Programmable Logic Controller Plc Market Report

Published Date: 22 January 2026 | Report Code: programmable-logic-controller-plc

Programmable Logic Controller Plc Market Size, Share, Industry Trends and Forecast to 2033

This report provides an in-depth analysis of the Programmable Logic Controller (PLC) market from 2023 to 2033, detailing market size, growth trends, regional insights, and key players to furnish stakeholders with strategic insights for informed decision-making.

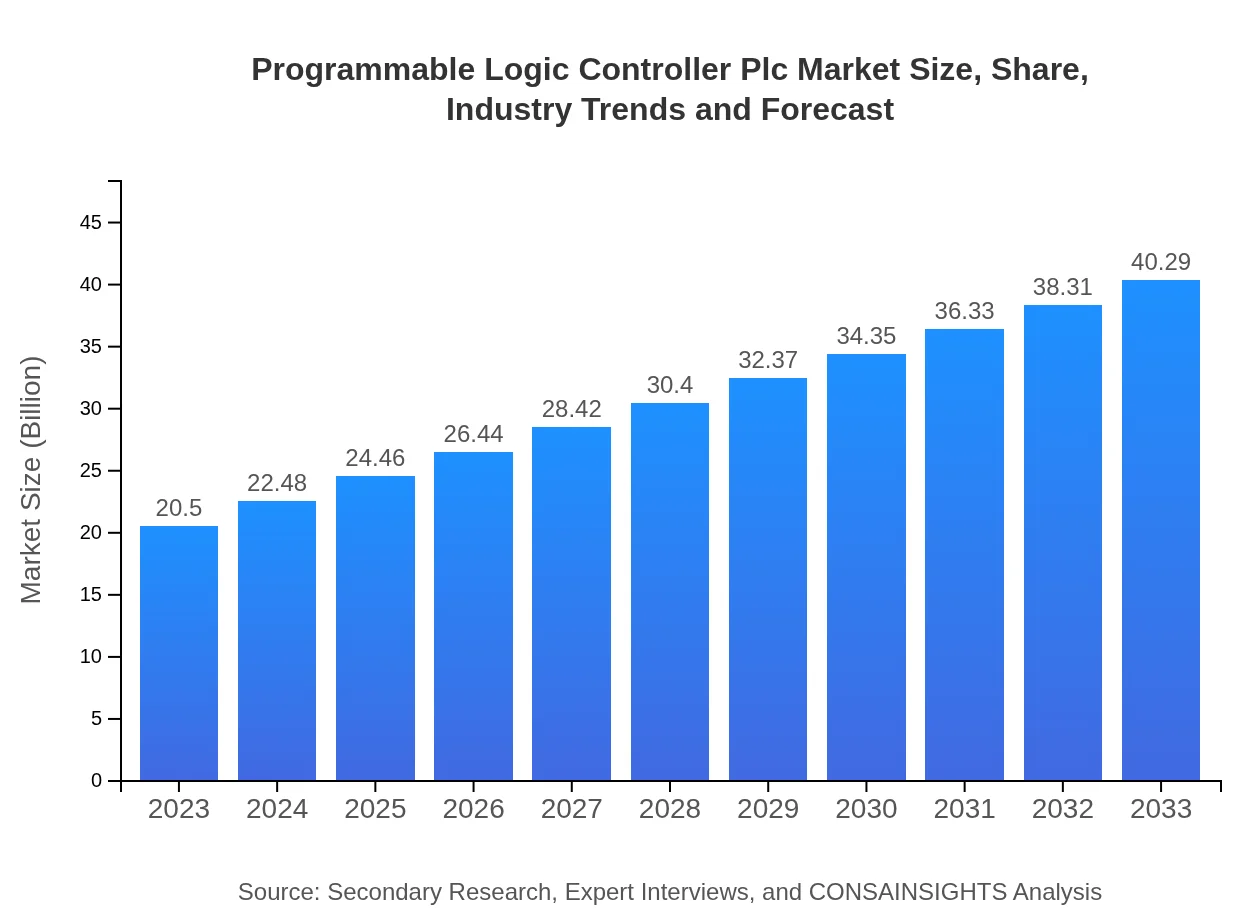

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $20.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $40.29 Billion |

| Top Companies | Siemens AG, Rockwell Automation, Inc., Schneider Electric, Mitsubishi Electric Corporation, Honeywell International Inc. |

| Last Modified Date | 22 January 2026 |

Programmable Logic Controller Plc Market Overview

Customize Programmable Logic Controller Plc Market Report market research report

- ✔ Get in-depth analysis of Programmable Logic Controller Plc market size, growth, and forecasts.

