Rice Milling Machinery Market Report

Published Date: 02 February 2026 | Report Code: rice-milling-machinery

Rice Milling Machinery Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Rice Milling Machinery market, covering key insights, trends, and projections from 2023 to 2033. It delves into market size, segmentation, regional dynamics, and leading players in the industry.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

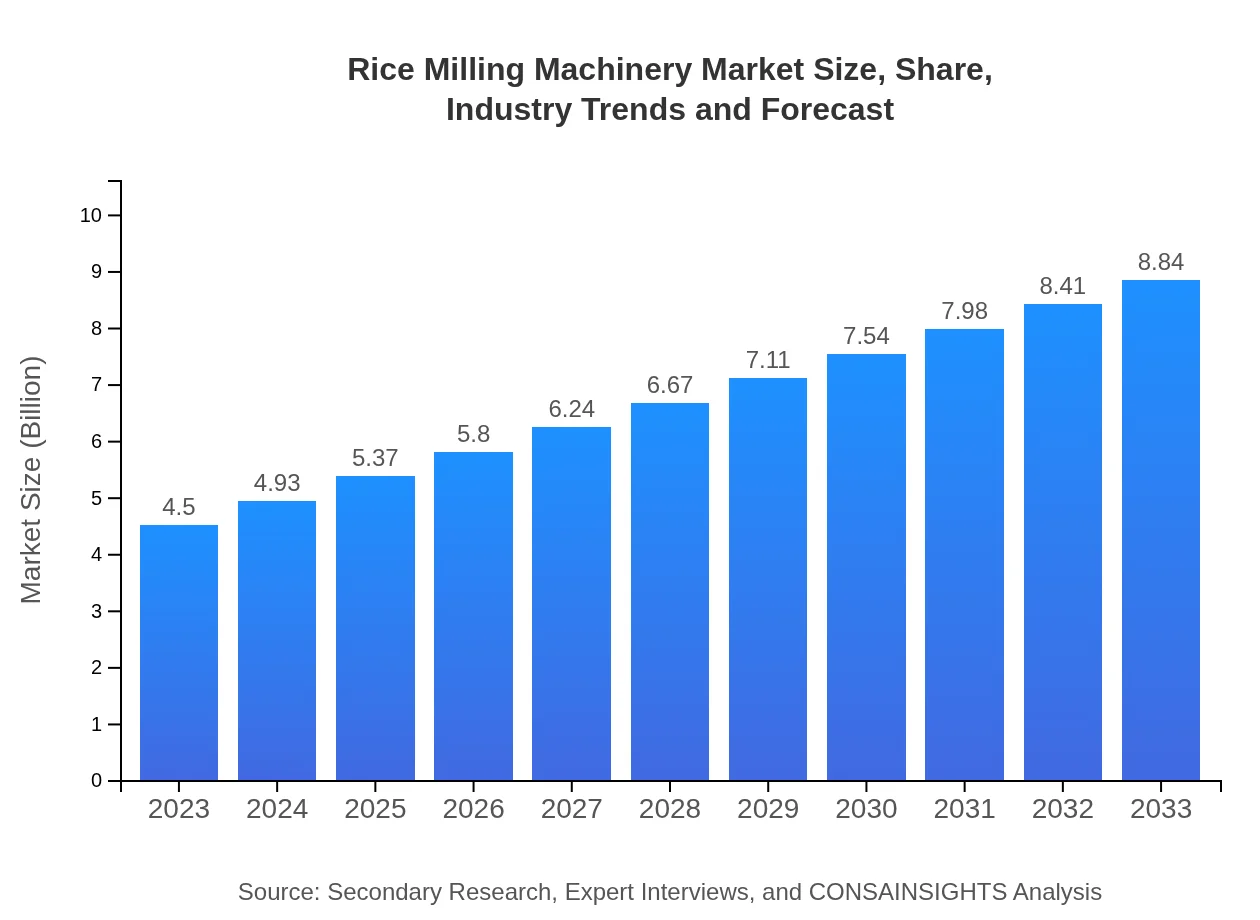

| 2023 Market Size | $4.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $8.84 Billion |

| Top Companies | Satake Corporation, Bühler Group, Köller Group, Paddy Engineering Co., Ltd. |

| Last Modified Date | 02 February 2026 |

Rice Milling Machinery Market Overview

Customize Rice Milling Machinery Market Report market research report

- ✔ Get in-depth analysis of Rice Milling Machinery market size, growth, and forecasts.

