Roughness And Contour Measuring Machine Market Report

Published Date: 22 January 2026 | Report Code: roughness-and-contour-measuring-machine

Roughness And Contour Measuring Machine Market Size, Share, Industry Trends and Forecast to 2033

This report encompasses a comprehensive analysis of the Roughness and Contour Measuring Machine market, focusing on market size, growth trends, segmentation, regional analysis, and industry forecasts for the period 2023 to 2033.

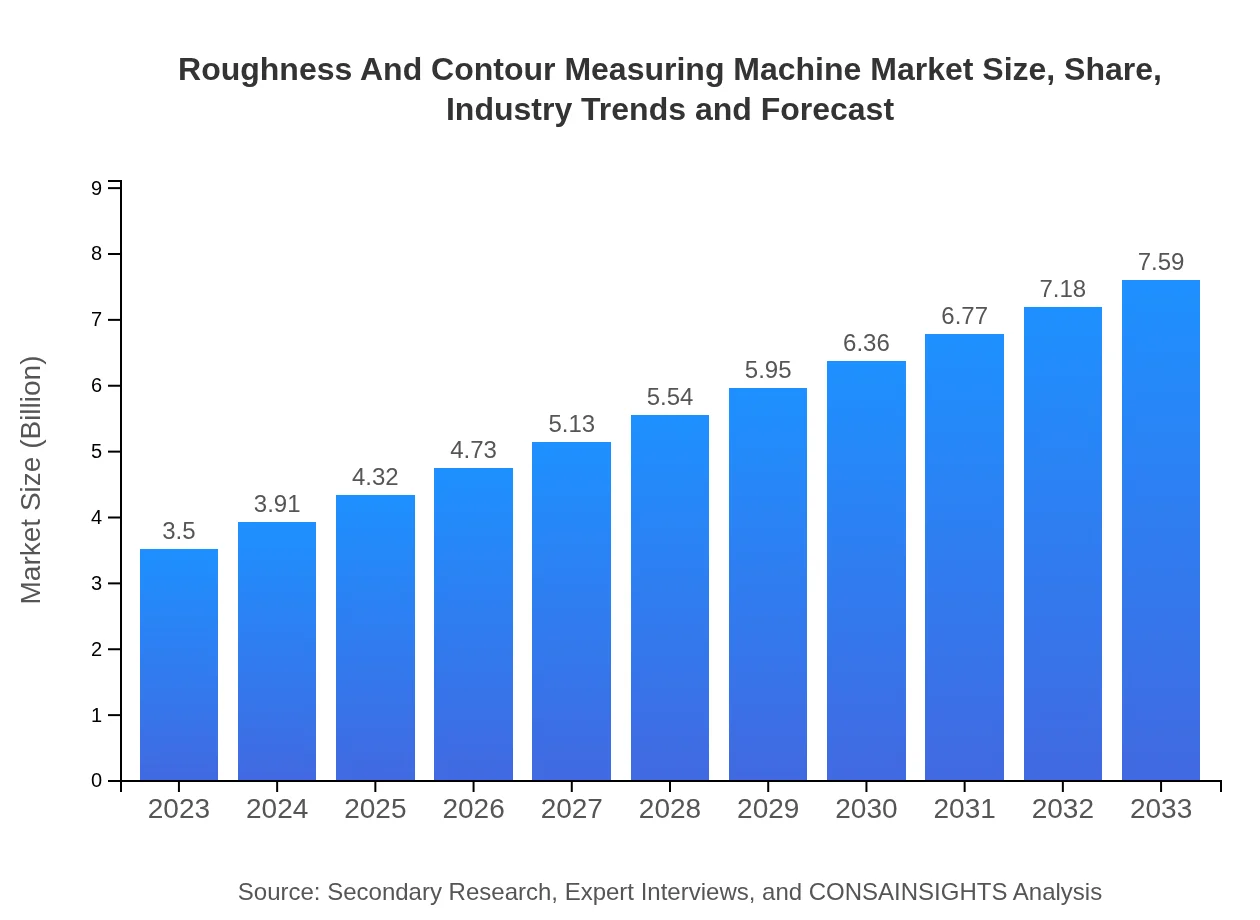

| Metric | Value |

|---|---|

| Study Period | 2023 - 2033 |

| 2023 Market Size | $3.50 Billion |

| CAGR (2023-2033) | 7.8% |

| 2033 Market Size | $7.59 Billion |

| Top Companies | Mitutoyo Corporation, Zeiss Group, Bowers Group, Taylor Hobson, Hexagon Manufacturing Intelligence |

| Last Modified Date | 22 January 2026 |

Roughness And Contour Measuring Machine Market Overview

Customize Roughness And Contour Measuring Machine Market Report market research report

- ✔ Get in-depth analysis of Roughness And Contour Measuring Machine market size, growth, and forecasts.

