Production Monitoring Market Report

Published Date: 22 January 2026 | Report Code: production-monitoring

Production Monitoring Market Size, Share, Industry Trends and Forecast to 2033

This report explores the Production Monitoring market, offering insights on market size, trends, and growth forecasts from 2023 to 2033, as well as detailed breakdowns by region, technology, and industry segments.

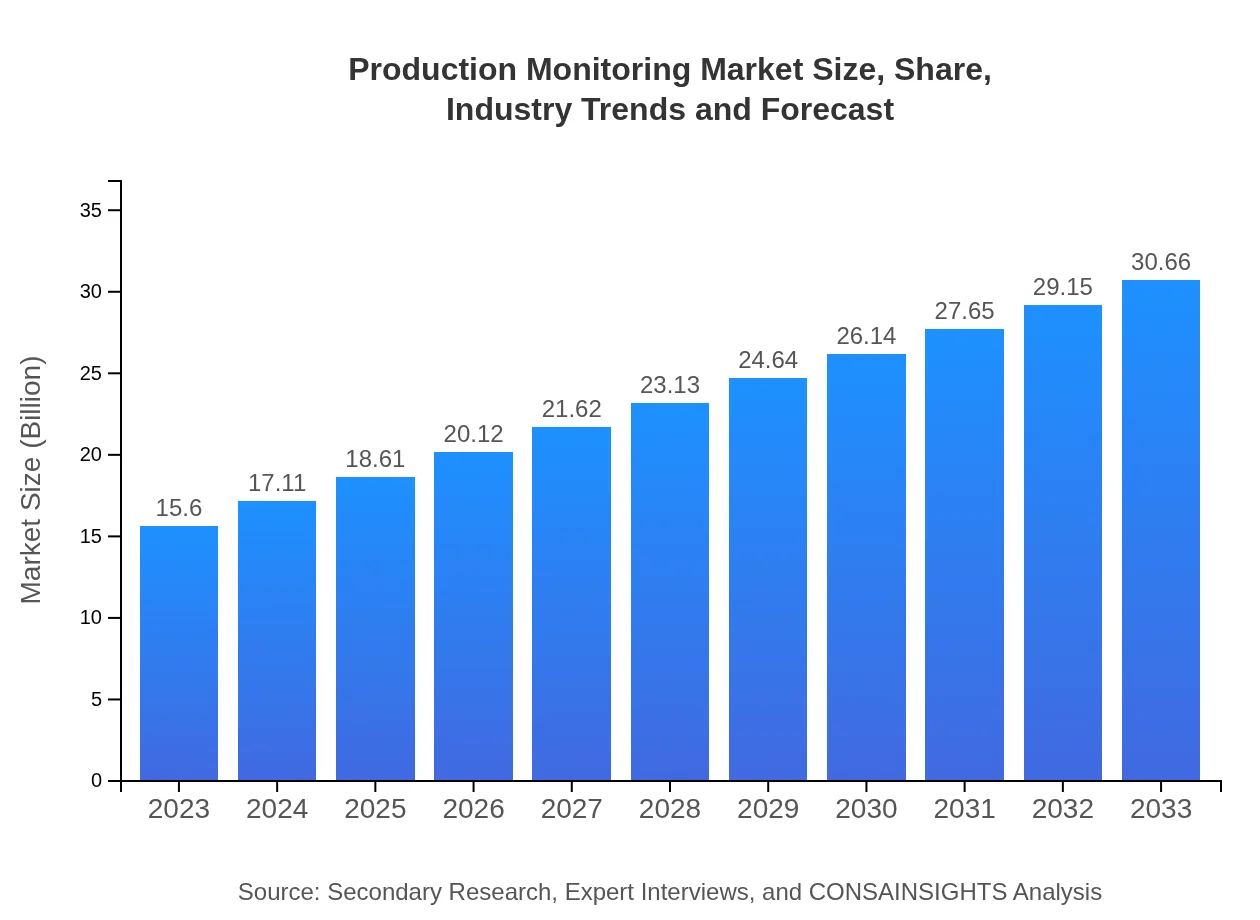

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $15.60 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $30.66 Billion |

| Top Companies | Siemens AG, Rockwell Automation, Honeywell International Inc., General Electric |

| Last Modified Date | 22 January 2026 |

Production Monitoring Market Overview

Customize Production Monitoring Market Report market research report

- ✔ Get in-depth analysis of Production Monitoring market size, growth, and forecasts.

