Robotic Arms In Laboratories Market Report

Published Date: 22 January 2026 | Report Code: robotic-arms-in-laboratories

Robotic Arms In Laboratories Market Size, Share, Industry Trends and Forecast to 2033

This report offers a comprehensive analysis of the Robotic Arms in Laboratories market, presenting insights on market dynamics, segmentation, and growth forecasts from 2023 to 2033, including factors driving the market and potential challenges ahead.

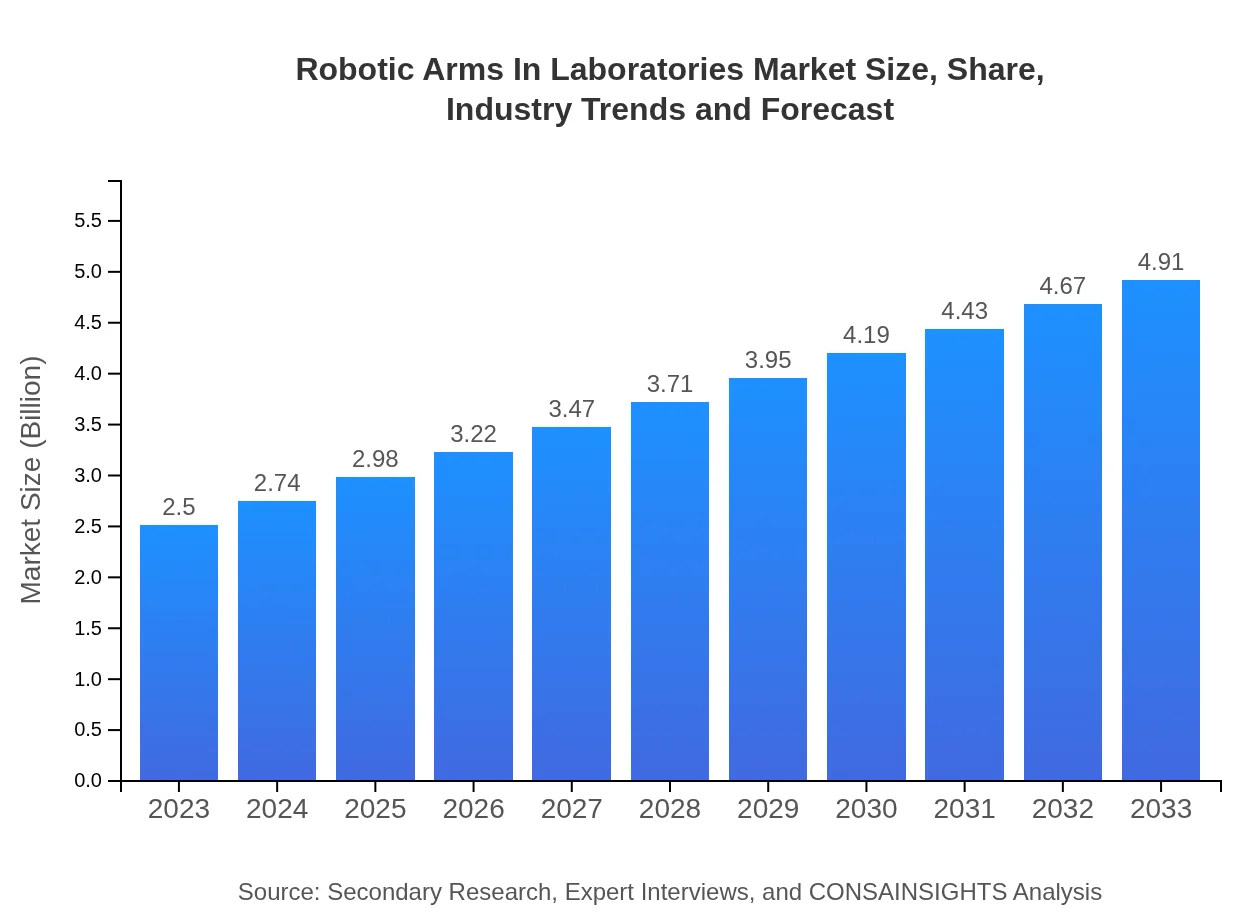

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 6.8% |

| 2033 Market Size | $4.91 Billion |

| Top Companies | KUKA AG, ABB Robotics, FANUC Corporation, Universal Robots |

| Last Modified Date | 22 January 2026 |

Robotic Arms In Laboratories Market Overview

Customize Robotic Arms In Laboratories Market Report market research report

- ✔ Get in-depth analysis of Robotic Arms In Laboratories market size, growth, and forecasts.

