Rapid Liquid Printing Market Report

Published Date: 31 January 2026 | Report Code: rapid-liquid-printing

Rapid Liquid Printing Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Rapid Liquid Printing market, examining key trends, segmentation, regional insights, and forecasts from 2023 to 2033. It includes an in-depth exploration of market dynamics, technological advancements, and leading players shaping the industry.

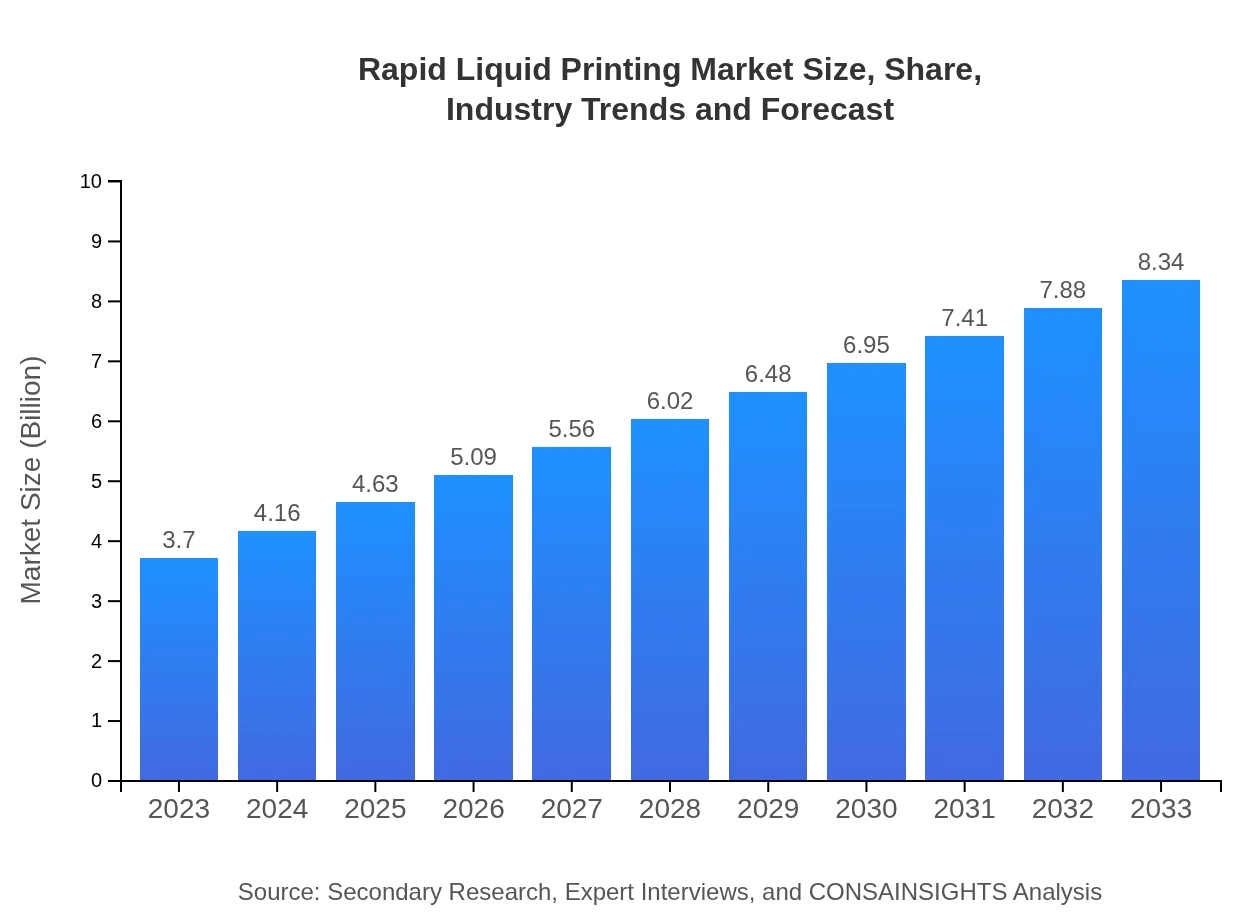

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.70 Billion |

| CAGR (2023-2033) | 8.2% |

| 2033 Market Size | $8.34 Billion |

| Top Companies | 3D Systems, Stratasys, Materialise, Carbon, Inc. |

| Last Modified Date | 31 January 2026 |

Rapid Liquid Printing Market Overview

Customize Rapid Liquid Printing Market Report market research report

- ✔ Get in-depth analysis of Rapid Liquid Printing market size, growth, and forecasts.

