Predictive Maintenance Market Report

Published Date: 22 January 2026 | Report Code: predictive-maintenance

Predictive Maintenance Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Predictive Maintenance market from 2023 to 2033, including insights on market size, growth trends, segmentation, regional developments, technological advancements, and key players.

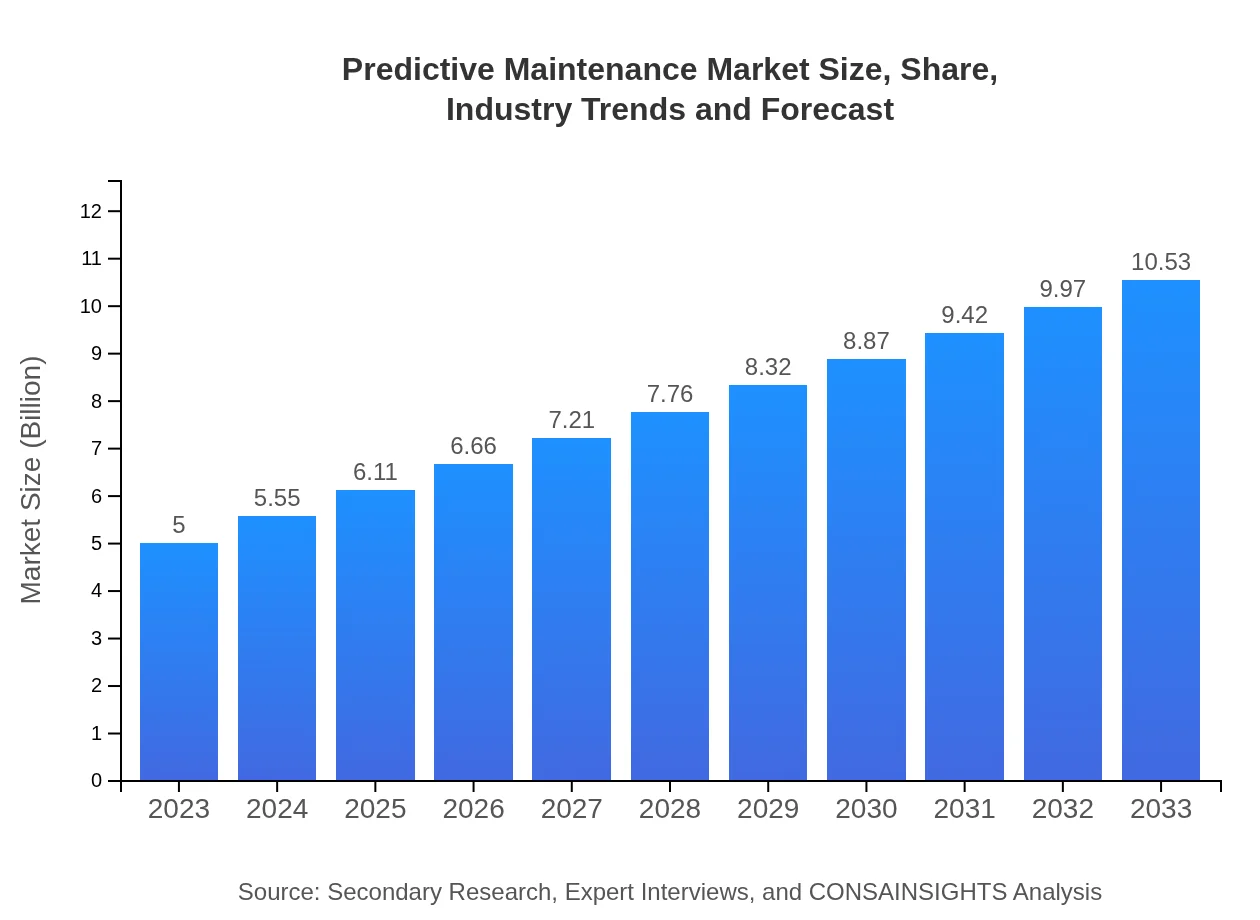

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | IBM, Siemens , GE Digital, PTC |

| Last Modified Date | 22 January 2026 |

Predictive Maintenance Market Overview

Customize Predictive Maintenance Market Report market research report

- ✔ Get in-depth analysis of Predictive Maintenance market size, growth, and forecasts.

