Power Plant Boiler Market Report

Published Date: 22 January 2026 | Report Code: power-plant-boiler

Power Plant Boiler Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive overview of the Power Plant Boiler market, analyzing the current trends, market size, forecasts from 2023 to 2033, and key drivers influencing the industry. It aims to present insights into market segmentation and regional growth.

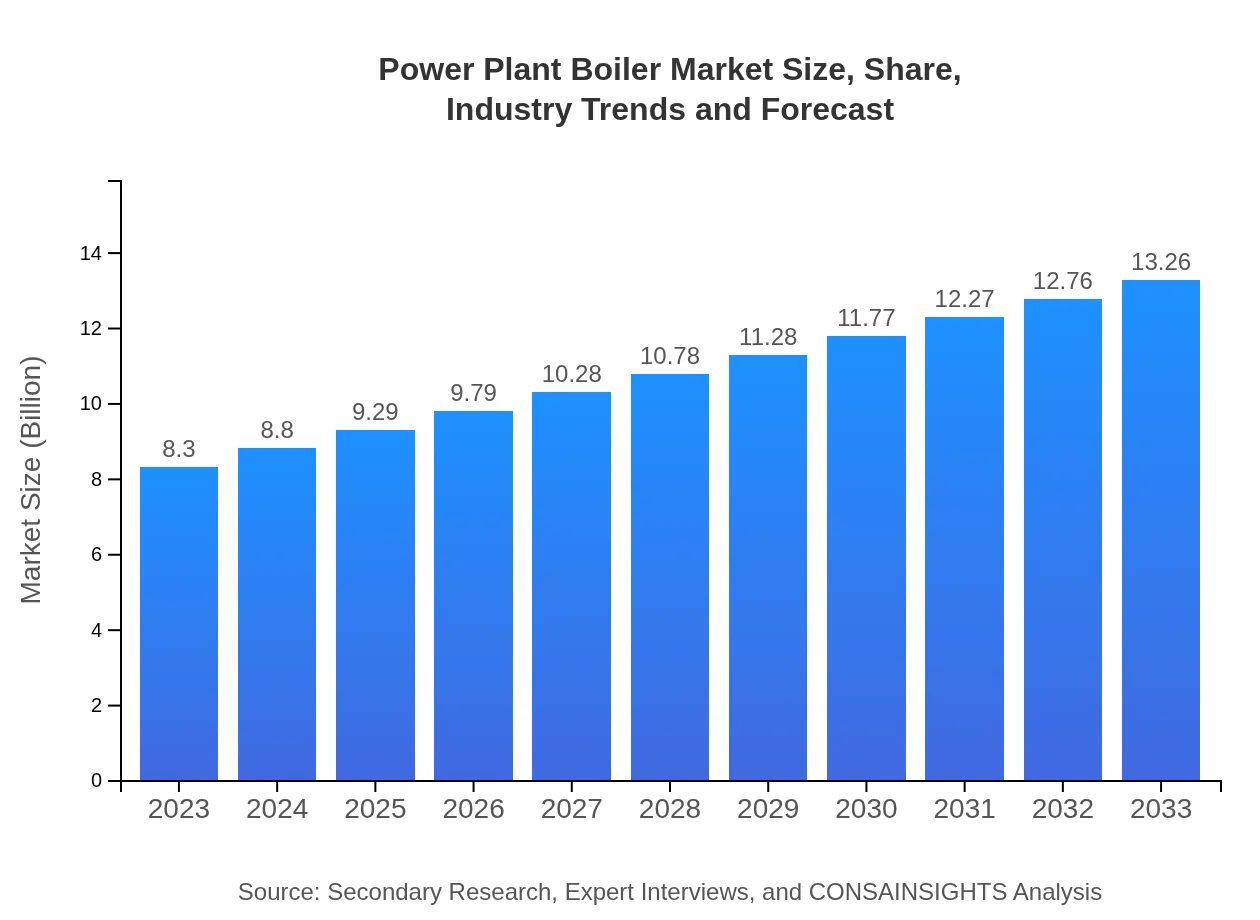

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $8.30 Billion |

| CAGR (2023-2033) | 4.7% |

| 2033 Market Size | $13.26 Billion |

| Top Companies | GE Power, Siemens AG, Mitsubishi Hitachi Power Systems, Babcock & Wilcox |

| Last Modified Date | 22 January 2026 |

Power Plant Boiler Market Overview

Customize Power Plant Boiler Market Report market research report

- ✔ Get in-depth analysis of Power Plant Boiler market size, growth, and forecasts.

