Rotary Vane Vacuum Pump Market Report

Published Date: 31 January 2026 | Report Code: rotary-vane-vacuum-pump

Rotary Vane Vacuum Pump Market Size, Share, Industry Trends and Forecast to 2033

This market report provides a comprehensive analysis of the Rotary Vane Vacuum Pump industry, highlighting key insights, market size, trends, and forecasts from 2023 to 2033, aimed at informing stakeholders of growth opportunities and challenges in the coming years.

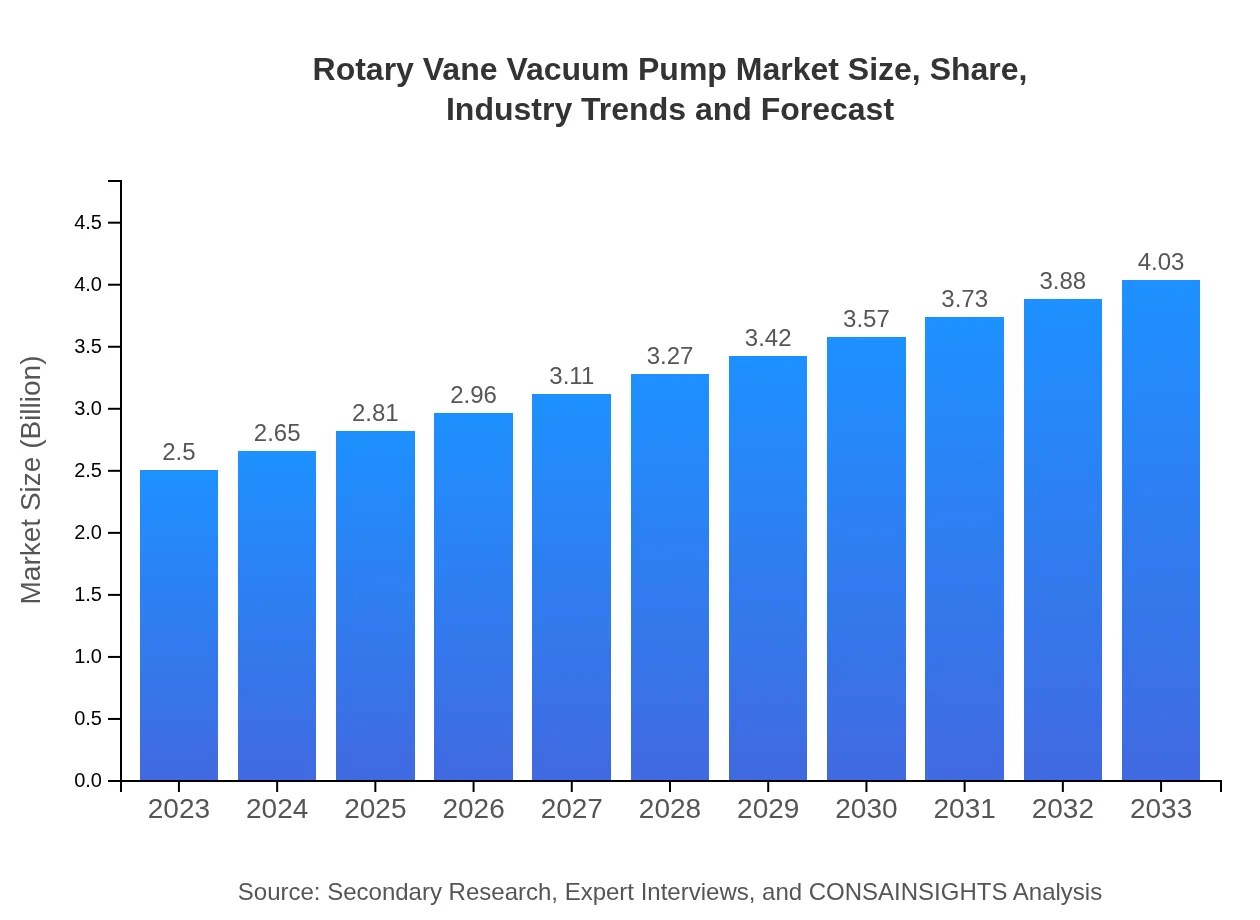

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $2.50 Billion |

| CAGR (2023-2033) | 4.8% |

| 2033 Market Size | $4.03 Billion |

| Top Companies | Edwards Vacuum, Gardner Denver, Busch Vacuum Solutions, Pfeiffer Vacuum |

| Last Modified Date | 31 January 2026 |

Rotary Vane Vacuum Pump Market Overview

Customize Rotary Vane Vacuum Pump Market Report market research report

- ✔ Get in-depth analysis of Rotary Vane Vacuum Pump market size, growth, and forecasts.