- ✔ Understand Robotic Arms In Laboratories's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Robotic Arms In Laboratories

What is the Market Size & CAGR of Robotic Arms In Laboratories market in 2023?

Robotic Arms In Laboratories Industry Analysis

Robotic Arms In Laboratories Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Robotic Arms In Laboratories Market Analysis Report by Region

Europe Robotic Arms In Laboratories Market Report:

The European market is set to grow from USD 0.67 billion in 2023 to USD 1.32 billion by 2033. A robust focus on technological advances and sustainability in laboratory environments bolsters the demand for robotic arms across academic and industrial sectors.Asia Pacific Robotic Arms In Laboratories Market Report:

In the Asia-Pacific region, the Robotic Arms in Laboratories market is expected to grow from USD 0.49 billion in 2023 to USD 0.96 billion in 2033. This growth is driven by increased investment in research and development across countries like China, India, and Japan, along with the growing adoption of AI and robotics technologies in laboratories.North America Robotic Arms In Laboratories Market Report:

North America, leading the market, is projected to advance from USD 0.81 billion in 2023 to USD 1.60 billion in 2033. With major players based in the U.S. and Canada, the region benefits from extensive R&D activities, as well as significant public and private sector investments in automation.South America Robotic Arms In Laboratories Market Report:

The South American market for Robotic Arms in Laboratories is estimated to see growth from USD 0.21 billion in 2023 to USD 0.40 billion in 2033. Factors such as rising educational advancements and government initiatives to foster technological innovations contribute to this growth.Middle East & Africa Robotic Arms In Laboratories Market Report:

In the Middle East and Africa, the market is expected to increase from USD 0.32 billion in 2023 to USD 0.63 billion in 2033. Growth in this region is driven by an increasing emphasis on automation technologies in laboratories to enhance efficiency and output.Tell us your focus area and get a customized research report.