- ✔ Understand Roughness And Contour Measuring Machine's regional dynamics and industry-specific trends.

- ✔ Identify potential applications, end-user demand, and growth segments in Roughness And Contour Measuring Machine

What is the Market Size & CAGR of Roughness And Contour Measuring Machine market in 2023?

Roughness And Contour Measuring Machine Industry Analysis

Roughness And Contour Measuring Machine Market Segmentation and Scope

Tell us your focus area and get a customized research report.

Roughness And Contour Measuring Machine Market Analysis Report by Region

Europe Roughness And Contour Measuring Machine Market Report:

Europe's market value was around $1.14 billion in 2023, projected to rise to $2.48 billion by 2033, supported by stringent quality regulations and innovations in measurement technologies across various industries.Asia Pacific Roughness And Contour Measuring Machine Market Report:

The Asia Pacific region recorded a market size of approximately $0.63 billion in 2023, projected to reach $1.36 billion by 2033. This growth is driven by increasing manufacturing activities across countries like China and India and rising investments in quality control measures.North America Roughness And Contour Measuring Machine Market Report:

North America is one of the largest markets, with a market size of $1.27 billion in 2023, expected to grow significantly to $2.74 billion by 2033. The presence of high-end manufacturing sectors and strict regulatory standards for product quality are key growth drivers.South America Roughness And Contour Measuring Machine Market Report:

In South America, the market is relatively small, with a size of $0.04 billion in 2023, anticipated to grow to $0.09 billion by 2033, reflecting a gradual adoption of advanced measurement technologies.Middle East & Africa Roughness And Contour Measuring Machine Market Report:

The Middle East and Africa region showed a market size of $0.42 billion in 2023, anticipated to increase to $0.91 billion by 2033, as industrialization accelerates and demands for precision measurement tools grow.Tell us your focus area and get a customized research report.