- ✔ Understand Programmable Logic Controller Plc's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Programmable Logic Controller Plc

What is the Market Size & CAGR of Programmable Logic Controller Plc market in 2023?

Programmable Logic Controller Plc Industry Analysis

Programmable Logic Controller Plc Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Programmable Logic Controller Plc Market Analysis Report by Region

Europe Programmable Logic Controller Plc Market Report:

The European PLC market will see growth from $6.01 billion in 2023 to $11.82 billion by 2033. Favorable regulatory frameworks and a high level of automation in industries such as automotive and pharmaceuticals are driving this growth.Asia Pacific Programmable Logic Controller Plc Market Report:

The Asia Pacific region is projected to grow from $3.47 billion in 2023 to $6.82 billion by 2033, showcasing a rapid growth rate fueled by industrialization, government initiatives in automation, and an increasing number of smart factories. Countries like China and India are major contributors to this growth due to their growing manufacturing sectors.North America Programmable Logic Controller Plc Market Report:

North America is one of the leading markets for PLCs, growing from $7.95 billion in 2023 to $15.63 billion by 2033. The growth is primarily attributed to the strong focus on technological innovation, presence of major market players, and the rapid adoption of automation technologies across various industries.South America Programmable Logic Controller Plc Market Report:

In South America, the PLC market is expected to grow from $1.48 billion in 2023 to $2.91 billion by 2033. This growth is driven by increasing investments in industrial infrastructure and demand for automation driven by efficiency improvements in manufacturing processes.Middle East & Africa Programmable Logic Controller Plc Market Report:

In the Middle East and Africa, the market is set to grow from $1.58 billion in 2023 to $3.11 billion by 2033, supported by increasing investments in infrastructure and oil and gas sector automation, contributing to higher demand for PLC systems.Tell us your focus area and get a customized research report.

