Robot End Effector Market Report

Published Date: 31 January 2026 | Report Code: robot-end-effector

Robot End Effector Market Size, Share, Industry Trends and Forecast to 2033

This report provides a comprehensive analysis of the Robot End Effector market from 2023 to 2033, focusing on market trends, size, key segments, regional insights, and leading companies within the industry.

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

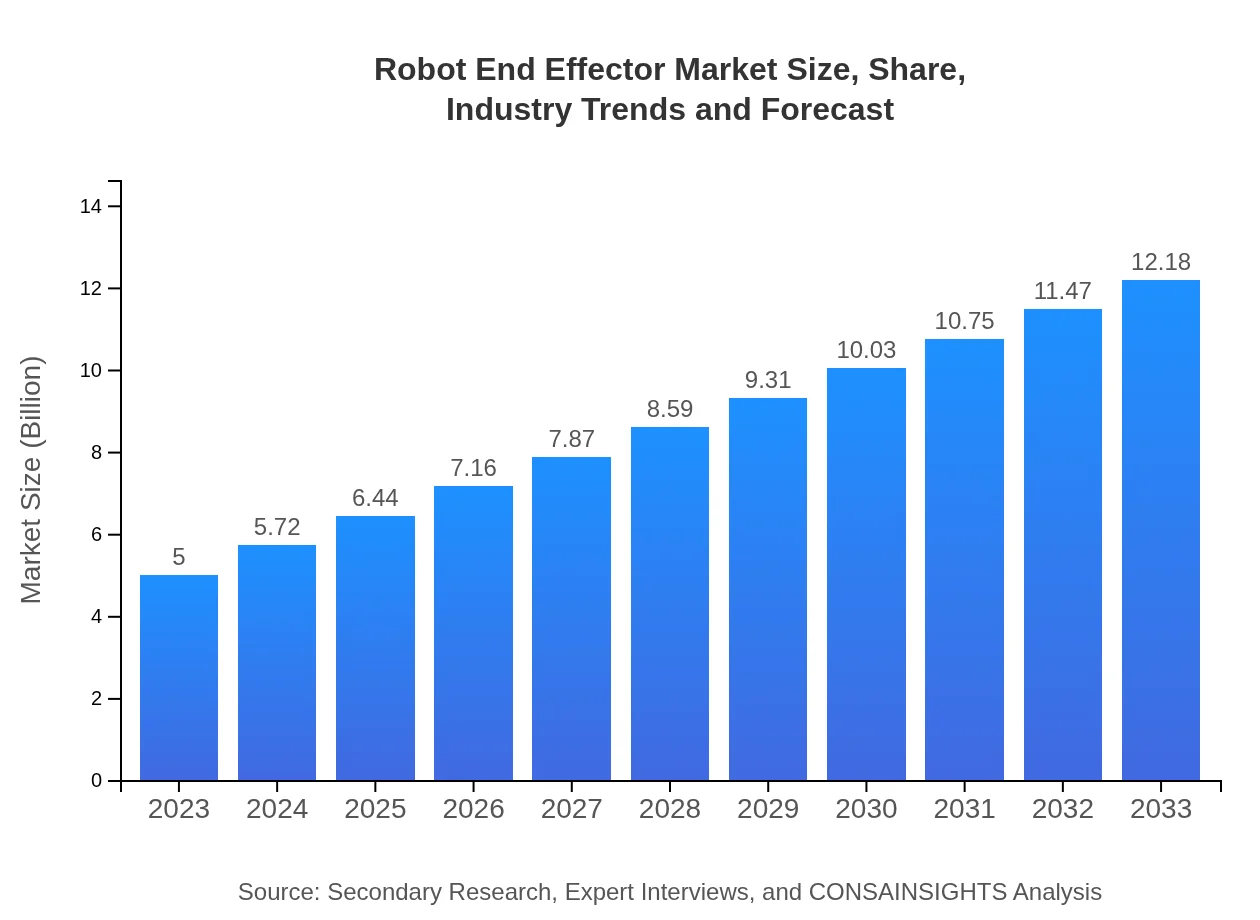

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 9% |

| 2033 Market Size | $12.18 Billion |

| Top Companies | SCHUNK, FANUC, ABB, KUKA |

| Last Modified Date | 31 January 2026 |

Robot End Effector Market Overview

Customize Robot End Effector Market Report market research report

- ✔ Get in-depth analysis of Robot End Effector market size, growth, and forecasts.

