Pvdf Membrane Market Report

Published Date: 22 January 2026 | Report Code: pvdf-membrane

Pvdf Membrane Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the PVDF membrane market from 2023 to 2033, covering market size, trends, segmentation, regional insights, and industry forecasts aimed at assisting stakeholders in informed decision-making.

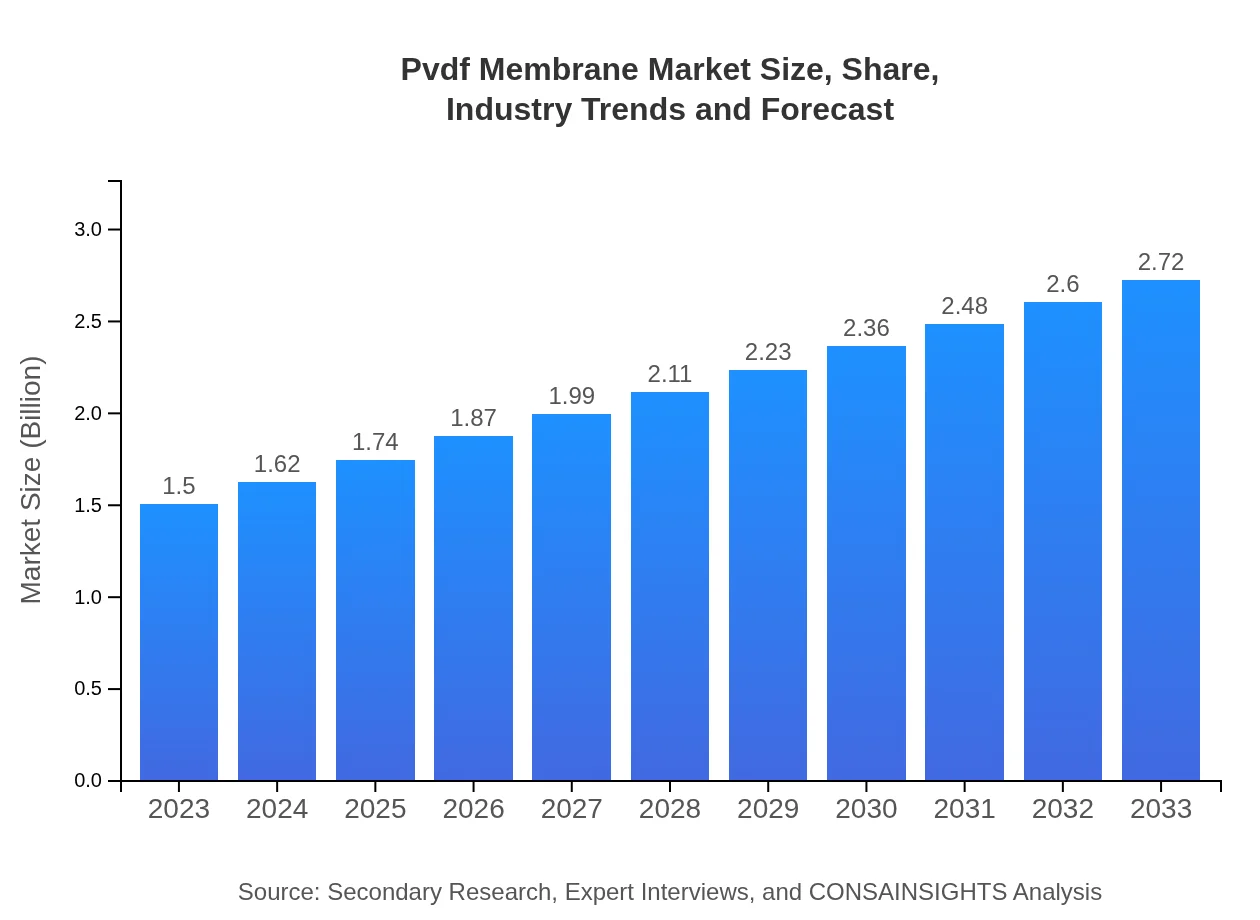

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $1.50 Billion |

| CAGR (2023-2033) | 6.0% |

| 2033 Market Size | $2.72 Billion |

| Top Companies | Pall Corporation, 3M, DuPont Water Solutions |

| Last Modified Date | 22 January 2026 |

PVDF Membrane Market Overview

Customize Pvdf Membrane Market Report market research report

- ✔ Get in-depth analysis of Pvdf Membrane market size, growth, and forecasts.

