Precast Concrete Market Report

Published Date: 22 January 2026 | Report Code: precast-concrete

Precast Concrete Market Size, Share, Industry Trends and Forecast to 2033

This report provides an insightful analysis of the precast concrete market from 2023 to 2033, highlighting market trends, growth forecasts, regional analysis, and the leading companies driving the industry. It aims to inform stakeholders about potential investment opportunities in this expanding market.

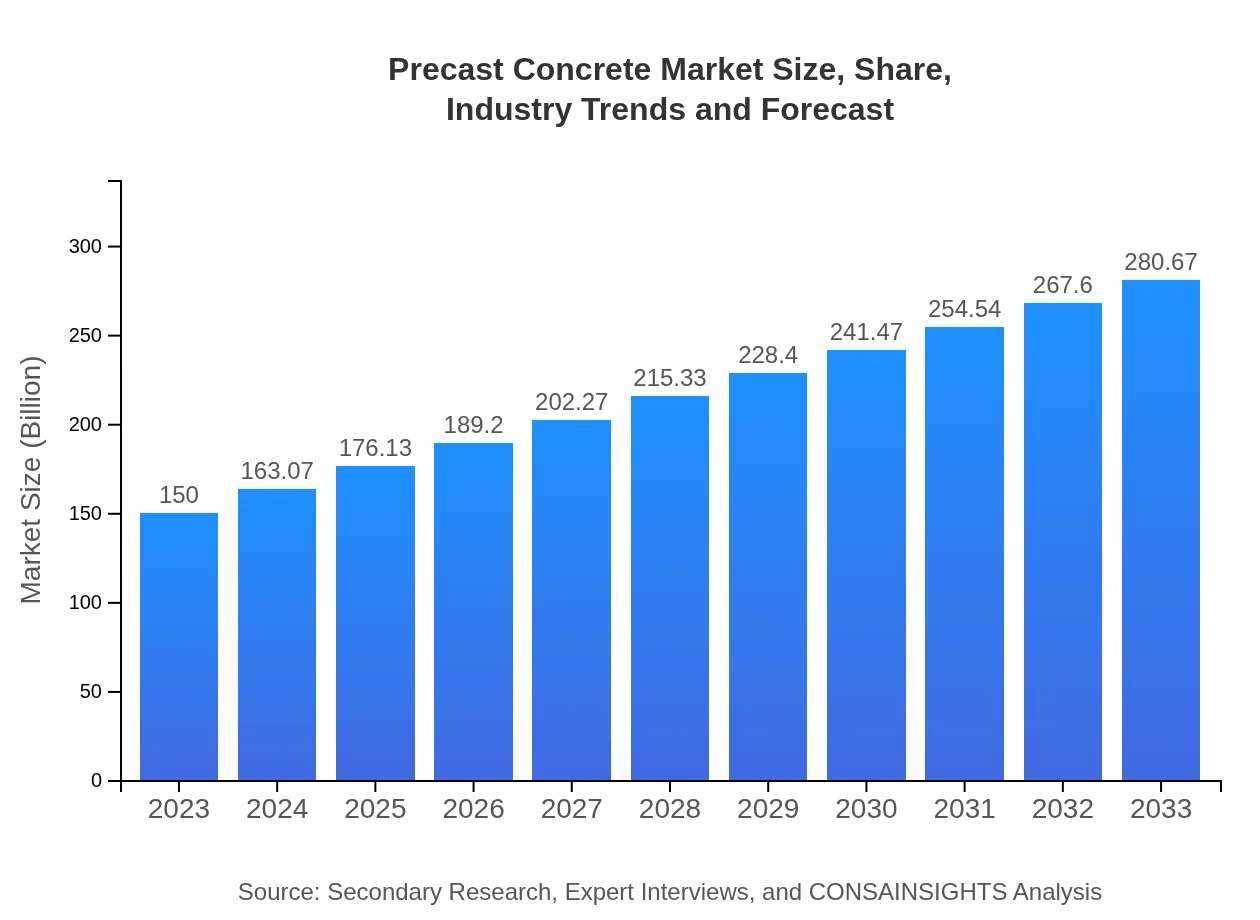

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $150.00 Billion |

| CAGR (2023-2033) | 6.3% |

| 2033 Market Size | $280.67 Billion |

| Top Companies | LafargeHolcim, Boral Limited, Cemex, Oldcastle Infrastructure |

| Last Modified Date | 22 January 2026 |

Precast Concrete Market Overview

Customize Precast Concrete Market Report market research report

- ✔ Get in-depth analysis of Precast Concrete market size, growth, and forecasts.