- ✔ Understand Robot End Effector's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Robot End Effector

What is the Market Size & CAGR of Robot End Effector market in 2023?

Robot End Effector Industry Analysis

Robot End Effector Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Robot End Effector Market Analysis Report by Region

Europe Robot End Effector Market Report:

In Europe, the market size was $1.47 billion in 2023, anticipated to increase to $3.57 billion by 2033. The European market’s growth is led by stringent labor laws and the push for productivity optimization across various sectors.Asia Pacific Robot End Effector Market Report:

In the Asia Pacific region, the Robot End Effector market was valued at $0.95 billion in 2023 and is projected to grow to $2.31 billion by 2033, driven by rising automation in manufacturing and increased adoption of robotics in industries like electronics and automotive.North America Robot End Effector Market Report:

The North America Robot End Effector market is valued at $1.86 billion in 2023 and is expected to reach $4.54 billion by 2033. The robust growth can be attributed to high automation levels in manufacturing and significant technological advancements in robotic systems.South America Robot End Effector Market Report:

The South American market for Robot End Effectors is smaller, with a value of $0.09 billion in 2023, expected to grow to $0.21 billion by 2033. Growth here is fueled by gradual industrialization and increasing investments in modernization processes.Middle East & Africa Robot End Effector Market Report:

For the Middle East and Africa, the market is valued at $0.64 billion in 2023, with expectations to grow to $1.55 billion by 2033. Increased adoption of automation in oil and gas, along with manufacturing, propels market growth in this region.Tell us your focus area and get a customized research report.