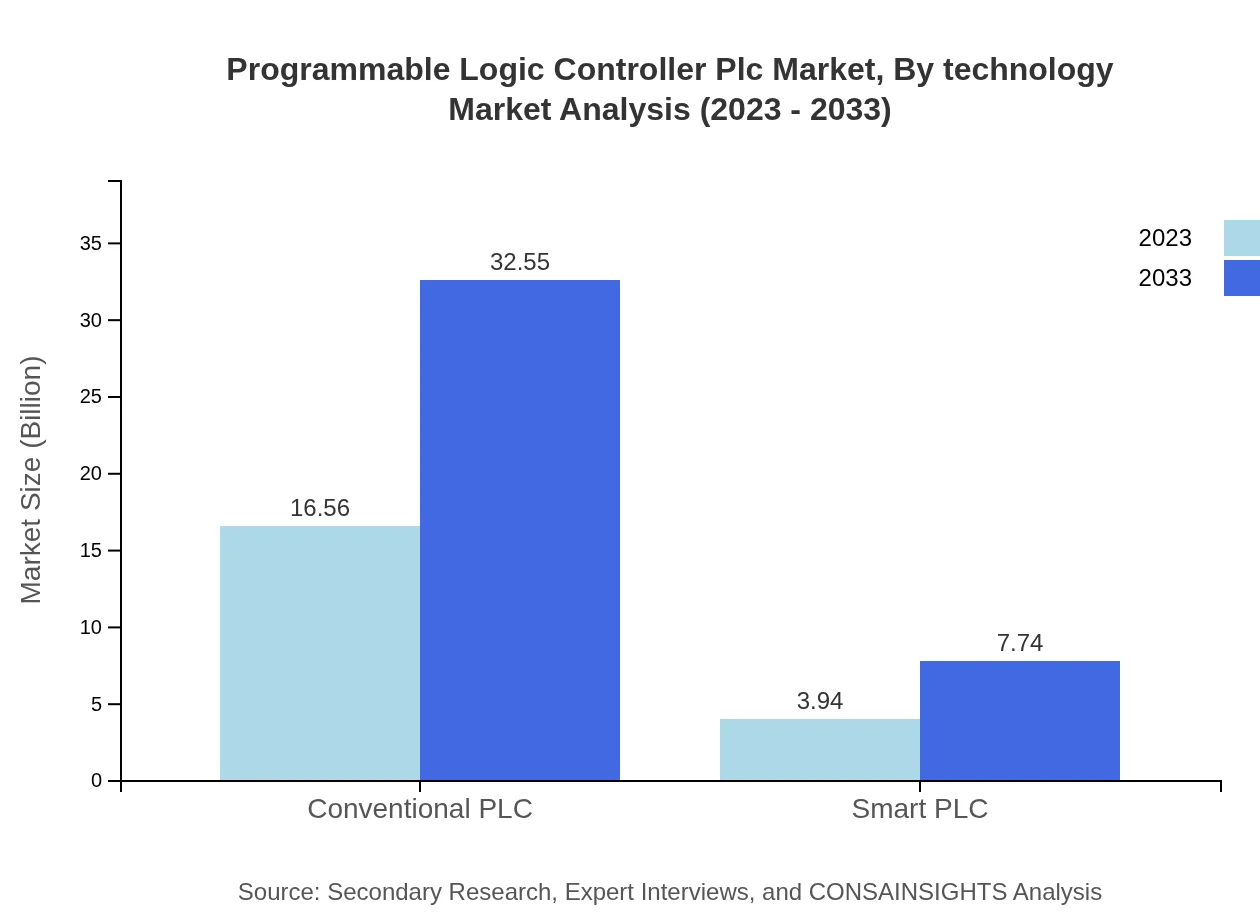

Programmable Logic Controller Plc Market Analysis By Technology

The PLC market is dominated by Conventional PLCs which account for a substantial market share of 80.79% in 2023, projected to remain stable through 2033. Smart PLCs, currently representing 19.21% of market share, are expected to see increased adoption due to their advanced features and integration with IoT systems.