- ✔ Understand Rotary Vane Vacuum Pump's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Rotary Vane Vacuum Pump

What is the Market Size & CAGR of Rotary Vane Vacuum Pump market in 2023?

Rotary Vane Vacuum Pump Industry Analysis

Rotary Vane Vacuum Pump Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Rotary Vane Vacuum Pump Market Analysis Report by Region

Europe Rotary Vane Vacuum Pump Market Report:

The European market is projected to grow from USD 0.64 billion in 2023 to USD 1.04 billion by 2033, with stringent regulations requiring energy-efficient solutions driving demand. The automotive and pharmaceuticals industries are significant contributors to this growth, alongside initiatives promoting sustainable practices.Asia Pacific Rotary Vane Vacuum Pump Market Report:

The Asia Pacific region is witnessing robust growth in the Rotary Vane Vacuum Pump market, poised to increase from USD 0.52 billion in 2023 to USD 0.83 billion by 2033. Driven by rapid industrialization in countries like China and India, alongside growing investments in the healthcare and automotive sectors, this region represents a significant opportunity for market players.North America Rotary Vane Vacuum Pump Market Report:

North America, being a mature market, anticipates a growth from USD 0.95 billion in 2023 to USD 1.54 billion by 2033. The key drivers include the ongoing modernization of manufacturing processes and the high adoption rate of advanced technologies in production lines, particularly within the automotive and aerospace sectors.South America Rotary Vane Vacuum Pump Market Report:

In the South America market, the Rotary Vane Vacuum Pump segment is expected to grow from USD 0.12 billion in 2023 to USD 0.20 billion in 2033. This growth is attributed to increasing urbanization and industrial activities, particularly in Brazil and Argentina, as they enhance their manufacturing capabilities.Middle East & Africa Rotary Vane Vacuum Pump Market Report:

In the Middle East and Africa region, the market size is expected to increase from USD 0.26 billion in 2023 to USD 0.42 billion by 2033, supported by infrastructure development and industrial growth primarily in the United Arab Emirates and South Africa. Focus on oil and gas applications further enhances market opportunities.Tell us your focus area and get a customized research report.

