Pressure Control Equipment Market Report

Published Date: 22 January 2026 | Report Code: pressure-control-equipment

Pressure Control Equipment Market Size, Share, Industry Trends and Forecast to 2033

This detailed market report explores the Pressure Control Equipment industry, providing insights into market size, growth forecasts from 2023 to 2033, and comprehensive analyses of trends, segmentation, and regional dynamics.

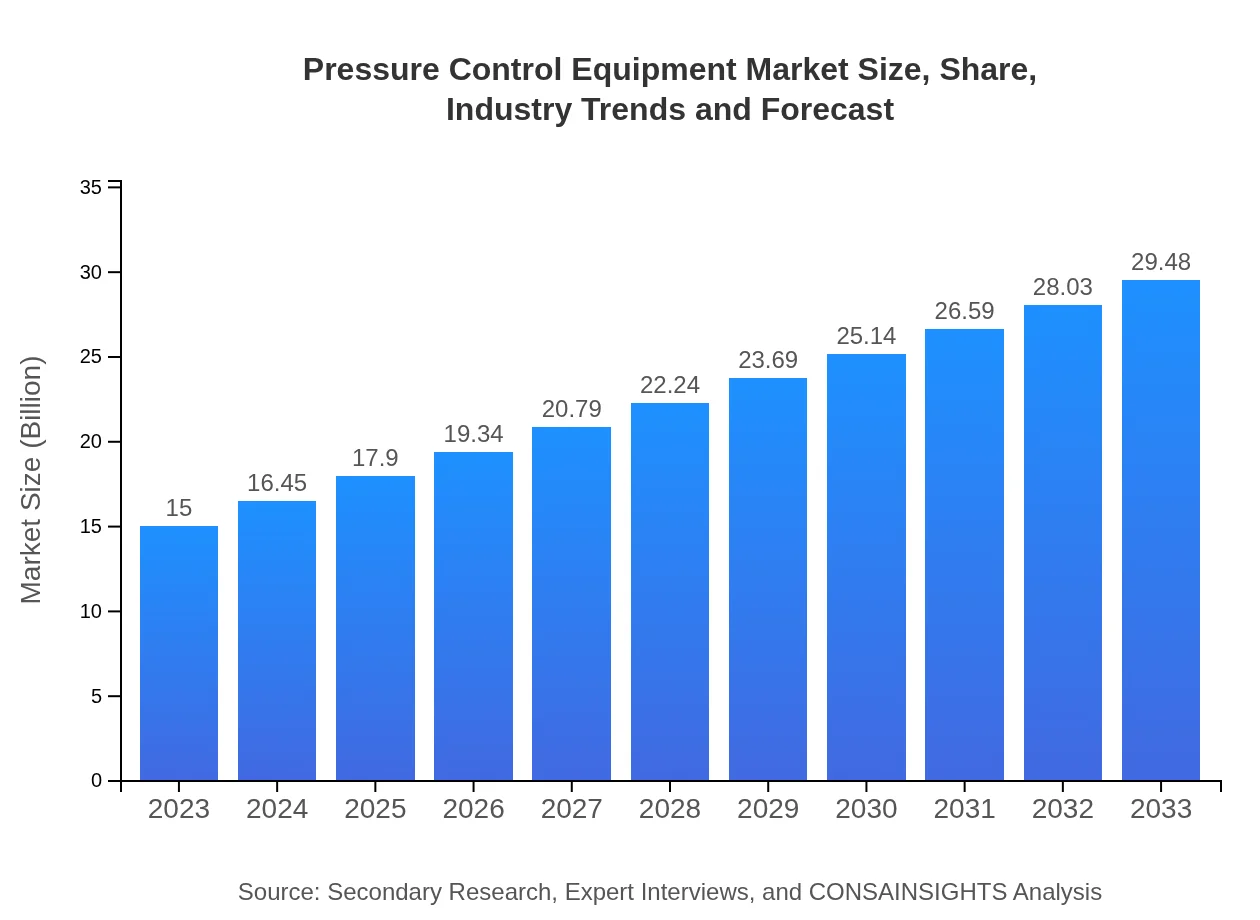

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $15.00 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $29.48 Billion |

| Top Companies | Emerson Electric Co., Schneider Electric, Honeywell International Inc., Flowserve Corporation |

| Last Modified Date | 22 January 2026 |

Pressure Control Equipment Market Overview

Customize Pressure Control Equipment Market Report market research report

- ✔ Get in-depth analysis of Pressure Control Equipment market size, growth, and forecasts.