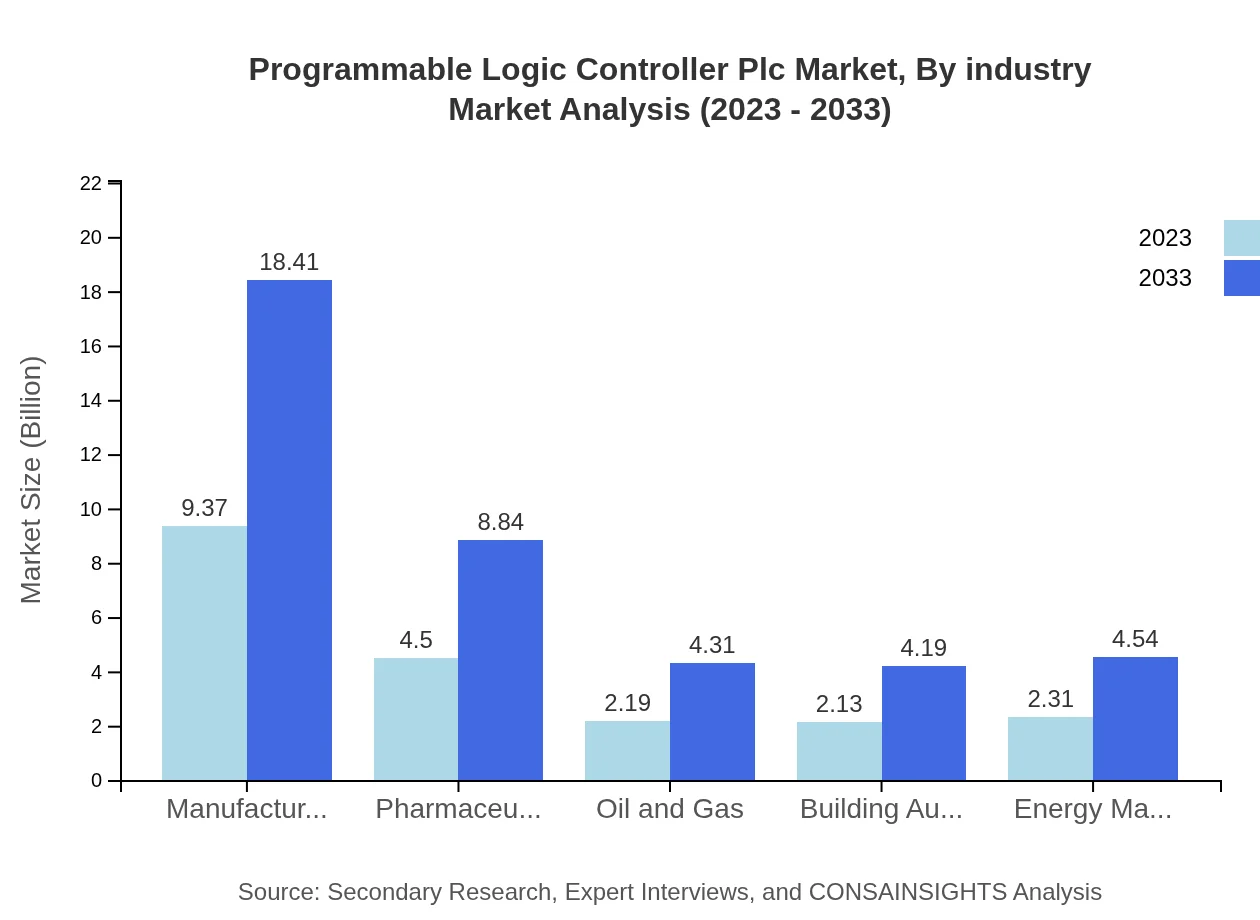

Programmable Logic Controller Plc Market Analysis By Industry

By industry, Manufacturing is the largest segment, growing from $9.37 billion in 2023 to $18.41 billion by 2033. Other significant segments include Pharmaceuticals ($4.50 billion in 2023) and Oil and Gas ($2.19 billion), indicating strong industry-specific demand.

