Robotic Drilling Market Report

Published Date: 31 January 2026 | Report Code: robotic-drilling

Robotic Drilling Market Size, Share, Industry Trends and Forecast to 2033

This report analyzes the Robotic Drilling market's current trends, growth forecasts until 2033, regional insights, and technological advancements. It provides a comprehensive overview of market dynamics, size, segmentation, and key players influencing the industry's future.

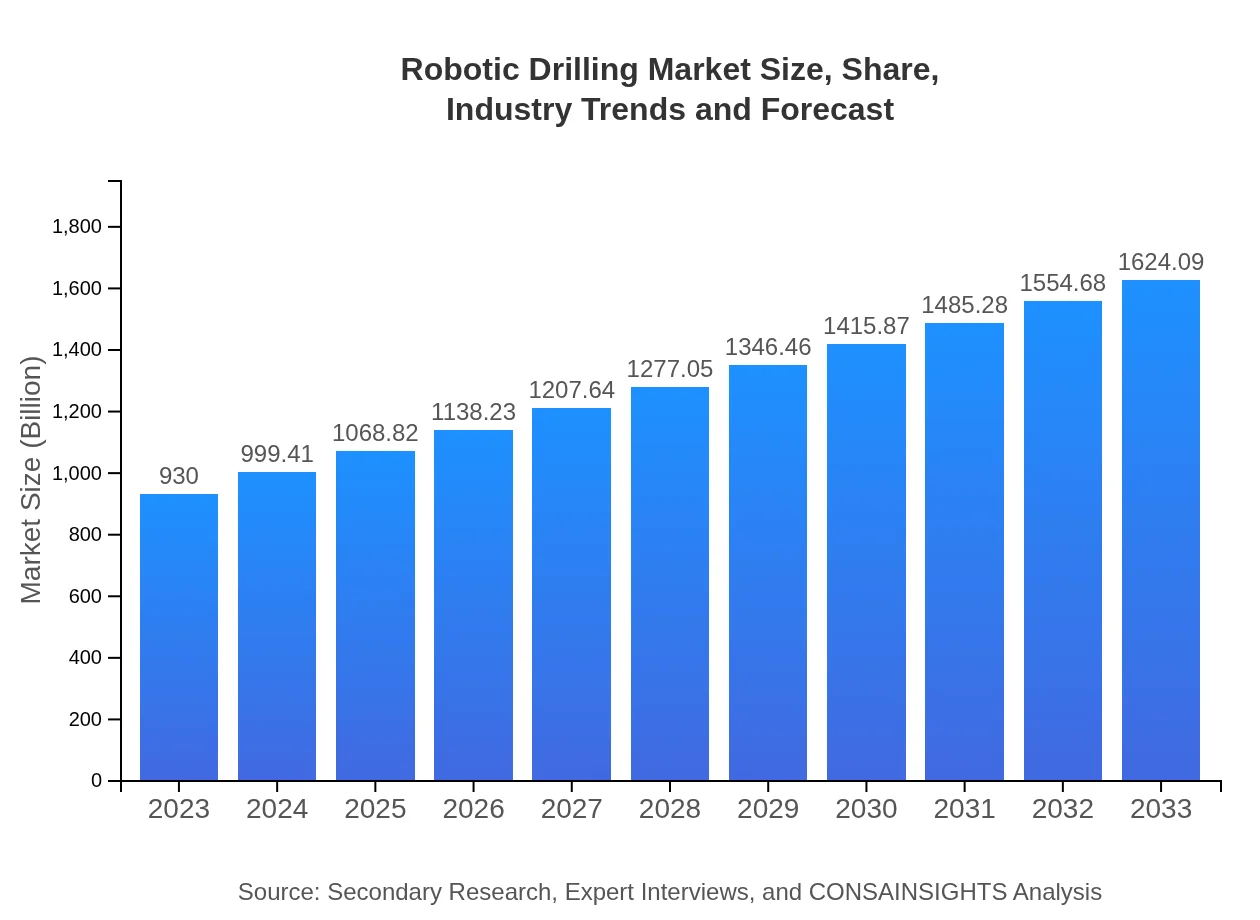

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $930.00 Million |

| CAGR (2023-2033) | 5.6% |

| 2033 Market Size | $1624.09 Million |

| Top Companies | Schlumberger, Halliburton, Baker Hughes, Emerson Electric Co. |

| Last Modified Date | 31 January 2026 |

Robotic Drilling Market Overview

Customize Robotic Drilling Market Report market research report

- ✔ Get in-depth analysis of Robotic Drilling market size, growth, and forecasts.