- ✔ Understand Production Monitoring's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Production Monitoring

What is the Market Size & CAGR of Production Monitoring market in 2023?

Production Monitoring Industry Analysis

Production Monitoring Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Production Monitoring Market Analysis Report by Region

Europe Production Monitoring Market Report:

Europe's Production Monitoring market stands at USD 4.41 billion in 2023, expected to reach USD 8.66 billion by 2033 as companies pivot to smart manufacturing approaches, enhancing operational efficiencies and supporting sustainability efforts.Asia Pacific Production Monitoring Market Report:

The Asia Pacific region, valued at USD 2.92 billion in 2023, is expected to grow to USD 5.73 billion by 2033, reflecting a strong CAGR as manufacturers ramp up investments in digital transformation and process automation to maintain competitive advantages in global supply chains.North America Production Monitoring Market Report:

North America boasts a market size of USD 6.03 billion in 2023, anticipated to increase to USD 11.86 billion by 2033. This region leads in technology adoption, fueled by strong industrial bases and innovation across manufacturing sectors.South America Production Monitoring Market Report:

In South America, the Production Monitoring market is projected to grow from USD 1.41 billion in 2023 to USD 2.78 billion by 2033. This growth is driven by increasing investments in advanced manufacturing technologies, particularly in Brazil and Argentina.Middle East & Africa Production Monitoring Market Report:

The Middle East and Africa region forecasted to grow from USD 0.83 billion in 2023 to USD 1.63 billion by 2033, is witnessing gradual adoption of smart technologies, largely driven by diversification efforts away from oil dependency.Tell us your focus area and get a customized research report.