- ✔ Understand Predictive Maintenance's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Predictive Maintenance

What is the Market Size & CAGR of Predictive Maintenance market in 2023?

Predictive Maintenance Industry Analysis

Predictive Maintenance Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Predictive Maintenance Market Analysis Report by Region

Europe Predictive Maintenance Market Report:

Europe's predictive maintenance market will grow from $1.27 billion in 2023 to $2.67 billion by 2033. Regulatory pressures for improved asset management and sustainability practices are major growth drivers.Asia Pacific Predictive Maintenance Market Report:

The Asia Pacific is emerging as a significant market for predictive maintenance, expected to grow from $0.96 billion in 2023 to $2.03 billion by 2033. Rapid industrialization, coupled with increased investments in smart technologies, drives this growth.North America Predictive Maintenance Market Report:

North America is at the forefront of predictive maintenance, with a market size increasing from $1.71 billion in 2023 to $3.61 billion in 2033. The region's strong technological advancements and early adoption of IoT solutions contribute significantly.South America Predictive Maintenance Market Report:

In South America, the Predictive Maintenance market is projected to grow from $0.45 billion to $0.94 billion over a decade. The need for modernization in infrastructure and industrial systems is a key growth factor.Middle East & Africa Predictive Maintenance Market Report:

In the Middle East and Africa, the Predictive Maintenance market is expected to rise from $0.61 billion to $1.29 billion. Investment in oil & gas, along with increased focus on automating traditional sectors, catalyzes growth in this region.Tell us your focus area and get a customized research report.