- ✔ Understand Robotic Drilling's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Robotic Drilling

What is the Market Size & CAGR of Robotic Drilling market in 2023?

Robotic Drilling Industry Analysis

Robotic Drilling Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Robotic Drilling Market Analysis Report by Region

Europe Robotic Drilling Market Report:

Europe's Robotic Drilling market, valued at $308.67 million in 2023, is projected to grow to $539.04 million by 2033. The growing focus on sustainability and safety standards in drilling practices is pushing companies to innovate, making robotic drilling solutions more mainstream.Asia Pacific Robotic Drilling Market Report:

In the Asia Pacific region, the Robotic Drilling market is projected to grow from $169.54 million in 2023 to $296.07 million in 2033. The growth is driven by rapid industrialization and increasing investments in automation, particularly in countries like China and India, which are scaling up their drilling operations to meet rising energy demands.North America Robotic Drilling Market Report:

In North America, the market is growing from $323.08 million in 2023 to $564.21 million in 2033. The surge is primarily fueled by the demand for automation in oil and gas extraction, particularly in the U.S. and Canada, where companies are increasingly adopting robotic solutions to enhance operational efficiency and reduce costs.South America Robotic Drilling Market Report:

South America is expected to see a rise in the Robotic Drilling market from $28.55 million in 2023 to $49.86 million by 2033. The mining sector in Brazil and Chile is a significant contributor to this growth, with enhanced drilling technologies improving extraction processes.Middle East & Africa Robotic Drilling Market Report:

The Robotic Drilling market in the Middle East and Africa is set to grow from $100.16 million in 2023 to $174.91 million by 2033. The region’s emphasis on resource extraction and management of geological data is propelling the adoption of advanced drilling technologies.Tell us your focus area and get a customized research report.

