Rotary Pumps Market Report

Published Date: 22 January 2026 | Report Code: rotary-pumps

Rotary Pumps Market Size, Share, Industry Trends and Forecast to 2033

This report provides an extensive analysis of the Rotary Pumps market from 2023 to 2033, focusing on market size, trends, key players, and growth opportunities. Insights include comprehensive breakdowns by region and segment, offering valuable information for stakeholders and decision-makers.

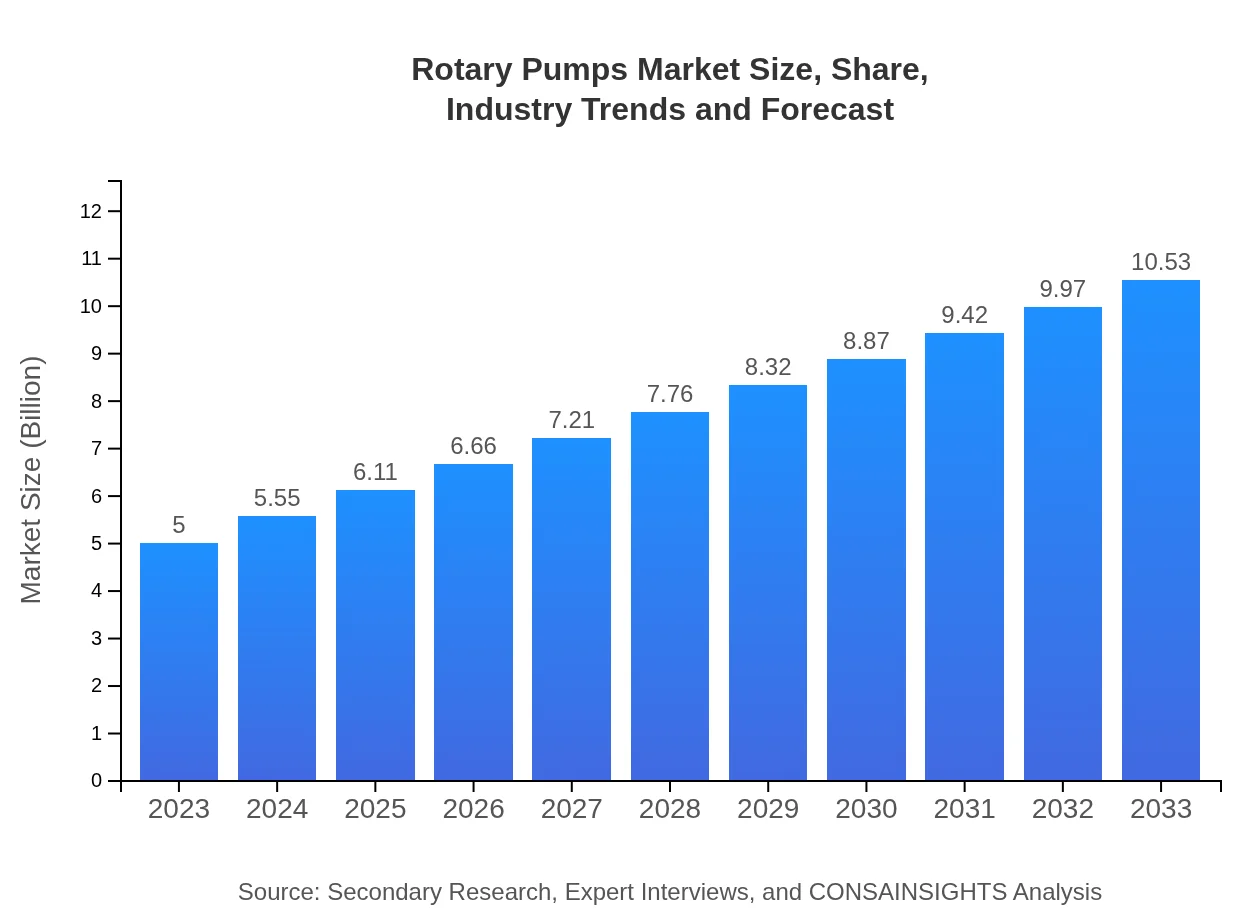

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $5.00 Billion |

| CAGR (2023-2033) | 7.5% |

| 2033 Market Size | $10.53 Billion |

| Top Companies | Grundfos, Xylem Inc., KSB SE & Co. KGaA, Ingersoll Rand |

| Last Modified Date | 22 January 2026 |

Rotary Pumps Market Overview

Customize Rotary Pumps Market Report market research report

- ✔ Get in-depth analysis of Rotary Pumps market size, growth, and forecasts.