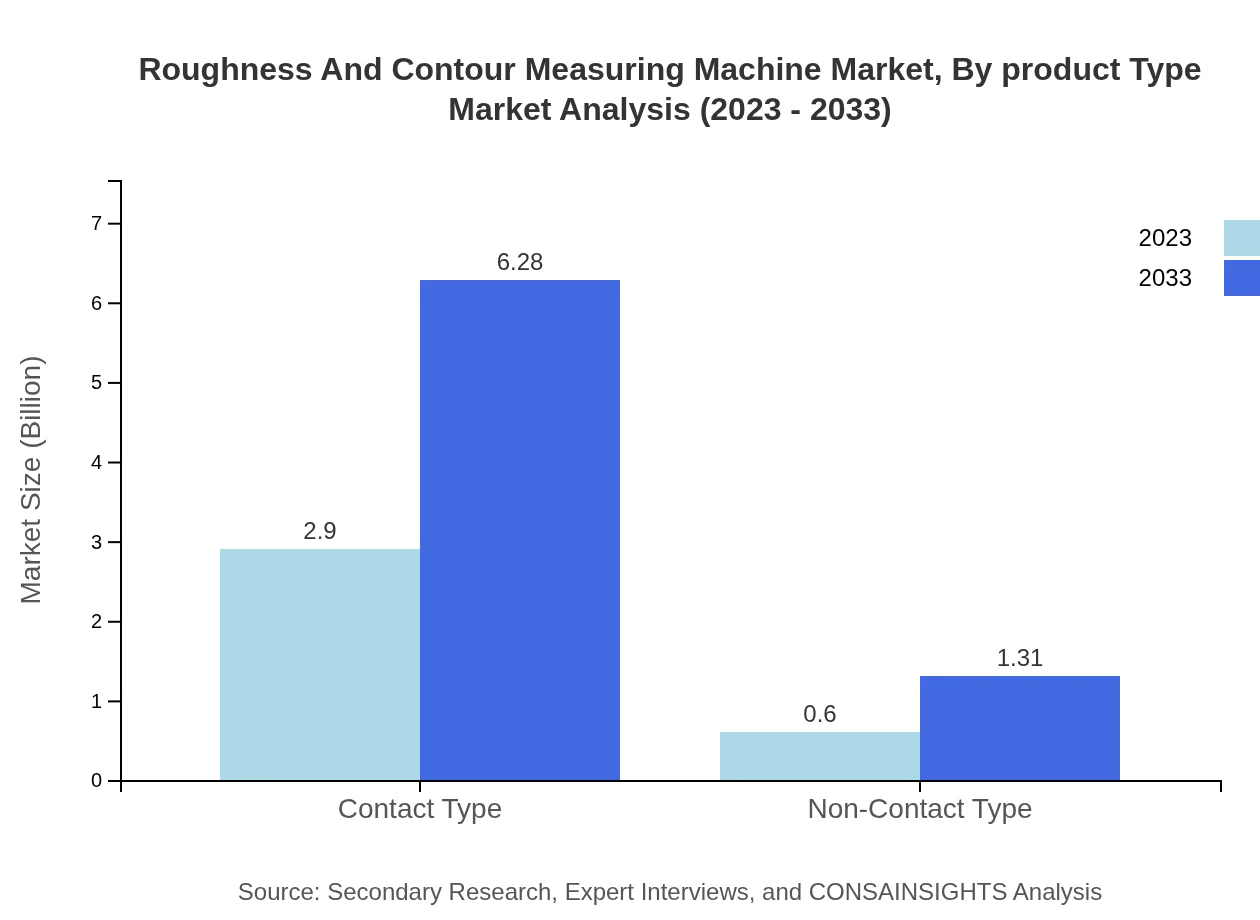

Roughness And Contour Measuring Machine Market Analysis By Product Type

The product types in the Roughness and Contour Measuring Machine market include traditional contact measuring machines and advanced non-contact options. The contact method, still dominant, accounted for a significant market share due to its reliability and established technology. However, non-contact methods are gaining traction, particularly in high-precision applications, with a projected CAGR higher than traditional methods.

