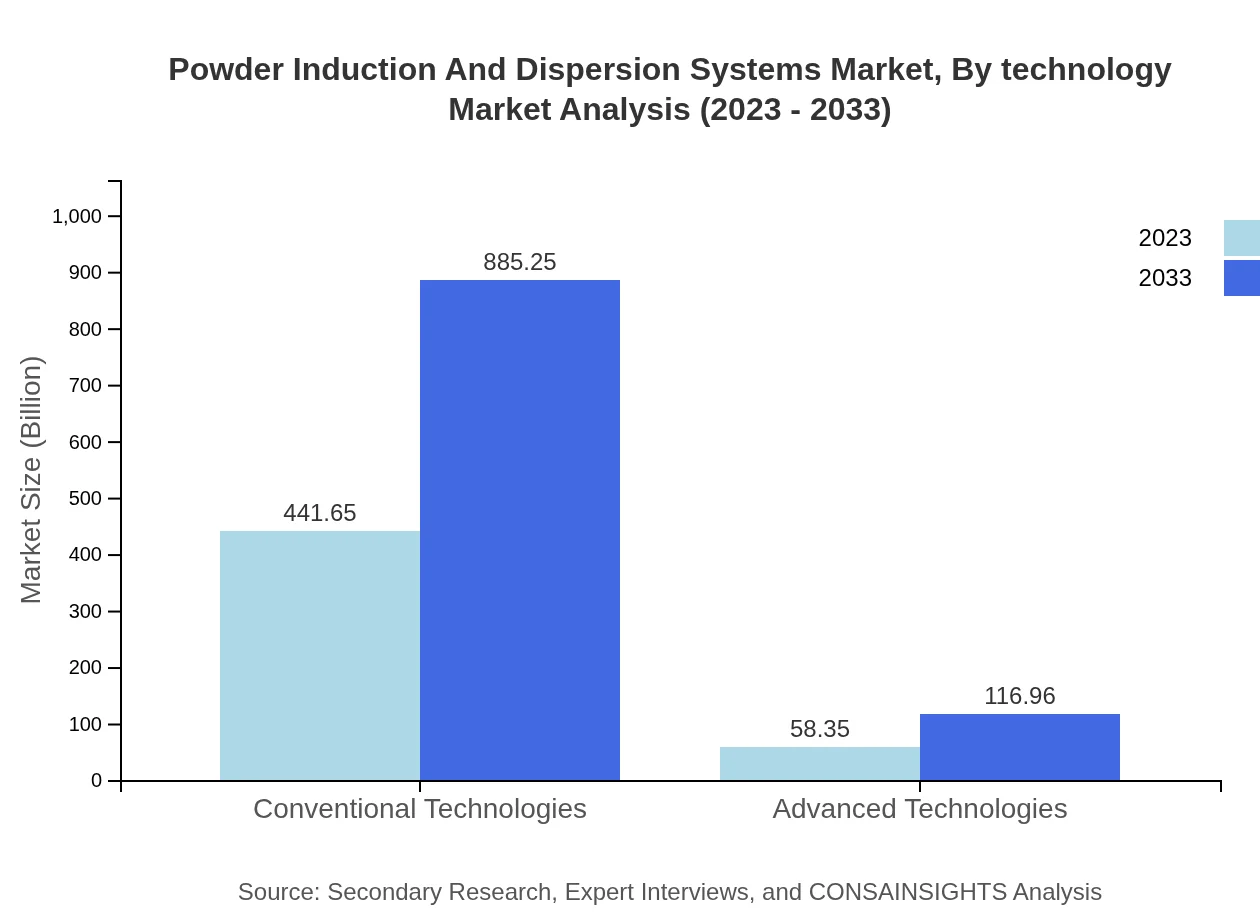

In 2023, the conventional technologies segment dominates the market with a size of $441.65 million, projected to reach $885.25 million by 2033. Advanced technologies, although smaller at $58.35 million in 2023, are expected to grow to $116.96 million during the same period. Mixers, blenders, and dispersion systems represent critical equipment types driving this segment.