- ✔ Understand Rotary Pumps's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Rotary Pumps

What is the Market Size & CAGR of Rotary Pumps market in 2023?

Rotary Pumps Industry Analysis

Rotary Pumps Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Rotary Pumps Market Analysis Report by Region

Europe Rotary Pumps Market Report:

Europe’s Rotary Pumps market is anticipated to increase from $1.57 billion in 2023 to $3.30 billion by 2033. The region’s push for energy-efficient solutions and stringent environmental regulations is expected to enhance the demand for advanced pumping solutions, particularly within wastewater treatment and chemical processing industries.Asia Pacific Rotary Pumps Market Report:

The Asia Pacific Rotary Pumps market is projected to grow from $0.85 billion in 2023 to $1.79 billion by 2033. Key drivers include rapid industrialization, urbanization, and increased investments in infrastructural projects. Countries like China and India are witnessing substantial growth in demand, propelled by sectors such as water treatment and energy production.North America Rotary Pumps Market Report:

North America is projected to expand significantly, with the market size growing from $1.91 billion in 2023 to $4.02 billion in 2033. The oil and gas industry, alongside the water management sector, is a critical growth contributor, driven by innovations and a shift towards sustainable practices.South America Rotary Pumps Market Report:

In South America, the Rotary Pumps market is expected to rise from $0.32 billion in 2023 to $0.68 billion by 2033. The growth is spurred by advancements in agricultural processes and extractive industries, which utilize rotary pumps for various applications, including irrigation and mineral processing.Middle East & Africa Rotary Pumps Market Report:

The Rotary Pumps market in the Middle East and Africa is expected to grow from $0.35 billion in 2023 to $0.74 billion by 2033, with notable growth in the oil & gas sector, driven by the demand for effective fluid transport solutions amid rising energy needs.Tell us your focus area and get a customized research report.