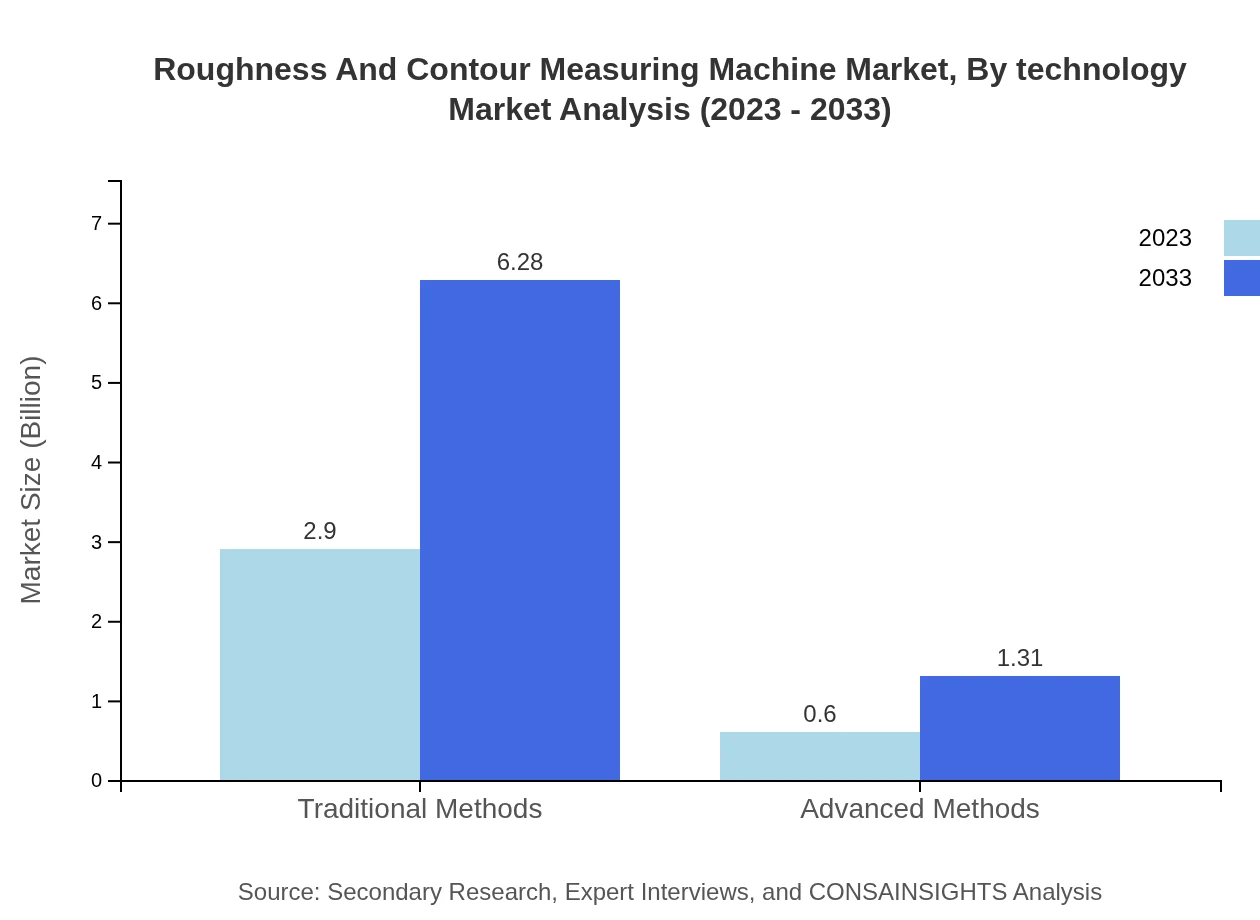

Roughness And Contour Measuring Machine Market Analysis By Technology

Technological advancements like laser scanning and optical measurement technologies are redefining the performance of roughness and contour measuring machines. These innovations lead to higher accuracy and efficiency, thus expanding their application across various sectors.