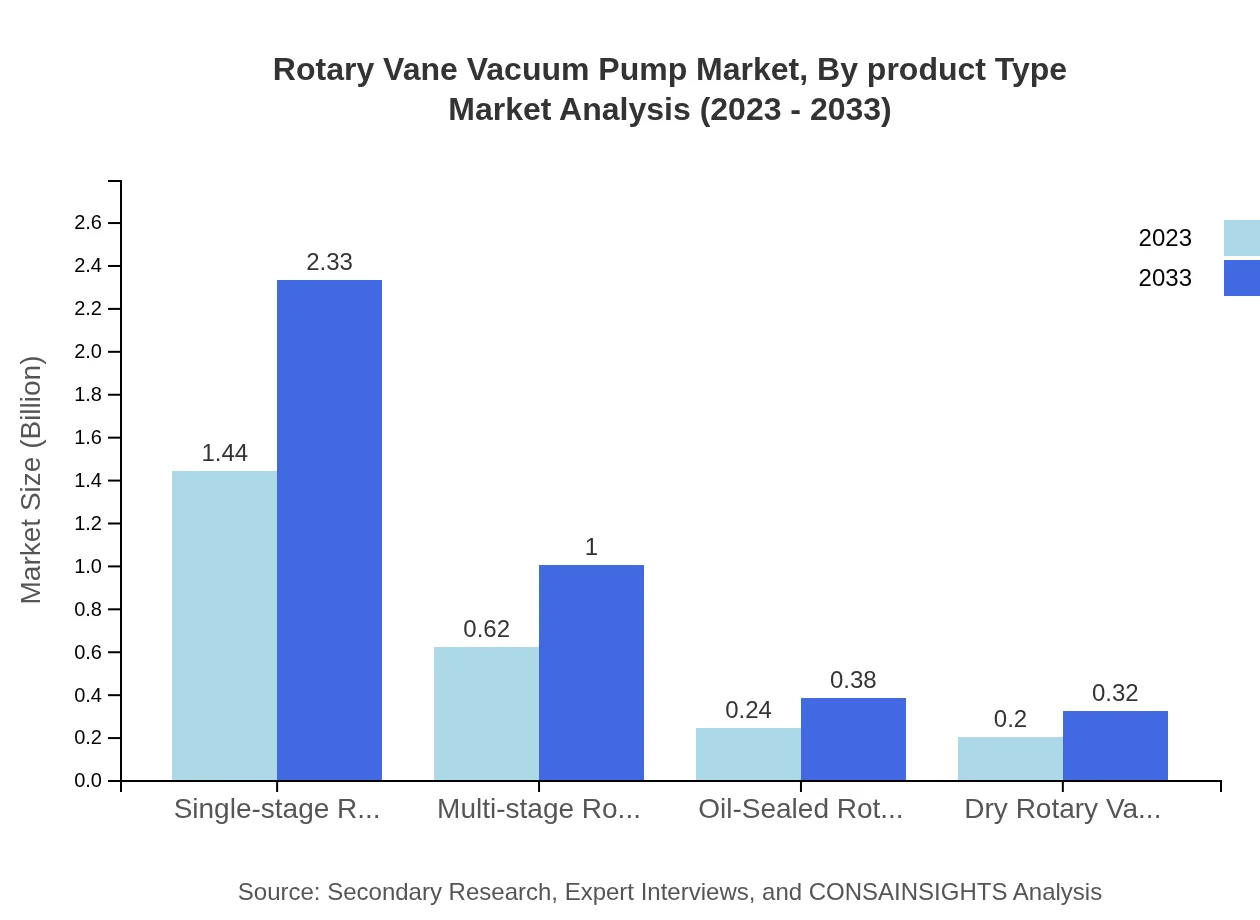

Rotary Vane Vacuum Pump Market Analysis By Product Type

The Rotary Vane Vacuum Pump market by product type is divided into single-stage, multi-stage, oil-sealed, and dry rotary vane vacuum pumps. As of 2023, single-stage pumps dominate the market with a size of USD 1.44 billion, expected to grow to USD 2.33 billion by 2033, representing 57.75% of market share, primarily due to their efficiency in low to moderate vacuum applications.