- ✔ Understand Power Plant Boiler's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Power Plant Boiler

What is the Market Size & CAGR of Power Plant Boiler market in 2023?

Power Plant Boiler Industry Analysis

Power Plant Boiler Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Power Plant Boiler Market Analysis Report by Region

Europe Power Plant Boiler Market Report:

Europe has a strong commitment to sustainable energy solutions, with the market projected to rise from $3.11 billion in 2023 to $4.97 billion in 2033. The region focuses on reducing carbon footprints, thus enhancing investments in modern boiler technologies that align with environmental goals.Asia Pacific Power Plant Boiler Market Report:

The Asia-Pacific region is experiencing rapid industrialization, leading to a robust market for Power Plant Boilers, with a market size projected to grow from $1.41 billion in 2023 to $2.26 billion in 2033. Significant investments in energy infrastructure and a shift towards renewable energy sources are shaping regional growth.North America Power Plant Boiler Market Report:

North America is forecasted to grow its Power Plant Boiler market from $2.69 billion in 2023 to $4.29 billion in 2033, driven by technology advancements, stringent regulations emphasizing cleaner energy solutions, and significant investment in upgrading aging power plants.South America Power Plant Boiler Market Report:

In South America, the market is relatively small, with a size expected to increase from $0.06 billion in 2023 to $0.09 billion in 2033. Growth factors include increased government initiatives for renewable energy and more industrial activities in countries like Brazil and Argentina.Middle East & Africa Power Plant Boiler Market Report:

The Middle East and Africa market is anticipated to expand from $1.03 billion in 2023 to $1.65 billion in 2033, driven by accelerated industrial growth and increased emphasis on energy efficiency and sustainability within the region, particularly in the United Arab Emirates and South Africa.Tell us your focus area and get a customized research report.