- ✔ Understand Pvdf Membrane's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Pvdf Membrane

What is the Market Size & CAGR of PVDF Membrane market in 2023?

PVDF Membrane Industry Analysis

PVDF Membrane Market Segmentation and Scope

Tell us your focus area and get a customized research report.

PVDF Membrane Market Analysis Report by Region

Europe Pvdf Membrane Market Report:

In Europe, the PVDF membrane market is valued at $0.44 billion in 2023 and is projected to reach $0.81 billion by 2033. Stringent environmental regulations and a growing focus on sustainable practices in the water treatment and food industries are significant factors influencing market dynamics in this region.Asia Pacific Pvdf Membrane Market Report:

The Asia Pacific region is a significant market for PVDF membranes, reflecting an estimated market size of $0.32 billion in 2023, projected to grow to $0.57 billion by 2033. The region’s rapid industrialization and growing environmental concerns drive the demand for effective water treatment solutions. Countries like China and India are leading contributors due to rising investments in infrastructure and clean water initiatives.North America Pvdf Membrane Market Report:

North America showcases a robust PVDF membrane market, with a current valuation of $0.49 billion projected to ascend to $0.90 billion by 2033. The region is characterized by sophisticated technological advancements and a strong emphasis on innovation, particularly in the oil and gas and water treatment sectors, stimulating market growth.South America Pvdf Membrane Market Report:

In South America, the PVDF membrane market is currently valued at $0.13 billion and is expected to reach $0.24 billion by 2033. The increasing focus on sustainable water management in countries like Brazil and Argentina aligns with the growing adoption of PVDF membranes for water filtration systems and environmental remediation efforts.Middle East & Africa Pvdf Membrane Market Report:

The Middle East and Africa region presents a growing market for PVDF membranes, currently sized at $0.12 billion, expected to expand to $0.21 billion by 2033. The increasing focus on desalination technology and efficient water purification systems, particularly in Gulf countries, is expected to drive the growth of the PVDF membrane market in this region.Tell us your focus area and get a customized research report.