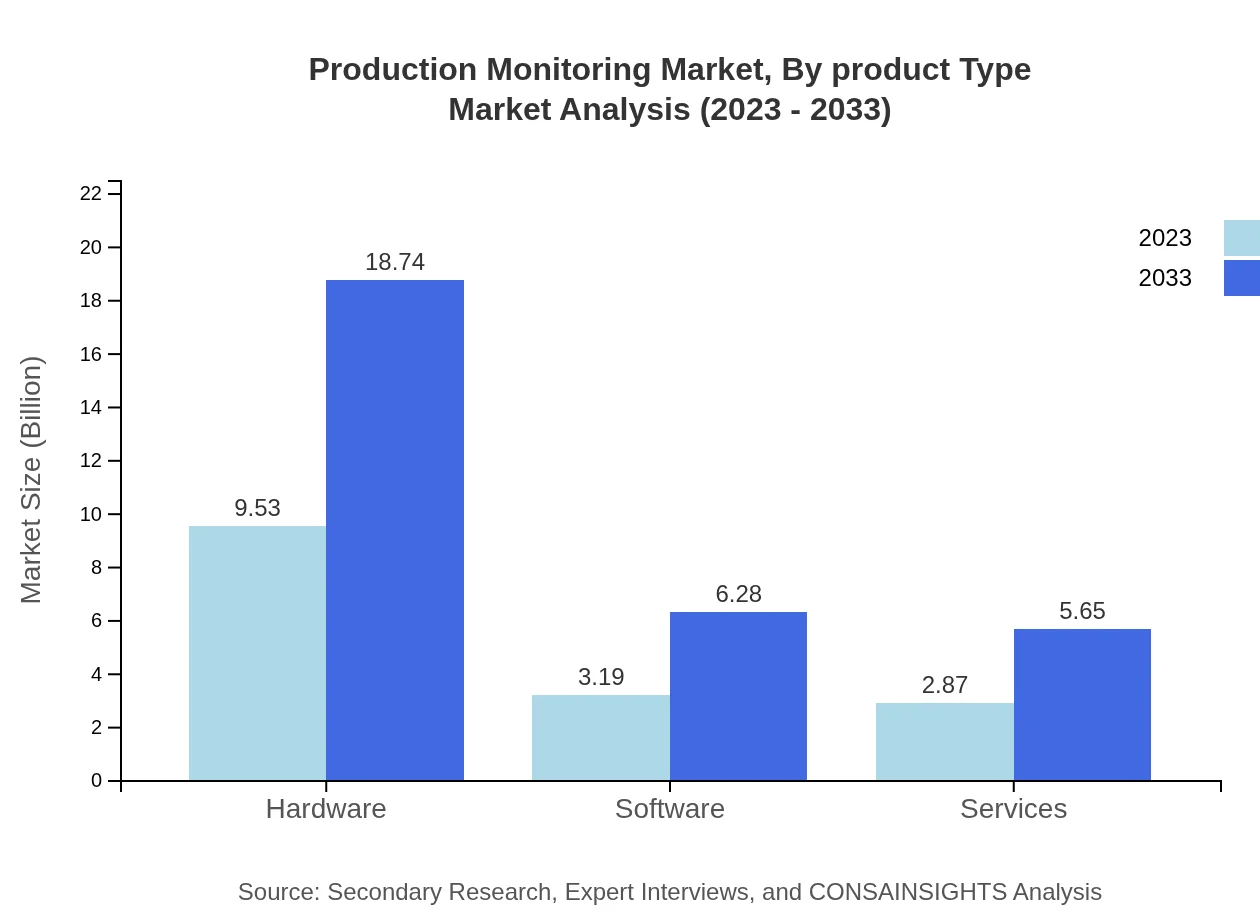

Production Monitoring Market Analysis By Product Type

In 2023, the global Production Monitoring market for product types is segmented as follows: Hardware (USD 9.53 billion), Software (USD 3.19 billion), and Services (USD 2.87 billion). Each segment plays a pivotal role; Hardware, driven largely by IoT devices, accounts for a significant share, indicating strong growth potential as factories evolve into smart environments.