- ✔ Understand Rapid Liquid Printing's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Rapid Liquid Printing

What is the Market Size & CAGR of Rapid Liquid Printing market in 2023?

Rapid Liquid Printing Industry Analysis

Rapid Liquid Printing Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Rapid Liquid Printing Market Analysis Report by Region

Europe Rapid Liquid Printing Market Report:

Europe’s market is expected to increase from $1.06 billion in 2023 to $2.38 billion by 2033. The region is witnessing strong growth facilitated by strict regulatory mandates for sustainable production and innovative research institutions.Asia Pacific Rapid Liquid Printing Market Report:

The Asia Pacific region, valued at $0.73 billion in 2023, is expected to reach $1.66 billion by 2033. Key factors driving growth include increasing investments in manufacturing technologies and a rise in local 3D printing startups catering to industries such as electronics and automotive.North America Rapid Liquid Printing Market Report:

The North American market, valued at $1.25 billion in 2023, is anticipated to expand significantly to $2.82 billion by 2033. The U.S. leads in technology adoption, with considerable demand from the aerospace and automotive sectors driving market growth.South America Rapid Liquid Printing Market Report:

In South America, the Rapid Liquid Printing market is estimated at $0.23 billion in 2023, projected to grow to $0.53 billion by 2033. Countries like Brazil and Argentina are beginning to invest in 3D printing technologies, particularly for healthcare applications.Middle East & Africa Rapid Liquid Printing Market Report:

In the Middle East and Africa, the market is forecasted to grow from $0.42 billion in 2023 to $0.95 billion by 2033. The interest in 3D printing in this region is growing mainly within the healthcare and consumer products sectors, spurred by government initiatives.Tell us your focus area and get a customized research report.