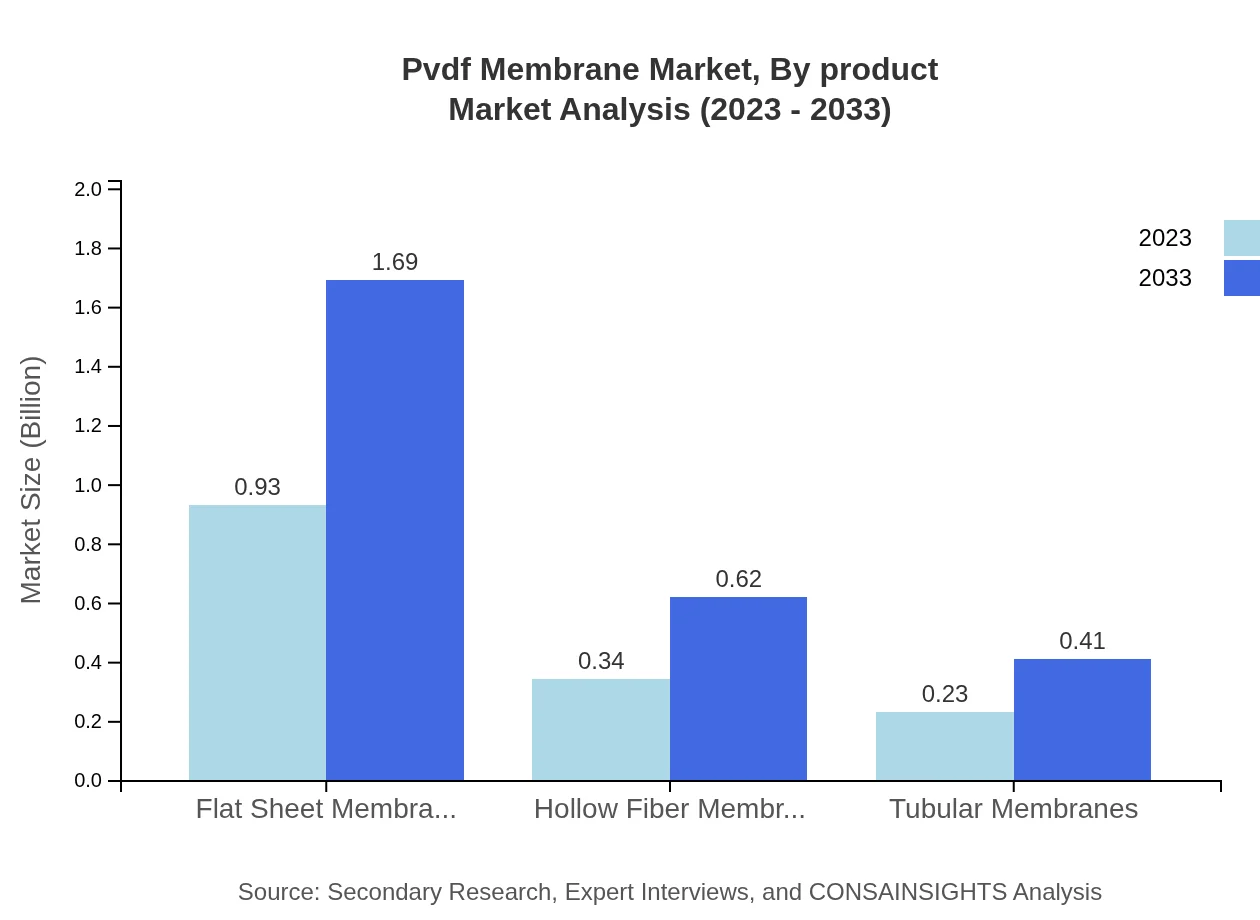

Pvdf Membrane Market Analysis By Product

The market demonstrates substantial growth across different product types. Flat sheet membranes represent the largest segment, estimated at $0.93 billion in 2023, and set to grow to $1.69 billion by 2033, maintaining a market share of 62.16%. Hollow fiber membranes, currently at $0.34 billion, will rise to $0.62 billion. Tubular membranes will also see incremental growth, expanding from $0.23 billion to $0.41 billion during the same period.