- ✔ Understand Rice Milling Machinery's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Rice Milling Machinery

What is the Market Size & CAGR of Rice Milling Machinery market in 2023?

Rice Milling Machinery Industry Analysis

Rice Milling Machinery Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Rice Milling Machinery Market Analysis Report by Region

Europe Rice Milling Machinery Market Report:

The European Rice Milling Machinery market is expected to reach $2.23 billion by 2033, growing from $1.13 billion in 2023. The rising trend towards sustainability and efficiency in food processing contributes to market growth, with countries like Italy and Spain implementing modern milling techniques.Asia Pacific Rice Milling Machinery Market Report:

In the Asia Pacific region, the Rice Milling Machinery market is expected to grow from $0.94 billion in 2023 to $1.86 billion by 2033. Strong rice production statistics in countries like India and China contribute significantly to this growth. The region’s focus on improving milling efficiency through modern machinery adoption is a substantial market driver.North America Rice Milling Machinery Market Report:

North America's market is projected to grow from $1.59 billion in 2023 to $3.13 billion by 2033. Increased demand for processed rice and advanced milling solutions, alongside a robust agribusiness sector, are vital to this region’s market expansion.South America Rice Milling Machinery Market Report:

The South American Rice Milling Machinery market is projected to increase from $0.22 billion in 2023 to $0.42 billion by 2033. The rise in local rice production and export potential are key factors, with Brazil leading in adopting advanced milling technologies to enhance productivity.Middle East & Africa Rice Milling Machinery Market Report:

The market in the Middle East and Africa is anticipated to grow from $0.61 billion in 2023 to $1.20 billion by 2033, as the region increases its rice production efforts and adopts advanced milling technology to optimize processing operations.Tell us your focus area and get a customized research report.