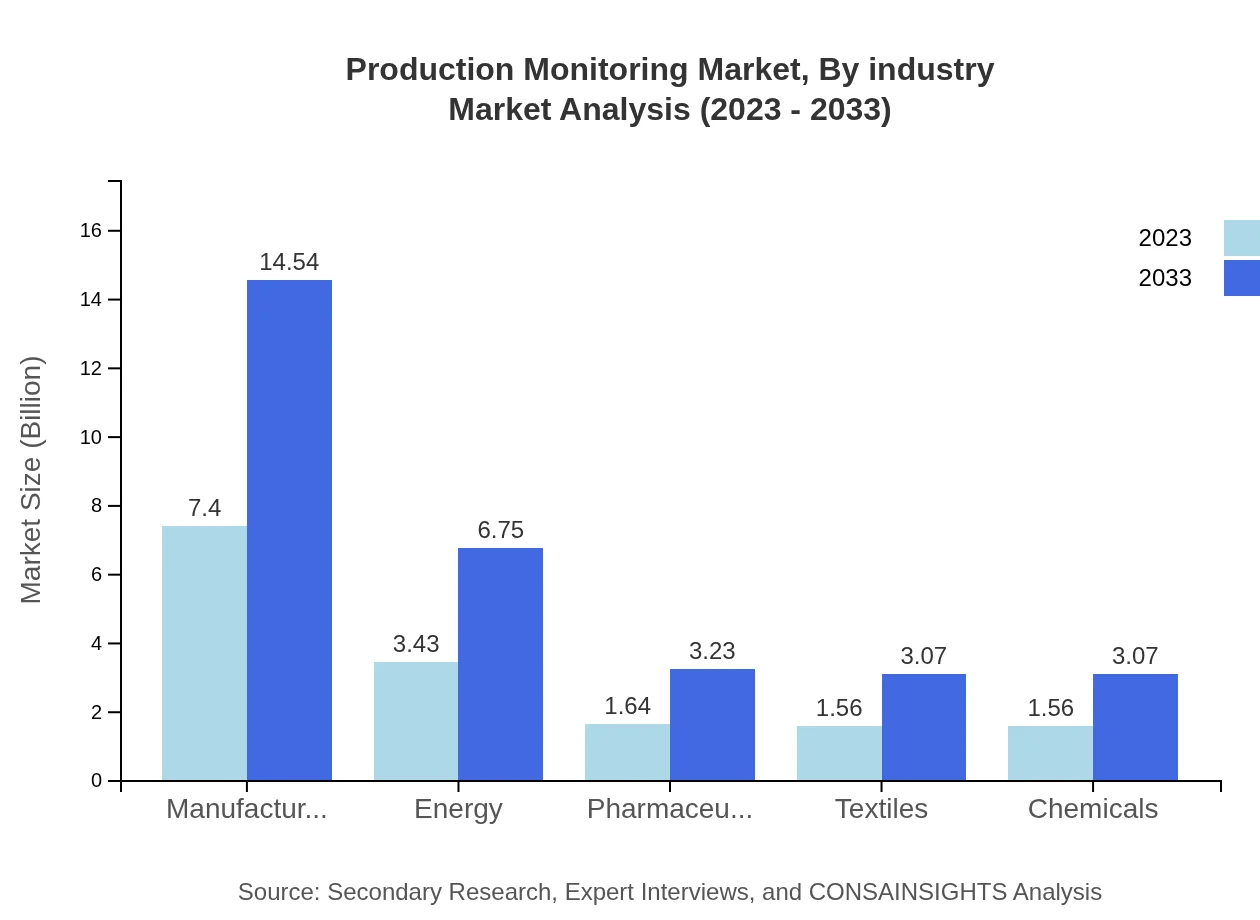

Production Monitoring Market Analysis By Industry

The industry analysis of Production Monitoring indicates strong performance across several sectors. Manufacturing is leading with an estimated market size of USD 7.40 billion in 2023, sharing 47.42% of the market. The energy sector follows with USD 3.43 billion, accounting for 22.01%, indicating its crucial role in smart grid and renewable energy projects.