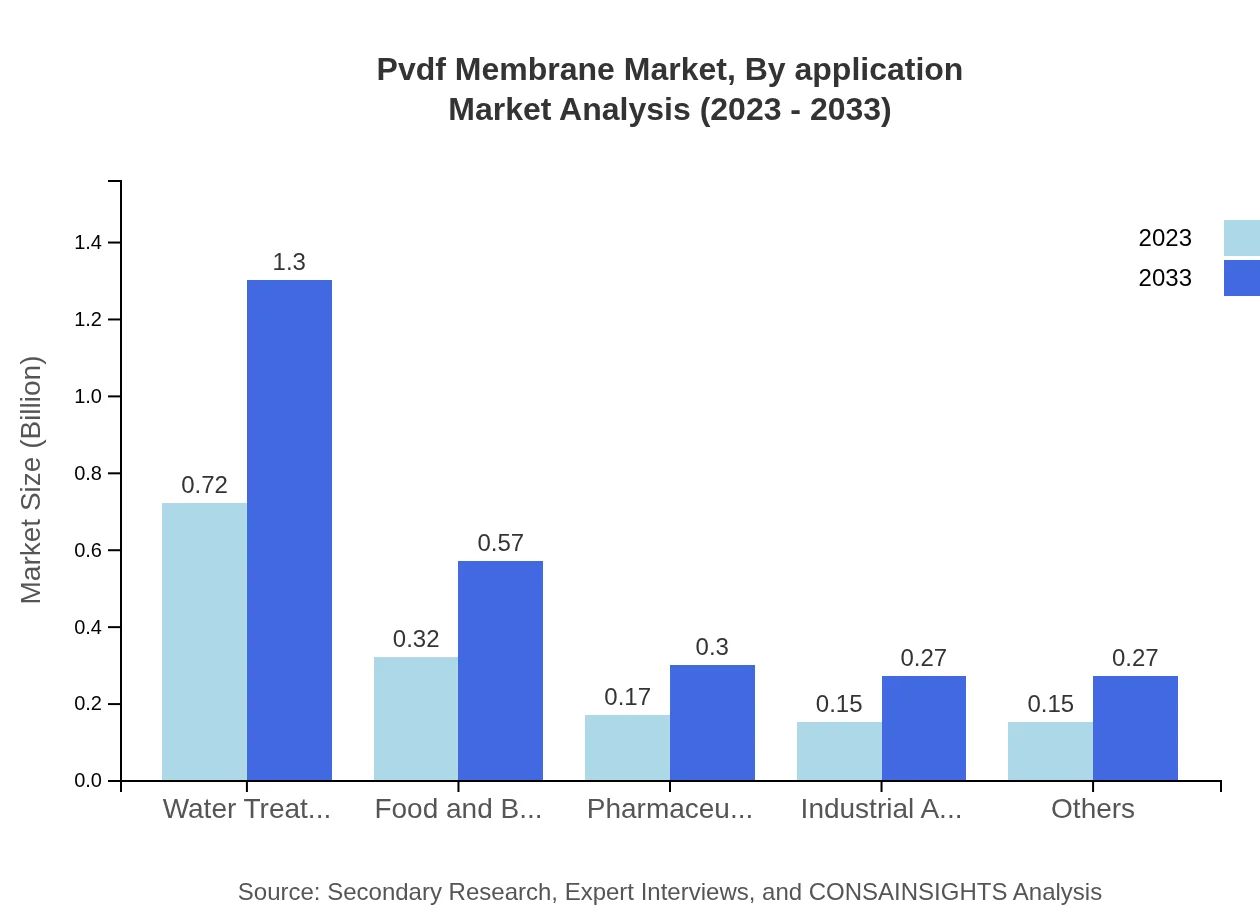

Pvdf Membrane Market Analysis By Application

The application segment is dominated by municipal water treatment, which accounts for about $0.72 billion, projected to grow to $1.30 billion by 2033. Microfiltration is another significant area, currently at $0.76 billion and expected to reach $1.39 billion. The food and beverage and pharmaceutical end-users are also notable, with sizes of $0.32 billion and $0.17 billion anticipated to increase considerably over the forecast period.