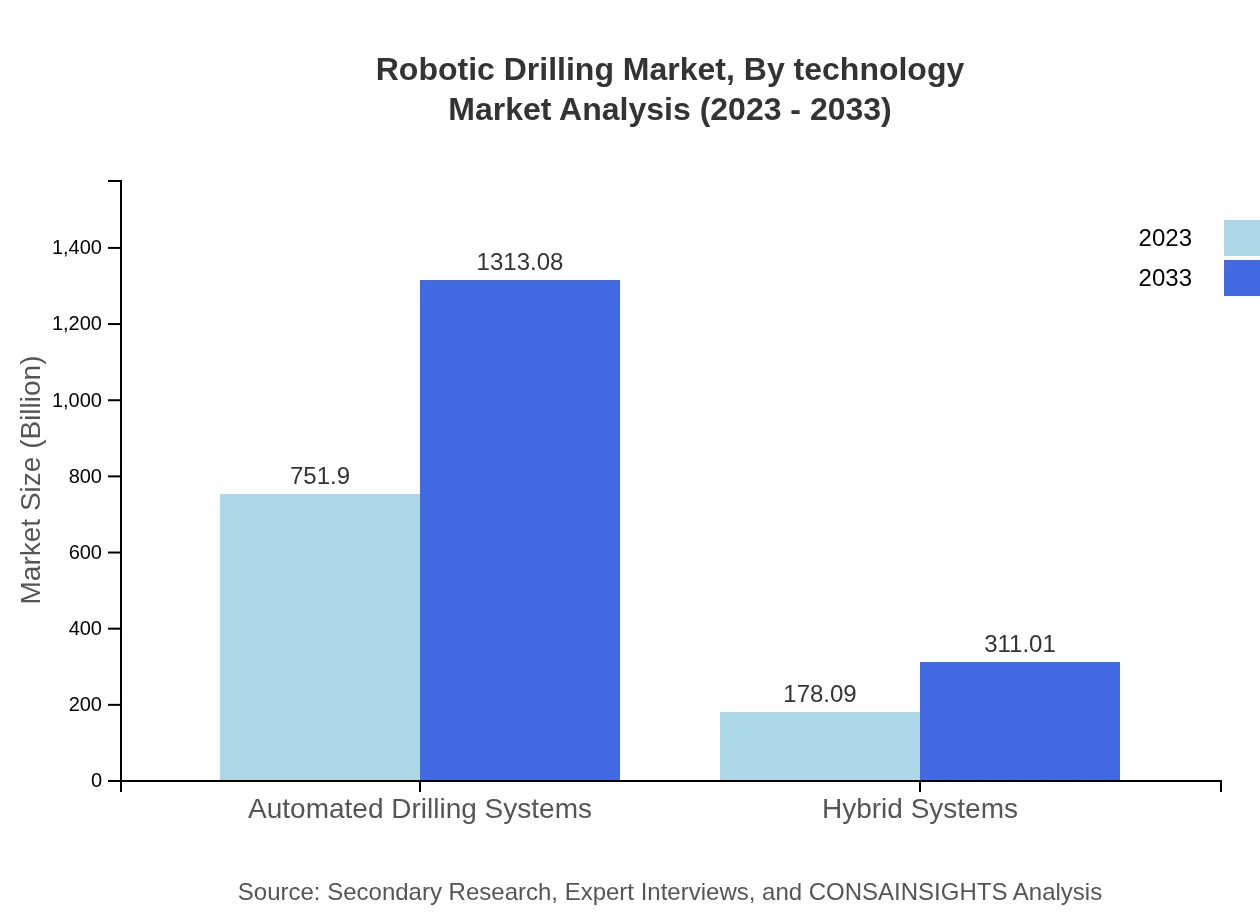

Robotic Drilling Market Analysis By Technology

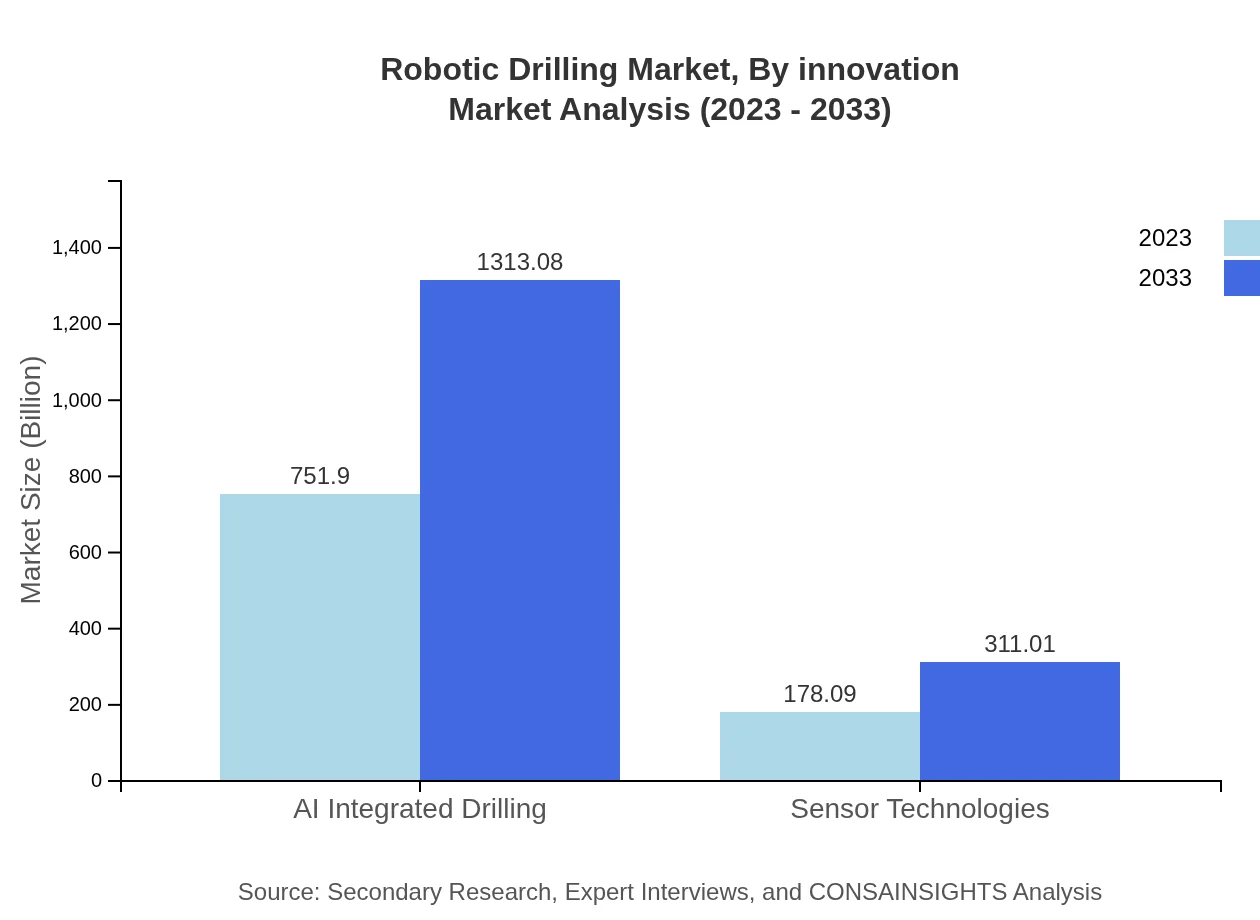

The Robotic Drilling market segment by technology showcases significant growth, especially in AI Integrated Drilling systems and Automated Drilling Systems. In 2023, the AI Integrated Drilling technology segment is valued at $751.90 million, expected to grow to $1.31 billion by 2033, indicating its dominance in the market. Similarly, Automated Drilling Systems are expected to demonstrate considerable growth, fostering innovations that enhance drilling productivity.