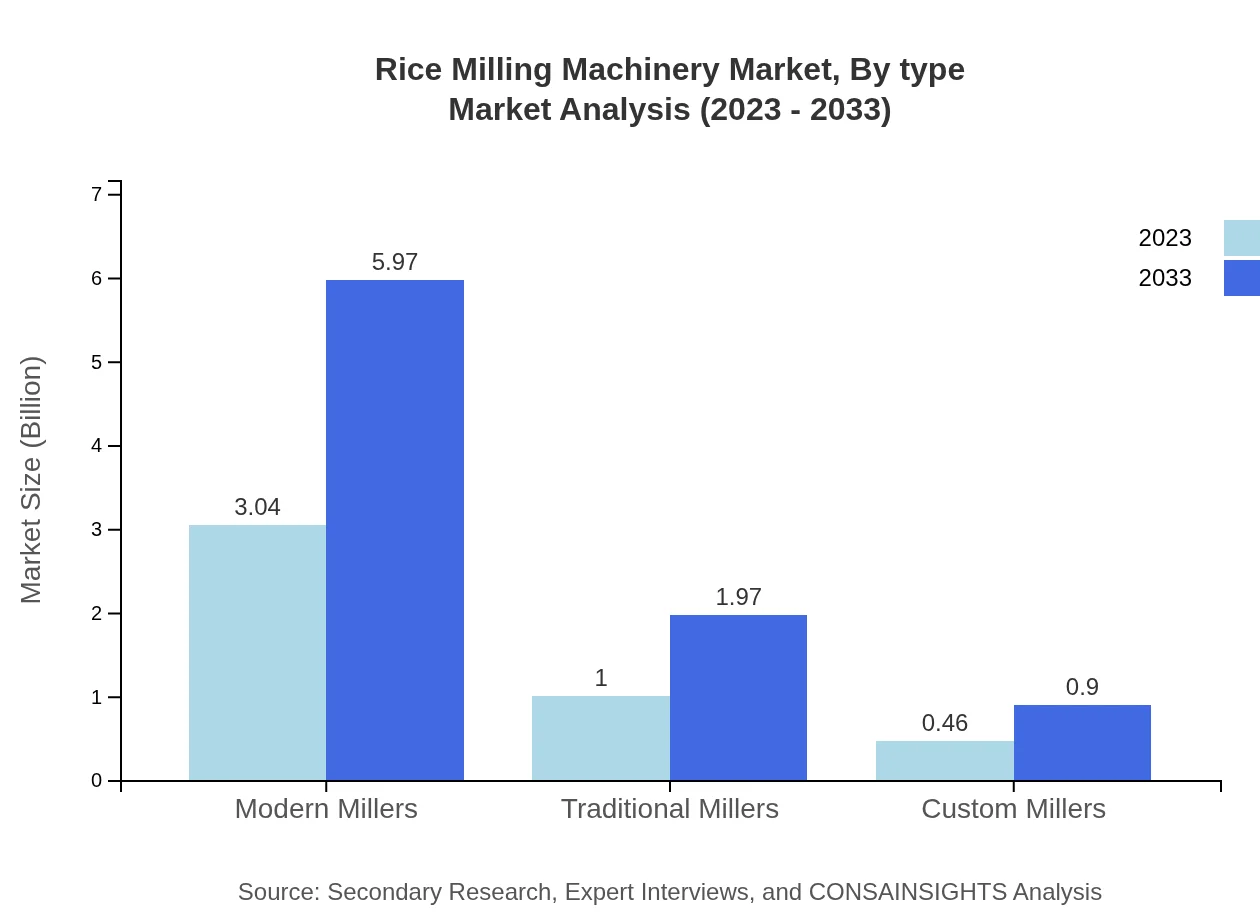

Rice Milling Machinery Market Analysis By Type

The segment highlights two primary types of rice milling: Modern and Traditional Millers. Modern Millers dominate the market with a size of $3.04 billion in 2023, expected to reach $5.97 billion by 2033. Traditional Millers account for a lesser yet significant market size of $1.00 billion in 2023, projected to grow to $1.97 billion by 2033.