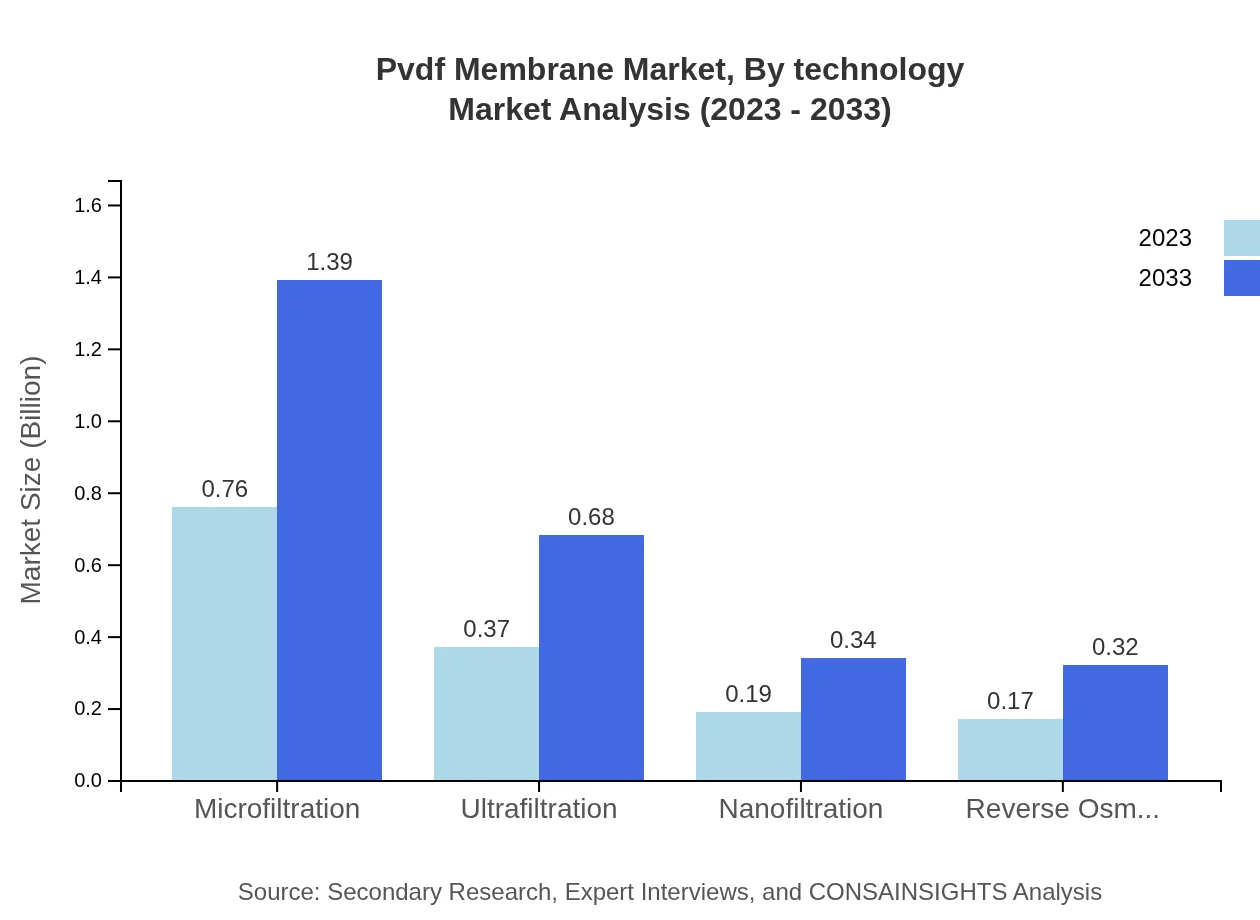

Pvdf Membrane Market Analysis By Technology

In terms of technology, significant traction is seen in microfiltration and ultrafiltration. Microfiltration accounts for about 50.87% of the market share in 2023 while ultrafiltration comprises around 24.95%. Enhanced technologies are key drivers, enabling the development of efficient filtration systems suitable for diverse applications in the water treatment and industrial sectors.