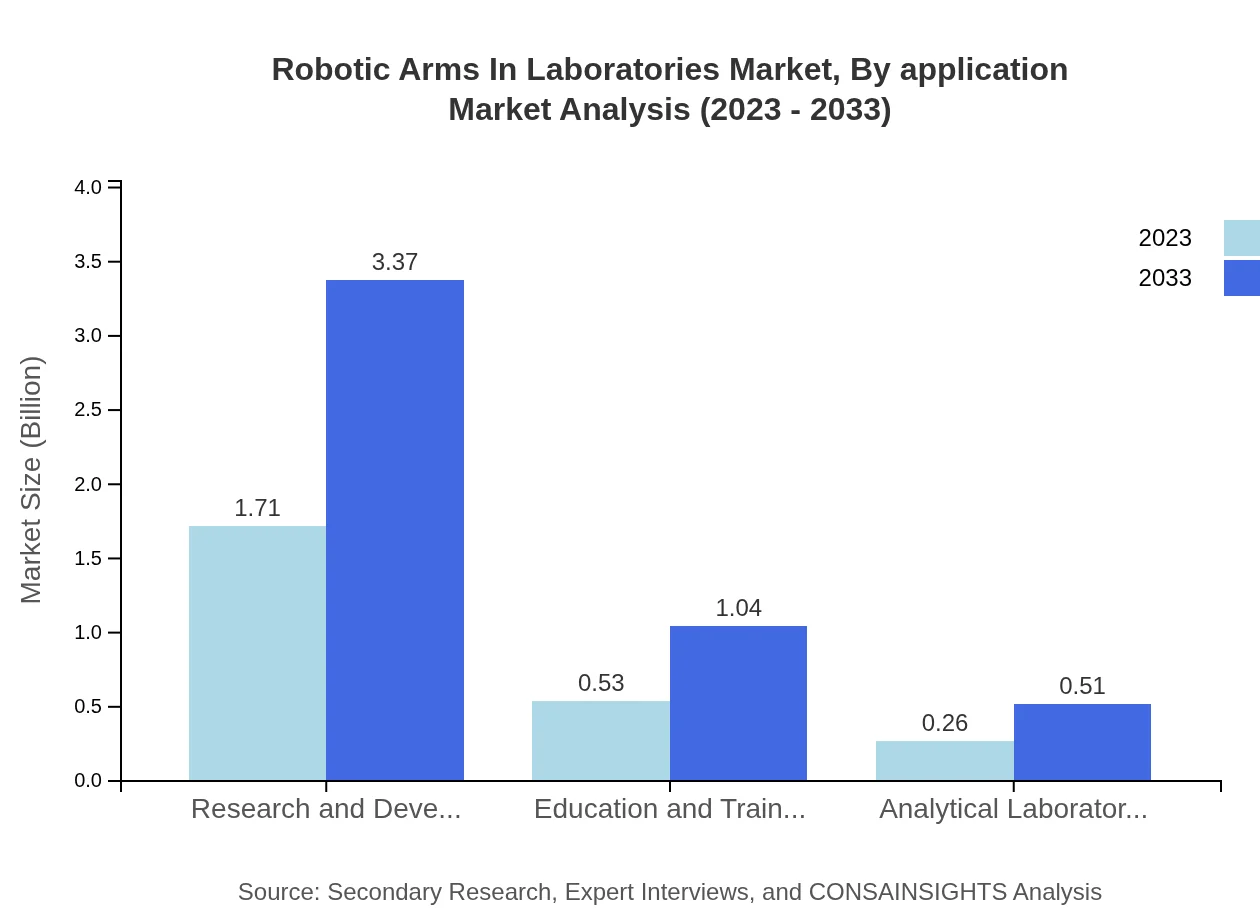

Robotic Arms In Laboratories Market Analysis By Application

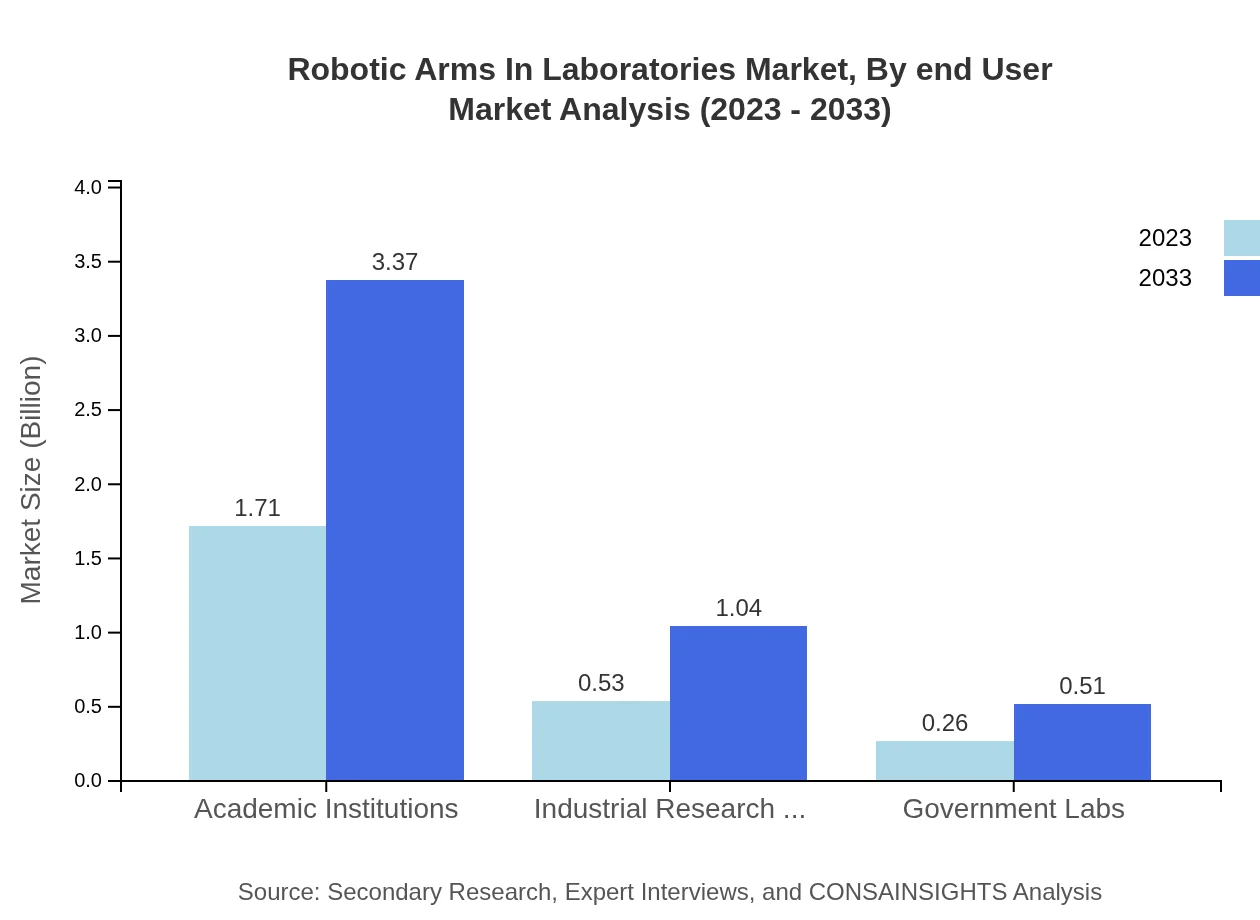

The application segment for Robotic Arms in Laboratories indicates that academic institutions will experience significant growth, increasing from USD 1.71 billion in 2023 to USD 3.37 billion in 2033, maintaining a market share of approximately 68.53%. Industrial research organizations are also notable, with an anticipated size increase from USD 0.53 billion to USD 1.04 billion, holding 21.12% of the market share. Government labs will see growth from USD 0.26 billion to USD 0.51 billion, consistent with a 10.35% market share in both years.