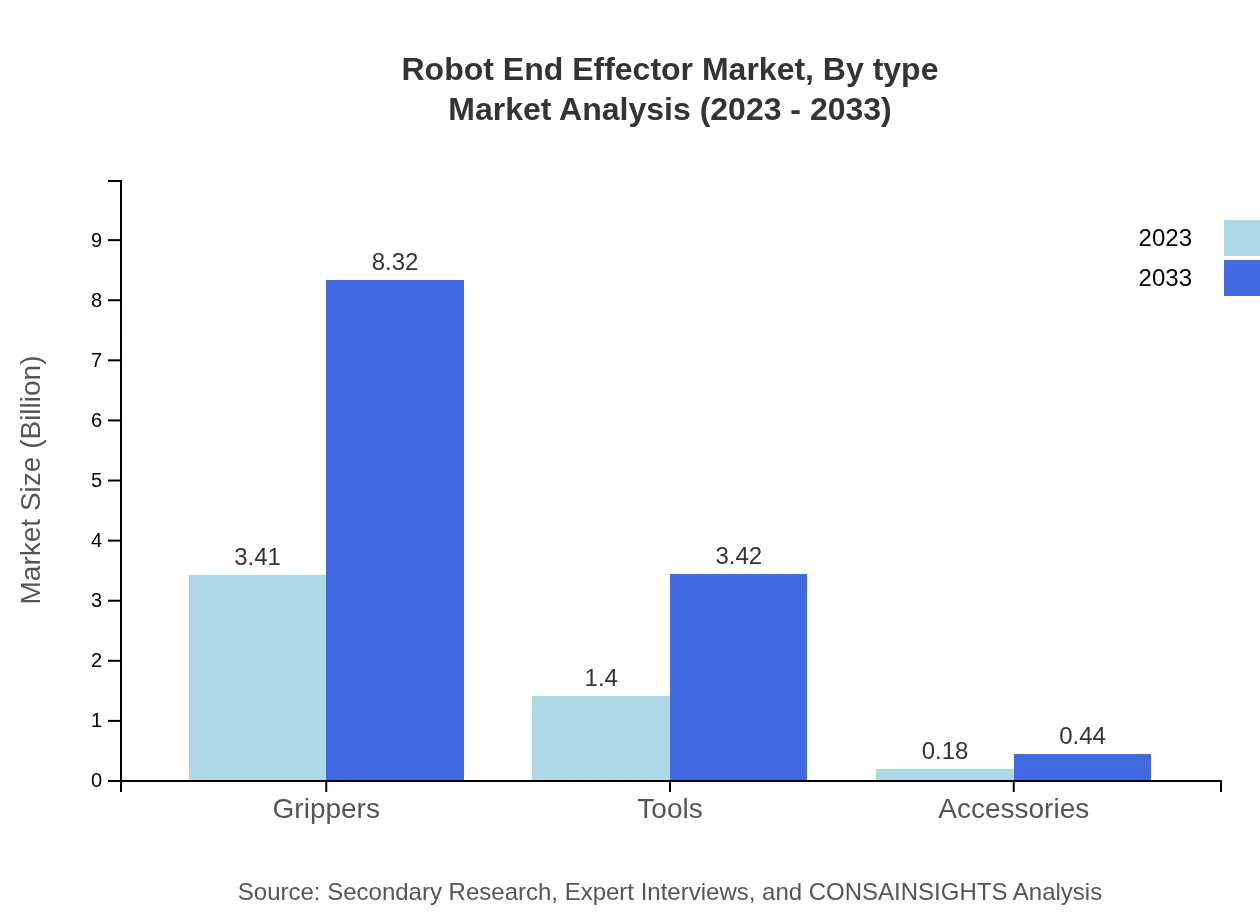

Robot End Effector Market Analysis By Type

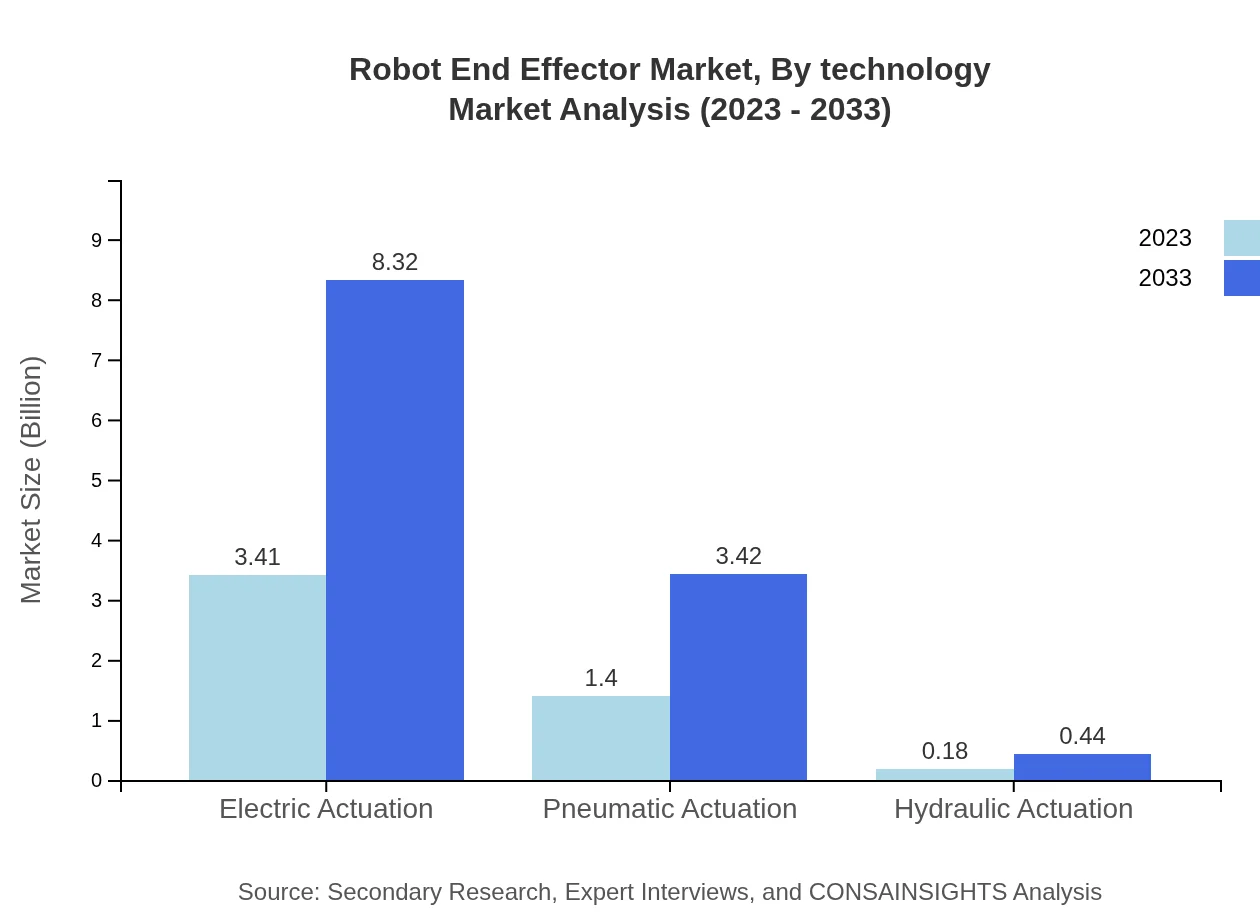

The grippers segment remains the largest in the Robot End Effector market, with a market size of $3.41 billion in 2023 and $8.32 billion in 2033. Tools and accessories also hold significant portions, with tools amounting to $1.40 billion in 2023 and expected to rise to $3.42 billion by 2033. Accessories stay comparatively smaller but are essential in niche applications.