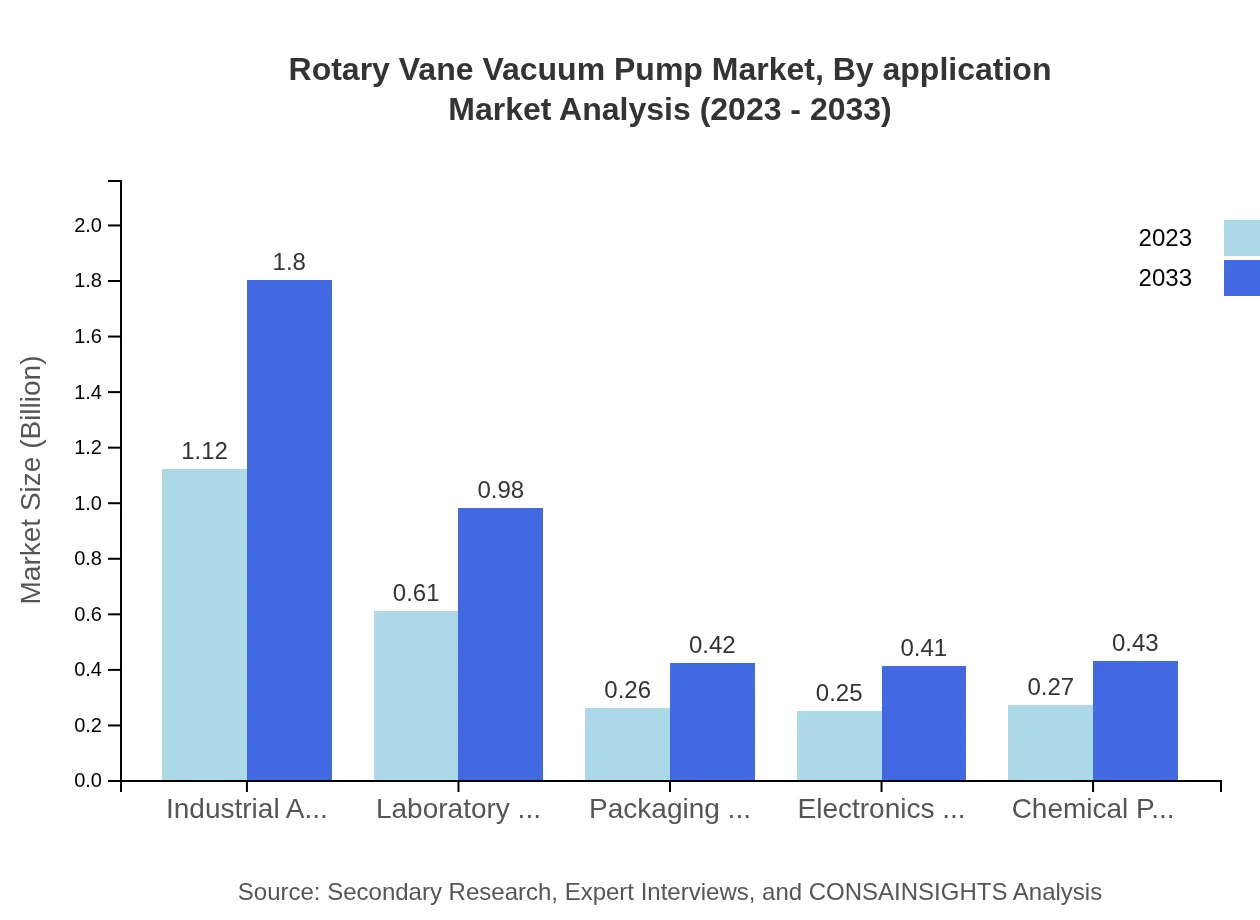

Rotary Vane Vacuum Pump Market Analysis By Application

Applications of Rotary Vane Vacuum Pumps span across automotive, healthcare, food and beverage, electronics, petrochemical, and industrial fields. In 2023, the automotive industry leads with a projected market size of USD 1.12 billion, which will rise to USD 1.80 billion by 2033, accounting for 44.64% of market share.