Robotic Arms In Laboratories Market Analysis By Technology

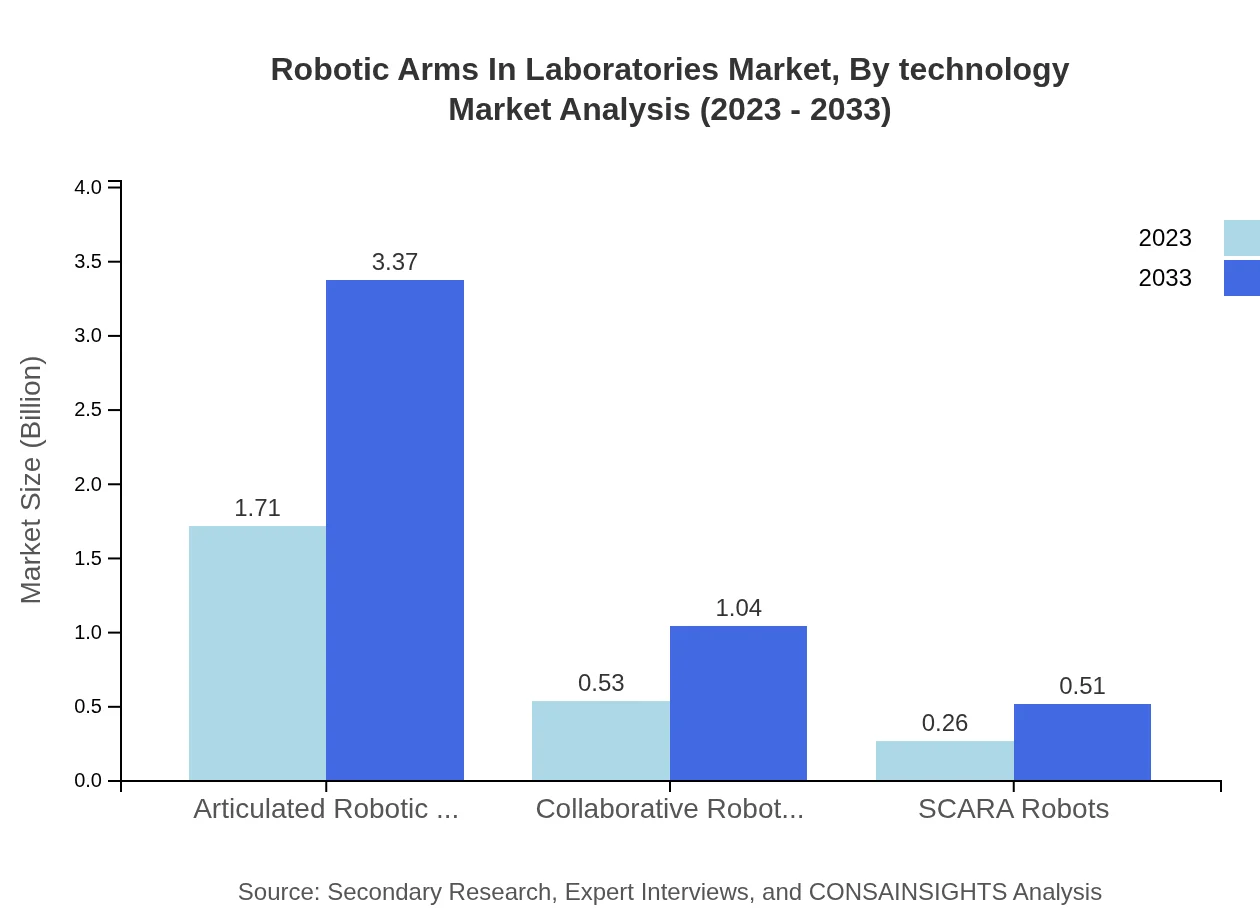

The technology segment indicates that articulated robotic arms are dominant, with a market size progression from USD 1.71 billion in 2023 to USD 3.37 billion in 2033, retaining a share of 68.53%. Collaborative robots (cobots) are also growing from USD 0.53 billion to USD 1.04 billion. SCARA robots, though smaller, still see a rise from USD 0.26 billion to USD 0.51 billion.

Robotic Arms In Laboratories Market Analysis By End User

In terms of end-user, research and development take the lead with a market size of USD 1.71 billion in 2023, rising to USD 3.37 billion by 2033, composing 68.53% of the market. The education and training sector is estimated to grow from USD 0.53 billion to USD 1.04 billion, and analytical laboratories will experience growth from USD 0.26 billion to USD 0.51 billion.