- ✔ Understand Precast Concrete's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Precast Concrete

What is the Market Size & CAGR of Precast Concrete market in 2023?

Precast Concrete Industry Analysis

Precast Concrete Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Precast Concrete Market Analysis Report by Region

Europe Precast Concrete Market Report:

Europe's precast concrete market is valued at $50.86 billion in 2023, with expectations of reaching $95.17 billion by 2033. The region is advancing in sustainable construction practices, contributing to the increasing preference for precast solutions.Asia Pacific Precast Concrete Market Report:

In the Asia Pacific region, the precast concrete market was valued at $26.33 billion in 2023 and is estimated to reach $49.26 billion by 2033. The growth is driven by rapid urbanization, increased disposable incomes, and a surge in infrastructure projects, particularly in countries like India and China.North America Precast Concrete Market Report:

North America accounted for a market size of $51.97 billion in 2023 and is anticipated to grow to $97.25 billion by 2033. The region is experiencing a robust construction boom, particularly in the commercial and infrastructure sectors, stimulating the demand for precast concrete.South America Precast Concrete Market Report:

The South American market reflects a value of $14.43 billion in 2023, projected to expand to $27.00 billion by 2033, fueled by government investments in residential and commercial building projects, as well as infrastructure improvements.Middle East & Africa Precast Concrete Market Report:

The Middle East and Africa market is smaller, standing at $6.40 billion in 2023 and set to grow to $11.98 billion by 2033, driven by ongoing development in urban construction and a growing focus on affordable housing.Tell us your focus area and get a customized research report.