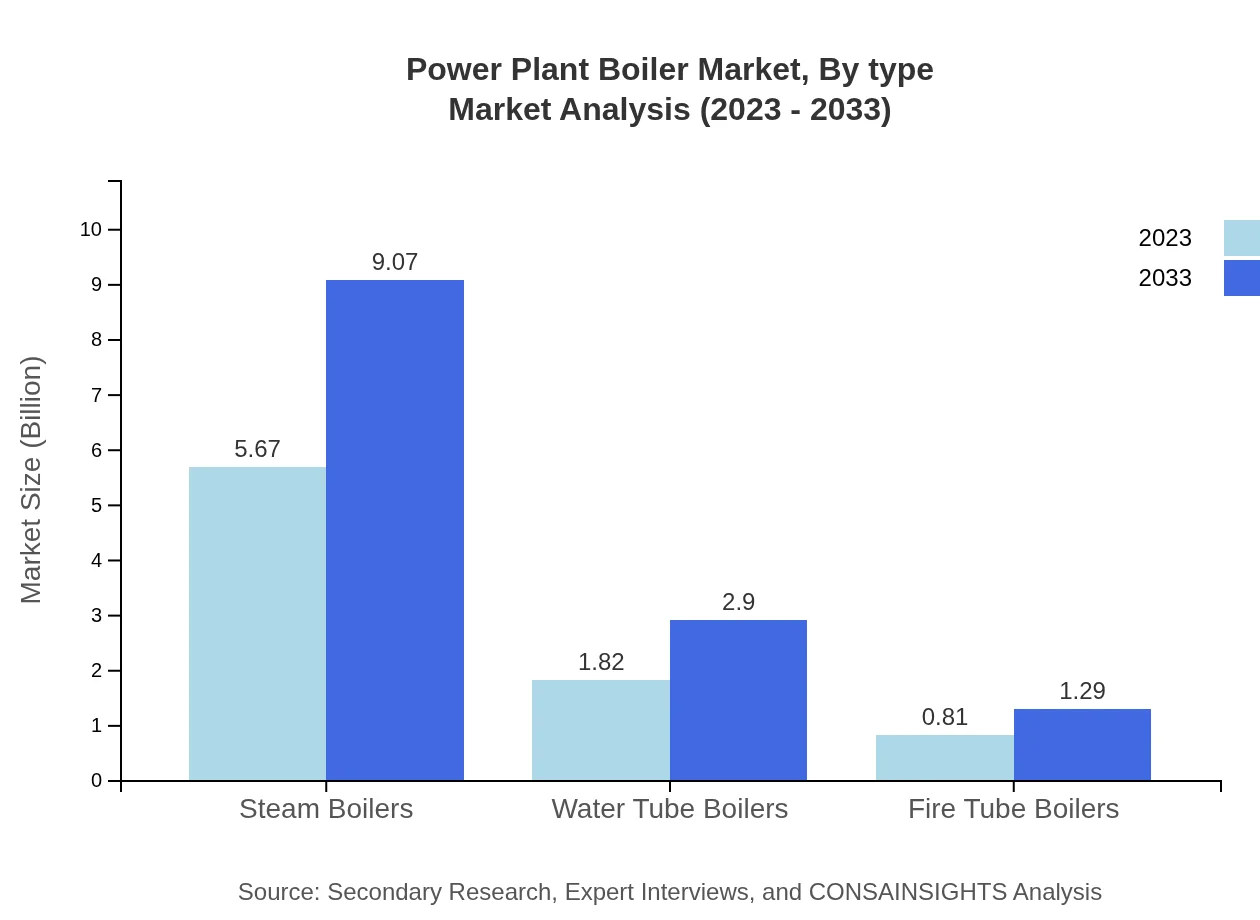

Power Plant Boiler Market Analysis By Type

The Power Plant Boiler Market by type is dominated by steam boilers, which accounted for a size of $5.67 billion in 2023, projected to rise to $9.07 billion by 2033, representing 68.37% of the market share. Water tube and fire tube boilers follow, with significant shares and specific roles in different applications. Innovations in modular and customized boilers are also notable, catering to diverse requirements across industries.