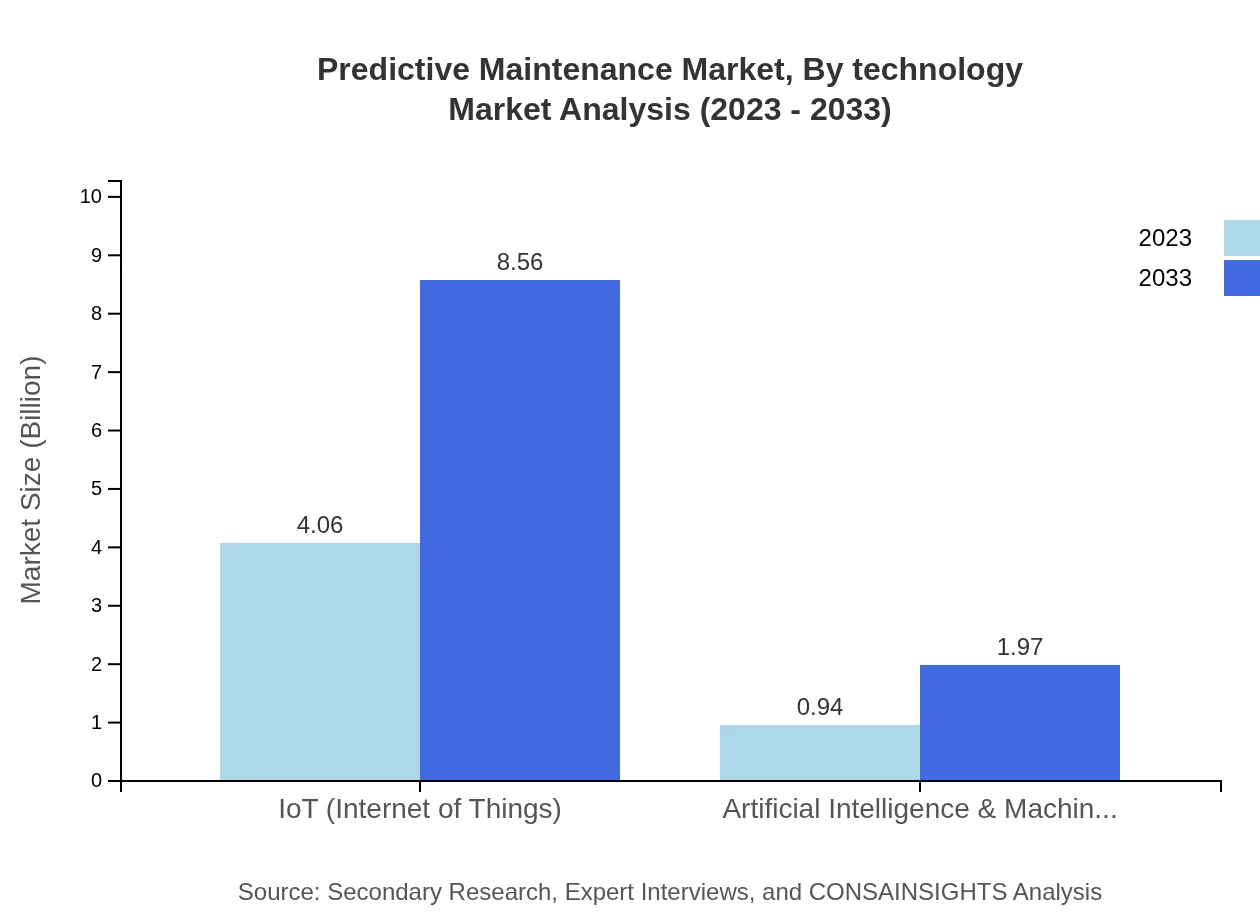

Predictive Maintenance Market Analysis By Technology

IoT holds a significant market share in predictive maintenance. In 2023, technologies like IoT account for $4.06 billion with an expected increase to $8.56 billion in 2033, noticing a share of 81.28%. AI & Machine Learning follow closely, with a market size of $0.94 billion, growing to $1.97 billion by 2033.