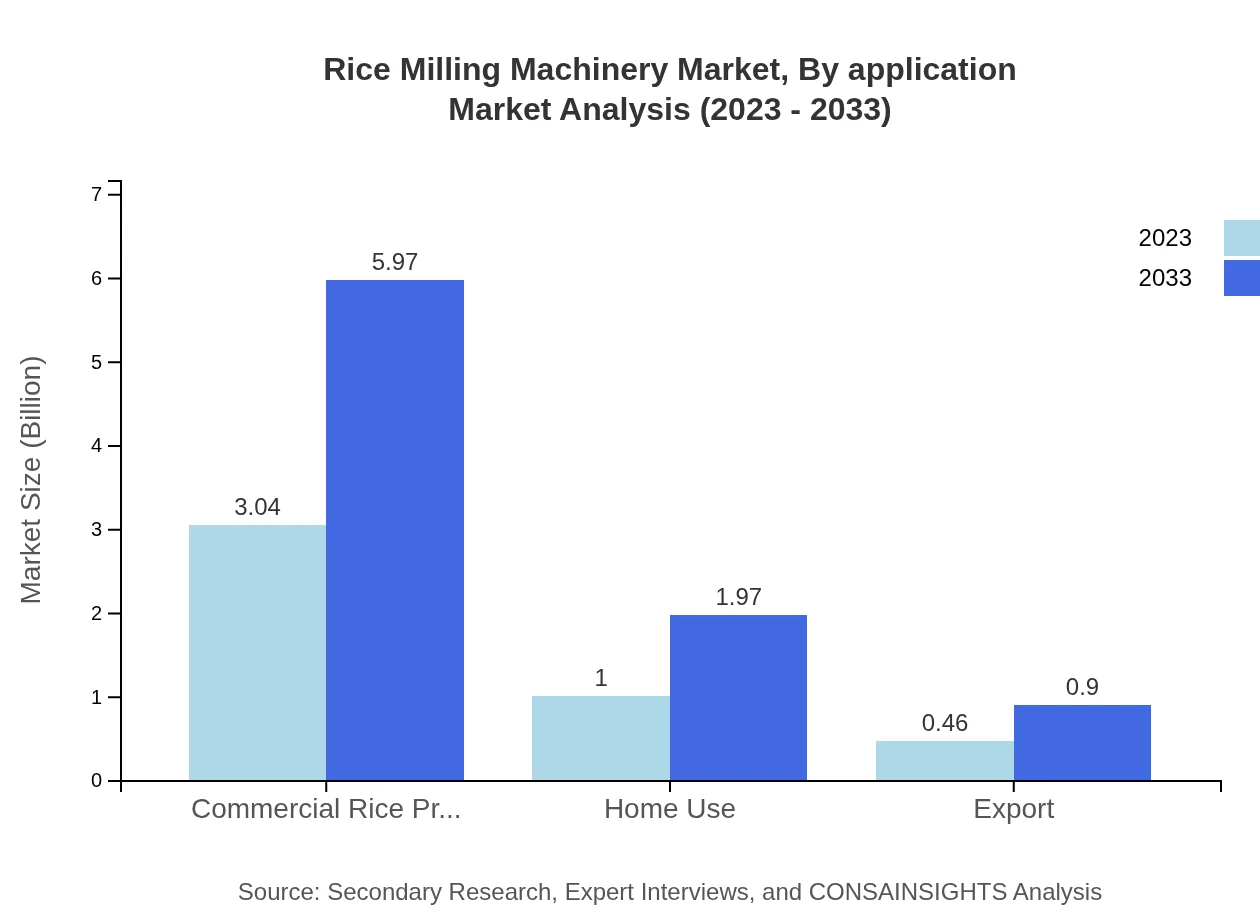

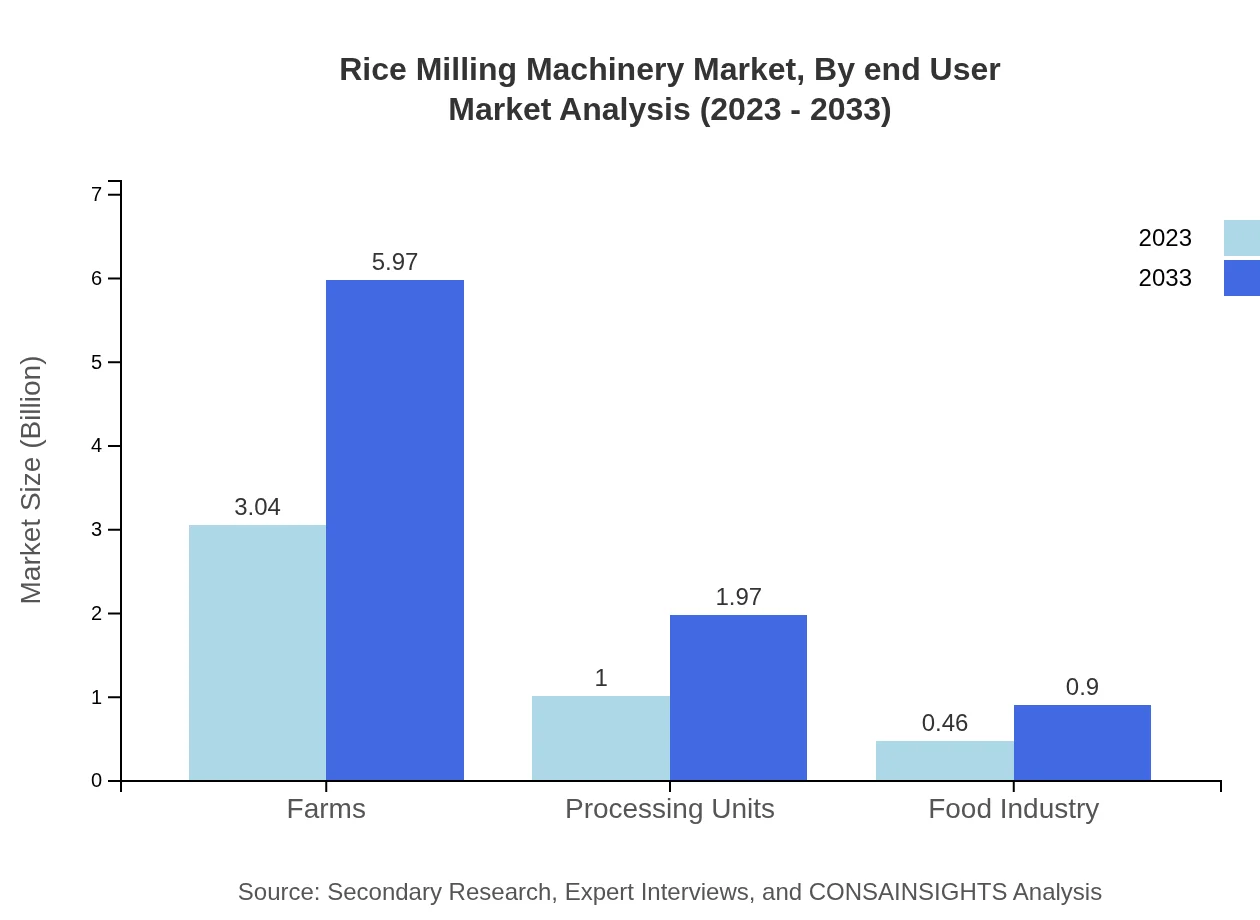

Rice Milling Machinery Market Analysis By Application

The application segment illustrates how various end-users contribute to the market. Farms represent a considerable portion with a size of $3.04 billion in 2023, increasing to $5.97 billion by 2033. Processing Units and the Food Industry show steady growth, aligning with the overall demand for rice products across sectors.

