Print Equipment Market Report

Published Date: 31 January 2026 | Report Code: print-equipment

Print Equipment Market Size, Share, Industry Trends and Forecast to 2033

This report covers the comprehensive analysis of the Print Equipment market from 2023 to 2033, offering insights on market trends, sizes, growth rates, and regional distributions. It aims to provide stakeholders with detailed data and forecasts to support informed decision-making.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

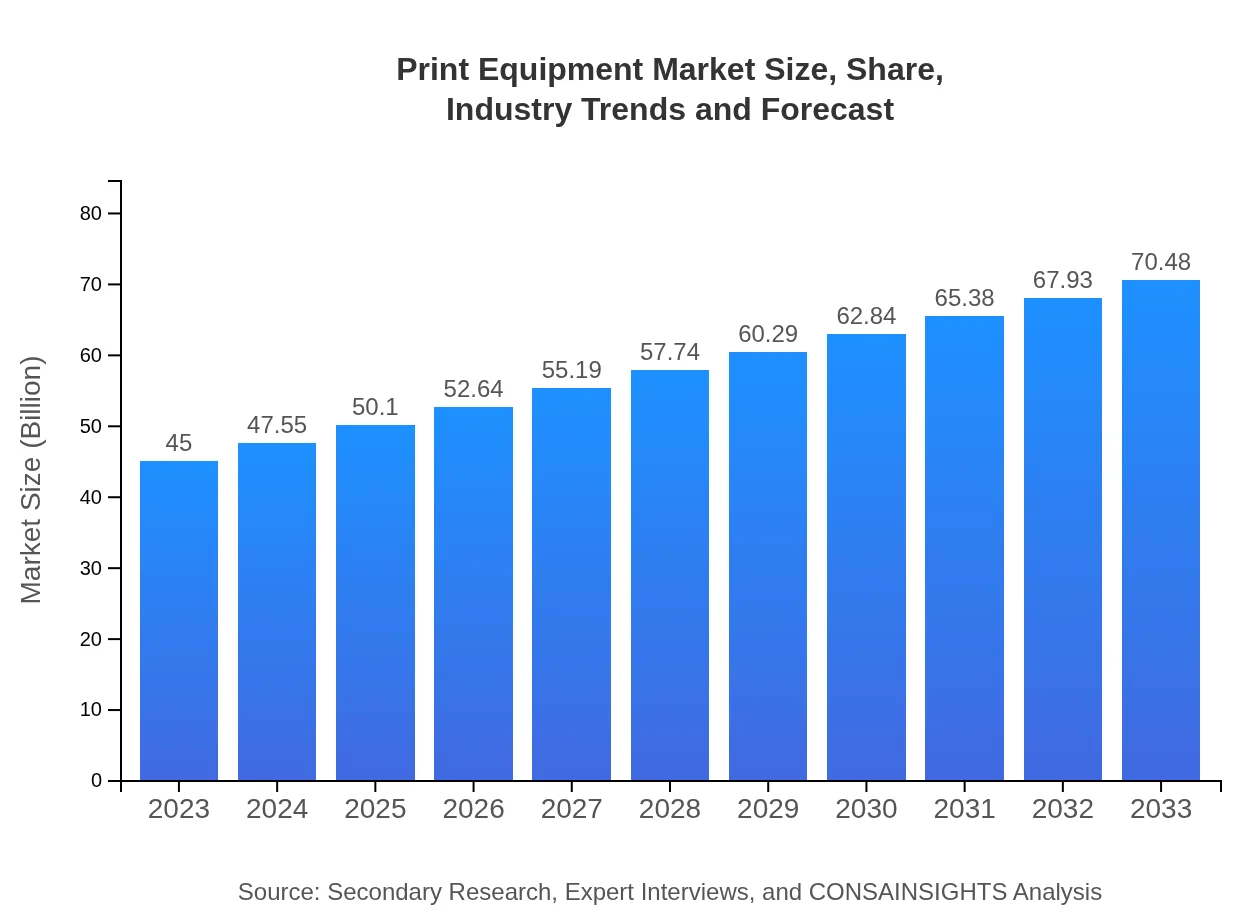

| 2023 Market Size | $45.00 Billion |

| CAGR (2023-2033) | 4.5% |

| 2033 Market Size | $70.48 Billion |

| Top Companies | HP Inc., Canon Inc., Xerox Corporation, Ricoh Company, Ltd., Epson America, Inc. |

| Last Modified Date | 31 January 2026 |

Print Equipment Market Overview

Customize Print Equipment Market Report market research report

- ✔ Get in-depth analysis of Print Equipment market size, growth, and forecasts.