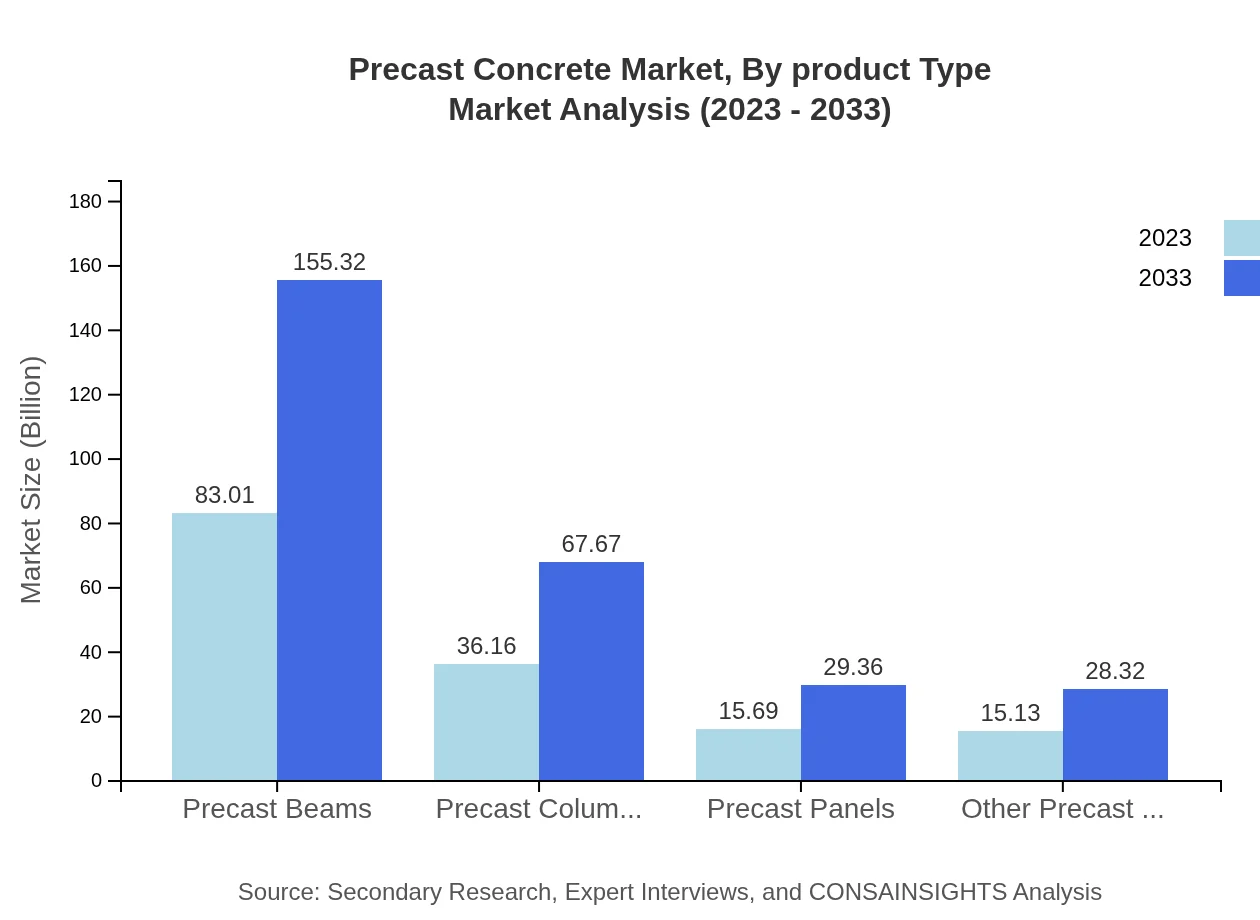

Precast Concrete Market Analysis By Product Type

In 2023, precast beams dominate the market with a size of $83.01 billion and are expected to grow to $155.32 billion by 2033. Precast columns and panels also show significant growth, corresponding to their applications in various constructions. Product segmentation reflects a burgeoning demand for innovative precast solutions in modern construction.