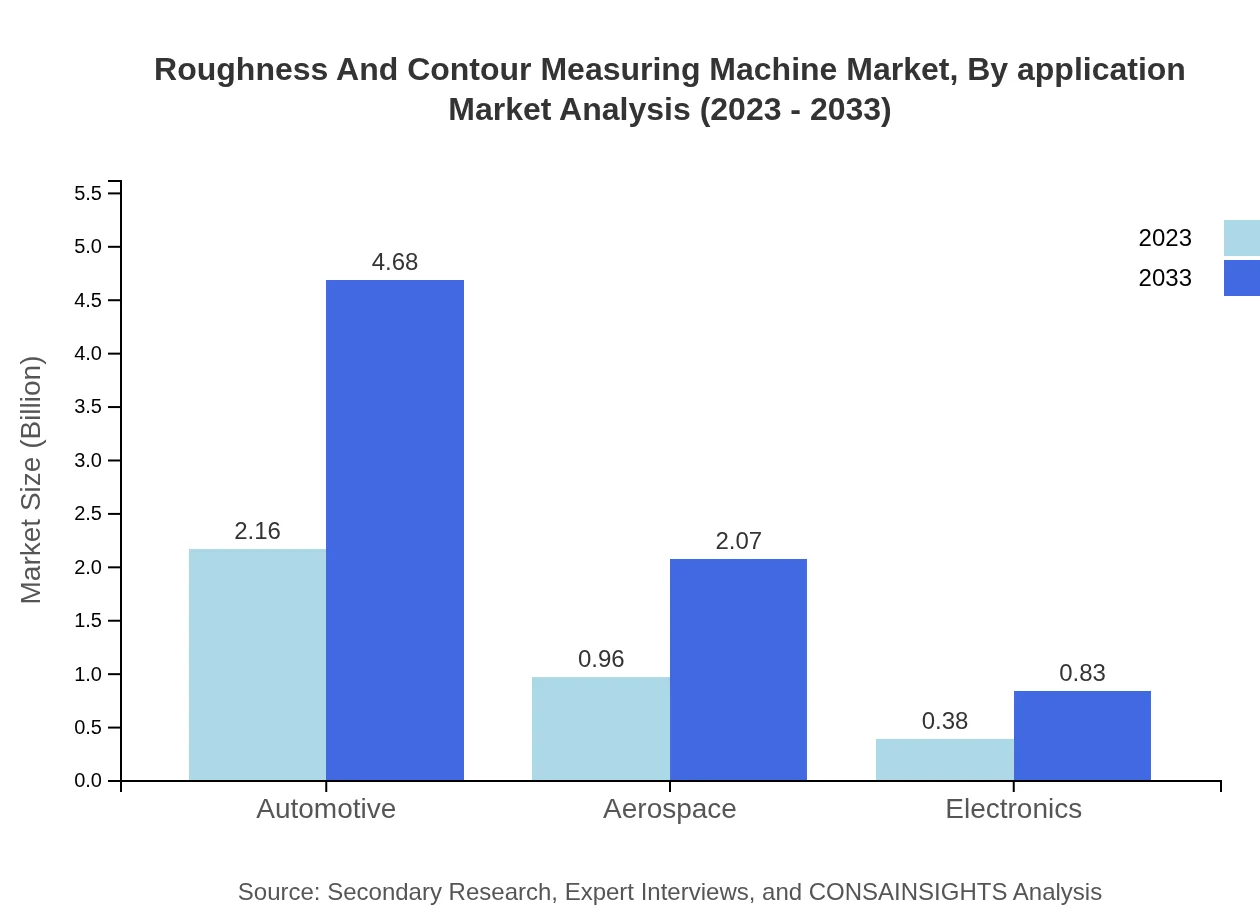

Roughness And Contour Measuring Machine Market Analysis By Application

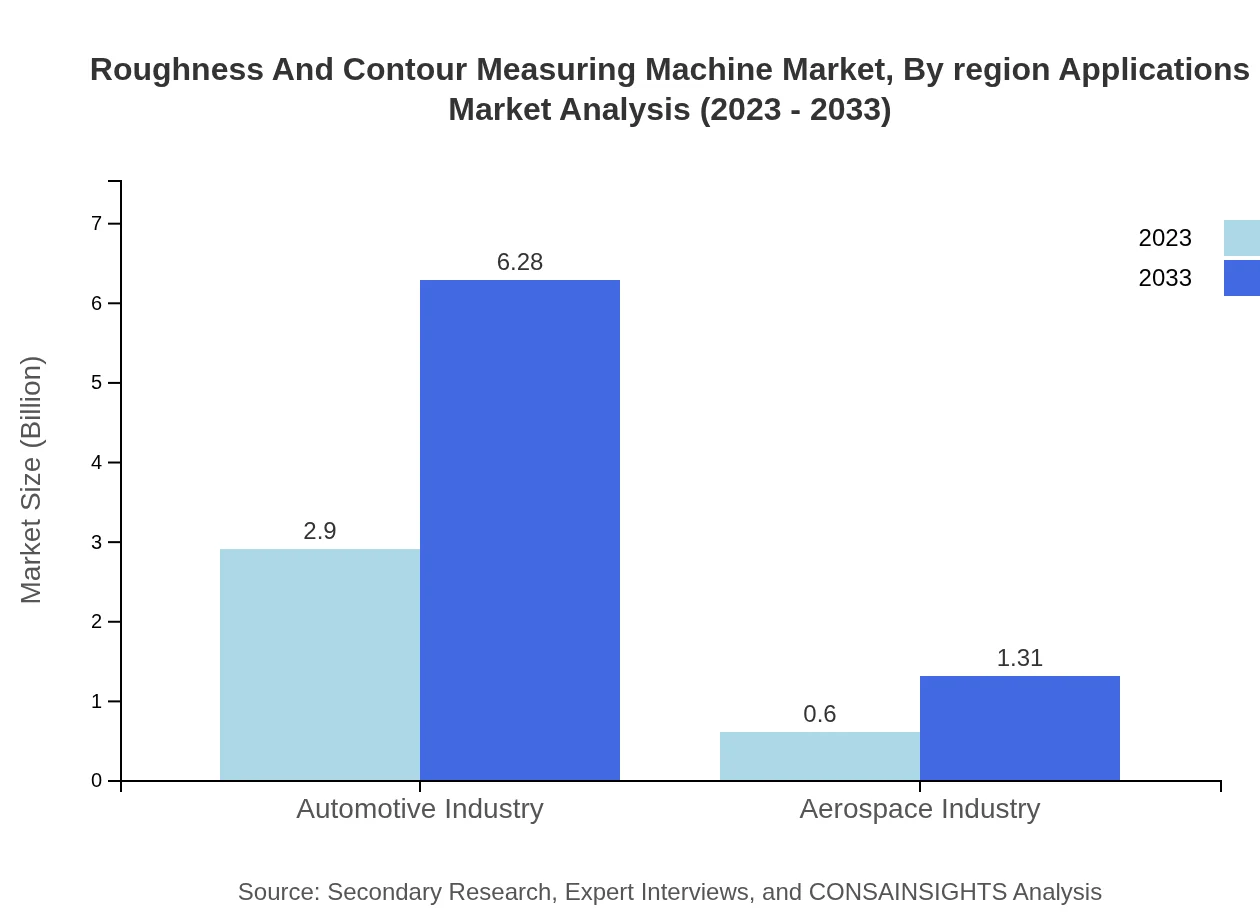

Key applications of roughness and contour measuring machines are found in manufacturing, automotive, aerospace, and medical fields. Each sector exhibits unique requirements, with automotive becoming a major user due to the increasing demand for surface integrity and performance in vehicles.