- ✔ Understand Print Equipment's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Print Equipment

What is the Market Size & CAGR of Print Equipment market in 2023?

Print Equipment Industry Analysis

Print Equipment Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Print Equipment Market Analysis Report by Region

Europe Print Equipment Market Report:

In Europe, the print equipment market is forecasted to grow from $11.89 billion in 2023 to $18.63 billion in 2033. The region is characterized by stringent regulations surrounding environmental sustainability, which promotes the adoption of eco-friendly printing technologies. Additionally, notable trends in digitalization among traditional print service providers are reshaping market dynamics.Asia Pacific Print Equipment Market Report:

In the Asia Pacific region, the print equipment market was valued at approximately $8.64 billion in 2023 and is projected to reach about $13.54 billion by 2033. The rapid industrialization and growing e-commerce sector are key drivers of this growth. Countries like China and India are leading the charge in adopting new print technologies to enhance production capabilities and overall efficiency.North America Print Equipment Market Report:

With a market size of approximately $16.71 billion in 2023, North America is expected to grow to $26.18 billion by 2033. The market here is driven by advanced technological integration and a strong emphasis on sustainability. Major retail and commercial sectors fuel the demand for print equipment, especially in packaging and advertising.South America Print Equipment Market Report:

The South American print equipment market stands at about $3.37 billion in 2023, with expectations to rise to $5.28 billion by 2033. Challenges in the region include economic fluctuations and high operational costs, which could impede faster growth. However, rising consumer demand for printed materials offers opportunities for market expansion.Middle East & Africa Print Equipment Market Report:

In the Middle East and Africa, the print equipment market is estimated at $4.38 billion in 2023, anticipating growth to $6.86 billion by 2033. Factors such as rapid urbanization and increased investments in both industrial and commercial sectors are bolstering the demand for advanced print technologies.Tell us your focus area and get a customized research report.