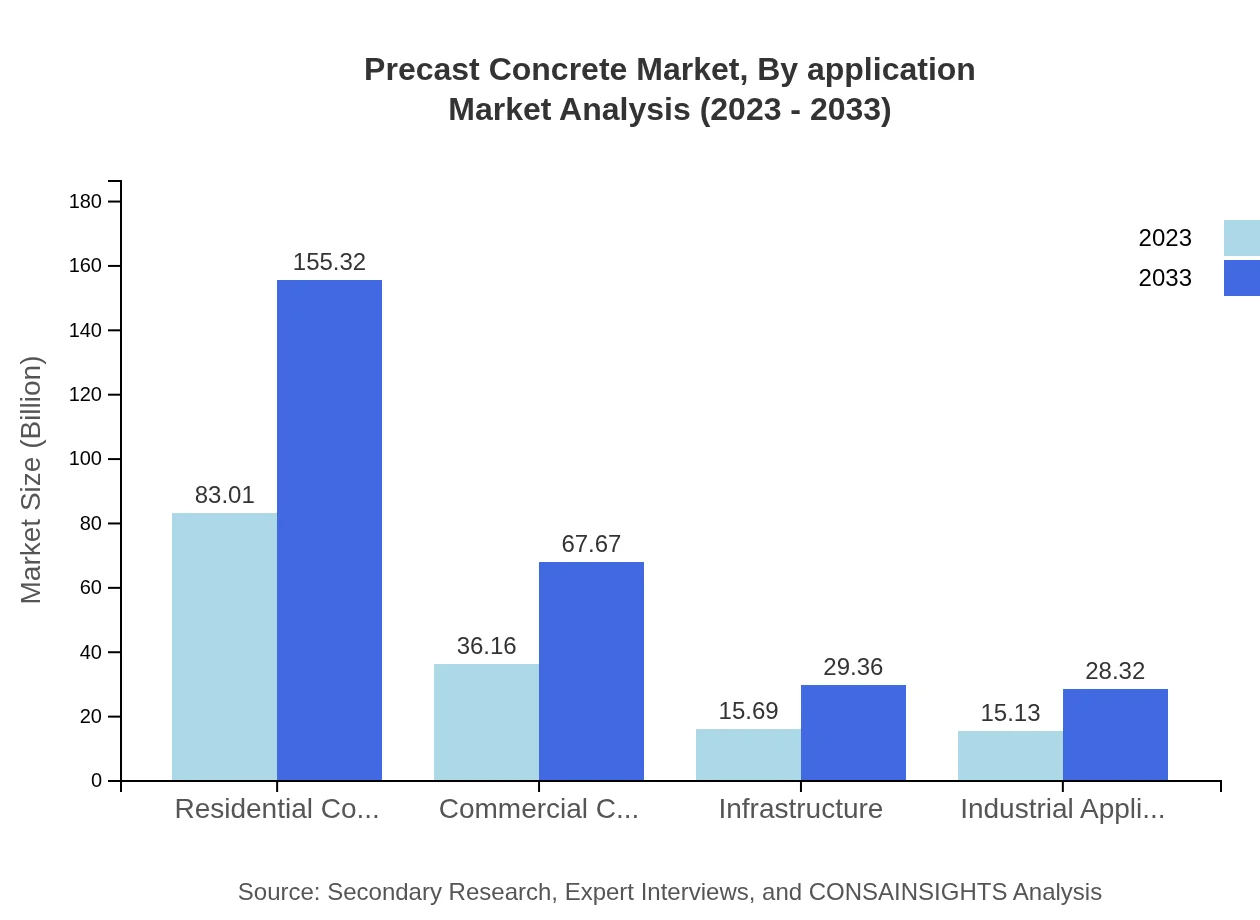

Precast Concrete Market Analysis By Application

The residential construction segment leads with a market size of $83.01 billion in 2023, expected to rise to $155.32 billion by 2033. Commercial and infrastructure applications are also significant, reflecting trends towards efficiency and innovation in construction.