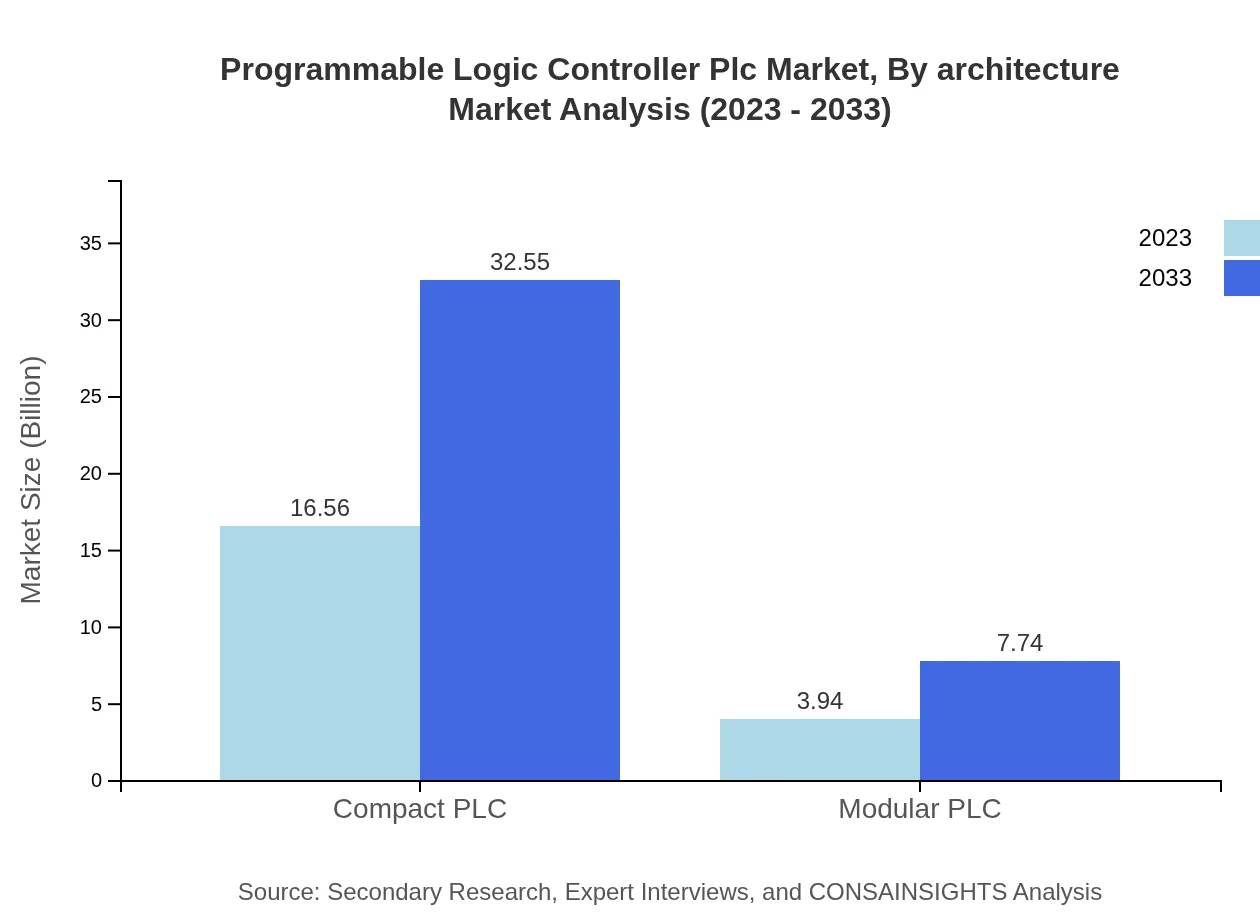

Programmable Logic Controller Plc Market Analysis By Architecture

The architecture segment is led by Compact PLCs, which command an 80.79% market share in 2023, increasing with the rise in automation adoption across sectors. Modular PLCs, offering flexibility and scalability, are also gaining traction.