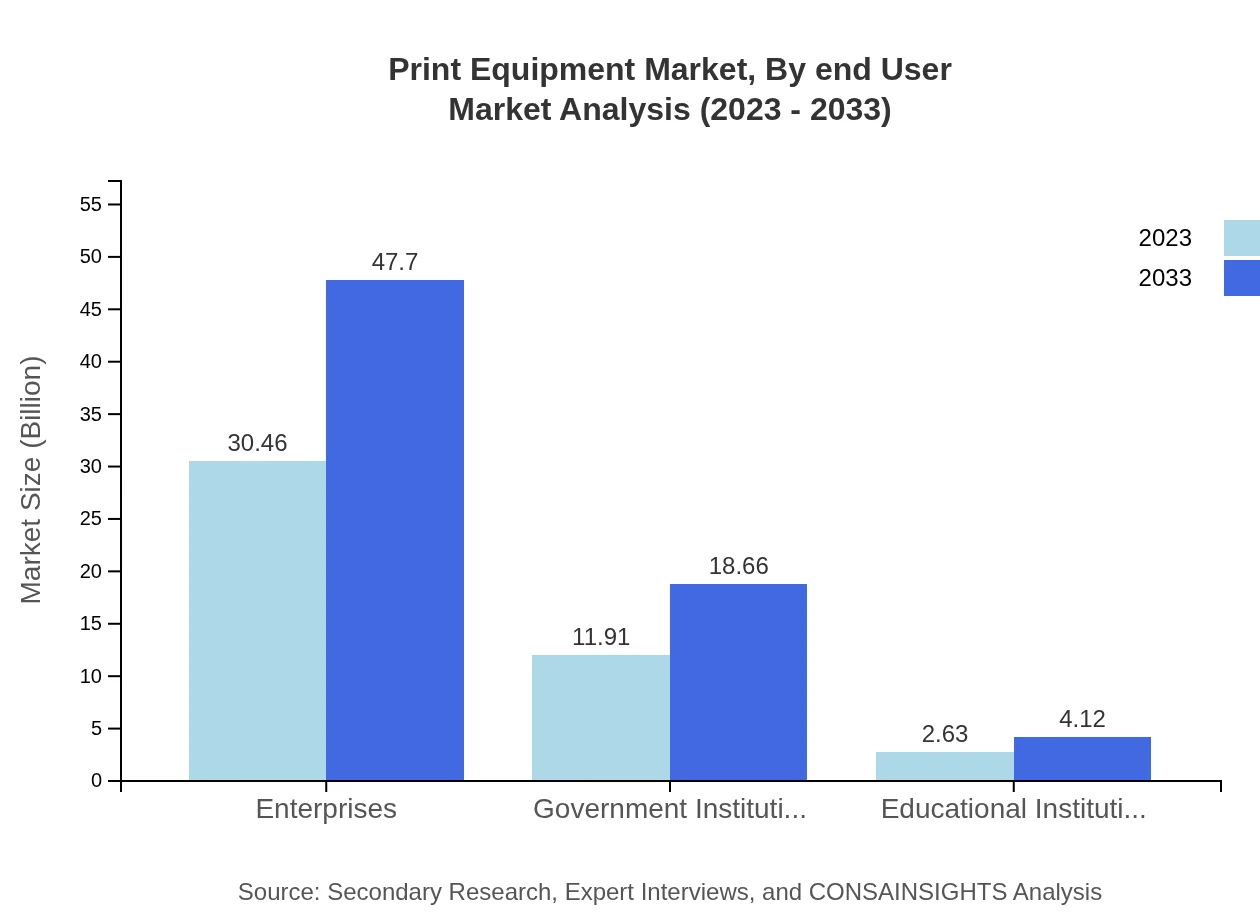

Print Equipment Market Analysis By End User

The end-user segmentation highlights enterprises as the leading category, with expected market sizes of $30.46 billion in 2023 and $47.70 billion in 2033. Government institutions account for significant shares as well, projected to grow from $11.91 billion to $18.66 billion in the same timeframe. Educational institutions represent the smallest segment but are also anticipated to see steady growth.