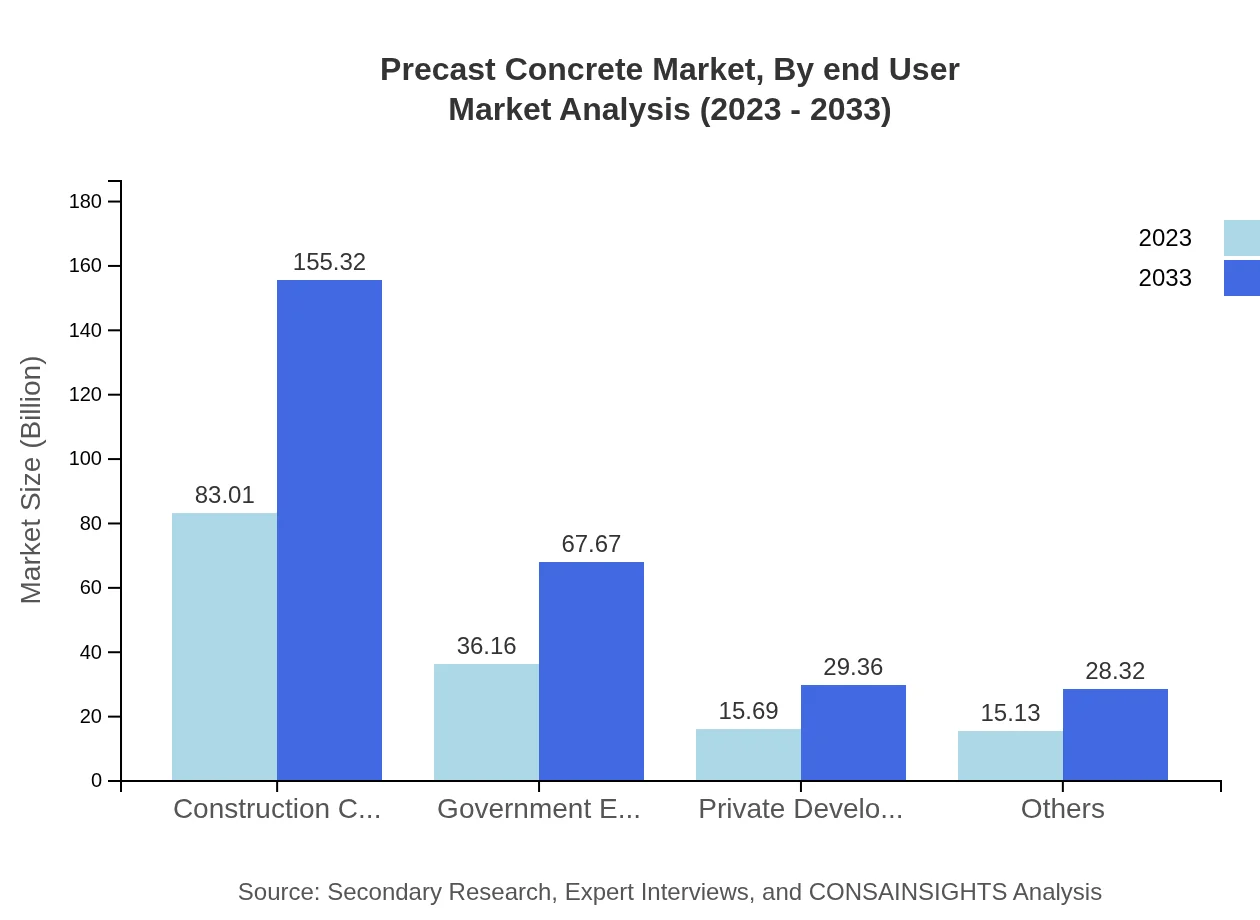

Precast Concrete Market Analysis By End User

Construction companies remain the primary end-users, with a 2023 market size of $83.01 billion, projected to grow to $155.32 billion by 2033. Government entities and private developers follow closely, demonstrating an integral role in the demand for precast concrete.