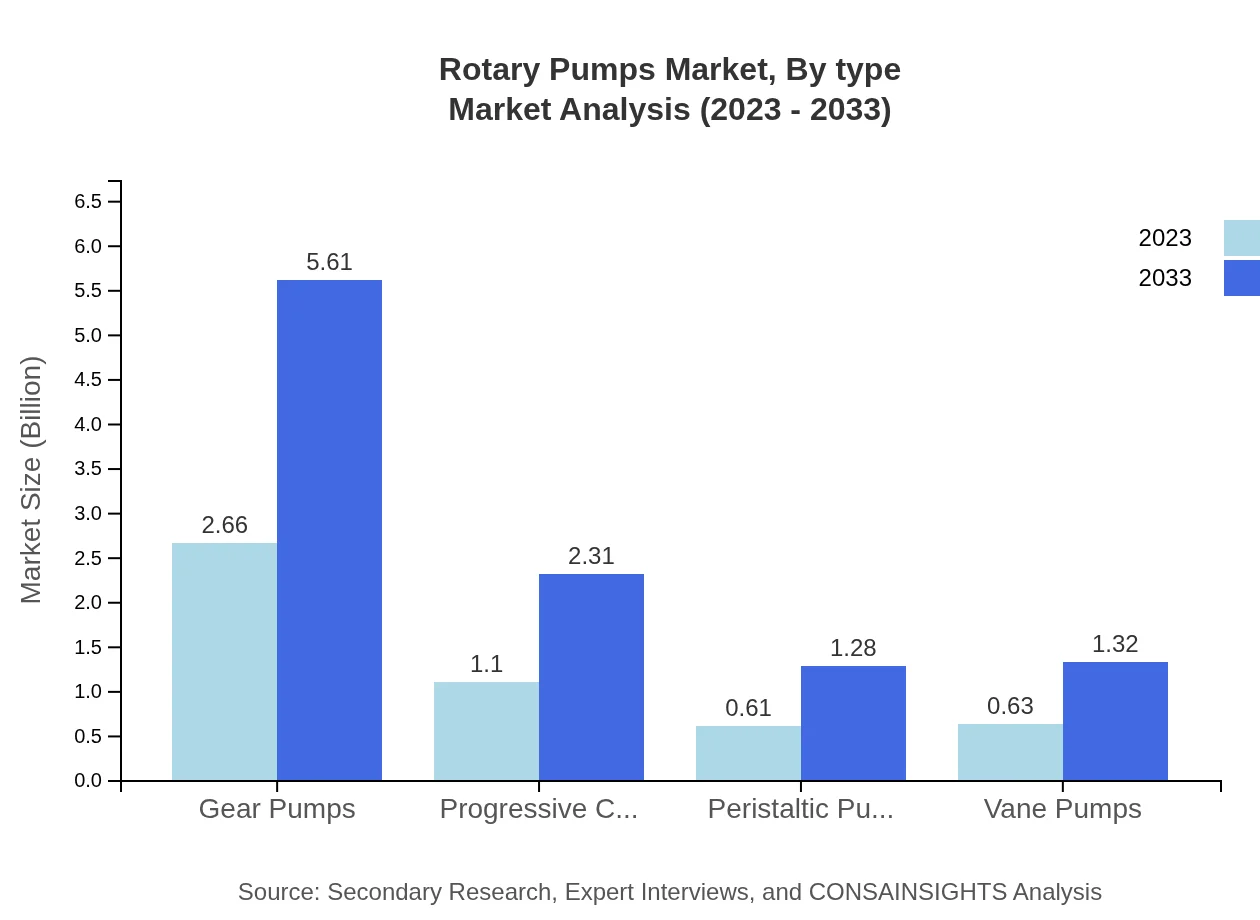

Rotary Pumps Market Analysis By Type

The market breakdown by type indicates that gear pumps lead the segment with a size expected to grow from $2.66 billion in 2023 to $5.61 billion by 2033, maintaining a market share of 53.26%. Progressive cavity pumps follow with an increase from $1.10 billion to $2.31 billion, capturing a market share of 21.97%. Peristaltic and vane pumps account for 12.19% and 12.58% market shares, respectively, demonstrating their value in specialized applications.