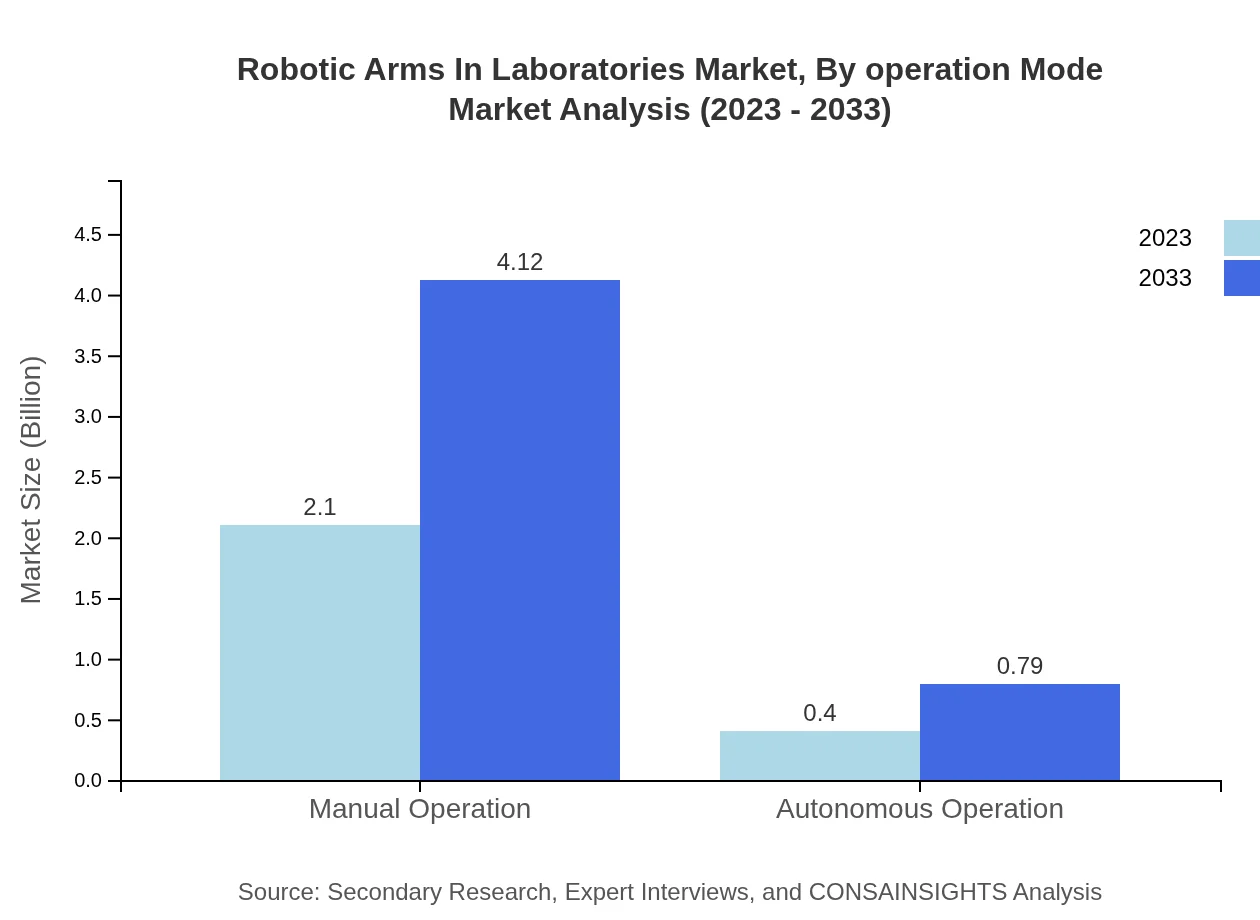

Robotic Arms In Laboratories Market Analysis By Operation Mode

The operation mode segment reveals manual operation dominating the market, showing a size of USD 2.10 billion in 2023, predicted to grow to USD 4.12 billion by 2033, and holding a substantial market share of 83.89%. Autonomous operation, while smaller, is expected to increase from USD 0.40 billion to USD 0.79 billion, capturing a 16.11% share.