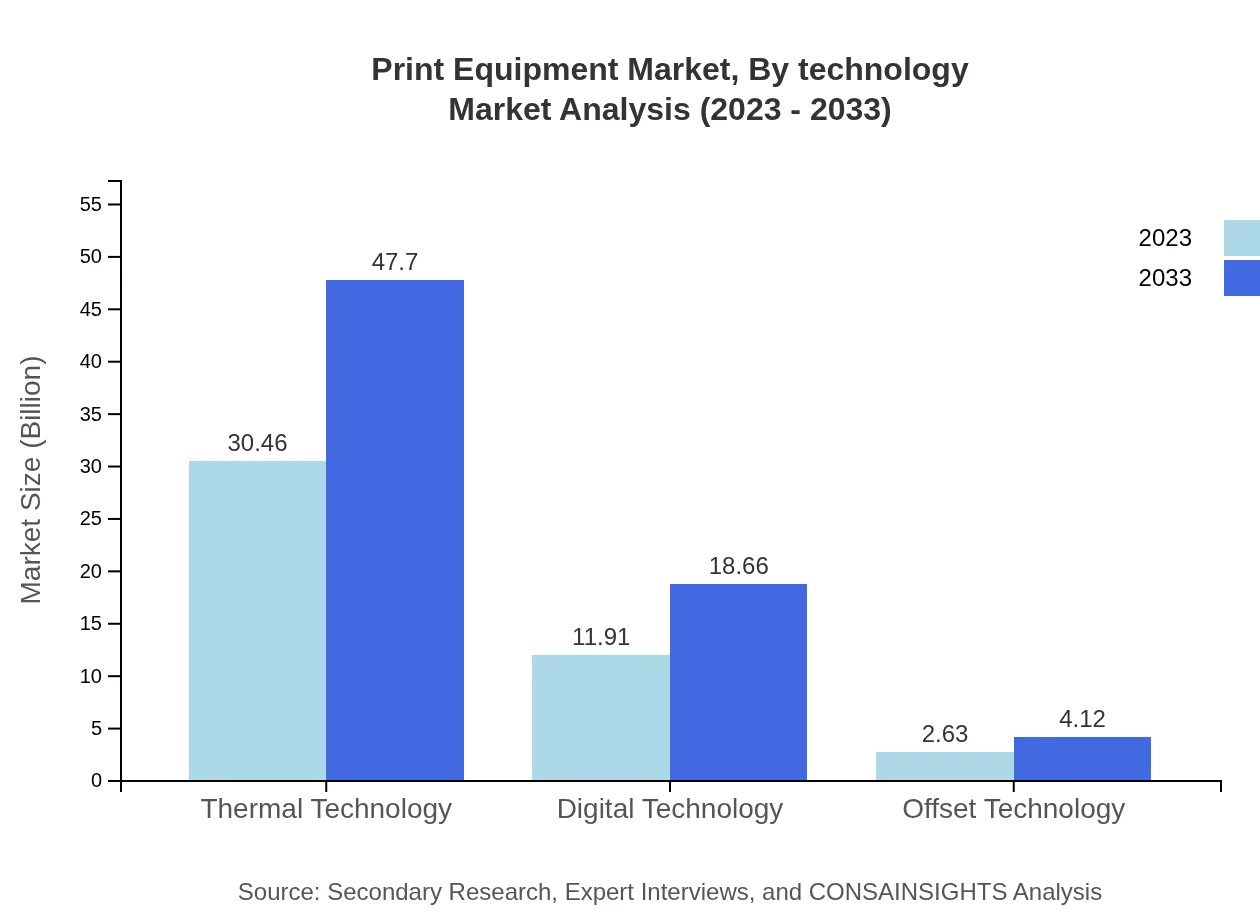

Print Equipment Market Analysis By Technology

Thermal technology leads the market segment with sizes of $30.46 billion in 2023 and $47.70 billion by 2033. Digital technology follows with a market size increasing from $11.91 billion to $18.66 billion in the same period. Offset technology, while smaller, is projected to see growth from $2.63 billion to $4.12 billion, indicating diverse market dynamics.