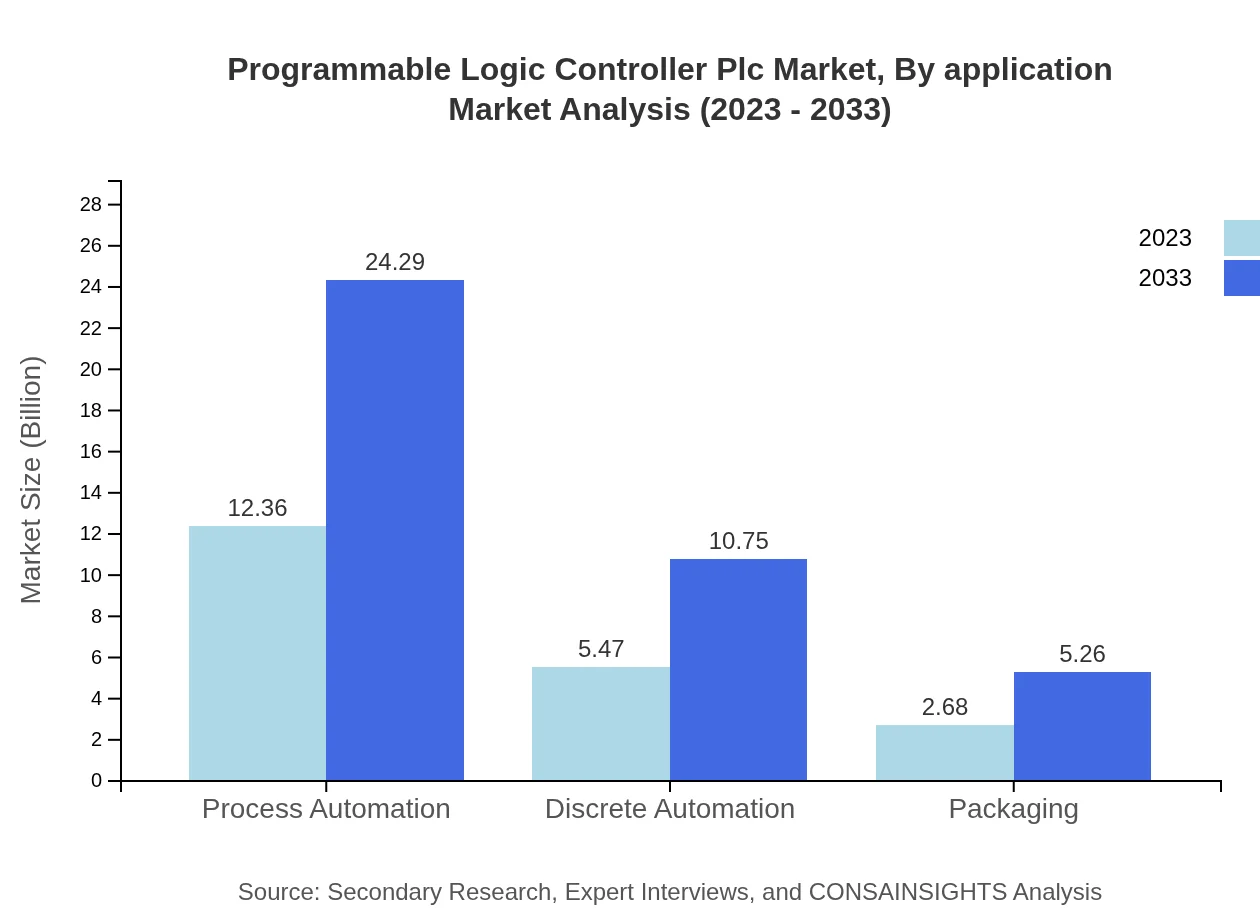

Programmable Logic Controller Plc Market Analysis By Application

Applications in Process Automation dominate the market, with a 60.28% share in 2023. As industries seek to increase efficiency, demand for advanced automation solutions in Discrete Automation is also rising.