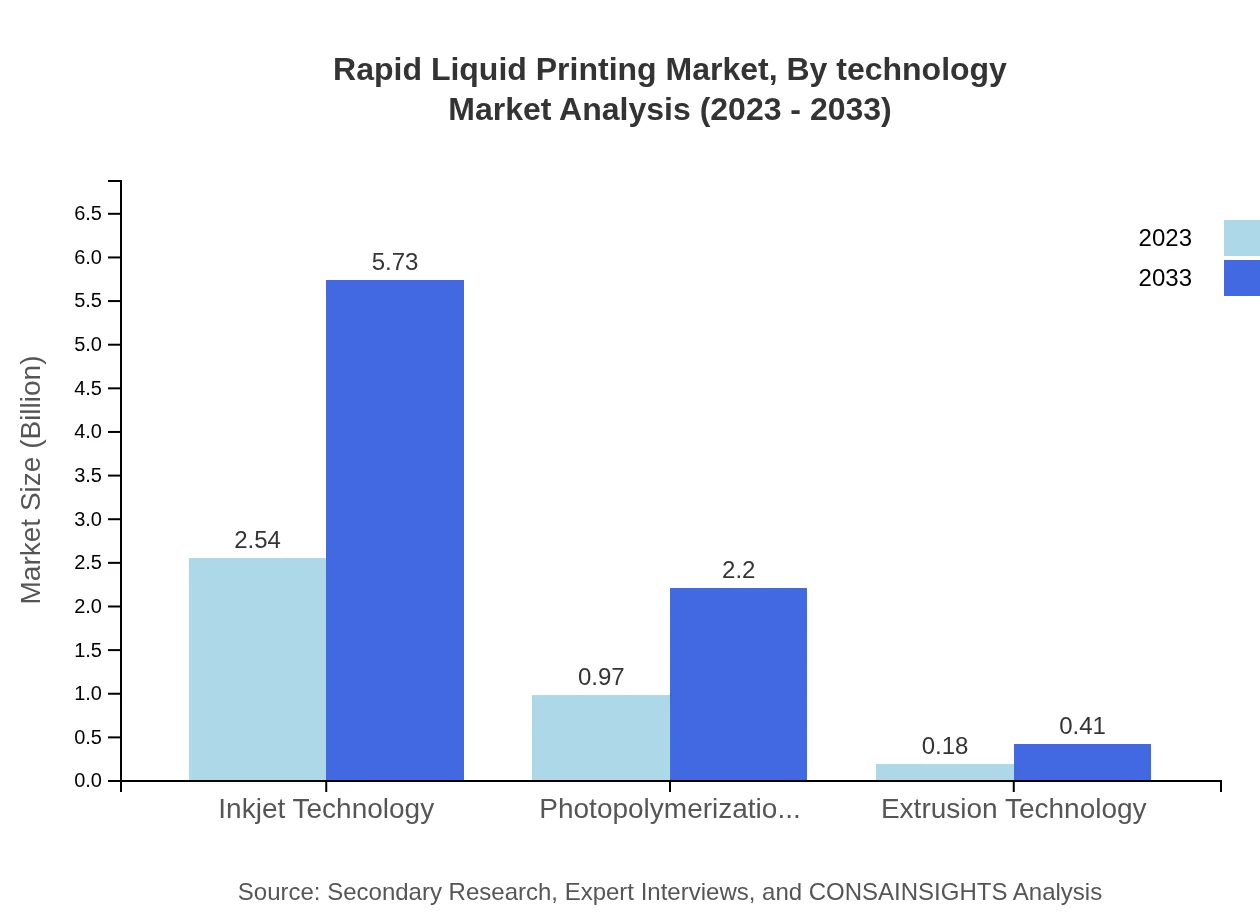

Rapid Liquid Printing Market Analysis By Technology

The technology segment of the Rapid Liquid Printing market is primarily driven by Inkjet Technology, which holds a significant share due to its efficiency in producing complex geometries. The market for Photopolymerization Technology is also expanding, showing promising growth as advancements continue to enhance the precision and quality of printed parts. In 2023, Inkjet Technology accounts for 68.74% of the market share, with expected growth reflecting increased adoption across various application sectors.