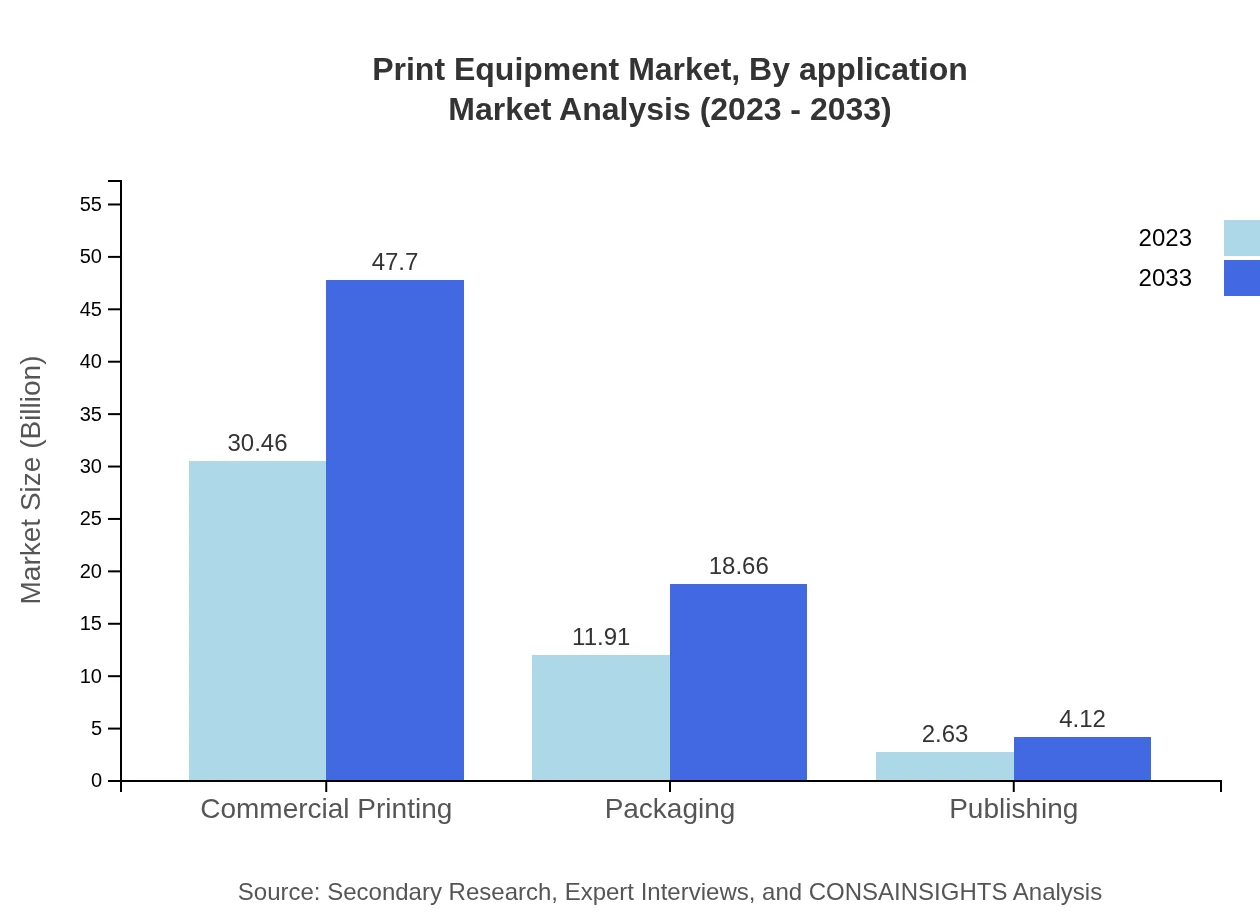

Print Equipment Market Analysis By Application

Commercial printing, packaging, and publishing form the main applications, with significant market sizes of $30.46 billion, $11.91 billion, and $2.63 billion respectively in 2023. Each segment is projected to demonstrate robust growth, with commercial printing leading the charge.