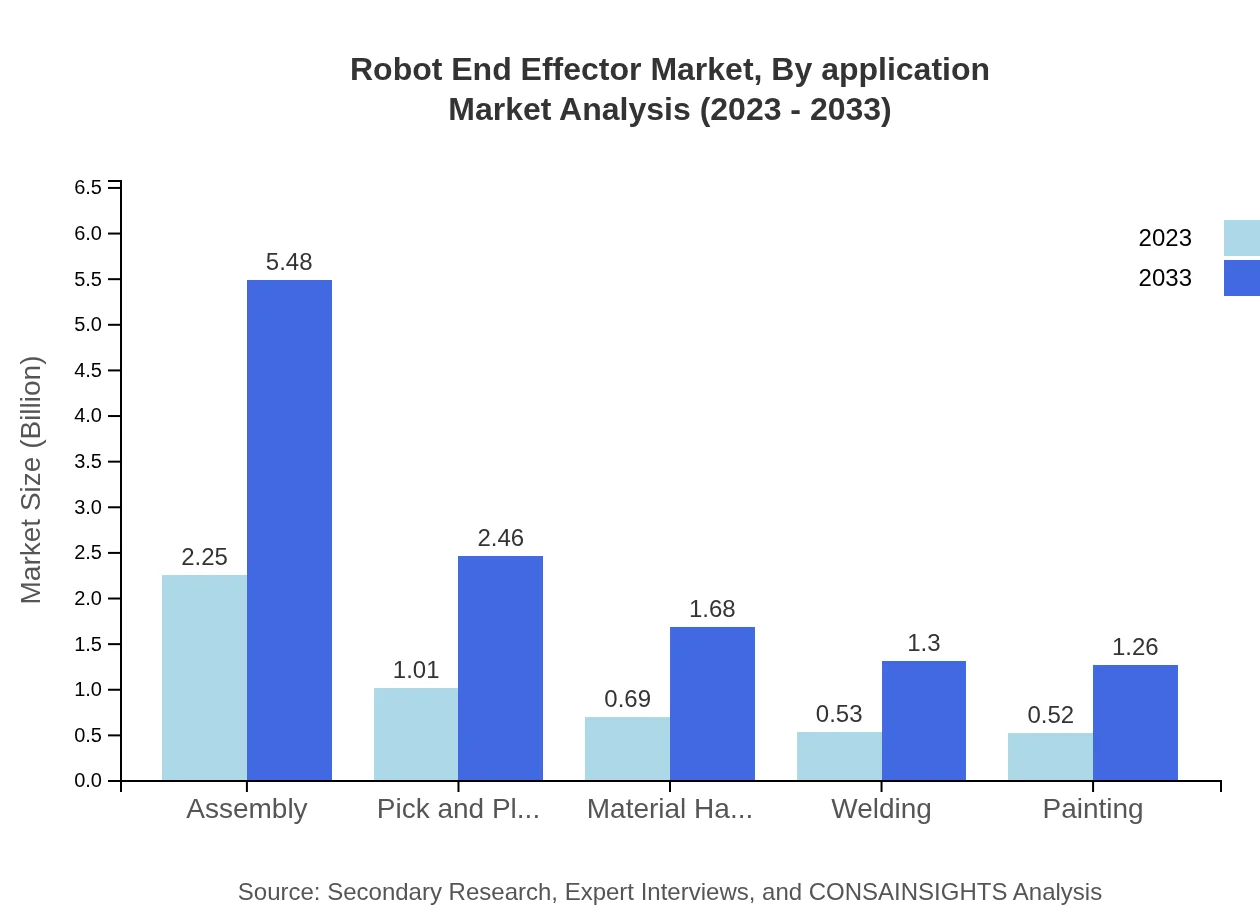

Robot End Effector Market Analysis By Application

Applications in automotive are significant, with a market size classifying it at $2.25 billion in 2023 and expected to grow to $5.48 billion by 2033. The electronics segment is also critical, currently valued at $1.01 billion and projected to reach $2.46 billion by 2033.