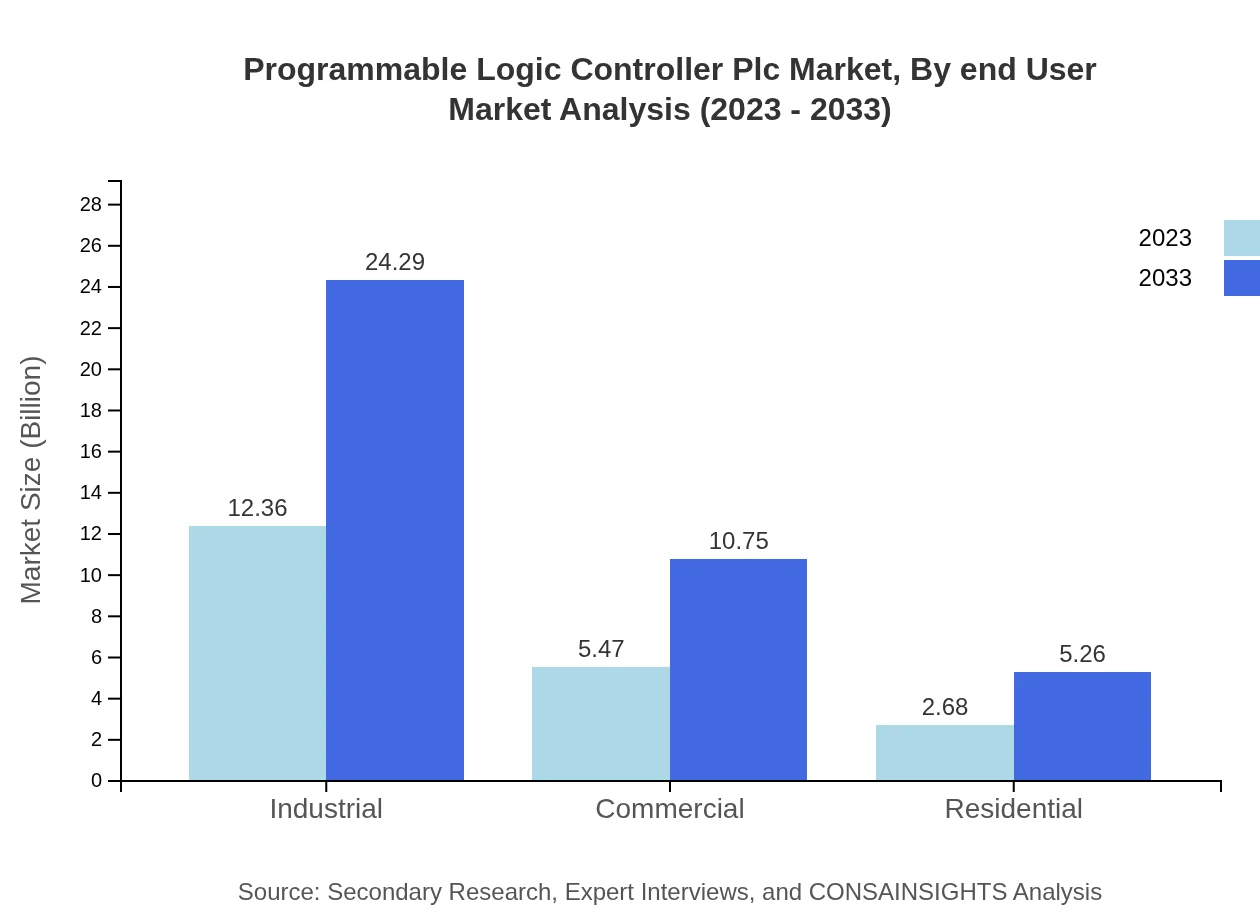

Programmable Logic Controller Plc Market Analysis By End User

The end-user segment is heavily skewed towards industrial applications, accounting for over 60% of market demand in various sectors. The growing trend towards smart manufacturing is pushing demand for PLCs in automotive and electronics manufacturing.

Programmable Logic Controller Plc Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Programmable Logic Controller Plc Industry

Siemens AG:

Siemens is a global leader in industrial automation and drive technology, providing a comprehensive range of PLCs known for their reliability and performance.Rockwell Automation, Inc.:

Rockwell Automation specializes in industrial automation and information technology, offering advanced PLC solutions that enhance efficiency and productivity.Schneider Electric:

Schneider Electric is a prominent player in the market, renowned for its innovative PLC systems and focus on sustainability and efficiency across industries.Mitsubishi Electric Corporation:

Mitsubishi Electric is known for its versatile PLC offerings which are used extensively in manufacturing processes worldwide.Honeywell International Inc.:

Honeywell provides integrated control systems that leverage advanced PLC technologies to support various industrial applications.We're grateful to work with incredible clients.

FAQs

What is the market size of programmable logic controller (PLC)?

The global market size for Programmable Logic Controllers (PLC) was valued at approximately $20.5 billion in 2023, with a projected CAGR of 6.8% through 2033, indicating a robust growth trajectory in the automation sector.

What are the key market players or companies in the PLC industry?

Major companies in the PLC market include Siemens, Rockwell Automation, Mitsubishi Electric, Schneider Electric, and ABB. These companies are pivotal in driving innovation and competitive dynamics within the industry.

What are the primary factors driving the growth in the PLC industry?

Growth in the PLC market is primarily driven by increased automation in manufacturing, advancements in technology, rising demand for smart factories, and the need for efficient industrial processes to enhance productivity.

Which region is the fastest Growing in the PLC market?

Asia Pacific is emerging as the fastest-growing region for the PLC market, expecting growth from $3.47 billion in 2023 to $6.82 billion by 2033, fuelled by rapid industrialization and technological advancements.

Does ConsaInsights provide customized market report data for the PLC industry?

Yes, ConsaInsights offers tailored market report data for the PLC industry, catering to specific client needs, ensuring that insights are relevant and actionable for various market segments.

What deliverables can I expect from the PLC market research project?

Clients can expect comprehensive reports, market analysis, trend assessments, competitive landscapes, and actionable insights tailored to their specific needs within the PLC market.

What are the market trends of programmable logic controllers (PLC)?

Current trends in the PLC market include the rise of smart PLCs, increased integration of IoT technologies, growing demand for cloud-based PLC solutions, and advancements in process automation methods.