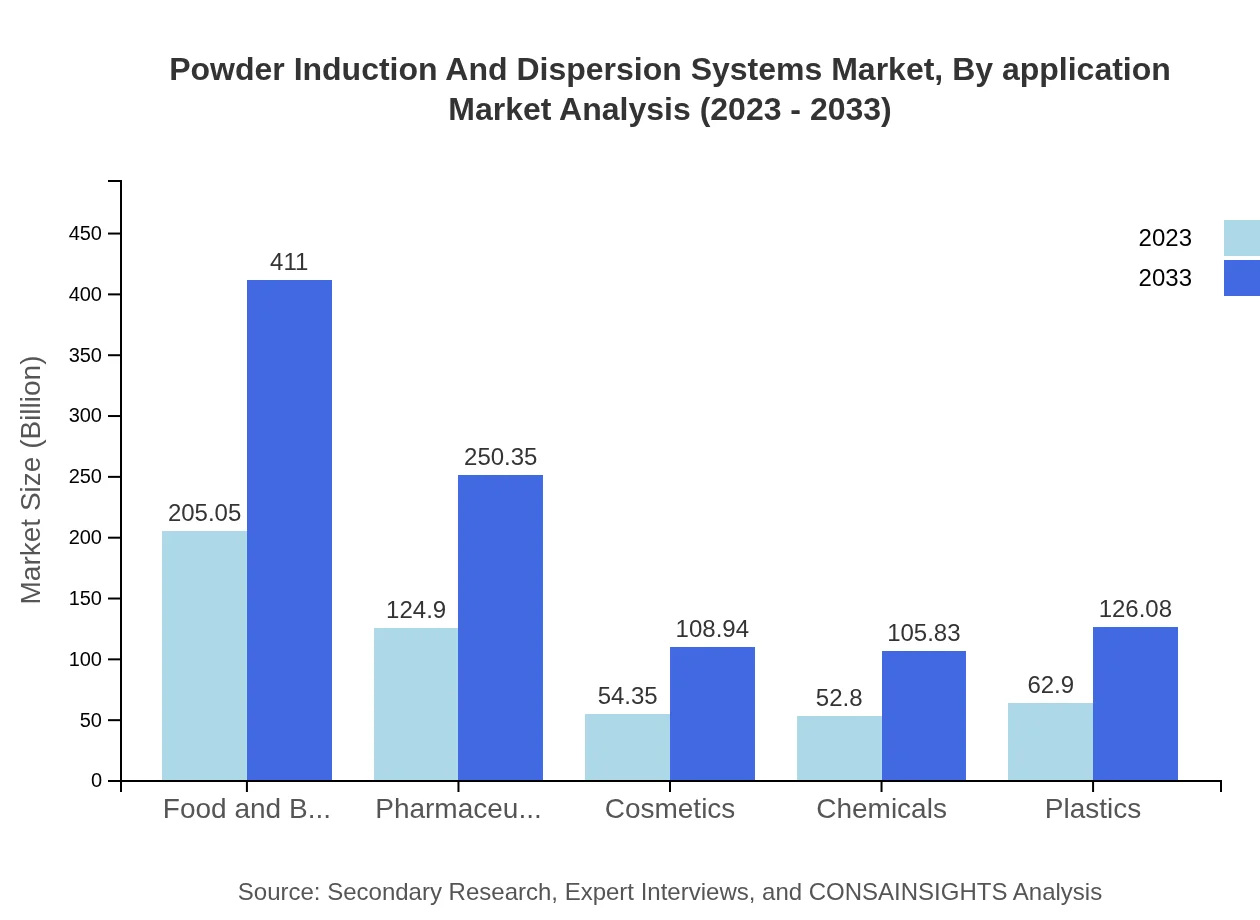

Powder Induction And Dispersion Systems Market Analysis By Application

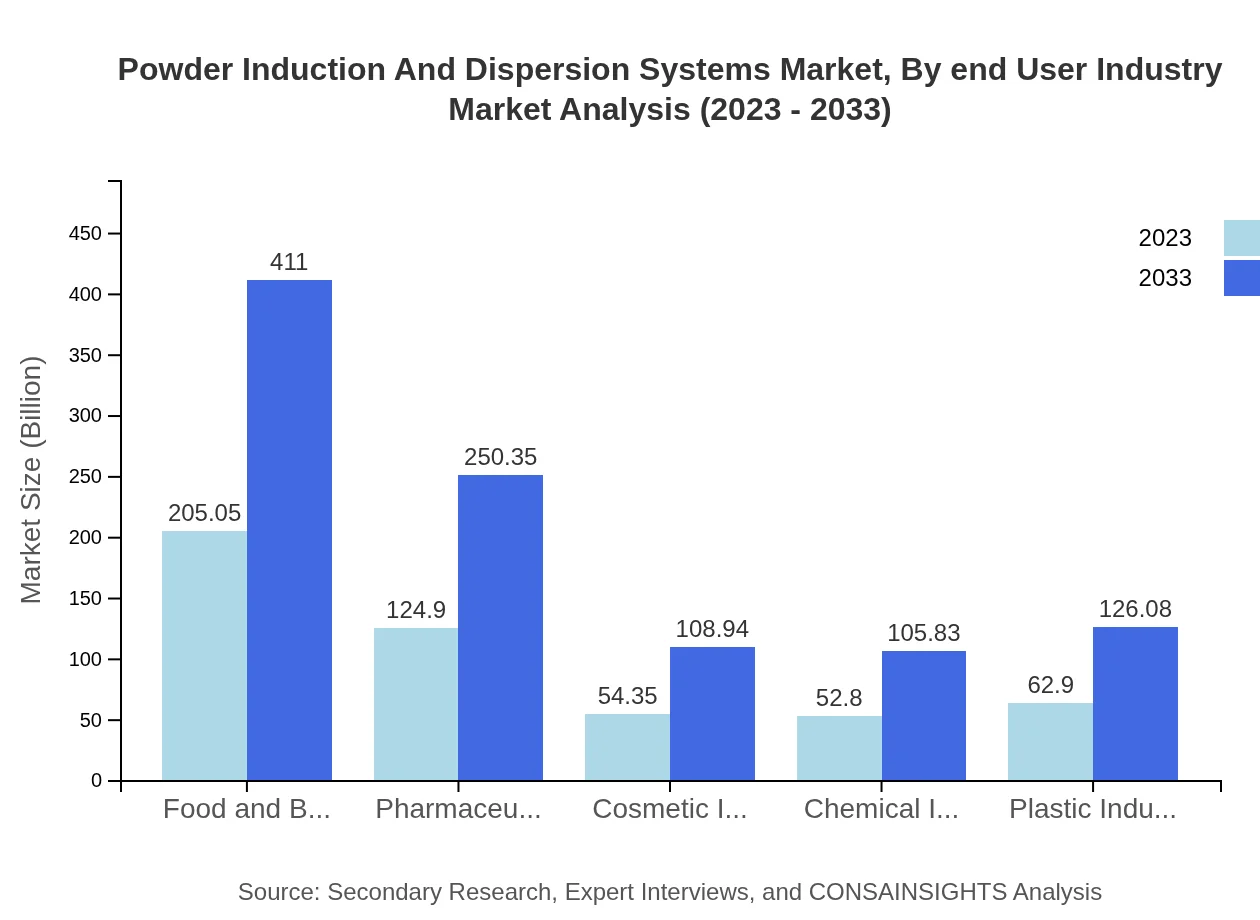

The food and beverage industry constitutes a significant share, valued at $205.05 million in 2023, projected to double by 2033. Following closely is the pharmaceutical industry, with a market size of $124.90 million in 2023, also expected to see substantial growth to $250.35 million by 2033, showcasing the importance of these systems in critical applications.