- ✔ Understand Pressure Control Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Pressure Control Equipment

What is the Market Size & CAGR of Pressure Control Equipment market in 2023?

Pressure Control Equipment Industry Analysis

Pressure Control Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Pressure Control Equipment Market Analysis Report by Region

Europe Pressure Control Equipment Market Report:

Europe's Pressure Control Equipment market is characterized by stringent regulations and a growing emphasis on safety and sustainability. The market is expected to expand from $3.79 billion in 2023 to approximately $7.44 billion by 2033, driven by advancements in technology and new manufacturing standards.Asia Pacific Pressure Control Equipment Market Report:

The Asia Pacific region is expected to witness substantial growth in the Pressure Control Equipment market, propelled by increasing industrialization, expanding energy projects, and significant investments in infrastructure, estimated at $2.95 billion in 2023 and projected to reach approximately $5.80 billion by 2033.North America Pressure Control Equipment Market Report:

North America remains the largest market for Pressure Control Equipment, driven by the extensive oil and gas sector and technological innovations. The market size is projected to grow from $5.51 billion in 2023 to around $10.83 billion by 2033, reflecting a robust demand for advanced pressure management solutions.South America Pressure Control Equipment Market Report:

South America presents a growing market for Pressure Control Equipment, particularly in oil and gas exploration activities. The market is anticipated to grow from approximately $1.47 billion in 2023 to about $2.89 billion by 2033 as investments in renewable energy sources increase.Middle East & Africa Pressure Control Equipment Market Report:

The Middle East and Africa region is also a significant player in the Pressure Control Equipment market, estimated to reach a value of $1.28 billion in 2023 and projected to grow to $2.52 billion by 2033, primarily due to ongoing oil and gas projects.Tell us your focus area and get a customized research report.