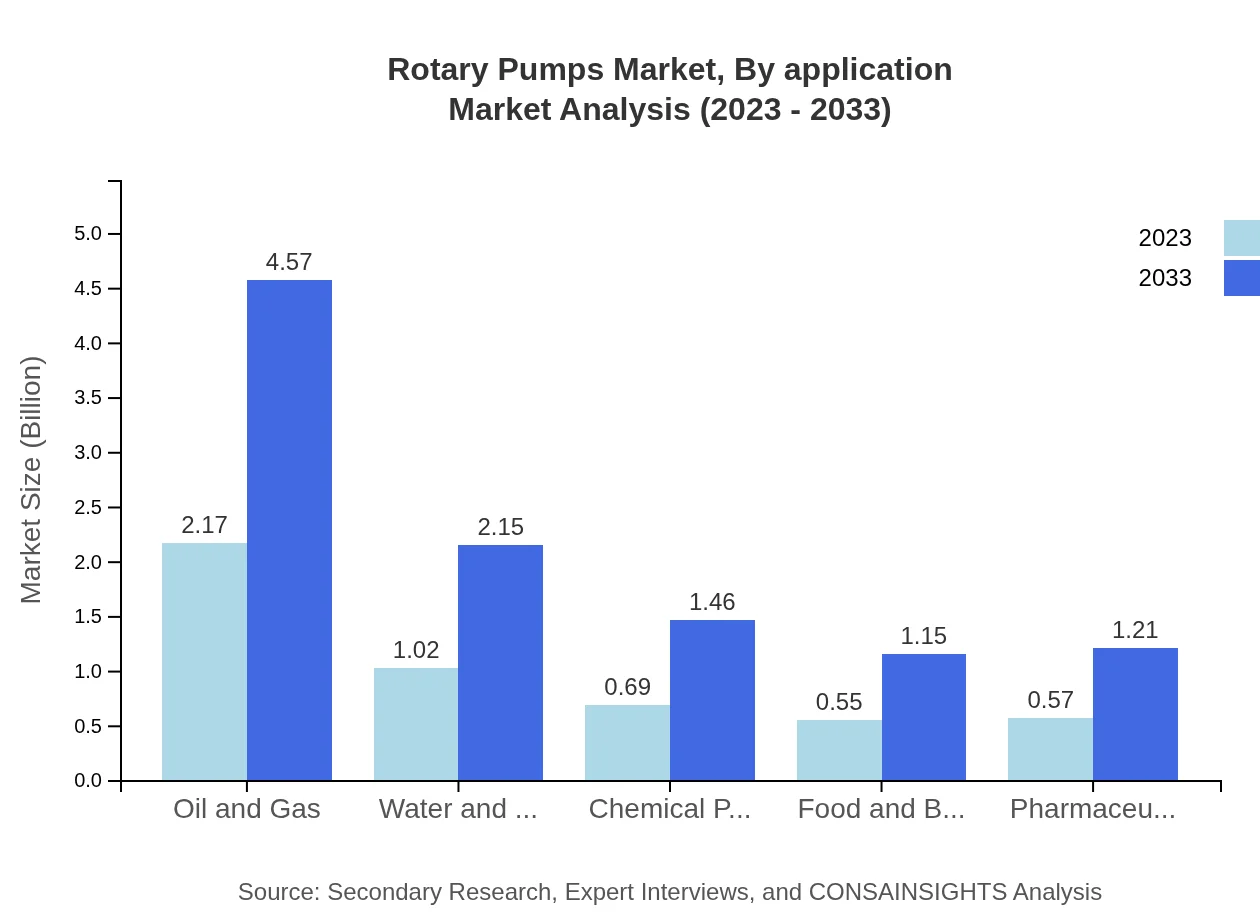

Rotary Pumps Market Analysis By Application

Industrial applications dominate the market with a size of $3.15 billion in 2023, projected to reach $6.62 billion by 2033, comprising 62.9% of the market. Oil and gas applications follow, increasing from $2.17 billion to $4.57 billion (43.39%). The chemical processing segment is anticipated to increment from $0.69 billion to $1.46 billion, while food and beverage and pharmaceutical sectors grow from $0.55 billion and $0.57 billion to $1.15 billion and $1.21 billion, respectively.