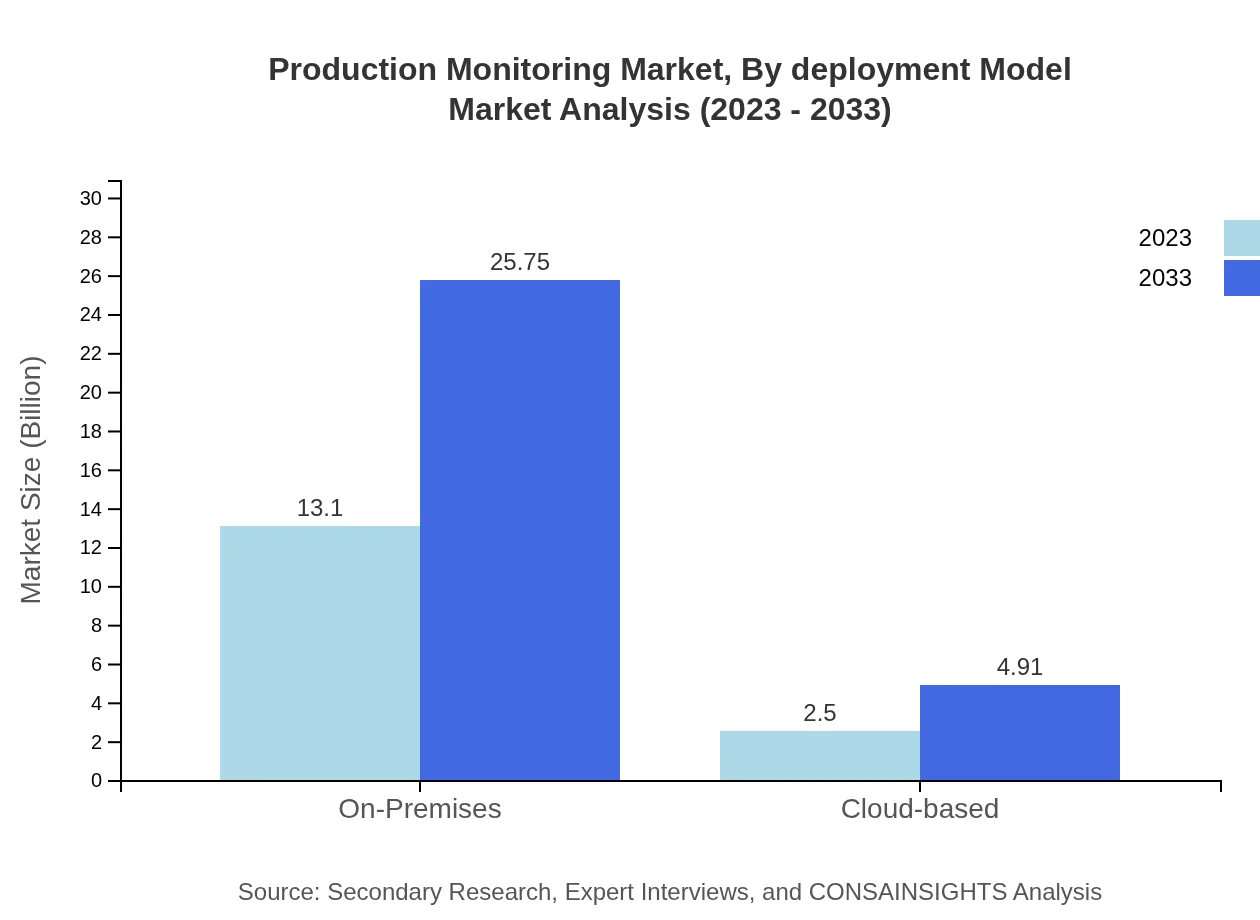

Production Monitoring Market Analysis By Deployment Model

On-Premises deployment leads the market with revenue of USD 13.10 billion in 2023, capturing 83.99% of market share due to security concerns. Cloud-based models, while smaller at USD 2.50 billion (16.01%), are gaining traction owing to their scalability, flexibility, and cost-effectiveness.