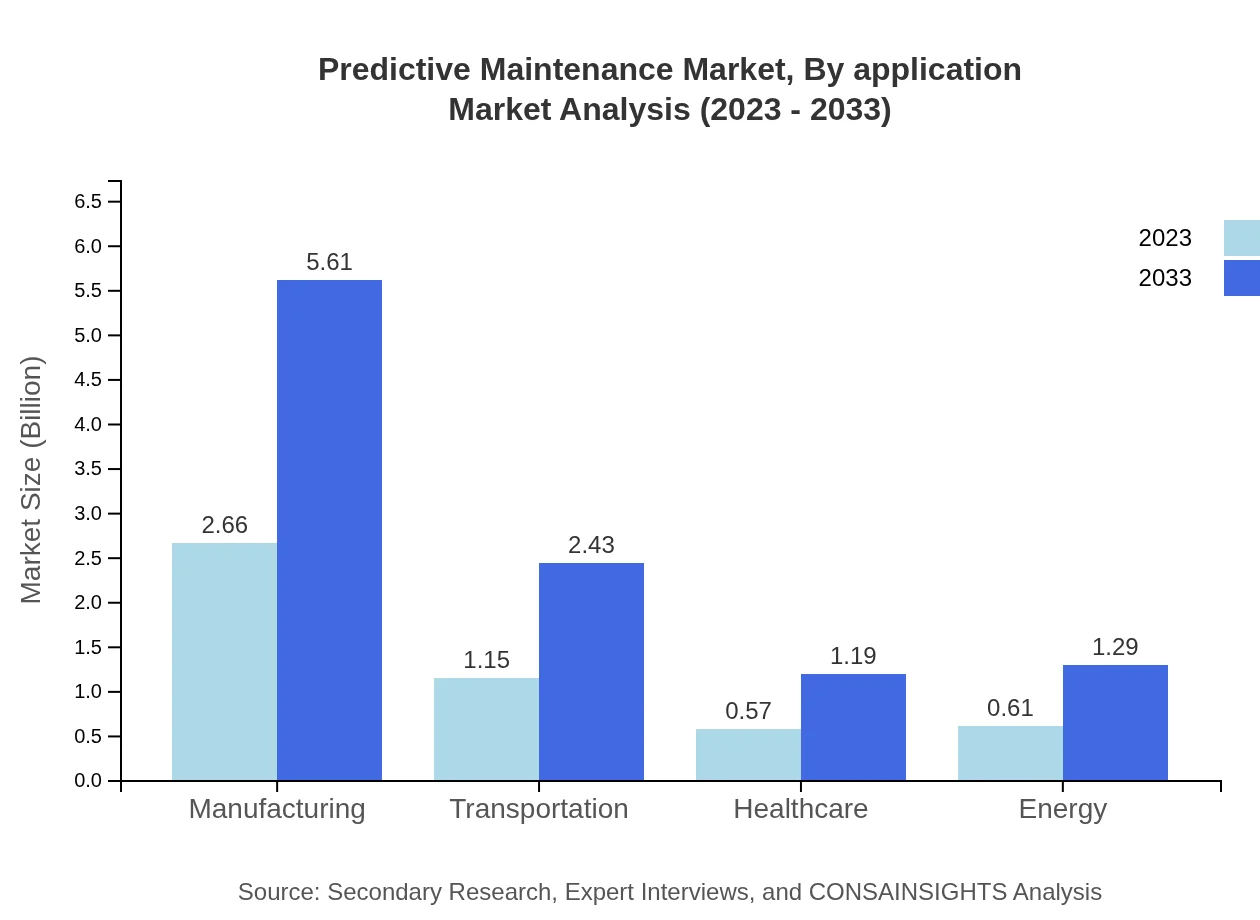

Predictive Maintenance Market Analysis By Application

Manufacturing remains the leading application for predictive maintenance, valued at $2.66 billion in 2023 and forecasted to reach $5.61 billion by 2033, retaining a market share of 53.27% through the period. Automotive applications also show growth potential, expanding from $1.15 billion in 2023 to $2.43 billion by 2033.