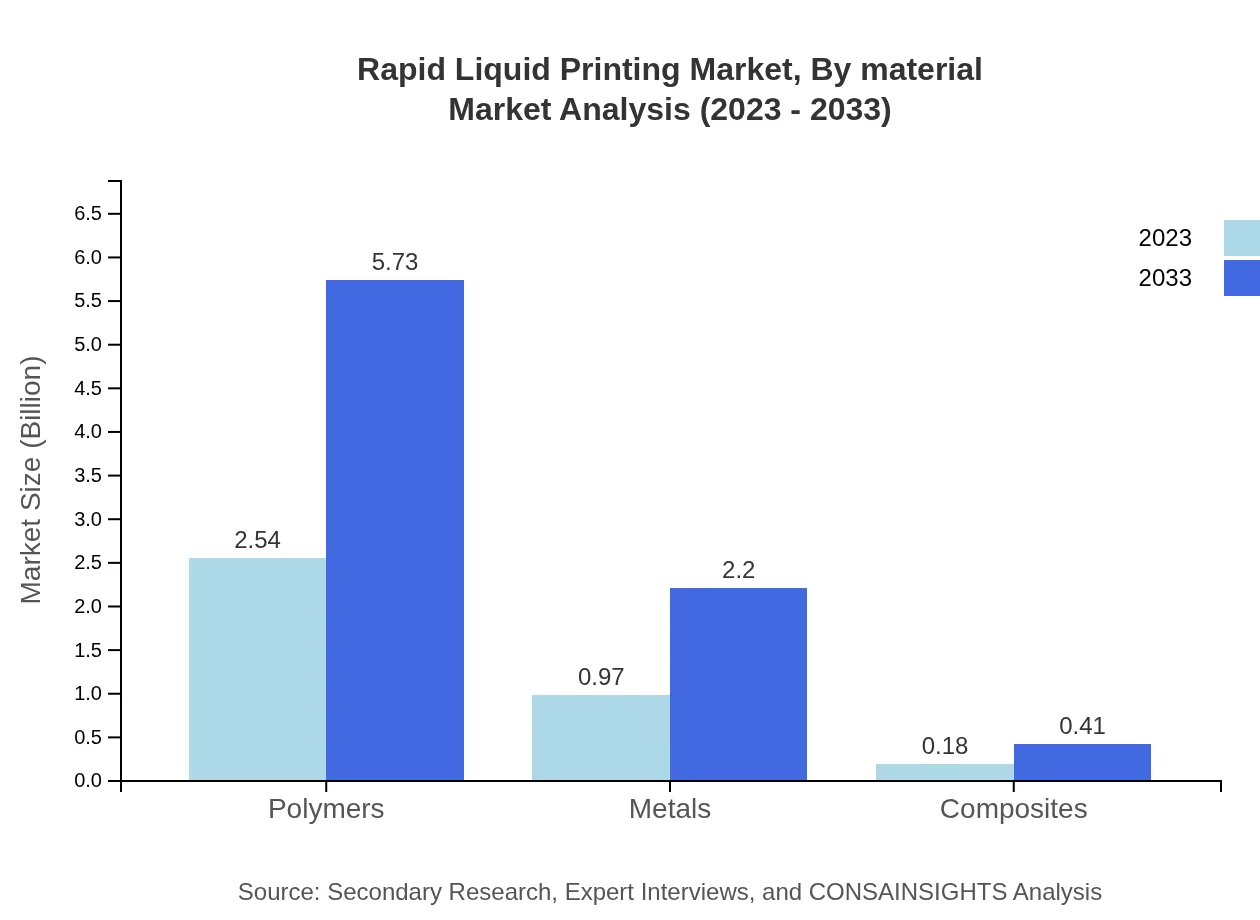

Rapid Liquid Printing Market Analysis By Material

Polymers remain the dominant material used in the Rapid Liquid Printing process, making up 68.74% of the market share in 2023. This segment will grow significantly due to the versatility and adaptability of polymer materials in different applications. Metals and composites, accounting for 26.35% and 4.91% respectively, are also gaining traction owing to their application in durable and high-performance products.