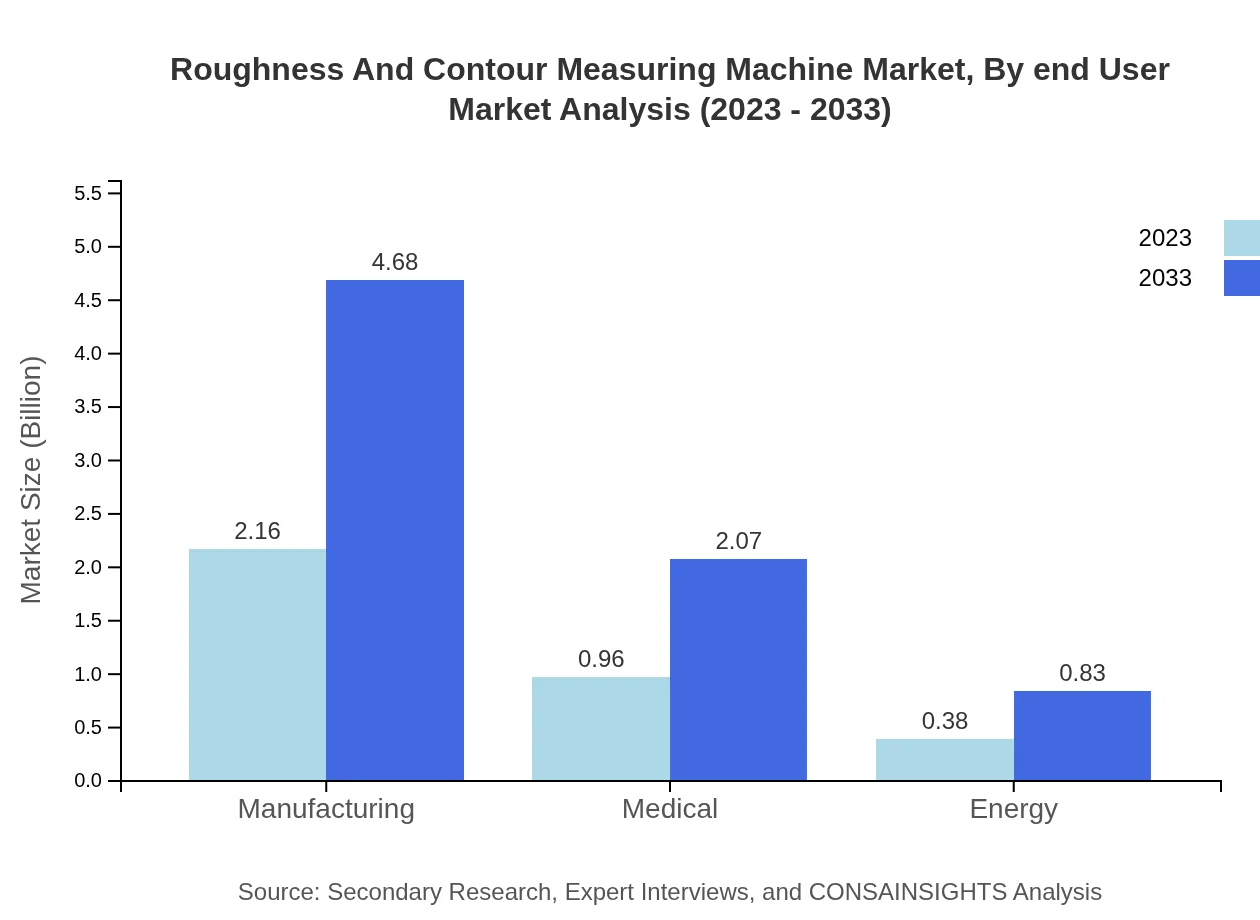

Roughness And Contour Measuring Machine Market Analysis By End User

The automotive industry is the primary end-user of roughness and contour measuring machines, utilizing them for quality assurance in vehicle parts. Aerospace and medical devices also demand high precision, making these sectors crucial for market growth.

Roughness And Contour Measuring Machine Market Analysis By Region Applications

Regionally, the demand for these measuring machines varies, with North America and Europe leading due to stringent regulatory environments and high-quality product expectations. Asia Pacific shows significant growth potential owing to rising industrial activities.

Roughness And Contour Measuring Machine Market Trends and Future Forecast

Tell us your focus area and get a customized research report.

Global Market Leaders and Top Companies in Roughness And Contour Measuring Machine Industry

Mitutoyo Corporation:

Mitutoyo is a leading manufacturer offering a wide range of precision measuring tools, highly regarded for their innovative solutions in roughness and contour measurement.Zeiss Group:

Zeiss provides advanced optical measurement systems that enhance precision in roughness and contour measurements, meeting the quality standards of various industries.Bowers Group:

Bowers specializes in manufacturing high-quality measuring instruments and offers products that ensure surface roughness and accuracy for various applications.Taylor Hobson:

Taylor Hobson is renowned for its high-precision equipment, particularly in surface measurement technology, catering to multiple industries.Hexagon Manufacturing Intelligence:

Hexagon offers integrated metrology solutions, combining advanced technologies for comprehensive surface measurement functionality.We're grateful to work with incredible clients.

FAQs

What is the market size of roughness And Contour Measuring Machine?

The global roughness and contour measuring machine market is currently valued at approximately $3.5 billion, with an expected compound annual growth rate (CAGR) of 7.8% from 2023 to 2033, indicating substantial growth and demand in various applications.

What are the key market players or companies in the roughness And Contour Measuring Machine industry?

Key players in the roughness and contour measuring machine market include top companies like Mitutoyo Corporation, Zeiss, and Taylor Hobson, which dominate due to their innovation in precision measurement technology and strong market presence in multiple regions.

What are the primary factors driving the growth in the roughness And Contour Measuring Machine industry?

The growth of the roughness and contour measuring machine industry is driven by increasing automation in manufacturing, demand for high precision in industries like aerospace and automotive, and the need for quality assurance in product development processes.

Which region is the fastest Growing in the roughness And Contour Measuring Machine?

The Asia Pacific region is the fastest-growing market for roughness and contour measuring machines, projected to grow from $0.63 billion in 2023 to $1.36 billion by 2033, driven by rising manufacturing capabilities and industrial investments.

Does Consainsights provide customized market report data for the roughness And Contour Measuring Machine industry?

Yes, Consainsights offers customized market report data for the roughness and contour measuring machine industry, tailoring insights to specific requirements and helping businesses make informed decisions based on unique market dynamics.

What deliverables can I expect from this roughness And Contour Measuring Machine market research project?

Deliverables from this market research project include comprehensive market analysis reports, segmentation data, trend forecasts, competitive landscape assessments, and actionable insights to guide strategic planning and decision-making.

What are the market trends of roughness And Contour Measuring Machine?

Current market trends include the increased adoption of advanced measuring technologies, integration of digital solutions for data analytics, and rising emphasis on sustainability and efficiency in manufacturing processes across various industries.