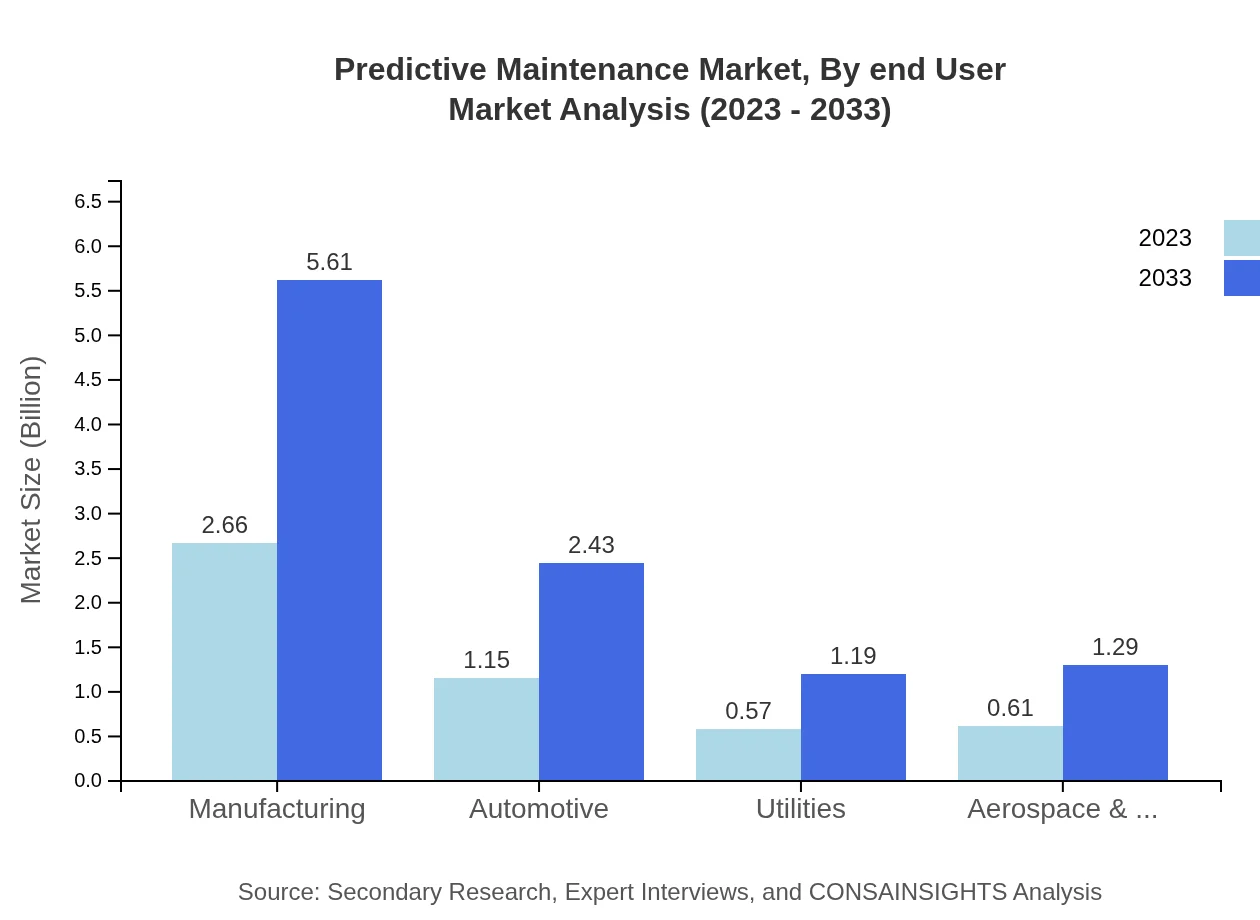

Predictive Maintenance Market Analysis By End User

The manufacturing and automotive sectors dominate the predictive maintenance landscape, contributing significantly to market size. The healthcare and energy sectors are also showing potential growth with a focused adoption of predictive maintenance technologies.