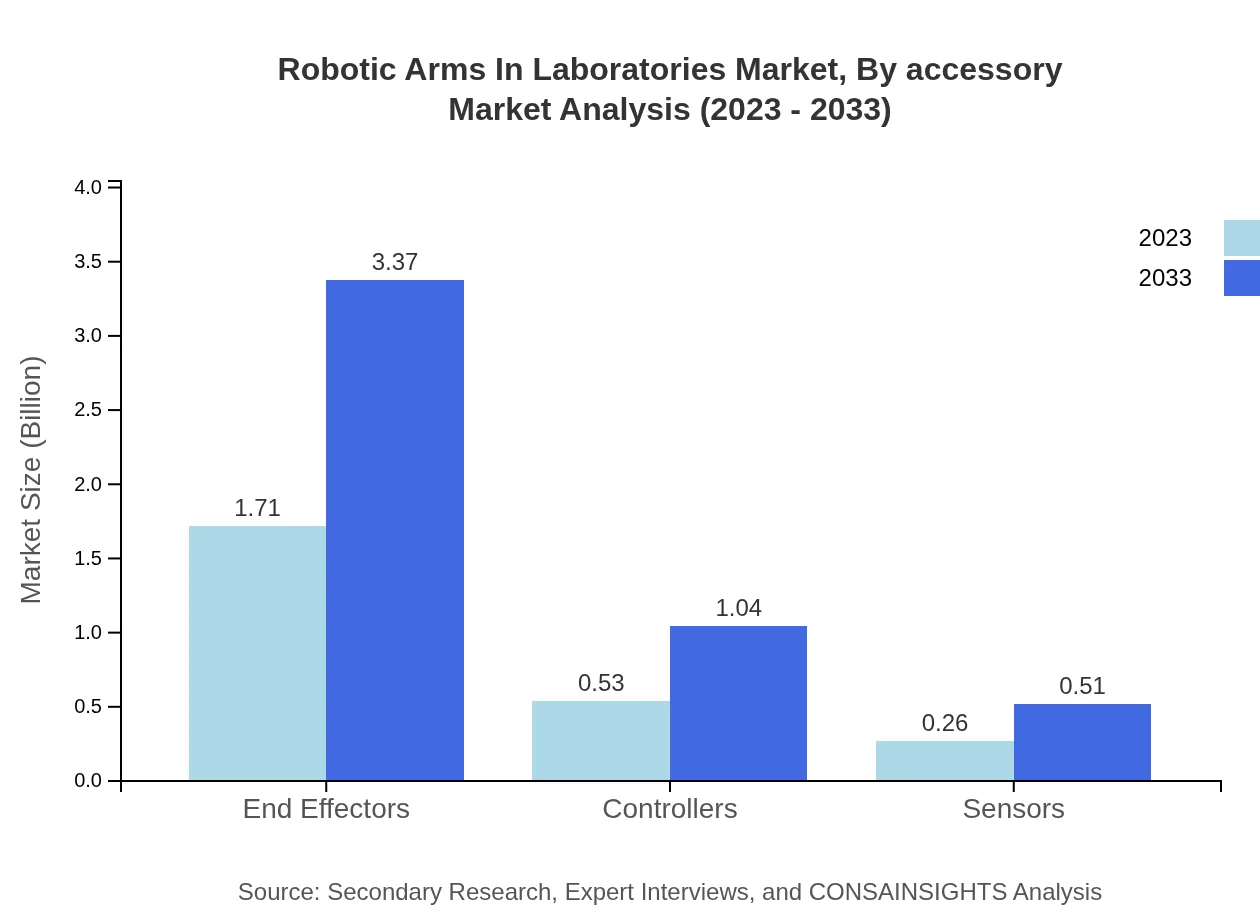

Robotic Arms In Laboratories Market Analysis By Accessory

In the accessory segment, end effectors are critical, growing from USD 1.71 billion in 2023 to USD 3.37 billion by 2033, maintaining a dominant share of 68.53%. Controllers and sensors are also significant, with expected sizes of USD 0.53 billion and USD 0.26 billion in 2023, growing to USD 1.04 billion and USD 0.51 billion, respectively.

Robotic Arms In Laboratories Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Robotic Arms In Laboratories Industry

KUKA AG:

KUKA AG is a leading manufacturer of industrial robots and automation solutions, known for its advanced robotic arms that are widely used in laboratories and industrial settings.ABB Robotics:

ABB Robotics specializes in robotics and automation technologies, offering a comprehensive range of robotic solutions suitable for various laboratory applications.FANUC Corporation:

FANUC Corporation offers a diverse range of industrial robotics solutions, providing cutting-edge robotic arms that enhance laboratory automation and efficiency.Universal Robots:

Universal Robots designs collaborative robots (cobots) widely utilized in laboratory environments, emphasizing ease of use and flexible operation.We're grateful to work with incredible clients.

FAQs

What is the market size of robotic Arms In Laboratories?

The global market size for robotic arms in laboratories is estimated to be $2.5 billion in 2023, with a projected CAGR of 6.8%. This growth reflects the increasing adoption of automation in laboratory settings that enhance efficiency and precision.

What are the key market players or companies in the robotic Arms In Laboratories industry?

Key players in the robotic arms in laboratories market include companies specializing in automation technologies and robotics solutions. Notable companies include ABB Ltd., KUKA AG, Yaskawa Electric Corporation, and Universal Robots, which contribute significantly to market innovation and growth.

What are the primary factors driving the growth in the robotic Arms In Laboratories industry?

Growth drivers for robotic arms in laboratories include the rise in automation demand, technological advancements in robotics, increasing precision requirements in research, and the growing number of laboratories worldwide. These factors collectively enhance productivity in research and testing environments.

Which region is the fastest Growing in the robotic Arms In Laboratories?

North America is the fastest-growing region for robotic arms in laboratories, projected to expand from $0.81 billion in 2023 to $1.60 billion by 2033. This growth is supported by high investments in research and the adoption of innovative technologies in laboratories.

Does ConsaInsights provide customized market report data for the robotic Arms In Laboratories industry?

Yes, ConsaInsights offers customized market report data tailored to the specific needs of businesses in the robotic arms in laboratories industry. Clients can request reports focusing on detailed segment analysis, regional insights, or competitive landscapes for informed decision-making.

What deliverables can I expect from this robotic Arms In Laboratories market research project?

Deliverables from the market research project include comprehensive reports detailing market size, growth projections, segment analysis, competitive landscape, and regional insights. Additionally, clients receive actionable recommendations and strategic guidelines based on market data.

What are the market trends of robotic Arms In Laboratories?

Current market trends include increased automation in laboratories, adoption of collaborative robots, and advancements in artificial intelligence for robotic systems. Predictive maintenance and enhanced sensor technologies also drive innovation within this sector, promoting efficiency and operational excellence.