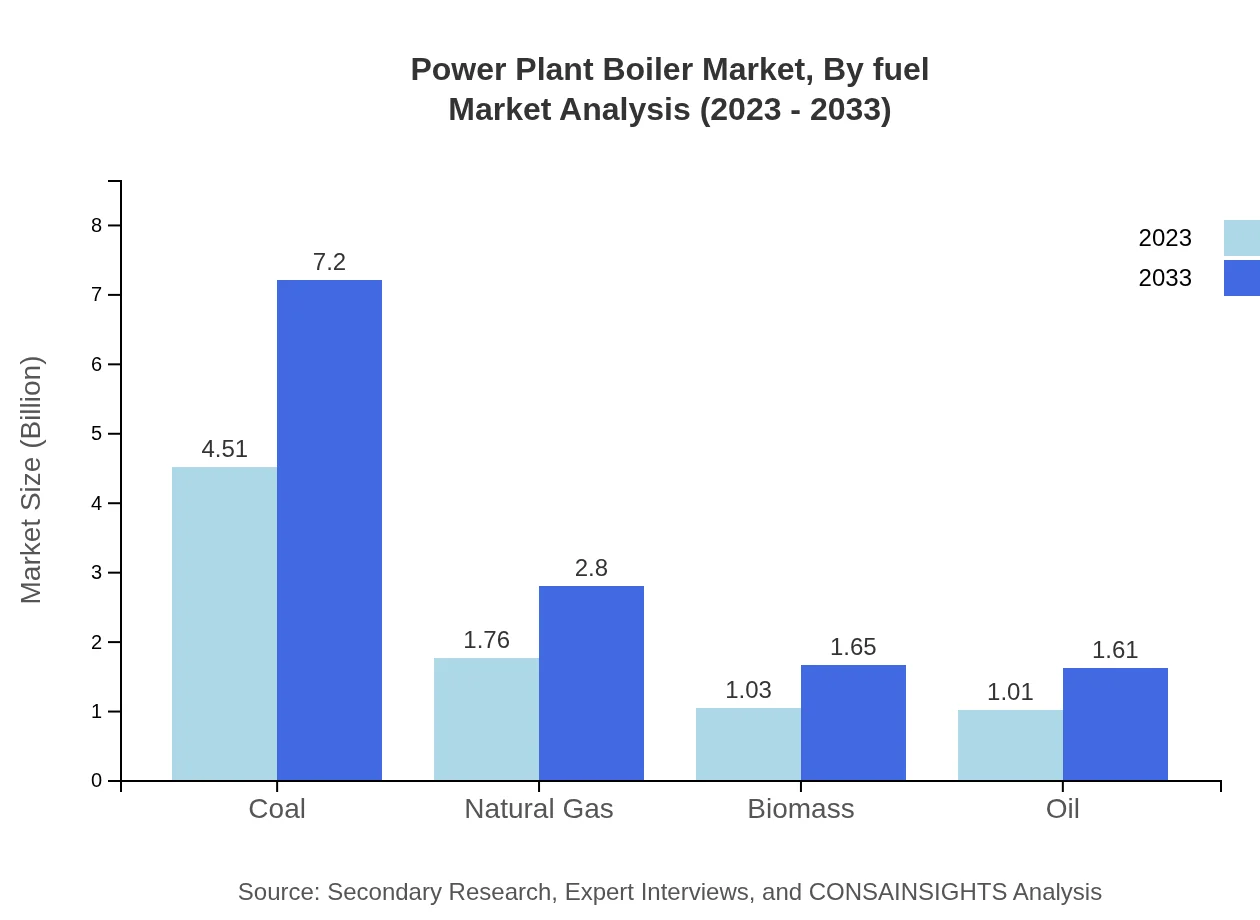

Power Plant Boiler Market Analysis By Fuel

Coal remains a major fuel source in the Power Plant Boiler Market, with a market size of $4.51 billion and a share of 54.32% in 2023, growing to $7.20 billion in 2033. Natural gas is also significant, capturing 21.15% of the market with a size increase projected from $1.76 billion to $2.80 billion. The shift towards biomass and other renewables is gradually transforming the fuel landscape in response to climate policies.