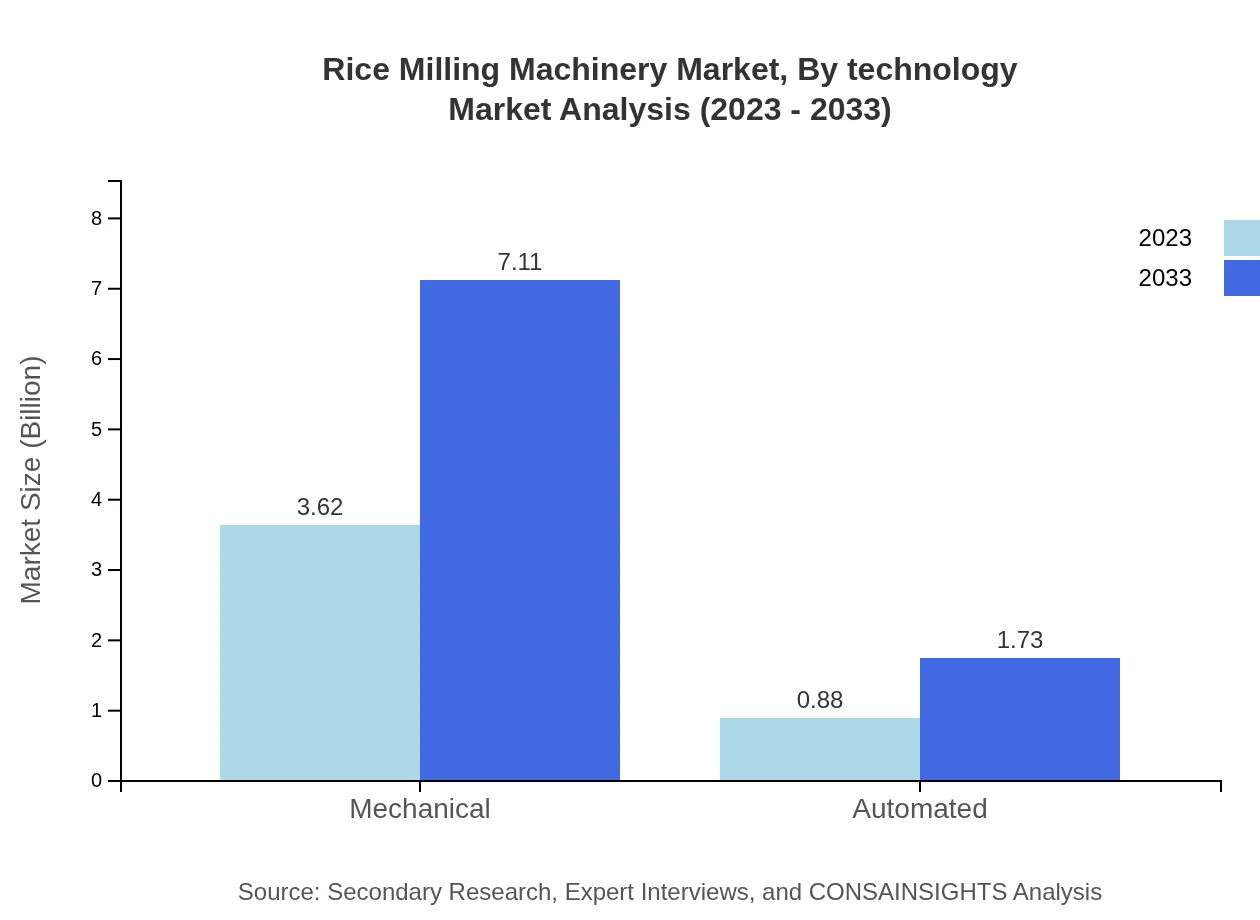

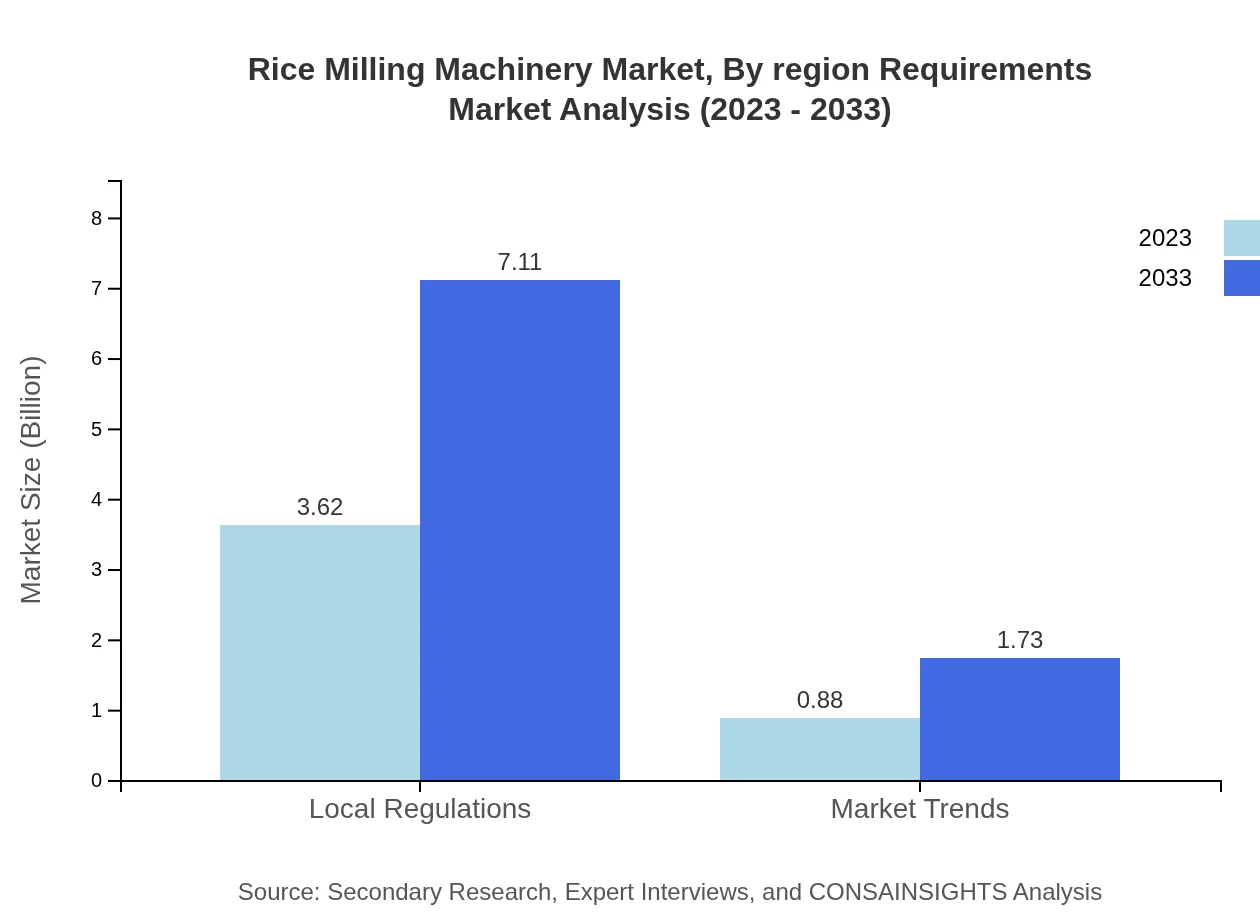

Rice Milling Machinery Market Analysis By Technology

The technology segment is split between Mechanical and Automated systems. Mechanical systems are predominant, with a market size of $3.62 billion in 2023, expected to reach $7.11 billion by 2033. Automated systems follow, growing from $0.88 billion in 2023 to $1.73 billion, driven by efficiency gains in processing.

Rice Milling Machinery Market Analysis By End User

In terms of end-user applications, Commercial Rice Processing leads with a size of $3.04 billion in 2023, projected to increase to $5.97 billion by 2033. Home Use and Export markets also see growth, though they maintain smaller market shares.

Rice Milling Machinery Market Analysis By Region Requirements

Regionally, varying requirements impact market dynamics. For instance, local regulations and sustainability initiatives push for modernized milling solutions across Europe and North America, while in Asia-Pacific, scaling production to meet growing demand is the priority.

Rice Milling Machinery Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Rice Milling Machinery Industry

Satake Corporation:

A leading global rice machinery manufacturer, Satake is known for its innovative milling technologies and contributions to improving rice processing efficiency.Bühler Group:

Offering a diverse range of milling equipment, Bühler Group integrates cutting-edge technology to enhance grain processing and food production.Köller Group:

Köller is recognized for its robust rice milling solutions and commitment to quality, supporting both industrial and small-scale milling operations.Paddy Engineering Co., Ltd.:

Specializing in rice milling and processing solutions, Paddy Engineering is a prominent player in modernizing milling technologies in Asia.We're grateful to work with incredible clients.