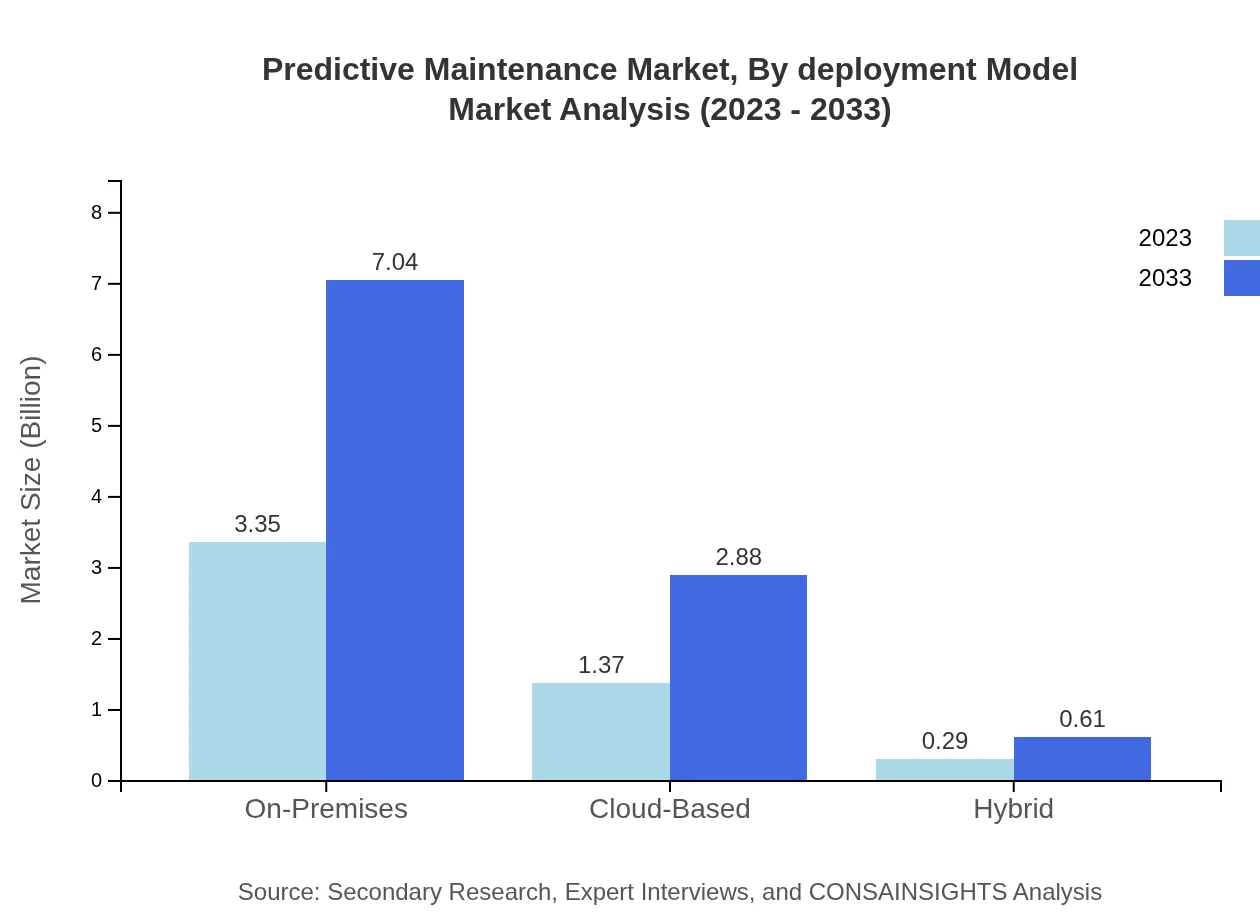

Predictive Maintenance Market Analysis By Deployment Model

On-premises solutions currently hold the largest market share at $3.35 billion in 2023 and are expected to expand to $7.04 billion by 2033, maintaining a share of 66.9%. Cloud-based deployments are seeing increased uptake, anticipated to grow from $1.37 billion to $2.88 billion.