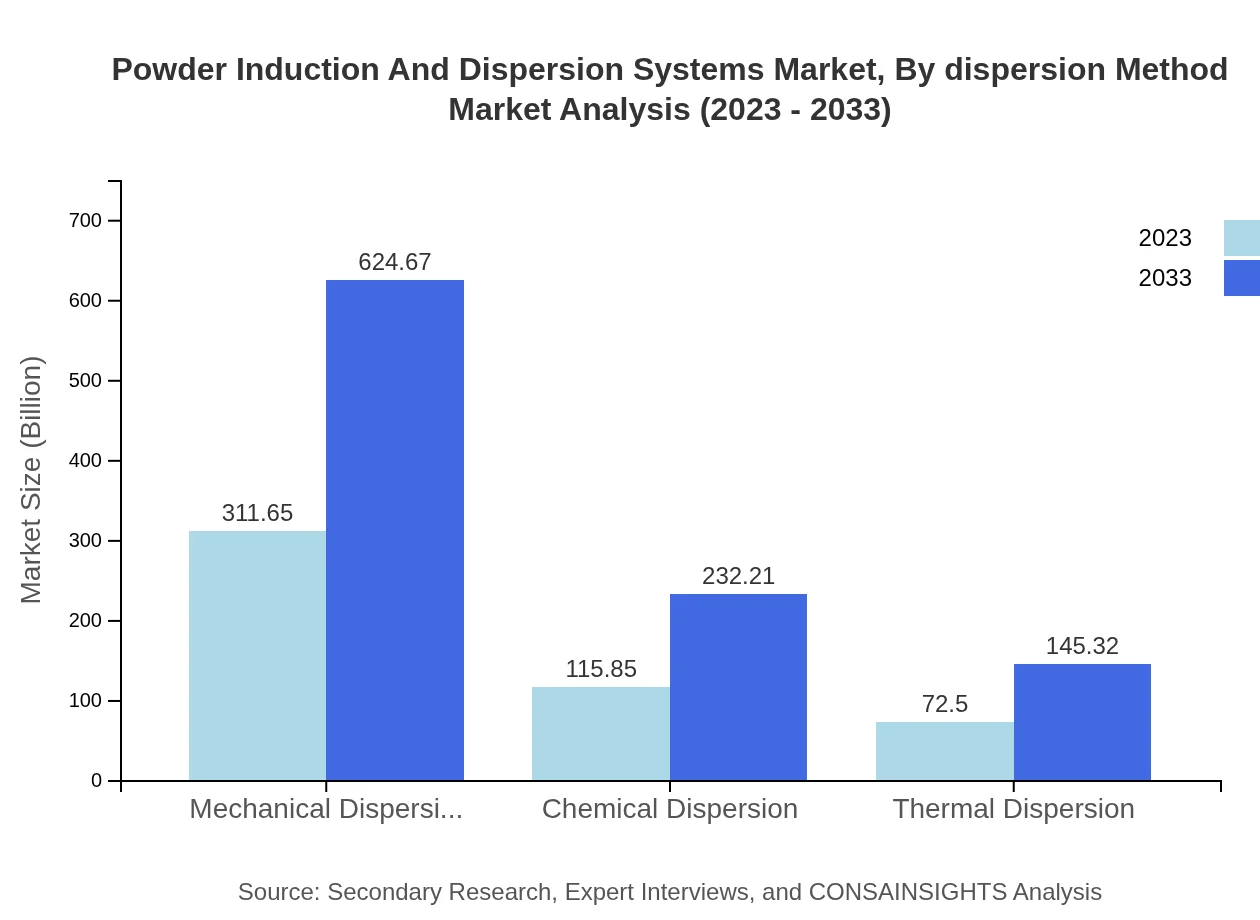

Powder Induction And Dispersion Systems Market Analysis By Dispersion Method

Mechanical dispersion remains the leading method employed, valued at $311.65 million in 2023, and expected to grow to $624.67 million by 2033. Chemical dispersion follows, currently valued at $115.85 million and projected to reach $232.21 million, reflecting the versatility of these methods in various industries.

Powder Induction And Dispersion Systems Market Analysis By End User Industry

Currently, food and beverage accounts for a market share of 41.01% as of 2023, with an expected increment in the coming years. The pharmaceutical industry also holds significant share at 24.98%, supporting its essential role in developing effective drug formulations.

Powder Induction And Dispersion Systems Market Analysis By Technology

The technology segment is shaped by conventional and advanced methodologies. Conventional technologies dominate the sector with a robust market share of 88.33% in 2023, while advanced technologies are expected to contribute substantially as they become more prevalent in new installations.

Powder Induction And Dispersion Systems Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Powder Induction And Dispersion Systems Industry

Charles Ross & Son Company:

A leading manufacturer specializing in mixing, dispersing, and milling equipment for various industries. Their innovative technologies enhance product quality and processing efficiency.Silverson Machines:

Well-known for its high shear mixing equipment, Silverson provides advanced solutions that cater to the needs of the pharmaceuticals and food industries, ensuring consistency and quality.GAlibrand Technologies,:

They offer state-of-the-art induction and mixing systems that are designed for efficiency and adaptability in modern manufacturing environments.We're grateful to work with incredible clients.

FAQs

What is the market size of powder Induction And Dispersion Systems?

The powder induction and dispersion systems market is valued at $500 million in 2023 and is projected to grow at a CAGR of 7% from 2023 to 2033, highlighting a robust growth trend in this sector.

What are the key market players or companies in this powder Induction And Dispersion Systems industry?

Key players in the powder induction and dispersion systems market include major industrial firms that produce mixing equipment, automation solutions, and customized systems, operating across various sectors such as food, pharmaceuticals, and chemicals.

What are the primary factors driving the growth in the powder Induction And Dispersion Systems industry?

Factors driving growth in this industry include the increasing demand for efficient mixing solutions, advancements in technology, expansion in end-user industries like food and beverages, pharmaceuticals, and the growing focus on operational efficiency.

Which region is the fastest Growing in the powder Induction And Dispersion Systems?

The Asia Pacific region is the fastest-growing market for powder induction and dispersion systems, with a projected market size of $190.92 million by 2033, reflecting significant industrial growth and innovation in the region.

Does ConsaInsights provide customized market report data for the powder Induction And Dispersion Systems industry?

Yes, ConsaInsights offers customized market report data tailored to client needs, ensuring insights reflect specific interests, industry trends, and detailed analyses pertinent to the powder induction and dispersion systems market.

What deliverables can I expect from this powder Induction And Dispersion Systems market research project?

Deliverables from this research project include detailed market analysis reports, segmentation data, growth forecasts, competitive landscape assessments, and comprehensive insights to guide strategic decision-making in the powder induction sector.

What are the market trends of powder Induction And Dispersion Systems?

Current trends in the powder induction and dispersion systems market include a shift toward automation, increased demand for eco-friendly technologies, innovations in material handling, and the rise of advanced mixing technologies catering to diverse industry applications.