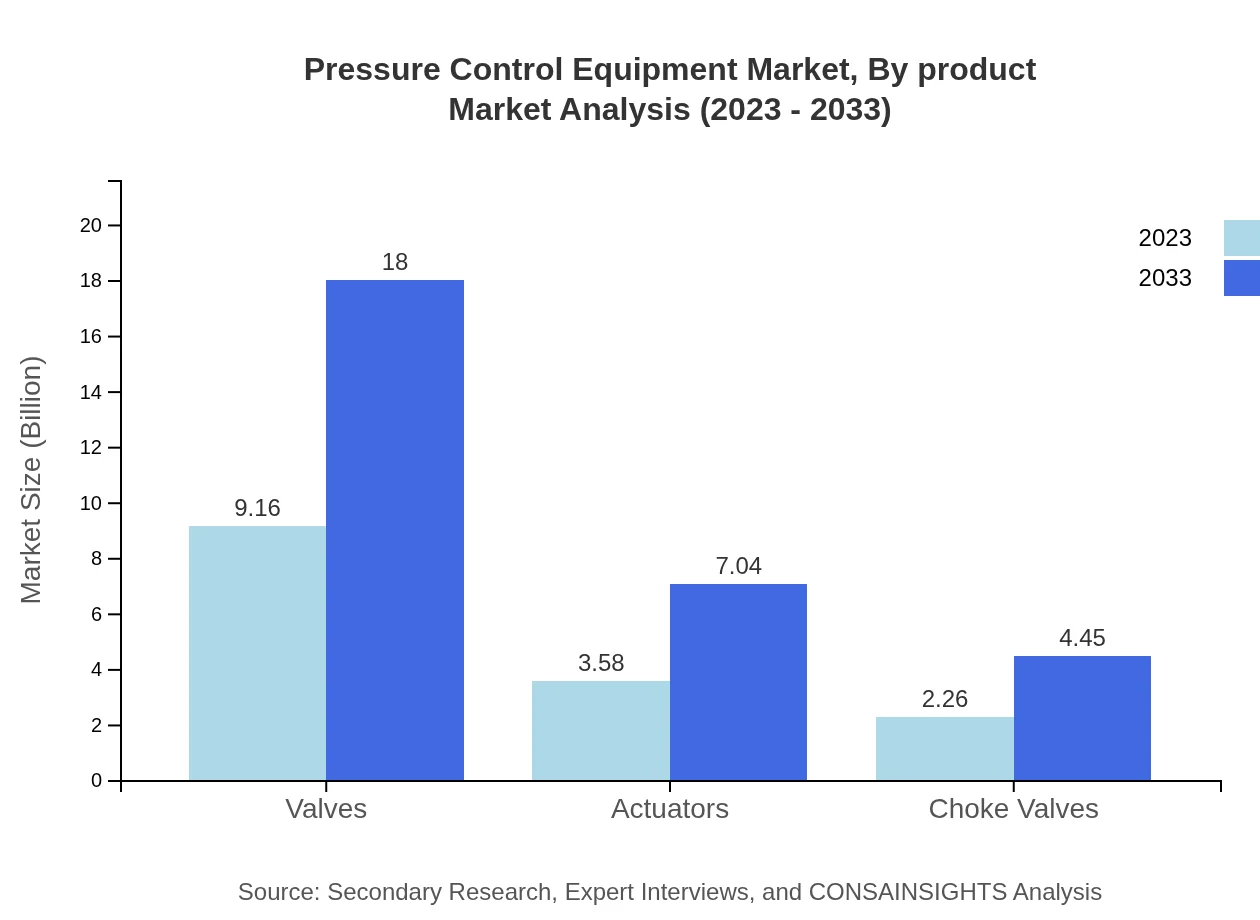

Pressure Control Equipment Market Analysis By Product

The Pressure Control Equipment market is predominantly led by valves, which account for a substantial share of the market size, valued at $9.16 billion in 2023 and expected to reach $18.00 billion by 2033. Actuators, another critical component, are projected to grow from $3.58 billion to $7.04 billion over the same period. Choke valves, while smaller in comparison, are also a vital segment, expanding from $2.26 billion to $4.45 billion.