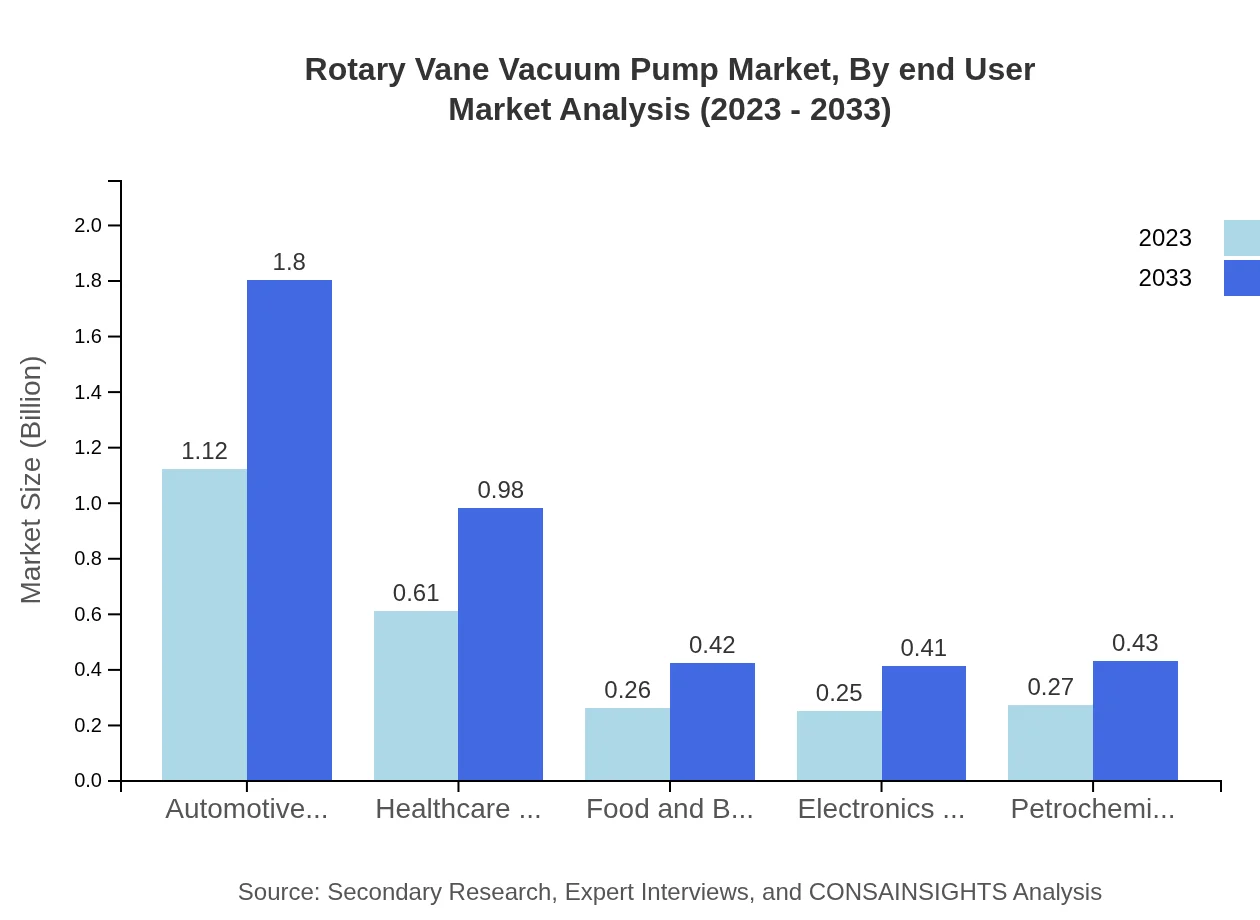

Rotary Vane Vacuum Pump Market Analysis By End User

Key end-users of Rotary Vane Vacuum Pumps include industries such as automotive, healthcare, food and beverage, and electronics manufacturing. The automotive sector leads with a significant size of USD 1.12 billion in 2023, translating to about 44.64% market share, where these pumps are extensively utilized for process management and maintenance.