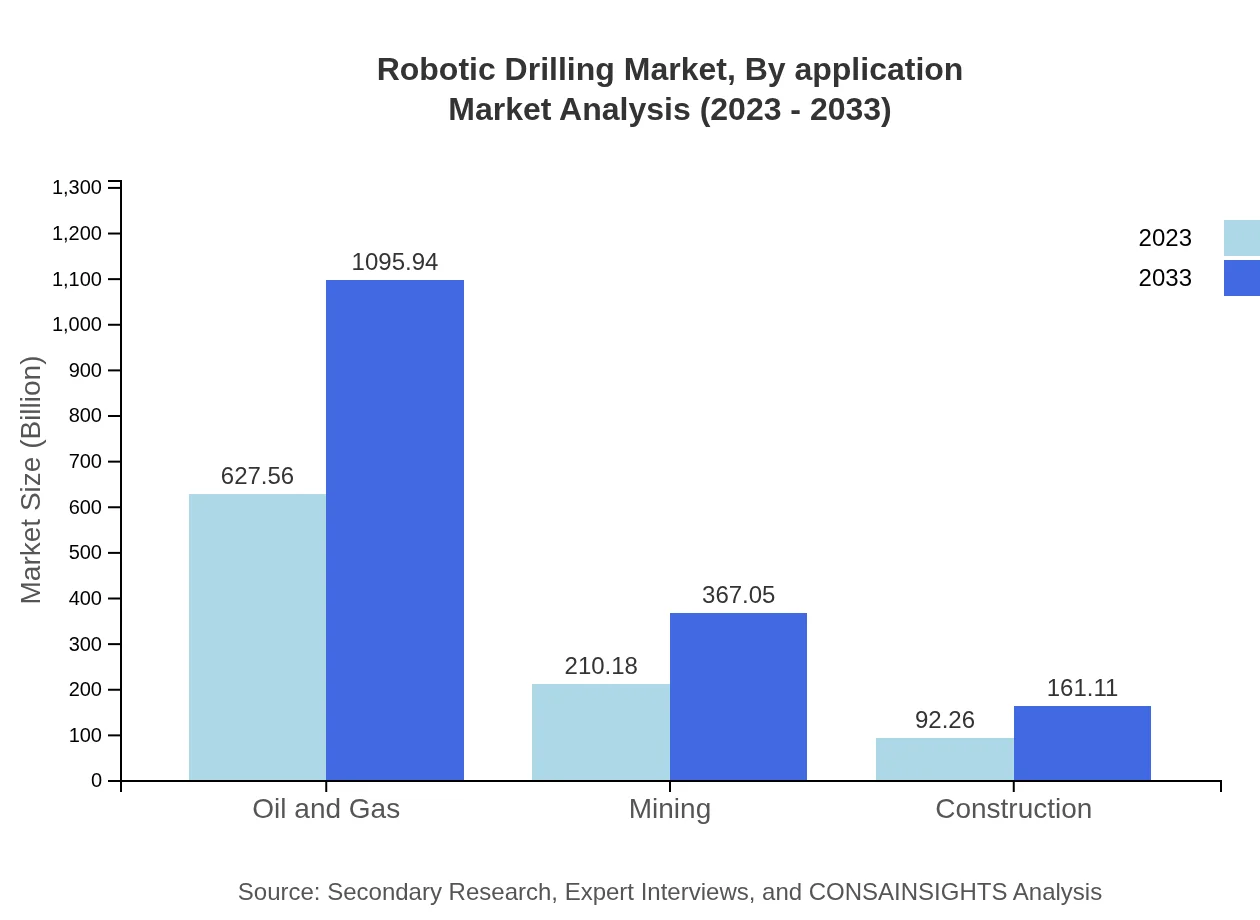

Robotic Drilling Market Analysis By Application

Segmented by application, the analysis reveals that oil and gas drilling takes the largest share. It estimated a market size of $627.56 million in 2023, set to grow to $1.1 billion by 2033. Other sectors, including mining and construction, also present significant growth opportunities as demand for mechanized drilling solutions increases.