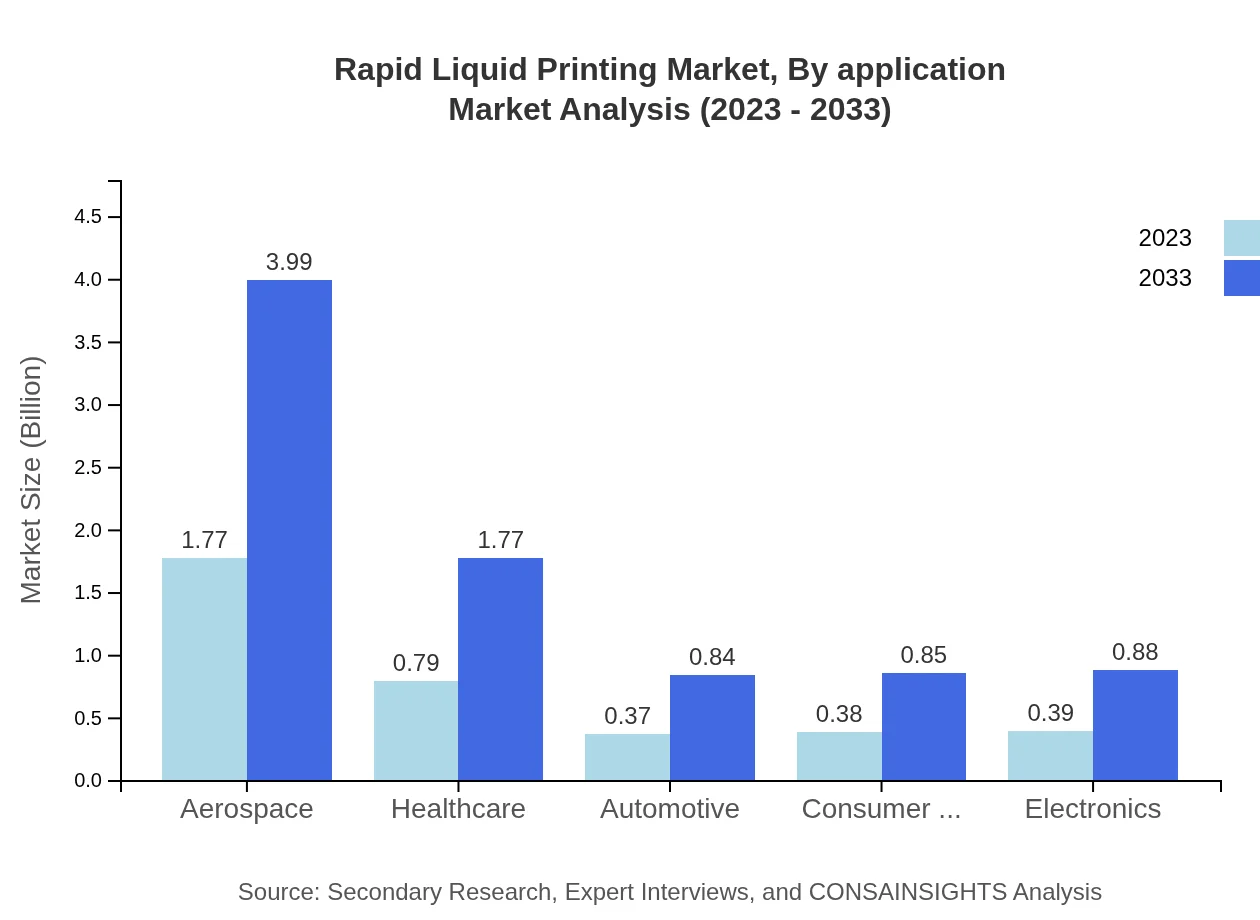

Rapid Liquid Printing Market Analysis By Application

The application segment is diverse, with aerospace leading due to its demand for rapid prototyping and production of complex parts. The market for healthcare applications is expanding as personalized medical devices gain popularity. Additionally, sectors like automotive, consumer products, and electronics are increasingly leveraging rapid liquid printing technology, contributing to its market growth.