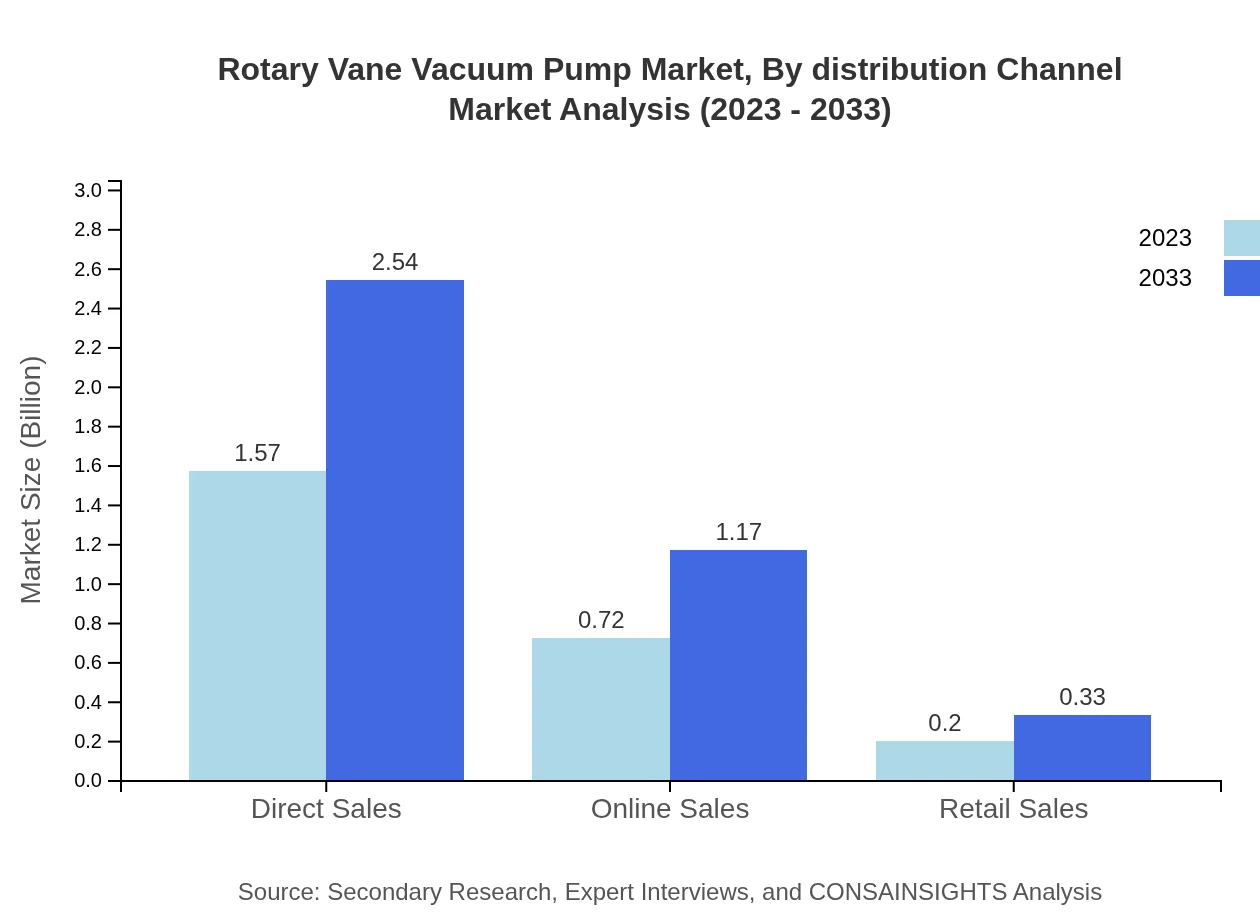

Rotary Vane Vacuum Pump Market Analysis By Distribution Channel

Distribution channels for Rotary Vane Vacuum Pumps include direct sales, online sales, and retail. Direct sales dominate this segment, with a market size of USD 1.57 billion in 2023, expected to climb to USD 2.54 billion by 2033, comprising approximately 62.93% market share owing to established relationships between manufacturers and end-users.

Rotary Vane Vacuum Pump Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Rotary Vane Vacuum Pump Industry

Edwards Vacuum:

A leading manufacturer of vacuum and abatement equipment, Edwards Vacuum provides innovative solutions for the semiconductor and industrial sectors.Gardner Denver:

Gardner Denver is known for producing a range of vacuum pumps and compressors used widely in various industries, including food processing and pharmaceuticals.Busch Vacuum Solutions:

Busch is a well-recognized name in the vacuum technology field, offering a wide range of rotary vane pumps known for their reliability and efficiency.Pfeiffer Vacuum:

Pfeiffer Vacuum specializes in high-quality vacuum pumps and systems, supporting industries such as aerospace, optics, and research.We're grateful to work with incredible clients.

FAQs

What is the market size of rotary Vane Vacuum Pump?

The global market size for rotary-vane vacuum pumps is currently valued at approximately $2.5 billion, with a projected compound annual growth rate (CAGR) of 4.8%. This indicates a steady growth trajectory for the market until 2033.

What are the key market players or companies in this rotary Vane Vacuum Pump industry?

Key players in the rotary-vane vacuum pump industry include leading manufacturers who specialize in vacuum technologies. They play a crucial role in driving innovation and competitiveness in the market, contributing to different sectors such as automotive, healthcare, and industrial applications.

What are the primary factors driving the growth in the rotary Vane Vacuum Pump industry?

The rotary-vane vacuum pump industry is primarily driven by increasing demand in automotive and healthcare applications, technological advancements, and growth in industries such as electronics and food processing. The versatility and reliability of these pumps also contribute to their widespread adoption.

Which region is the fastest Growing in the rotary Vane Vacuum Pump?

The fastest-growing region for rotary-vane vacuum pumps is North America, with a market projection growing from $0.95 billion in 2023 to $1.54 billion by 2033. Other significant growth is observed in Europe and Asia Pacific, indicating broad geographical demand.

Does ConsaInsights provide customized market report data for the rotary Vane Vacuum Pump industry?

Yes, ConsaInsights offers customized market reports tailored to the specific needs of clients in the rotary-vane vacuum pump industry. This allows companies to gain insights that are directly relevant to their market strategy and operational goals.

What deliverables can I expect from this rotary Vane Vacuum Pump market research project?

Deliverables from the rotary-vane vacuum pump market research project include comprehensive market size data, segment analysis, competitive landscape reports, and growth forecasts. These insights will support strategic decision-making and business development.

What are the market trends of rotary Vane Vacuum Pump?

Current market trends in the rotary-vane vacuum pump sector include a shift towards more efficient and eco-friendly models, increased automation in manufacturing processes, and a growing emphasis on customization to meet specific industrial applications.