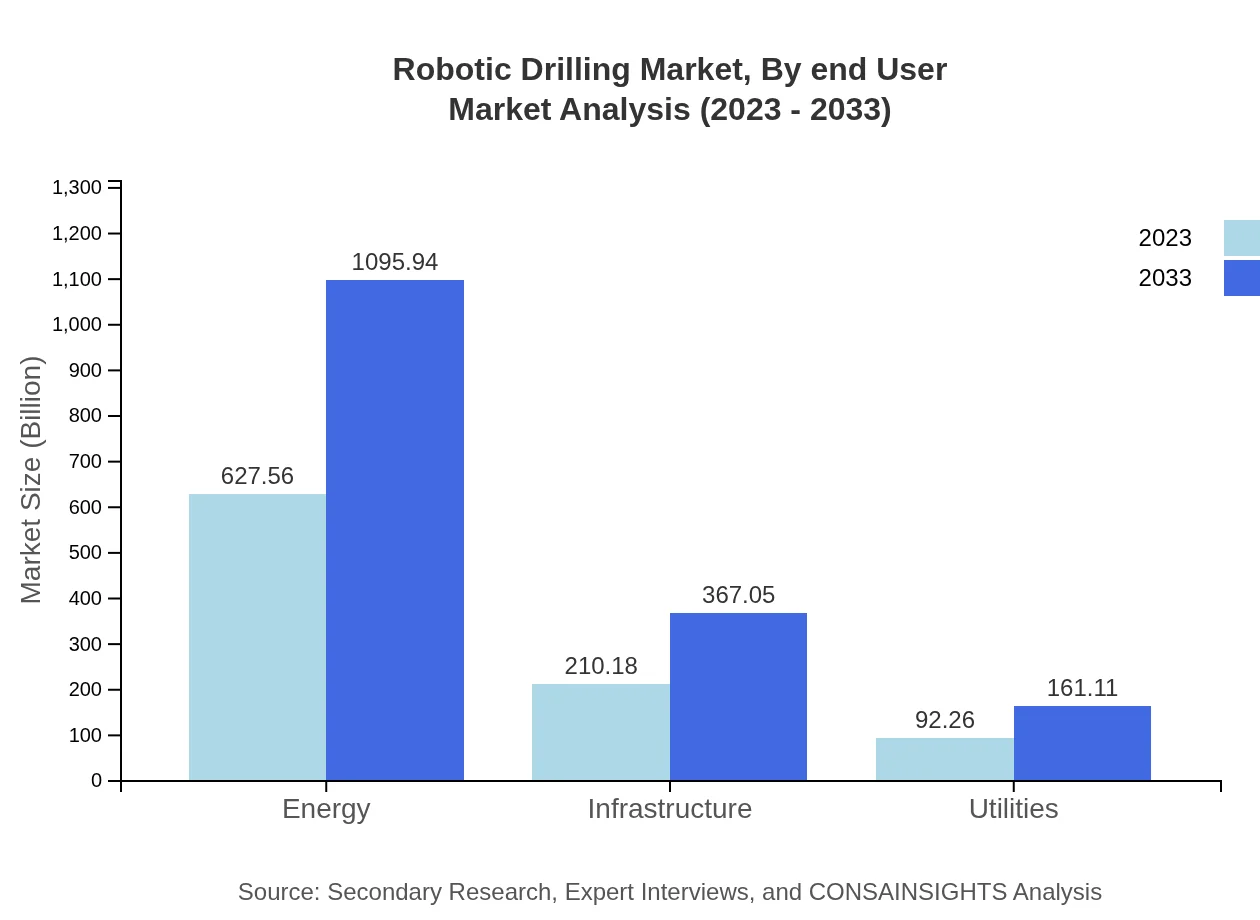

Robotic Drilling Market Analysis By End User

End-user analysis indicates the oil and gas industry remains the largest consumer of robotic drilling technologies with a market size of $627.56 million in 2023, marking 67.48% of the market share. The mining sector is also significant, projected to expand from $210.18 million to $367.05 million by 2033, evidencing the importance of robotics in resource extraction.