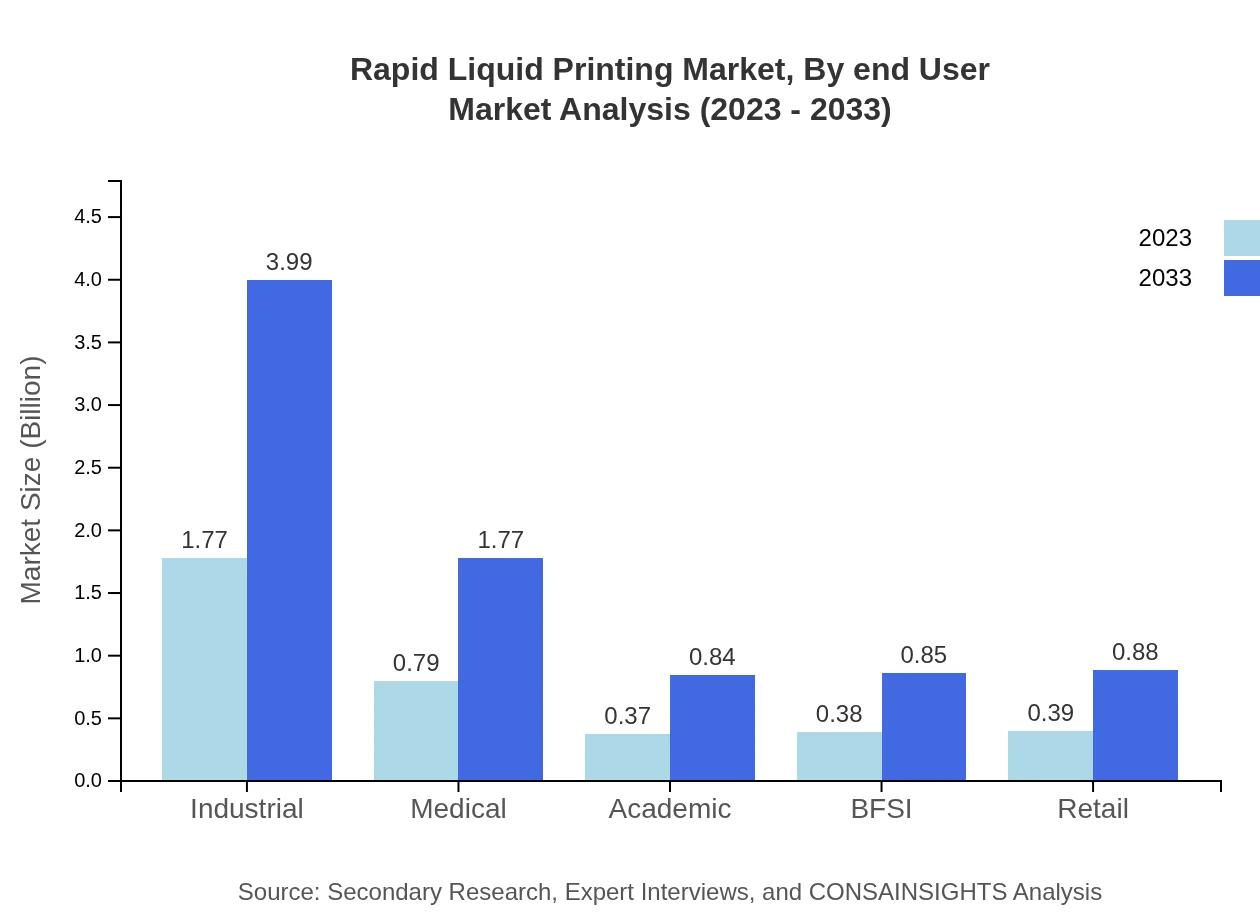

Rapid Liquid Printing Market Analysis By End User

Industrial applications lead the market, generating significant revenue due to the need for rapid prototyping and production. The medical segment is also growing, driven by investments in personalized medicine and custom solutions. Other key end-user industries include academia, BFSI, and retail, each contributing to the changing landscape of rapid manufacturing.

Rapid Liquid Printing Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Rapid Liquid Printing Industry

3D Systems:

3D Systems is a pioneer in the 3D printing industry, providing end-to-end solutions and a wide range of materials for rapid liquid printing.Stratasys:

Stratasys is recognized for its advanced 3D printing technologies and materials, particularly in the aerospace and automotive sectors.Materialise:

Materialise specializes in software solutions and services for 3D printing, contributing significantly to the rapid liquid printing landscape.Carbon, Inc.:

Carbon, Inc. is noted for its innovative DLS technology, allowing for the production of high-performance polymers at speeds that surpass conventional methods.We're grateful to work with incredible clients.

FAQs

What is the market size of Rapid Liquid Printing?

The global rapid liquid printing market is projected to reach $3.7 billion by 2033, growing at a CAGR of 8.2% from 2023. The increasing adoption of this technology across various sectors drives this growth, making it a significant market to monitor.

What are the key market players or companies in the Rapid Liquid Printing industry?

Key players in the rapid liquid printing industry include prominent companies engaged in advanced manufacturing processes and 3D printing technologies. Their innovative solutions and investment in R&D play a crucial role in capturing market share and driving industry growth.

What are the primary factors driving the growth in the Rapid Liquid Printing industry?

The growth of the rapid liquid printing industry is primarily driven by technological advancements in 3D printing, increased demand for customized and complex products, and the expanding applications of rapid prototyping across diverse sectors such as healthcare, aerospace, and automotive.

Which region is the fastest Growing in the Rapid Liquid Printing?

The Asia Pacific region is the fastest-growing in the rapid liquid printing market, with a projected market growth from $0.73 billion in 2023 to $1.66 billion by 2033. This growth is spurred by rising industrialization and adoption of advanced printing technologies.

Does ConsaInsights provide customized market report data for the Rapid Liquid Printing industry?

Yes, ConsaInsights offers customized market report data tailored to specific requirements within the rapid liquid printing industry. This includes detailed analyses, segmentation, and insights based on client needs, ensuring relevant and actionable data.

What deliverables can I expect from this Rapid Liquid Printing market research project?

From the rapid liquid printing market research project, you can expect comprehensive reports detailing market trends, segment analysis, competitive landscape, growth forecasts, and insights into emerging technologies and their impact on the industry.

What are the market trends of Rapid Liquid Printing?

Current trends in the rapid liquid printing market include the increasing use of polymers and metals, advancements in inkjet technology, and a growing focus on sustainability. These trends indicate a shift towards more efficient and eco-friendly printing solutions across various sectors.