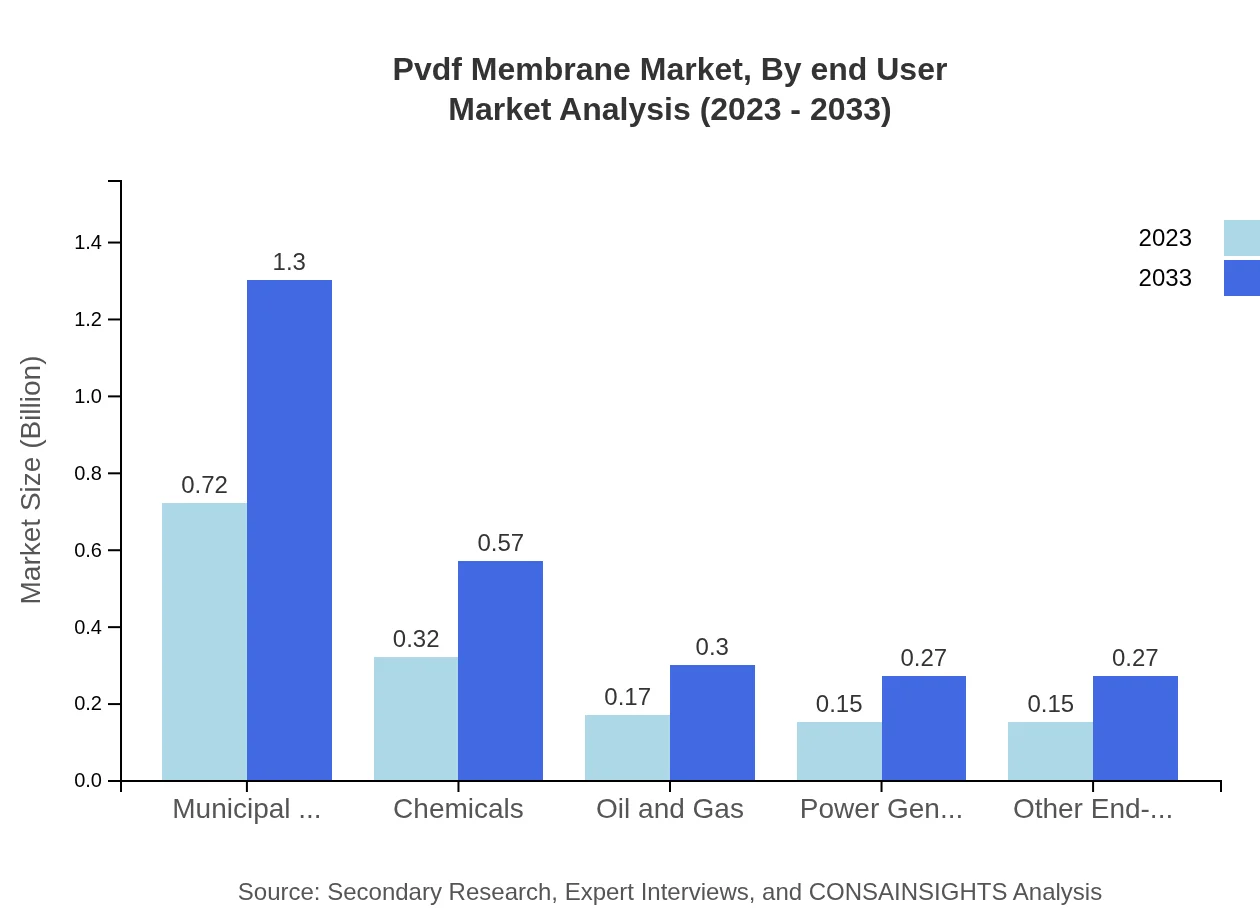

Pvdf Membrane Market Analysis By End User

Among end-users, the municipal water treatment sector leads with a current valuation of $0.72 billion and a share of 47.75%. Following are the chemical and food/beverage industries, making distinct contributions to the market. The pharmaceutical sector holds an 11.17% share, emphasizing the growing demand for high-purity filtration solutions in drug manufacturing processes.

PVDF Membrane Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in PVDF Membrane Industry

Pall Corporation:

A leading global supplier of PVDF membranes, Pall Corporation specializes in advanced filtration technologies, delivering innovative solutions for various industries, including pharmaceuticals and food and beverage.3M:

3M is recognized for its innovative membrane technologies, offering a range of PVDF products aimed at enhancing filtration performance and efficiency in water treatment applications.DuPont Water Solutions:

DuPont is a global leader in water filtration, providing high-performance PVDF membranes designed for END-USER applications in water treatment, food processing, and pharmaceuticals.We're grateful to work with incredible clients.

FAQs

What is the market size of pvdf Membrane?

The PVDF membrane market is valued at approximately $1.5 billion as of 2023, with an expected CAGR of 6.0% from 2023 to 2033, indicating significant growth potential in various applications.

What are the key market players or companies in this pvdf Membrane industry?

Key players in the PVDF membrane market include companies specializing in advanced filtration technologies, particularly those focusing on membrane manufacturing and water treatment solutions, significantly contributing to market advancements.

What are the primary factors driving the growth in the pvdf Membrane industry?

Growth in the PVDF membrane industry is driven by increasing demand for water treatment solutions, advancements in filtration technology, and the rise in industrial applications in sectors such as pharmaceuticals and food processing.

Which region is the fastest Growing in the pvdf Membrane?

The Asia Pacific region is the fastest-growing market for PVDF membranes, projected to increase from $0.32 billion in 2023 to $0.57 billion by 2033, driven by rising industrial activities and environmental regulations.

Does ConsaInsights provide customized market report data for the pvdf Membrane industry?

Yes, ConsaInsights offers customized market report data for the PVDF membrane industry, facilitating tailored insights based on specific client needs, market segments, and geographical areas.

What deliverables can I expect from this pvdf Membrane market research project?

Deliverables include comprehensive market analysis reports, strategic insights, segment and regional data, detailed competitor analysis, and forecasts that support informed decision-making in the PVDF membrane market.

What are the market trends of pvdf Membrane?

Current trends in the PVDF membrane market reflect increased adoption in sustainable water treatment methods, innovative filtration technologies, and an emphasis on eco-friendly products, aligning with global environmental goals.