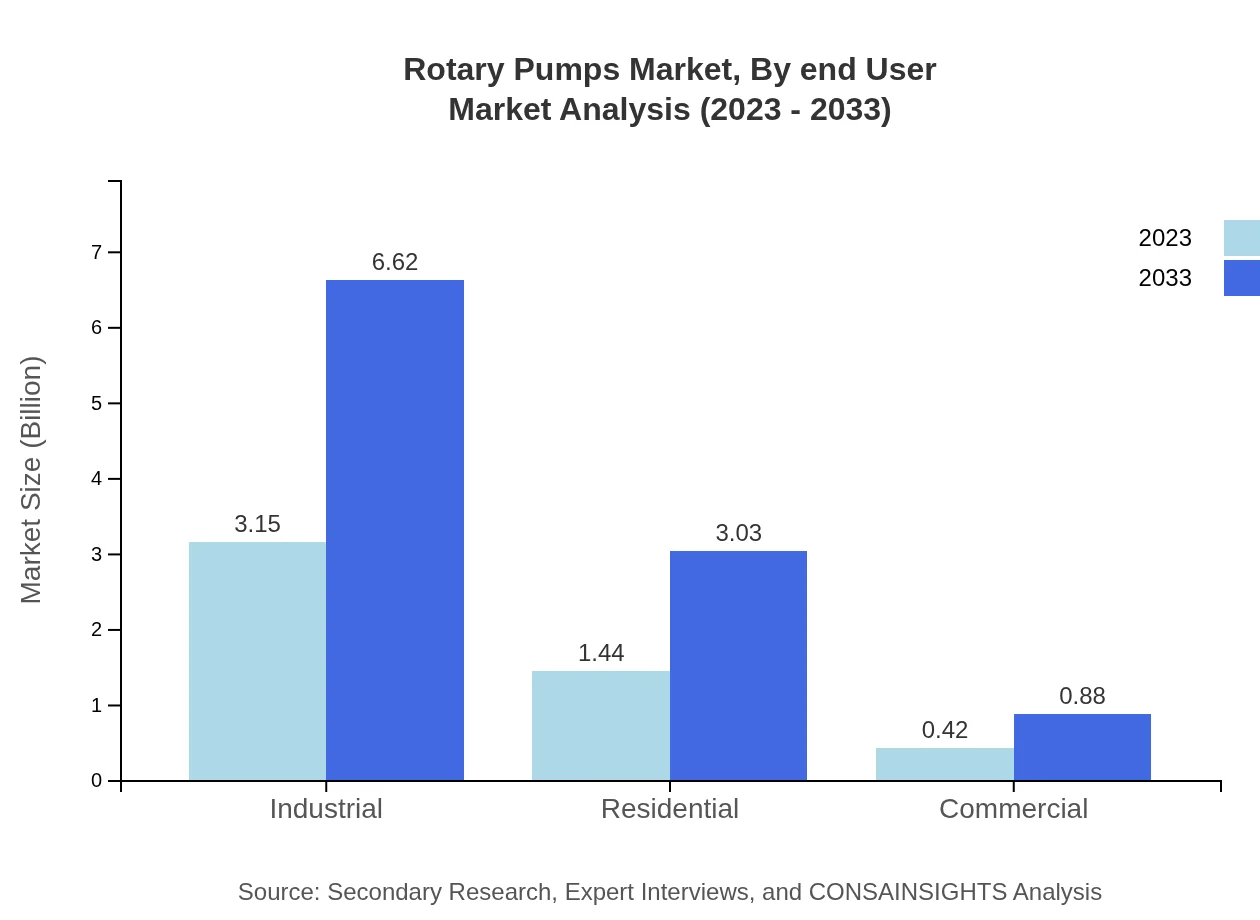

Rotary Pumps Market Analysis By End User

The industrial end-user segment is the largest, expected to grow from $3.15 billion in 2023 to $6.62 billion in 2033. Residential applications also show potential, with an increase from $1.44 billion to $3.03 billion reflecting the residential needs for water management solutions. The commercial segment's growth from $0.42 billion to $0.88 billion highlights evolving market dynamics.