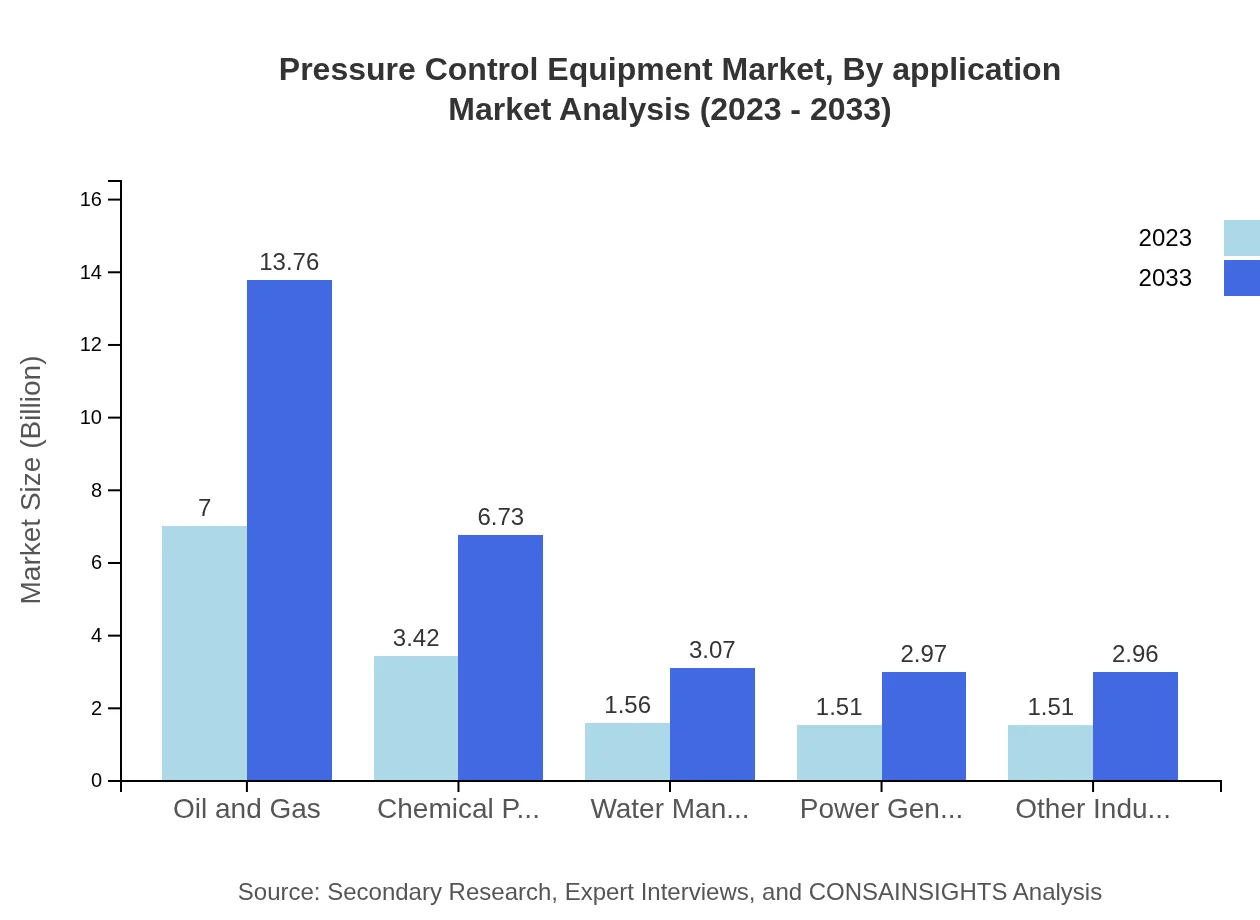

Pressure Control Equipment Market Analysis By Application

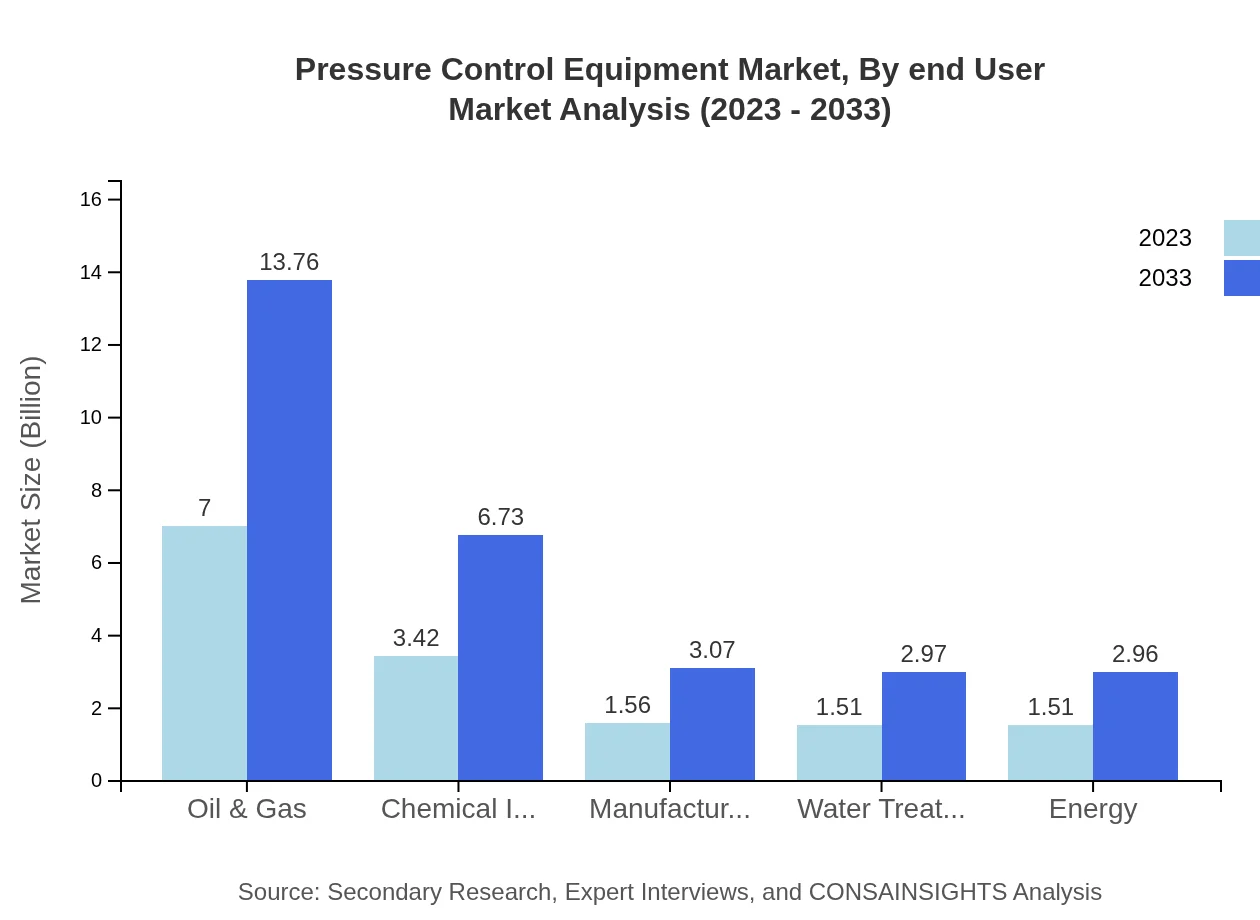

The application segment of the Pressure Control Equipment market is largely dominated by the oil and gas sector, accounting for $7.00 billion in 2023 and a projected $13.76 billion by 2033. Other essential applications include the chemical industry, valued at $3.42 billion, and water treatment applications, which stand at $1.51 billion, both showing significant growth potential in the coming years.