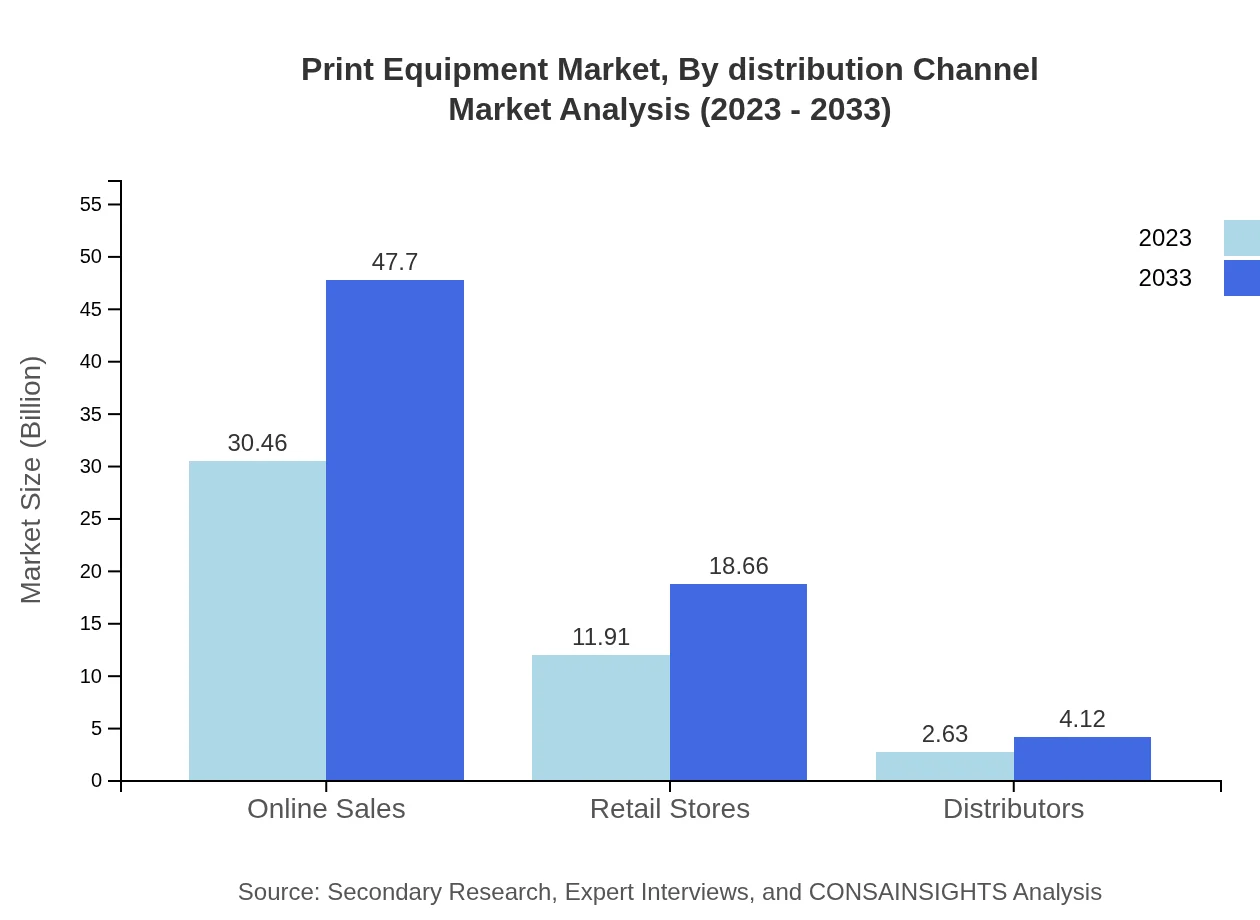

Print Equipment Market Analysis By Distribution Channel

Online sales vastly dominate the distribution channels with a size of $30.46 billion in 2023 and an expected growth to $47.70 billion by 2033. Retail stores and distributors follow but with comparatively smaller market sizes, indicative of shifting consumer habits toward online purchasing.

Print Equipment Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Print Equipment Industry

HP Inc.:

HP Inc. is a global leader in digital printing technologies, offering innovative printing solutions for both consumers and enterprises, focusing on sustainable technologies.Canon Inc.:

Canon is a prominent manufacturer of imaging and printing solutions, known for its high-quality printers and technologies that cater to commercial and creative industries.Xerox Corporation:

Xerox is renowned for its multipart print technologies, delivering software and services that focus on increasing work efficiency and reducing environmental impact.Ricoh Company, Ltd.:

Ricoh specializes in office automation and industrial printing equipment, promoting digital transformation for companies seeking innovative print solutions.Epson America, Inc.:

Epson produces a variety of printers renowned for their eco-friendly technologies and high-quality outputs, catering to both home and business markets.We're grateful to work with incredible clients.

FAQs

What is the market size of print Equipment?

The global print equipment market is valued at approximately $45 billion in 2023, with a projected growth rate of CAGR 4.5% leading to significant expansion in the coming years. By 2033, the market is expected to grow and adapt to new technologies.

What are the key market players or companies in this print Equipment industry?

Major players in the print equipment industry include companies globally recognized for their technology and innovation. These companies dominate segments such as inkjet, laser, and 3D printing, maintaining competitiveness through continuous advancements and customer engagement.

What are the primary factors driving the growth in the print Equipment industry?

Key growth factors include technological advancements, increasing demand for custom printing solutions, and the rise of digital marketing. Additionally, expansion in sectors like packaging and commercial printing fuels the market expansion globally.

Which region is the fastest Growing in the print Equipment?

North America is currently the fastest-growing region in the print equipment market, projected to increase from $16.71 billion in 2023 to $26.18 billion by 2033. Europe follows, showcasing strong growth potential as well, reaching $18.63 billion in the same period.

Does ConsaInsights provide customized market report data for the print Equipment industry?

Yes, ConsaInsights offers customized reports tailored to specific needs, including in-depth market analysis, trends, and forecasts across different segments and regions of the print equipment industry, ensuring valuable insights for stakeholders.

What deliverables can I expect from this print Equipment market research project?

The deliverables for the print equipment market research project usually include comprehensive reports, market forecasts, detailed segmentation analysis, competitive landscape assessments, and actionable insights tailored to the client's strategic needs.

What are the market trends of print equipment?

Current trends in the print equipment market include a shift towards digital printing technologies, growth in sustainable printing solutions, and increasing consumer demand for personalization. The integration of IoT and AI in printing processes is also gaining momentum.