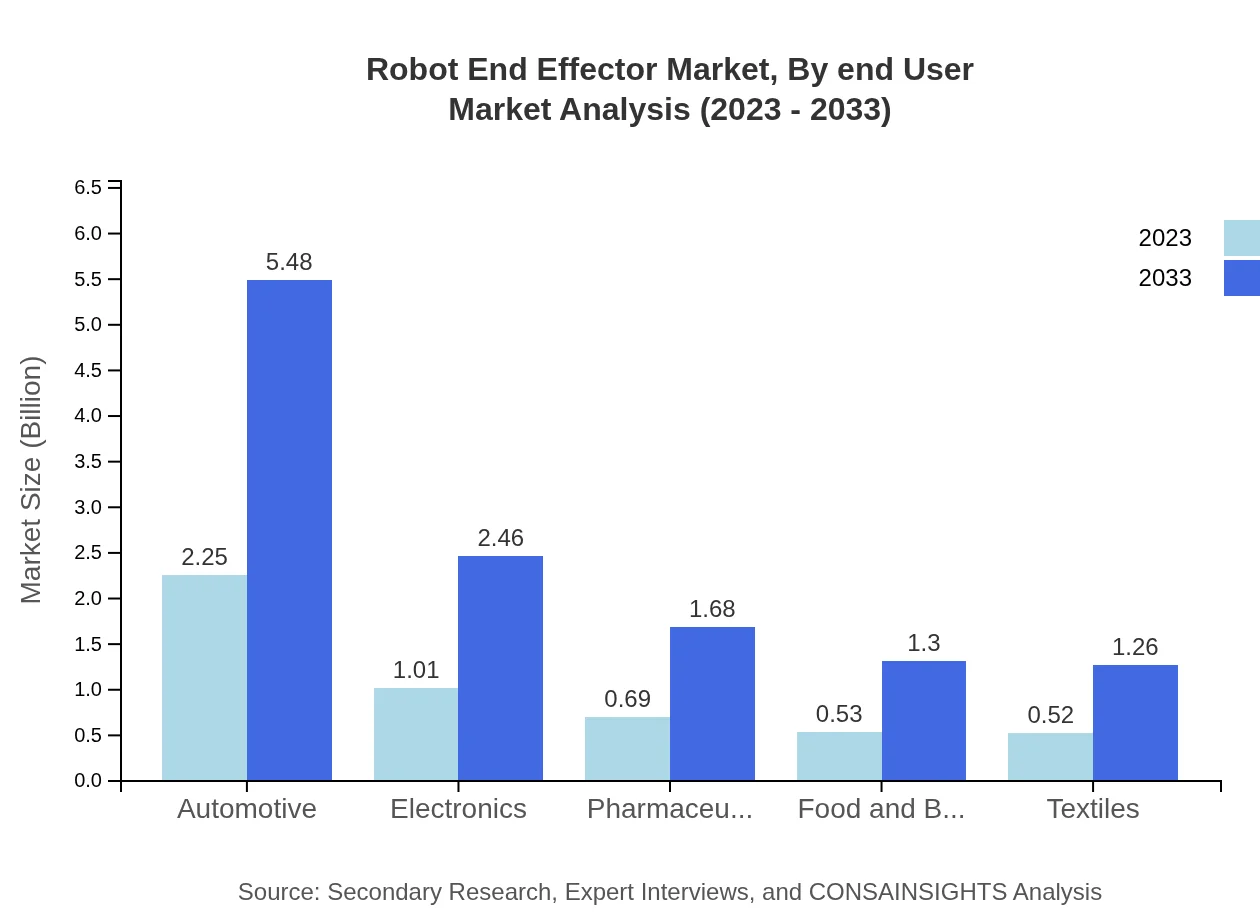

Robot End Effector Market Analysis By End User

The automotive industry accounts for nearly 45% of the Robot End Effector market share, emphasizing the critical role these tools play in automotive manufacturing processes. In contrast, industries like food & beverage and textiles show smaller, yet significant contributions.