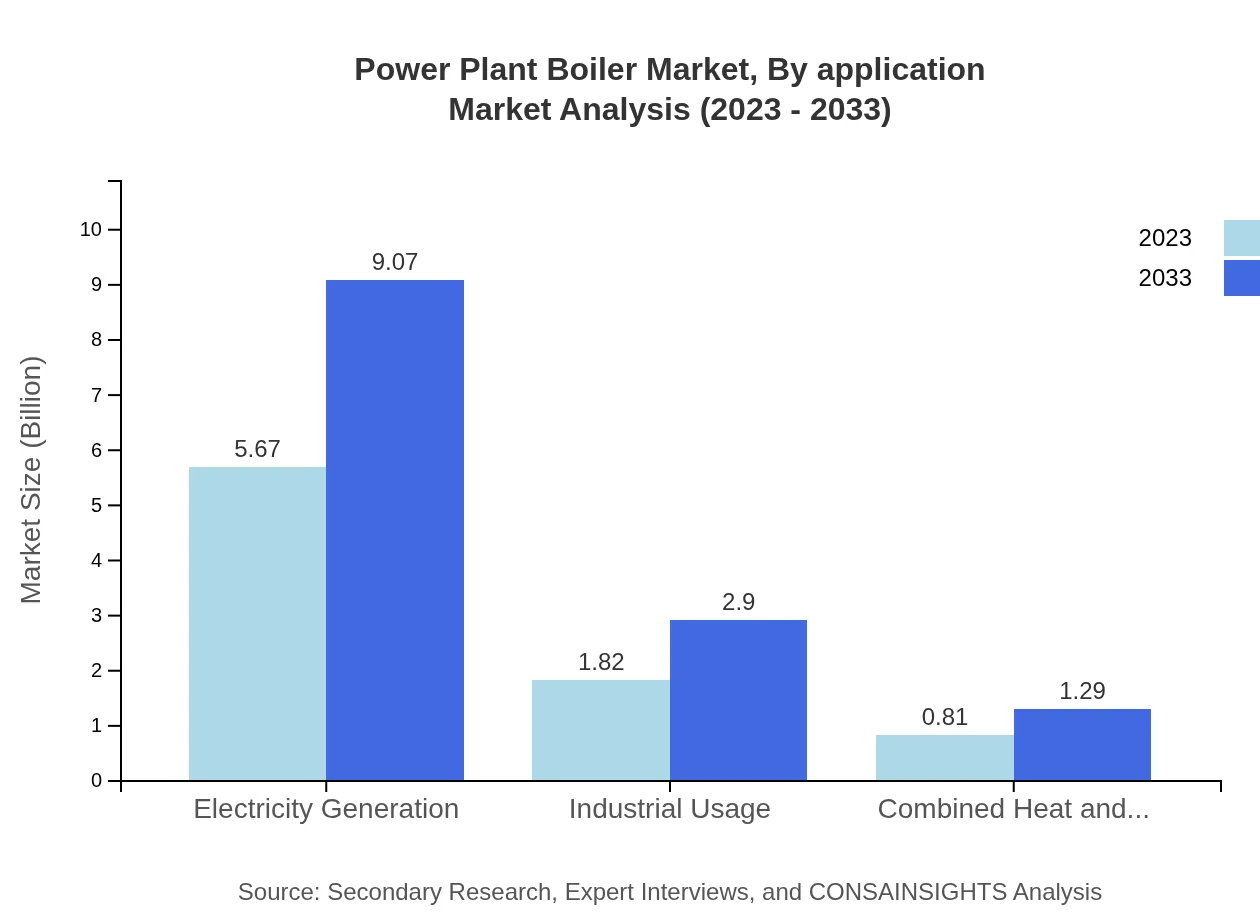

Power Plant Boiler Market Analysis By Application

Electricity generation holds the major share of the application segment, with a size of $5.67 billion and 68.37% of the total market in 2023, anticipated to grow to $9.07 billion by 2033. Industrial usage is also pertinent, representing 21.90% of applications, triggered by expanding manufacturing sectors.