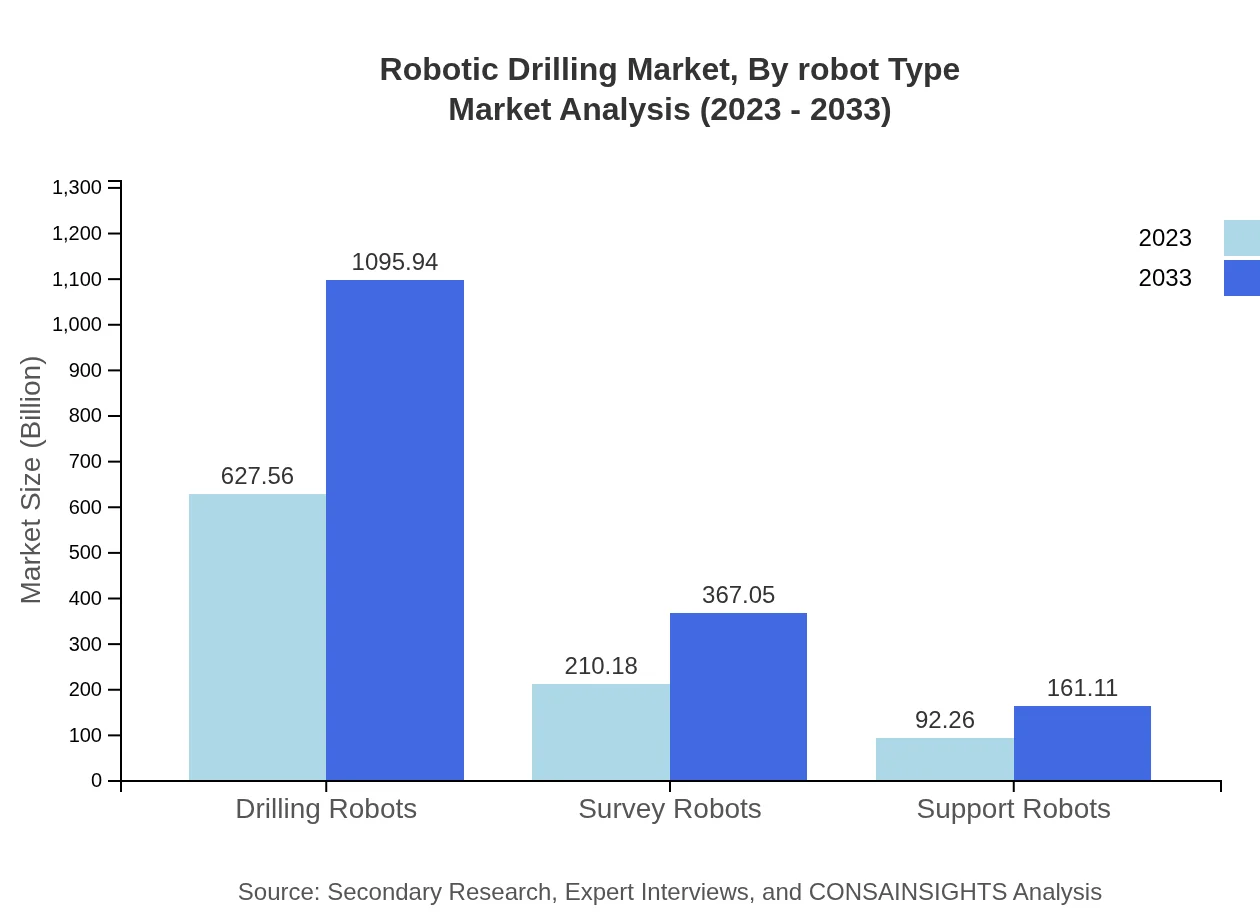

Robotic Drilling Market Analysis By Robot Type

Different types of robots include Survey Robots and Support Robots, with the Survey Robots segment expected to command a market share of 22.6% in 2023. The Drilling Robots category is also competitive, indicating a major trend towards adopting more specialized robotic systems within drilling operations.

Robotic Drilling Market Analysis By Innovation

Innovation is at the heart of the Robotic Drilling market, with significant advancements occurring in sensor technologies. The integration of real-time data analytics from AI and enhanced automation features is transforming traditional practices, leading to more accurate and efficient drilling processes.

Robotic Drilling Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Robotic Drilling Industry

Schlumberger:

A leading oilfield services company, Schlumberger is renowned for its innovative technologies, including advanced robotic systems that optimize drilling operations.Halliburton:

Halliburton is one of the largest providers of products and services to the energy industry, specializing in robotic drilling solutions and integrated project management.Baker Hughes:

Baker Hughes is known for its cutting-edge technology and services in various sectors, including oil and gas, and significantly contributes to robotic drilling advancements.Emerson Electric Co.:

Emerson leverages its expertise in automation technology to enhance drilling processes across multiple industries, focusing on efficiency and reliability.We're grateful to work with incredible clients.

FAQs

What is the market size of robotic Drilling?

The global robotic drilling market is valued at approximately $930 million in 2023, with projections indicating a compound annual growth rate (CAGR) of 5.6% through 2033.

What are the key market players or companies in this robotic Drilling industry?

Key players in the robotic drilling market include major technology firms and specialized robotics manufacturers focusing on automation within energy, mining, and construction sectors.

What are the primary factors driving the growth in the robotic drilling industry?

Growth in the robotic drilling market is driven by increasing demand for automation, advancements in AI technologies, the need for efficiency in resource extraction, and enhanced safety standards.

Which region is the fastest Growing in the robotic drilling market?

North America is the fastest-growing region in the robotic drilling market, with forecasts showing market growth from $323.08 million in 2023 to $564.21 million by 2033.

Does ConsaInsights provide customized market report data for the robotic drilling industry?

Yes, ConsaInsights provides customized market report data tailored to specific needs and focuses within the robotic drilling industry, serving diverse stakeholder interests.

What deliverables can I expect from this robotic Drilling market research project?

Expect detailed market analysis, segmented data, regional insights, competitive landscape assessments, and forecasts that aid strategic decision-making in the robotic drilling field.

What are the market trends of robotic drilling?

Trends include the rise of AI-driven drilling technologies, greater integration of sensor technologies, increasing automation in drilling practices, and a shift towards efficiency and sustainability.