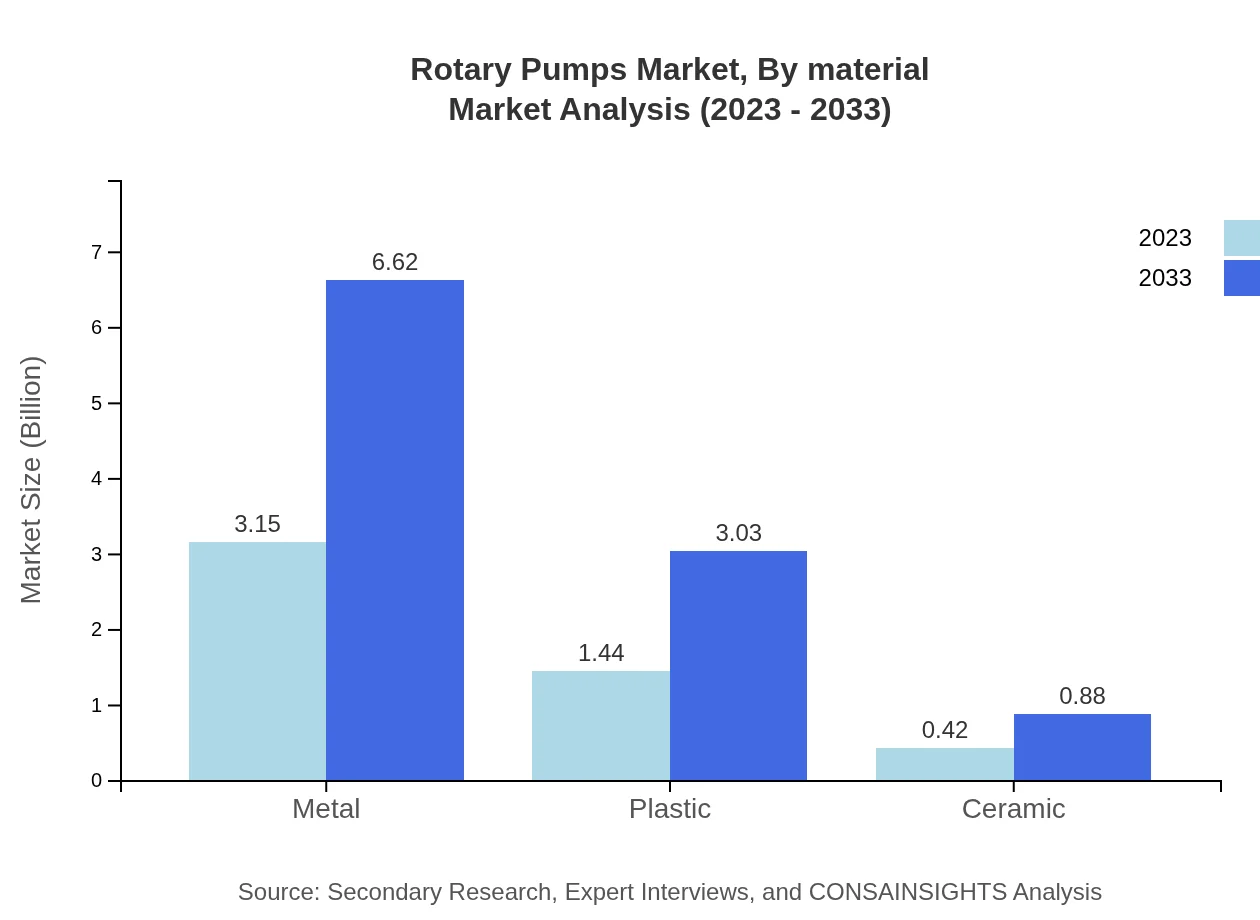

Rotary Pumps Market Analysis By Material

Metal materials dominate with a size expected to grow from $3.15 billion to $6.62 billion (62.9% market share), while plastic and ceramic materials contribute to the market, indicating a diversified approach to enhancing durability and adaptability in various environments.