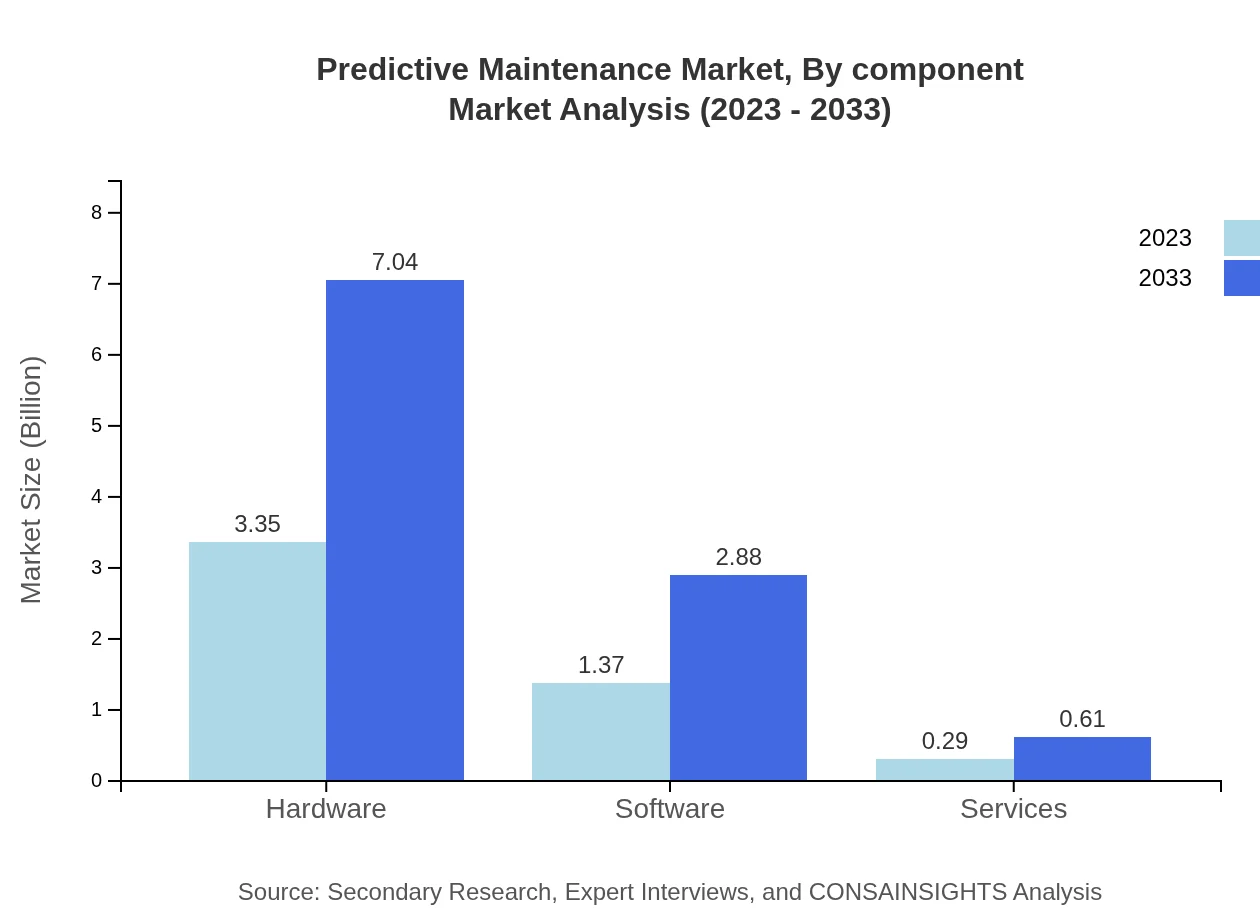

Predictive Maintenance Market Analysis By Component

Hardware remains a critical component of the predictive maintenance ecosystem, projected to increase from $3.35 billion in 2023 to $7.04 billion in 2033, constituting 66.9% of the total market, while software and services also note substantial growth.

Predictive Maintenance Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Predictive Maintenance Industry

IBM:

IBM offers predictive maintenance solutions leveraging Watson IoT platform, providing advanced analytics and machine learning capabilities.Siemens :

Siemens uses its Mindsphere platform to deliver predictive maintenance services across manufacturing and infrastructure.GE Digital:

GE Digital’s Predix platform allows industrial organizations to maximize operational efficiency through predictive analytics.PTC:

PTC provides IoT-enabled smart factory solutions that drive predictive maintenance initiatives in various sectors.We're grateful to work with incredible clients.

FAQs

What is the market size of predictive Maintenance?

The global predictive maintenance market is currently valued at approximately $5 billion and is expected to grow at a CAGR of 7.5%. This growth indicates substantial investment in maintenance technologies across various sectors by 2033.

What are the key market players or companies in this predictive Maintenance industry?

Key players in the predictive maintenance industry include major technology firms and specialized service providers focused on equipment efficiency and operational excellence. They leverage advanced analytics, IoT, and AI to optimize maintenance procedures.

What are the primary factors driving the growth in the predictive Maintenance industry?

Growth in the predictive maintenance industry is driven by the increasing need for operational efficiency, reduction of downtime, and advancement in technologies such as AI, IoT, and machine learning. Companies seek to minimize costs and maximize equipment reliability.

Which region is the fastest Growing in the predictive Maintenance?

North America is the fastest-growing region in the predictive maintenance market, projected to increase from $1.71 billion in 2023 to $3.61 billion by 2033. Other growing regions include Europe and Asia Pacific with significant market expansion.

Does ConsaInsights provide customized market report data for the predictive Maintenance industry?

Yes, ConsaInsights offers customized market report data tailored to the specific needs of businesses within the predictive maintenance industry, enabling stakeholders to access comprehensive insights that drive strategic decisions.

What deliverables can I expect from this predictive Maintenance market research project?

Deliverables from the predictive maintenance market research project include detailed market analysis, regional forecasts, segment insights, and strategic recommendations tailored to stakeholders in the industry for informed decision-making.

What are the market trends of predictive Maintenance?

Current trends in the predictive maintenance market include the integration of AI and machine learning technologies, an increasing focus on IoT applications, and a shift towards cloud-based solutions for enhanced service delivery and operational agility.