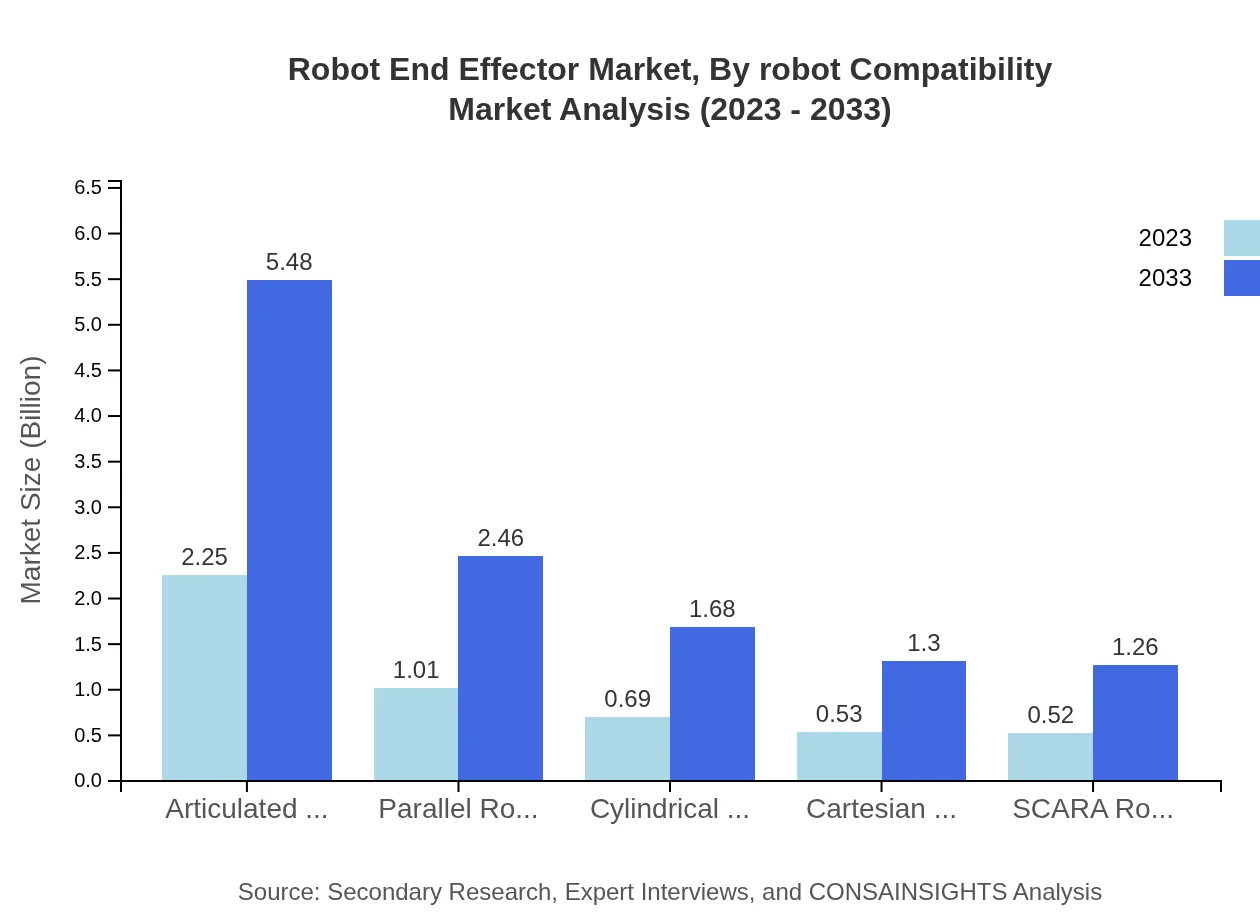

Robot End Effector Market Analysis By Robot Compatibility

Articulated robots dominate compatibility, with their segment valued at $2.25 billion in 2023 and growing to $5.48 billion by 2033. SCARA and cylindrical robots capture portions, reflecting the need for specialized end effectors across different robotic platforms.

Robot End Effector Market Analysis By Technology

Electric actuation remains the leading technology type for end effectors, with a size of $3.41 billion in 2023 and expected growth. Meanwhile, pneumatic actuation holds significant relevance in traditional manufacturing applications.

Robot End Effector Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Robot End Effector Industry

SCHUNK:

A pioneer in clamping and gripping technology, SCHUNK is recognized for its innovative solutions in the Robot End Effector space.FANUC:

FANUC is a leading manufacturer of robotics and automation, providing advanced end effectors that enhance the efficiency of autonomous operations.ABB:

ABB specializes in smart manufacturing solutions, including robotic systems and end effectors designed for diverse applications.KUKA:

KUKA is known for its advanced robotic technology and offers a range of end effectors tailored for industries like automotive and electronics.We're grateful to work with incredible clients.

FAQs

What is the market size of the robot end effector?

The global market size for robot end effectors is estimated at approximately $5 billion in 2023, with a robust CAGR of 9% expected through 2033. This growth reflects increasing automation across various sectors.

What are the key market players or companies in the robot end effector industry?

Key market players in the robot end effector industry include companies such as SCHUNK, Zimmer Group, Applied Robotics, and Robot System Products. These firms lead the market by offering innovative solutions and high-quality products.

What are the primary factors driving the growth in the robot end effector industry?

The growth in the robot end effector industry is primarily driven by the increasing demand for automation, advancements in robotic technology, and the need for manufacturing efficiency in industries like automotive and electronics.

Which region is the fastest Growing in the robot end effector?

The Asia Pacific region is the fastest-growing market for robot end effectors, expecting to rise from $0.95 billion in 2023 to $2.31 billion by 2033, fueled by rapid industrialization and technological advancements.

Does ConsaInsights provide customized market report data for the robot end effector industry?

Yes, ConsaInsights offers customized market report data tailored to specific needs in the robot end effector industry, providing insights based on parameters such as regions, segments, and growth drivers.

What deliverables can I expect from this robot end effector market research project?

Deliverables from this market research project will typically include comprehensive reports on market size, segmentation analysis, competitor profiling, regional breakdowns, and future growth projections for the robot end effector market.

What are the market trends of robot end effector?

Market trends for robot end effectors include increased integration of AI and machine learning, a shift towards collaborative robots, and growing applications in diverse fields such as pharmaceuticals, automotive, and food processing.