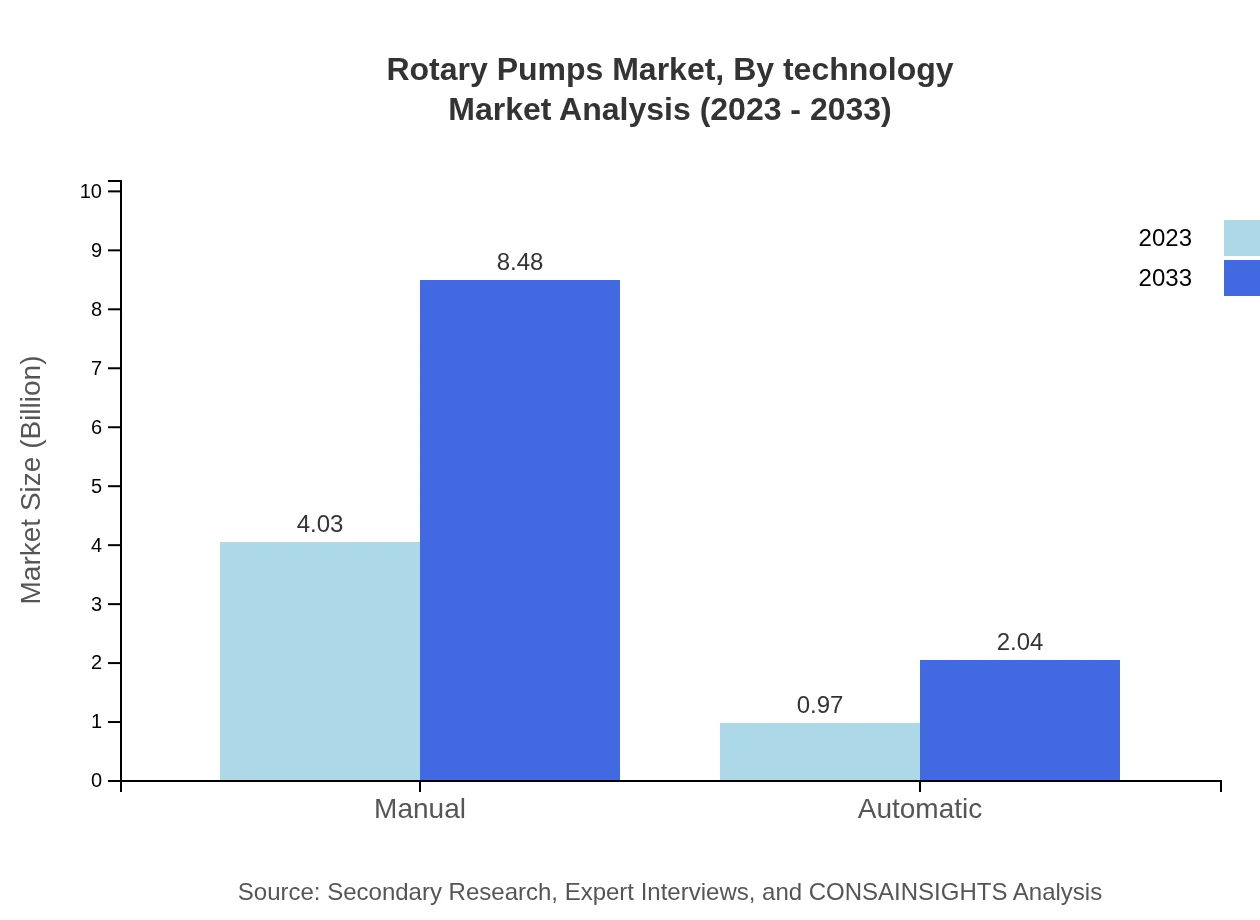

Rotary Pumps Market Analysis By Technology

Manual technology is the leader in the Rotary Pumps market, with a size expected to grow from $4.03 billion to $8.48 billion. Automatic technologies are gaining traction, projected to increase from $0.97 billion to $2.04 billion, reflecting a growing preference for smart solutions.

Rotary Pumps Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Rotary Pumps Industry

Grundfos:

Grundfos is a global leader in advanced pump solutions, offering innovative rotary pumps widely used across various industries, particularly in water treatment and HVAC solutions.Xylem Inc.:

Xylem Inc. specializes in water technology and advanced pumping solutions, with a strong presence in rotary pumps for municipal and commercial applications.KSB SE & Co. KGaA:

KSB is known for its reliable and efficient pumping solutions, including rotary pumps tailored for different industrial processes.Ingersoll Rand:

Ingersoll Rand offers a range of rotary pumps focused on industrial applications, emphasizing reliability and performance.We're grateful to work with incredible clients.

FAQs

What is the market size of Rotary Pumps?

The global rotary pumps market is projected to reach approximately $5 billion by 2033, growing at a CAGR of 7.5% from its 2023 valuation. This growth reflects increasing demand across various industrial applications.

What are the key market players or companies in the Rotary Pumps industry?

Key players in the rotary pumps market include manufacturers such as Grundfos, Gardner Denver, and Flowserve. These companies dominate the market through innovative technologies, extensive distribution networks, and strong customer relationships.

What are the primary factors driving the growth in the Rotary Pumps industry?

The growth of the rotary pumps market is driven by rising industrial automation, increasing demand for water treatment solutions, and advancements in pump technology for efficiency and reliability in various sectors such as chemicals and food processing.

Which region is the fastest Growing in the Rotary Pumps market?

North America and Europe are the fastest-growing regions for rotary pumps, with North America projected to grow from $1.91 billion in 2023 to $4.02 billion by 2033, driven by technological advancements and increased industrial activities.

Does ConsaInsights provide customized market report data for the Rotary Pumps industry?

Yes, ConsaInsights offers tailored market report data for the rotary pumps industry, allowing clients to gain specific insights about market dynamics, trends, and competitive analysis customized to their business needs.

What deliverables can I expect from this Rotary Pumps market research project?

Expected deliverables from the rotary pumps market research project include detailed reports, market forecasts, competitive landscape analysis, and segment breakdowns, providing a comprehensive view of industry trends and growth opportunities.

What are the market trends of Rotary Pumps?

Current trends in the rotary pumps market include increasing demand for energy-efficient pumps, automation in pump systems, a shift towards smart pumps, and growing applications in sectors such as pharmaceuticals, food and beverage, and wastewater management.