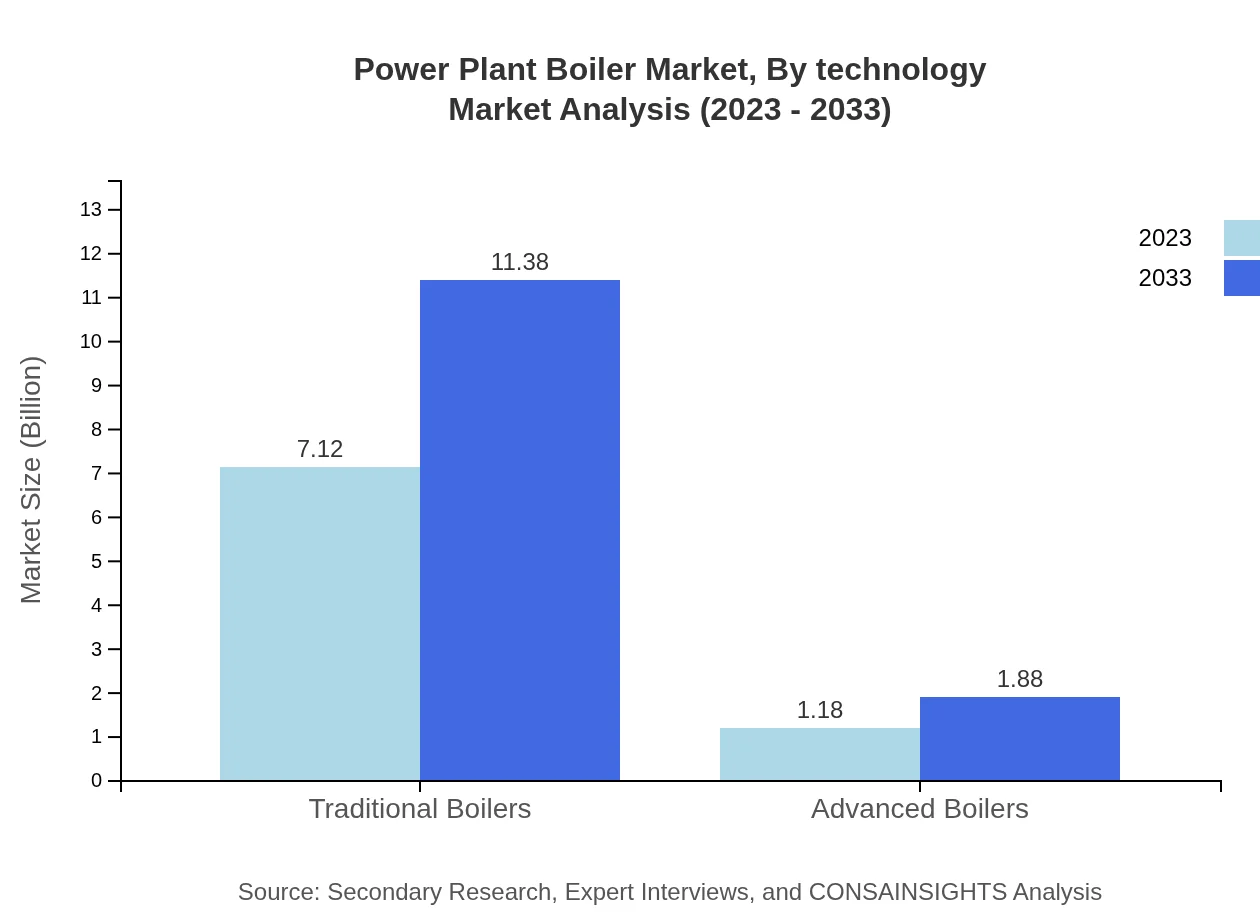

Power Plant Boiler Market Analysis By Technology

Technological advancements are pivotal in the Power Plant Boiler segment. Traditional boilers still possess a large market share, but advanced boilers are emerging rapidly, accounting for significant investment as companies look to enhance efficiency and meet stringent environmental regulations.