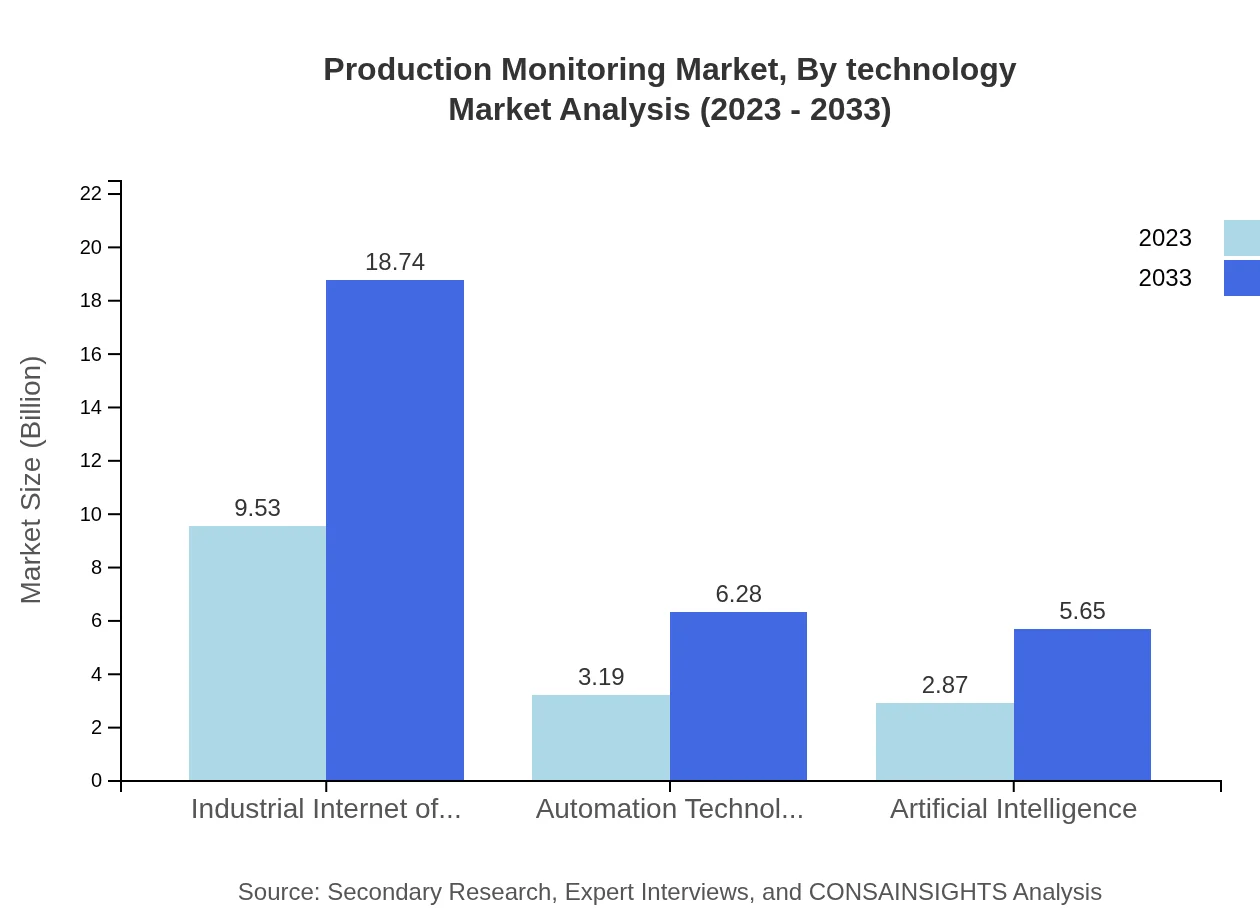

Production Monitoring Market Analysis By Technology

The technology segment, particularly Industrial Internet of Things (IIoT), is dominant and forecasted to reach USD 9.53 billion in 2023, capturing 61.11% market share. The rise of automation technologies, valued at USD 3.19 billion, and artificial intelligence at USD 2.87 billion, showcases the increasing integration of smart technologies in monitoring processes.

Production Monitoring Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Production Monitoring Industry

Siemens AG:

Siemens plays a pivotal role in the smart manufacturing landscape with its comprehensive automation solutions and digital twins technology, which enhance production efficiency.Rockwell Automation:

Specializing in industrial automation and information technology, Rockwell Automation drives innovations in production monitoring and provides integrated solutions to optimize industrial operations.Honeywell International Inc.:

Honeywell offers a range of industry-specific solutions that leverage IoT and advanced analytics to provide insights into production processes, helping manufacturers achieve improved operational efficiency.General Electric:

GE's Predix platform is a prominent player in industrial analytics, providing powerful tools for monitoring and optimizing manufacturing processes, particularly in sectors like energy and aviation.We're grateful to work with incredible clients.

FAQs

What is the market size of Production Monitoring?

The global market size for the Production Monitoring industry is projected to reach approximately $15.6 billion by 2033, growing at a compound annual growth rate (CAGR) of 6.8% from 2023. This growth reflects the increasing reliance on technology in manufacturing processes.

What are the key market players or companies in the Production Monitoring industry?

Key players in the Production Monitoring industry typically include major technology firms specializing in Industrial Internet of Things (IIoT), software solutions, and automation technologies. Their presence is crucial for driving innovation and market growth.

What are the primary factors driving the growth in the Production Monitoring industry?

The primary factors fueling growth in the Production Monitoring industry include technological advancements, rising demand for automation, increased efficiency in manufacturing processes, and the integration of data analytics for real-time monitoring.

Which region is the fastest Growing in the Production Monitoring market?

The fastest-growing region in the Production Monitoring market is Europe, with market sizes expected to increase from $4.41 billion in 2023 to $8.66 billion by 2033. Asia Pacific is also on the rise, anticipating substantial growth during the same period.

Does ConsInsights provide customized market report data for the Production Monitoring industry?

Yes, ConsInsights offers customized market report data tailored to specific needs within the Production Monitoring industry. This enables clients to obtain targeted insights relevant to their unique market requirements.

What deliverables can I expect from this Production Monitoring market research project?

Deliverables from the Production Monitoring market research project typically include detailed reports on market size, segments analysis, competitive landscape, trends, and growth forecasts. Additionally, tailored recommendations can be provided based on client goals.

What are the market trends of Production Monitoring?

Current market trends in Production Monitoring include the adoption of IIoT technologies, increased focus on sustainability, data-driven decision-making through analytics, and the growth of cloud-based solutions to enhance accessibility and scalability.