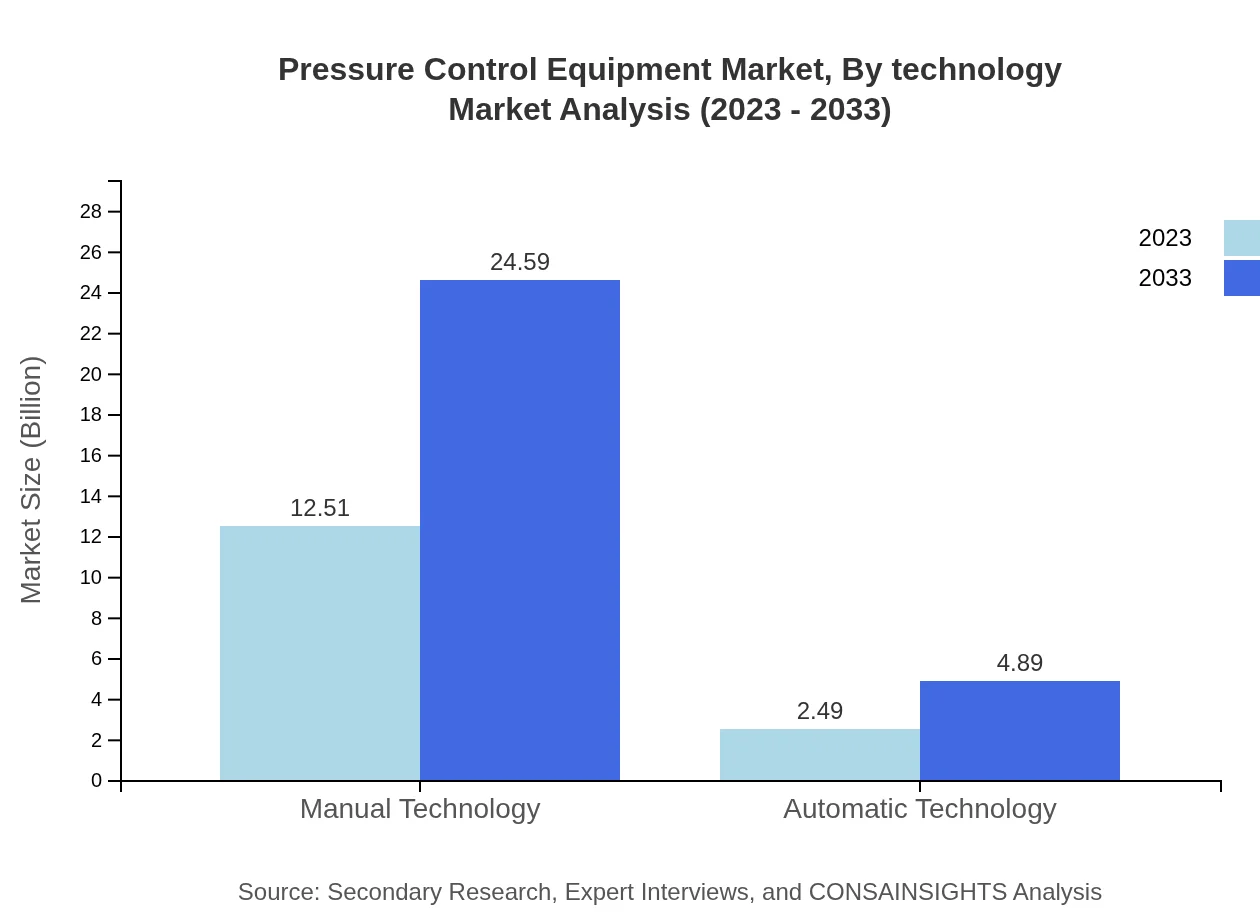

Pressure Control Equipment Market Analysis By Technology

In terms of technology, the market has a strong inclination toward manual control systems, which are projected to expand from $12.51 billion to $24.59 billion. However, automatic technologies are gaining traction, with expected growth from $2.49 billion to $4.89 billion, as industries seek to integrate more automation to enhance operational efficiency.

Pressure Control Equipment Market Analysis By End User

The end-user segment reveals that industries like oil and gas dominate, comprising 46.66% of the market share. The chemical processing and water management sectors also significantly contribute at 22.83% and 10.41%, respectively, showcasing the critical role of pressure control in various industrial applications.

Pressure Control Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Pressure Control Equipment Industry

Emerson Electric Co.:

Emerson is a leader in automation solutions, providing a wide array of pressure control devices that enhance industrial efficiency and safety.Schneider Electric:

Specializing in digital transformation and energy management, Schneider Electric offers innovative pressure control solutions to various industries.Honeywell International Inc.:

Honeywell manufactures advanced pressure control equipment essential for safety and efficiency in industrial processes, including oil and gas production.Flowserve Corporation:

Flowserve is renowned for its precision-engineered pumps and valves that are vital in pressure control across critical applications.We're grateful to work with incredible clients.

FAQs

What is the market size of pressure Control Equipment?

The pressure control equipment market is projected to reach approximately 15 billion by 2033, growing at a CAGR of 6.8% from its current size. This growth is driven by increased demand across various industries, highlighting its importance in ensuring operational safety.

What are the key market players or companies in this pressure Control Equipment industry?

Key players in the pressure control equipment market include established companies and emerging players innovating in technology and services. These companies are pivotal in enhancing market dynamics by offering advanced solutions tailored to diverse customer needs.

What are the primary factors driving the growth in the pressure Control Equipment industry?

Key factors driving the growth include the expanding oil and gas sector, increasing safety regulations, and technological advancements in pressure control systems. These elements contribute to higher demand and the need for reliable equipment across industries.

Which region is the fastest Growing in the pressure Control Equipment?

North America is the fastest-growing region, expected to reach 10.83 billion by 2033, driven by technological advancements and significant investments in infrastructure. Europe and Asia Pacific also show strong growth, with emerging markets bolstering demand.

Does ConsaInsights provide customized market report data for the pressure Control Equipment industry?

Yes, ConsaInsights offers customized reports tailored to individual client needs in the pressure control equipment market, providing comprehensive insights, analysis, and data that cater to specific requirements for strategic decision-making.

What deliverables can I expect from this pressure Control Equipment market research project?

Clients can expect detailed market analysis, segmentation data, and regional insights, along with growth forecasts and competitive landscape assessments, enabling informed business strategies and market entry decisions.

What are the market trends of pressure Control Equipment?

Current trends include the shift towards automation, increased focus on safety standards, and the integration of advanced monitoring technologies, which enhance operational efficiency and system reliability in pressure control practices.