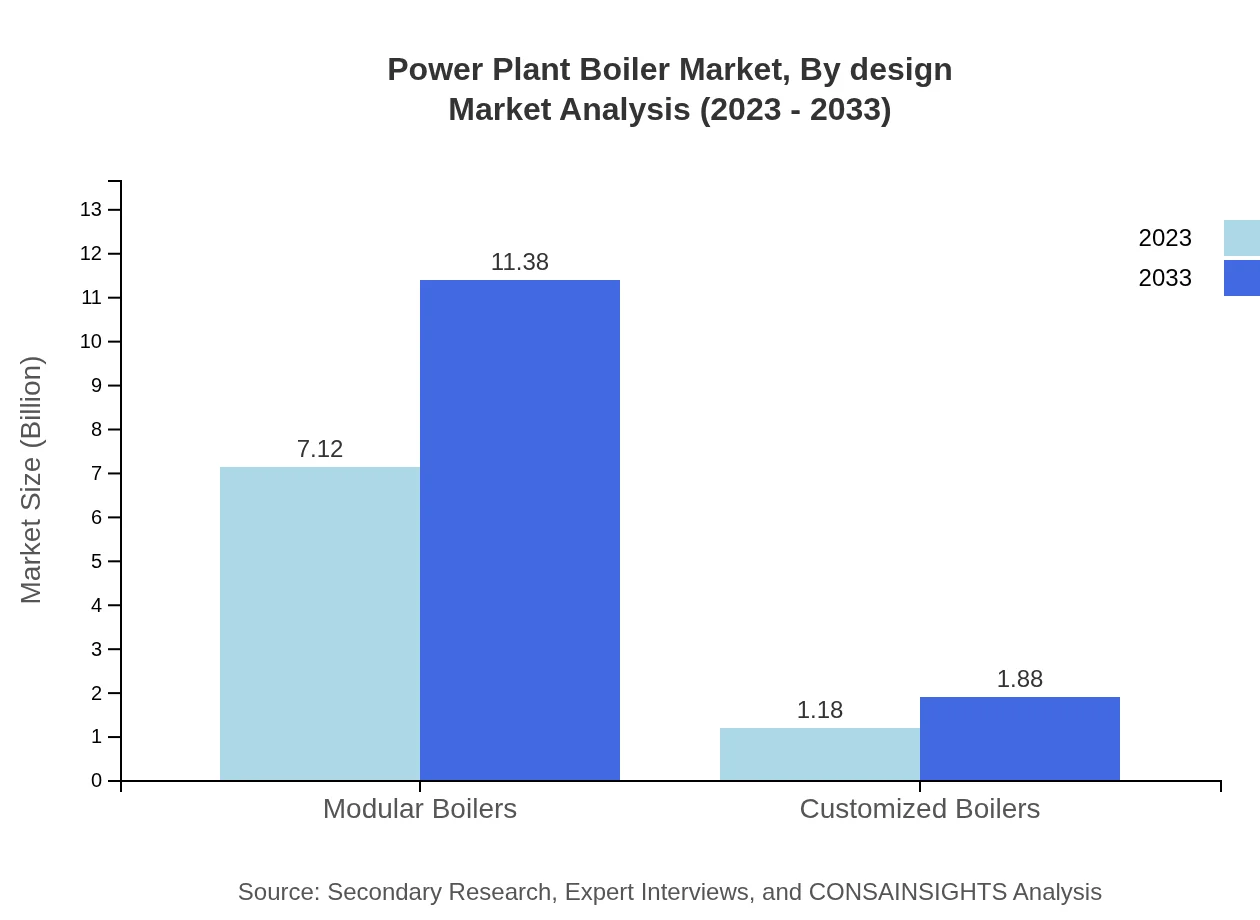

Power Plant Boiler Market Analysis By Design

The market for modular boilers has captured a substantial segment, with a size of $7.12 billion and a share of 85.79% in 2023, expected to rise to $11.38 billion by 2033. This design is favored for its flexibility and efficiency, catering to both industrial and commercial applications.

Power Plant Boiler Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Power Plant Boiler Industry

GE Power:

GE Power is a global leader in the energy sector, providing advanced technologies and services aimed at optimizing energy efficiency and environmental sustainability across the world.Siemens AG:

Siemens AG designs and manufactures boilers that cater to various energy needs, emphasizing innovative, efficient, and sustainable solutions for power generation.Mitsubishi Hitachi Power Systems:

This company specializes in designing, manufacturing, and servicing power generation equipment including high-efficiency boilers, aiming for lower emissions and enhanced operational efficiency.Babcock & Wilcox:

Committed to enhancing energy production efficiency, Babcock & Wilcox specializes in steam generation solutions and provides comprehensive boiler systems for various applications.We're grateful to work with incredible clients.

FAQs

What is the market size of power Plant Boiler?

The global power plant boiler market is valued at approximately $8.3 billion in 2023, with a projected CAGR of 4.7%, emphasizing steady growth through 2033.

What are the key market players or companies in this power Plant Boiler industry?

Key players in the power plant boiler market include major manufacturers and suppliers specializing in boiler systems. These companies dominate market share through innovation, sustainable practices, and technological advancements.

What are the primary factors driving the growth in the power Plant Boiler industry?

Growth in the power-plant-boiler industry is driven by rising energy demand, policy support for clean energy, technological advancements, and increased investments in infrastructure and power generation.

Which region is the fastest Growing in the power Plant Boiler?

The Asia Pacific region is emerging as the fastest-growing market for power plant boilers, rising from $1.41 billion in 2023 to $2.26 billion by 2033, driven by industrial expansion and energy needs.

Does ConsaInsights provide customized market report data for the power Plant Boiler industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the power plant boiler sector, ensuring comprehensive insights tailored to client requirements.

What deliverables can I expect from this power Plant Boiler market research project?

Deliverables from the power plant boiler market research project will include detailed reports, market forecasts, competitive analysis, industry trends, and segment-wise data for informed decision-making.

What are the market trends of power Plant Boiler?

Current trends in the power plant boiler market include increased adoption of modular and advanced boiler technologies, a shift towards renewable energy sources, and heightened focus on energy efficiency and emissions reduction.