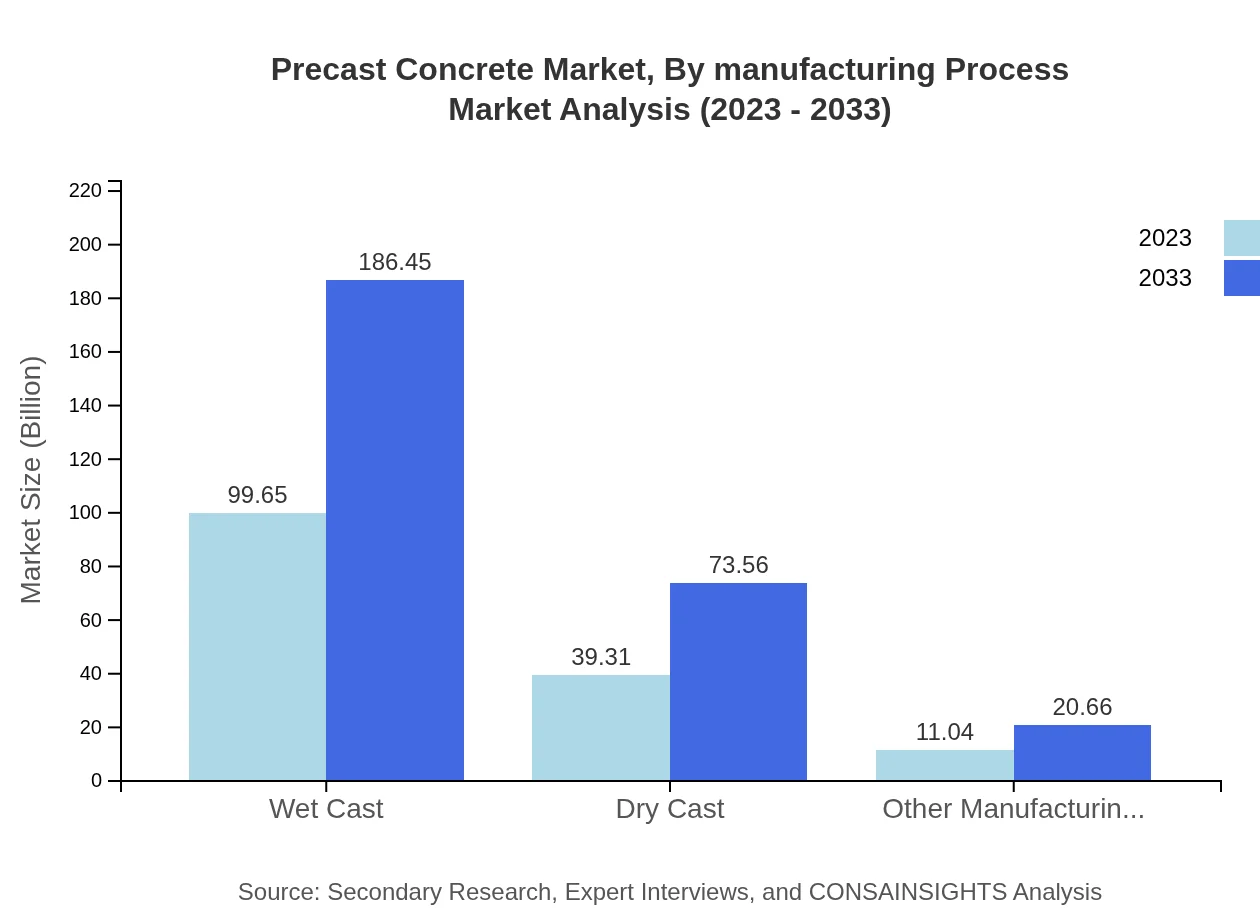

Precast Concrete Market Analysis By Manufacturing Process

Wet cast methods currently dominate the market at $99.65 billion in 2023, set to reach $186.45 billion by 2033. Dry cast and other manufacturing methods are also witnessing increased adoption, driven by technological improvements and market demand for customized solutions.

Precast Concrete Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Precast Concrete Industry

LafargeHolcim:

A leading global building materials company, LafargeHolcim specializes in cement, aggregates, and precast concrete products, focusing on sustainable construction solutions.Boral Limited:

An international supplier of construction materials, Boral Limited provides extensive precast concrete solutions, emphasizing innovation and customer-focused approaches.Cemex:

Cemex is recognized for its high-quality precast concrete products that cater to various construction segments while promoting sustainability in operations.Oldcastle Infrastructure:

Part of CRH plc, Oldcastle Infrastructure serves the North American market with robust precast concrete products, addressing infrastructure and industry demands.We're grateful to work with incredible clients.

FAQs

What is the market size of precast Concrete?

The global precast concrete market is valued at approximately $150 billion as of 2023, with projections indicating a growth rate (CAGR) of 6.3% through 2033, reflecting increasing demand in construction and infrastructure sectors.

What are the key market players or companies in the precast Concrete industry?

Key players in the precast concrete market include companies such as Coreslab Structures, Balfour Beatty PLC, and Elematic, which are noted for their innovation in manufacturing and a strong presence in both residential and commercial segments.

What are the primary factors driving the growth in the precast concrete industry?

The primary drivers of growth in the precast concrete industry include urbanization trends, increased construction of residential and commercial buildings, and advancements in production technology enhancing efficiency and reducing costs.

Which region is the fastest Growing in the precast Concrete market?

Asia Pacific is currently the fastest-growing region in the precast concrete market, with a projected increase from $26.33 billion in 2023 to $49.26 billion by 2033, fueled by rapid urbanization and infrastructure development.

Does ConsaInsights provide customized market report data for the precast Concrete industry?

Yes, ConsaInsights offers tailored market report data for the precast concrete industry, allowing clients to obtain specific insights and analyses relevant to their needs and strategic objectives.

What deliverables can I expect from this precast Concrete market research project?

From the precast concrete market research project, expect comprehensive reports detailing market size, growth trends, regional analyses, competitive landscape, and segment performance to aid strategic decision-making.

What are the market trends of precast concrete?

Current trends in the precast concrete market include increasing adoption of sustainable construction practices, innovations in products like smart precast elements, and a shift towards automated manufacturing processes to enhance production efficiency.