FAQs

What is the market size of Rice Milling Machinery?

The rice milling machinery market is valued at $4.5 billion in 2023, with a significant growth projection of a 6.8% CAGR, indicating strong demand and expansion potential over the next decade.

What are the key market players or companies in the Rice Milling Machinery industry?

Key players in the rice milling machinery industry include established manufacturers and innovators focusing on advanced milling technologies, automation, and sustainability, which drive competitive growth.

What are the primary factors driving the growth in the Rice Milling Machinery industry?

Key growth factors include increasing rice consumption, technological advancements in milling equipment, and rising demand for automated solutions to enhance efficiency and reduce labor costs.

Which region is the fastest Growing in the Rice Milling Machinery?

The Asia Pacific region represents the fastest-growing market, expected to expand from $0.94 billion in 2023 to $1.86 billion by 2033, driven by increasing agricultural production and modernization efforts.

Does ConsaInsights provide customized market report data for the Rice Milling Machinery industry?

Yes, ConsaInsights offers customized market reports tailored to the rice milling machinery industry, providing businesses specific insights and data based on their requirements.

What deliverables can I expect from this Rice Milling Machinery market research project?

Deliverables include comprehensive market analysis reports, detailed segment data, regional insights, trend forecasts, competitive landscape evaluations, and strategic recommendations.

What are the market trends of Rice Milling Machinery?

Current market trends show a shift towards greater automation in milling processes, increasing investment in environmentally sustainable technologies, and a focus on custom solutions for various milling needs.